-

水力压裂技术的成功应用为页岩气增产开采提供重要保障[1-2]。然而,近年来,该技术所造成的负面环境影响受到愈发广泛的关注[3-4],其中以水资源消耗和水环境污染问题最为突出[4-5]。页岩气单井压裂液注入量超过1万m3,10%~70%的注入液会在井的整个生命周期返回地表,形成页岩气压裂返排液[2,6]。返排液通常含有高浓度的总溶解固体(total dissolved solids,TDS)、复杂有害的有机化合物及天然放射性物质等[7-8]。对返排液管理不当或意外泄露可能造成严重的环境污染。因此,妥善管理返排液对于保障页岩气行业可持续发展、降低环境风险具有重要意义。

目前,返排液管理办法主要包括深井灌注、内部回用以及外部回用等[2, 9]。深井灌注伴随污染地下水、诱发地震等风险,且由于我国灌注井数量有限,页岩气开采主要集中于西南地区,地形复杂,运输成本高,故深井灌注并不是我国返排液主要的处置方法。内部回用是指将返排液经过简单处理后再次用于配置压裂液,由于其兼具环保和经济的优势,已成为现阶段最主要的管理方式。然而随着未来页岩气行业的逐渐成熟以及开采速率的下降,返排液深度处理以实现外部回用(如外排、农田灌溉等)将成为返排液的最终管理办法。

在返排液回用过程中,混凝[10]、吸附[11]、氧化[12-14]、生物降解[15-16]、膜分离(包括超滤、反渗透、正渗透、膜蒸馏等)[6, 17-21]等处理技术均有一定报道。然而,这些报道主要集中于实验室规模的小试研究,缺乏中试或实际工程实验进一步探究处理技术或组合工艺应用的可行性。

因此,本研究选择了一套运行稳定、处理效率高且占地小的“磁分离-精细过滤-超滤(uItrafiltration,UF)-碟管式反渗透(disk tube reverse osmosis,DTRO)”返排液处理回用组合工艺并构建了中试装置,开展现场实验研究。在优化运行条件下,对各工艺阶段出水水质进行全面检测,分析污染物去除机理并探究该工艺装置高效回用返排液的潜力,为实现压裂返排液妥善管理、保障页岩气行业长足发展提供技术支撑。

-

本研究在内江资中某页岩气开采区块开展现场实验。储存池主要收集周边页岩气压裂作业井的返排液,返排液经自然沉降后作为本研究的工艺原水。

主要采用的化学药剂包括聚合氯化铝(polyaluminum chloride,PAC,质量分数28%)、精制铁粉(粒径0.05 mm)、聚丙烯酰胺(polyacrylamide,PAM,阳离子)等。

-

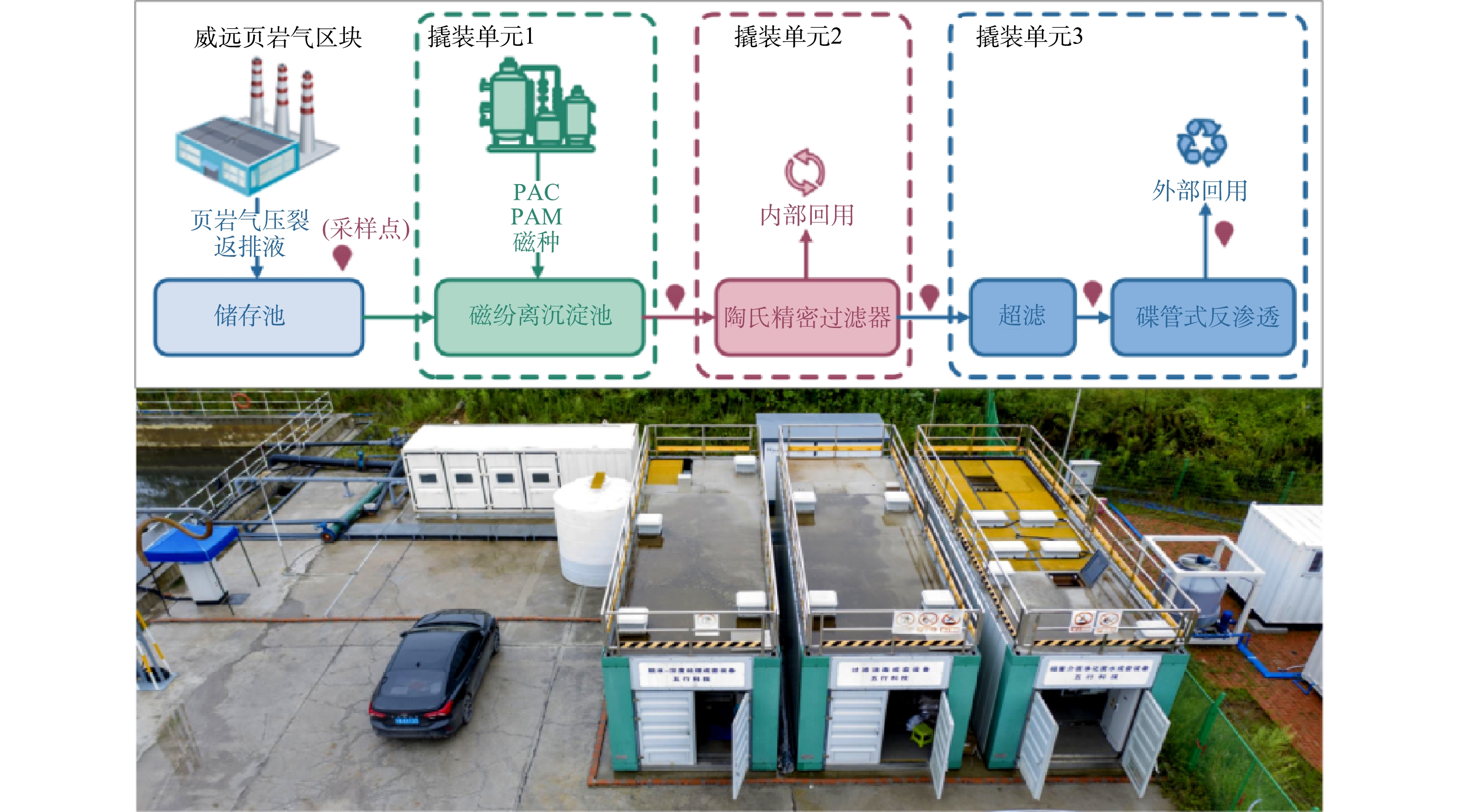

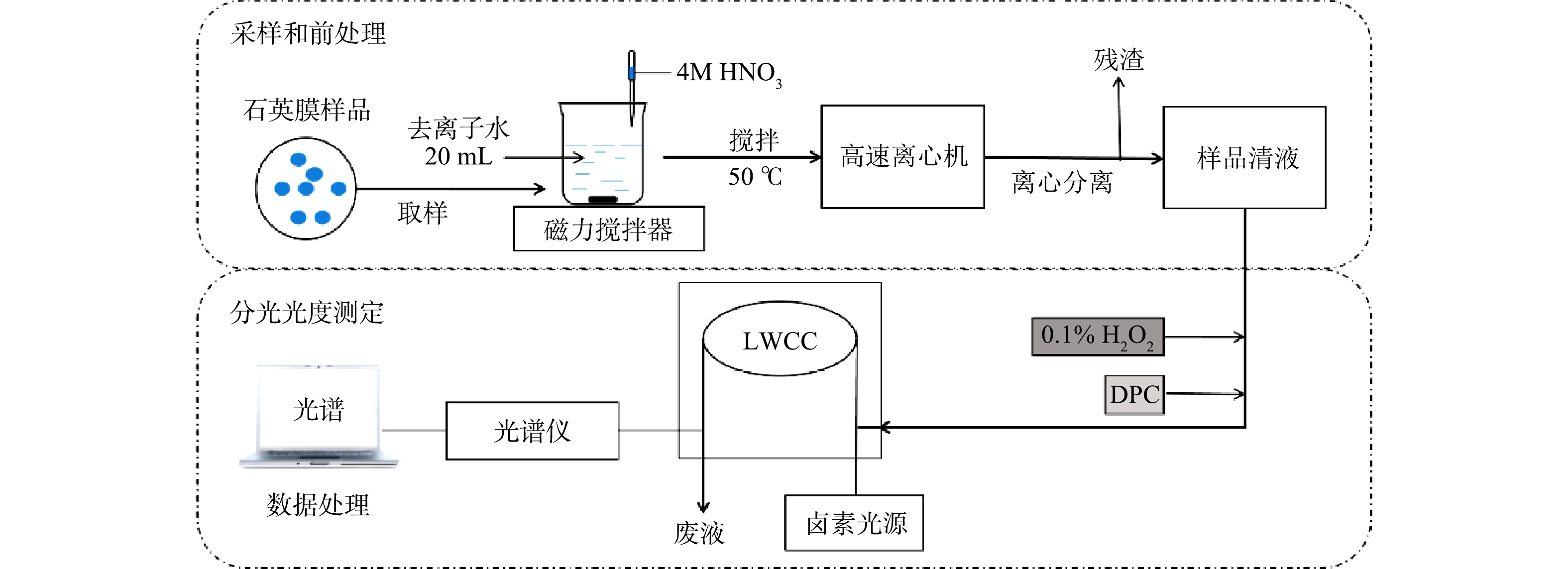

本研究采用的处理回用工艺为“磁分离-精细过滤-超滤(UF)-碟管式反渗透(DTRO)”组合工艺。该实验装置主要由3套撬装式废水净化设备组成,包括:磁分离成套设备、过滤成套设备以及深度除盐成套设备。具体工艺流程及实验装置如图1所示。磁分离成套设备中主要包括三级混凝反应器、磁重介质澄清器、加药附属设备及磁重介质回收设备等;过滤成套设备中主要包括陶氏精密颗粒过滤器;深度除盐成套设备主要包括超滤、碟管式反渗透及相关附属设备。该装置的处理能力为65 m3·h−1,深度除盐成套设备处理能力为1 m3·h−1。3套撬装设备的尺寸均为10 m×3 m×3 m,便于交通运输。

压裂返排液通过废水提升泵提升至磁分离废水净化单元,在三级混凝反应器中,分别向返排液中投加PAC、精制铁粉、PAM、磁重介质以及絮凝剂。PAC、精制铁粉、PAM三者作为混凝剂,优化投量分别为30、10、1 mg·L−1。三级混凝反应器每一级水力停留时间为5 min,前2级搅拌速率为120 r·min−1,最后一级搅拌速率为80 r·min−1。经过三级混凝反应器后,返排液中的悬浮颗粒及胶体聚集形成较大的含磁重介质的絮凝体,然后进入磁重介质澄清器(水力停留时间为30 min),经重力快速沉降后,去除水体中大部分的悬浮物、胶体等污染物,出水自流进入过滤中间水箱。此后,过滤提升泵将中间水箱的水提升至高精度过滤器,进一步去除返排液中悬浮颗粒及胶体,过滤出水一部分进入内部回用水池,另一部分进入超滤中间水箱(1 m3·h−1)。超滤单元所用膜材料为平板陶瓷超滤膜(氧化铝,平均孔径为100 nm),操作压力为0.4 MPa,过滤模式为浸没式死端过滤。废水经过超滤后,可满足DTRO进水水质要求,超滤出水进入反渗透中间水箱。最后,通过高压柱塞泵将中间水箱的水泵入DRTO系统,有效去除水体中的无机盐分及有机污染物等。DTRO所用膜材料为聚酰胺有机复合膜,操作压力为5.0 MPa,设计回收率为70%。

本研究采样点标注在图1工艺流程中,所采集样品分别是储存池压裂返排液原水、磁分离处理出水、陶氏精密过滤器出水、超滤出水以及反渗透出水。为探究该装置处理页岩气压裂返排液的效能,当系统在优化操作参数下运行稳定后,于上述5个采样点采集样品。

-

浊度采用美国哈希2100Q便携式浊度仪测定;PH采用德国赛多利斯PB-10 PH计测定;总溶解性固体(TDS)和电导率(electrical conductivity,EC)采用美国麦隆Ultrameter II 6PFC多功能水质检测仪测定;UV254及化学需氧量(chemical oxygen demand,COD)采用美国赛默飞Orion AquaMate 8000分光光度计测定;溶解性有机碳(dissolved organic carbon,DOC)及总溶解性氮(total dissolved nitrogen,TDN)采用日本岛津总有机碳分析仪TOC-L CPH和总氮测定单元TNM-L测定;无机离子(Na+、K+、Mg2+、Ca2+、Sr2+、F−、Cl−、Br−及SO42-)质量浓度采用美国戴安ICS-1100离子色谱仪测定,阳离子和阴离子质量浓度测定分别采用CS12A和AS11-HC型色谱柱;总铁(Fe)和总铜(Cu)质量浓度采用美国珀金埃尔默PinAAcle 900T原子吸收光谱仪测定。

有机物的疏水/亲水特性通过XAD-8树脂(Supelite,美国)和XAD-4树脂(Amberlite,美国)进行测定。XAD-8和XAD-4树脂分别能够吸附返排液中的疏水和过渡性有机物,而亲水性有机组分可以通过两种树脂,以此可检测样品中的亲疏水有机组分的占比。

采用日本日立F-7000荧光分光光度计测定返排液中荧光有机物组成,获得样品的的荧光激发-发射矩阵(excitation-emission matrix,EEM)光谱。所有返排液样品经0.45 μm混合纤维素微孔滤膜过滤,并稀释至UV254<0.05 cm−1后进行检测。激发波长(excitation,Ex)范围为200~400 nm,采样间隔为5 nm;发射波长(emission,Em)为200~550 nm,采样间隔为1 nm。样品的EEM光谱需减去现场空白的EEM光谱。

-

表1与表2分别展示了本装置不同工艺阶段样品的常规水质指标和离子浓度。由表1可知,页岩气压裂返排液原水水质特征如下:盐度较高(TDS为20 580 mg·L−1),氯化物和钠离子质量浓度分别为11 469.5 mg·L−1和8 617.8 mg·L−1,但低于美国马塞勒斯等地返排液盐度主要范围(40 000~280 000 mg·L−1)[6, 22];中高浓度有机物(DOC为33.26 mg·L−1,COD为625.43 mg·L−1);硬度较低,Mg2+、Ca2+、Sr2+质量浓度分别为75.91、414.6、51.25 mg·L−1,且所有样品中总铁和总铜质量浓度均低于检测限(<0.01 mg·L−1,故未在表2中展示)。

从表1可以看出磁分离和精细过滤工艺可有效去除浊度:原水经过磁分离单元处理后,浊度从161 NTU下降到14.33 NTU,下降了91.1%,经过过滤器过滤后,浊度下降到7.25 NTU,相较原水下降了95.5%。此外,由于磁分离工艺的吸附和卷扫作用[23],磁分离对Sr2+也有较高的去除效率(85.4%)。超滤几乎完全去除了浊度(0.28 NTU),较原水去除率达99.8%,可满足DTRO进水要求。但磁分离、精细过滤、超滤工艺对返排液中TDS、DOC、COD及主要无机离子均没有明显的去除效果。DTRO工艺几乎可以有效截留返排液中所有污染物。经DTRO处理之后,COD值,DOC和TN质量浓度分别下降至1.14(较原水去除率为99.8%)、0.38(98.8%)、和1.06(96.5%) mg·L−1,氯离子和硫酸根离子质量浓度分别降至3.62(99.9%)、0.39(94.8%) mg·L−1,其他指标去除率都大于99%。这些结果证实,DTRO工艺可有效去除返排液中各种污染物(无机离子及有机污染物)并将这些污染物转移到浓缩液中。

针对本研究测试的主要水质参数,根据《页岩气储层改造第3部分:压裂返排液回收和处理方法》 (NB/T14002.3-2015)回用水推荐水质主要控制指标(悬浮固体含量≤1 000 mg·L−1,总硬度≤800 mg·L−1,总铁≤10 mg·L−1,总矿化度≤20 000 mg·L−1),页岩气返排液精细过滤出水可达到内部回用标准。因此,本装备过滤出水一部分(64 m3·h−1)进入内部回用水池,这部分出水再经过消毒杀菌(避免微生物生长繁殖造成设备设施腐蚀和采收率下降等问题)后即可配置新的压裂液,目前已成功回用于该平台周边页岩气井的压裂开采;另一部分进入超滤中间水箱(1 m3·h−1),作为深度除盐成套设备的进水以对UF-DTRO工艺处理返排液开展进一步研究。过滤出水相应的去向在图1(工艺流程)中也进行了明确标注。值得注意的是,返排液水质随着开采井地质条件、开采深度的差异以及返排时间的不同存在较大的变化[24-26]。本研究返排液具有pH适中、低硬度等特点,故经过上述处理后可达内部回用要求。而对于pH偏酸或偏碱的返排液,需要在磁分离处理前先通过投加碱或酸将其pH调节至近中性以保证混凝及后续工艺的处理效果和正常运行;对于硬度或铁含量等较高的返排液,可考虑在磁分离工艺中同时投加化学沉淀剂(如碳酸盐、硫酸盐)去除硬度。

通过将本装置DTRO出水水质与《污水综合排放标准》(GB 8978-1996)和《农田灌溉水质标准》(GB 5084-2021)进行对比发现,DTRO出水指标均满足标准规定的限值。本研究中,DTRO出水经收集后排放至附近河流(图1),也可用作装备运行过程中部分所需生产用水(如药剂配制用水、膜材料清洗用水等)。ZHOU等[27]跟踪检测了返排液处理后排放在2 a内对河流生态系统的影响,其中返排液采用A2O-MBR-芬顿氧化-沉淀过滤工艺进行处理,出水达《污水综合排放标准》(GB 8978-1996),返排液排放对河流河水化学组成、底栖无脊椎动物群落结构和生物多样性影响均非常有限,并且未发现典型有毒有机化合物(包括16种美国环保署优先控制的多环芳烃和6种邻苯二甲酸酯)在河流沉积物种的积累。ZHOU等[28]探究了使用这种受返排液排放影响的河水进行稻田灌溉对农业生态系统的影响,结果表明:土壤和稻米中均未发生重金属的积累,且土壤微生物多样性在灌溉2 a后呈增加趋势。值得注意的是,上述2项研究中返排液处理出水各项水质指标均显著高于本研究中DTRO出水,因此本工艺装备DTRO出水具有更为显著的外部回用(外排、农田灌溉)潜力。然而,相比于无机组成,返排液及其处理出水中有机组成尚未得到充分解析[7],因此,更长期的排放和灌溉对环境生态系统、作物品质和产量可能造成的负面影响仍然值得广泛关注,进一步鉴定工艺出水中特定关键有机化合物对于正确认识出水环境风险和外部回用可行性具有重要意义。

此外,反渗透浓缩液的有效管理也是反渗透工艺应用中面临的巨大挑战。本研究中产生的DTRO浓缩液直接排放进返排液储存池,因此没有特别关注。然而,浓缩液的处理处置是中试实验放大到实际工程过程中必须要考虑的问题。大量研究应用吸附、高级氧化、氧化-生物耦合工艺等来降低浓缩液中的有机污染物浓度[29];而电渗析、正渗透、膜蒸馏、机械蒸汽再压缩等技术有望对浓缩液进一步浓缩,实现整个工艺的近零排放[30]。因此,进一步探究返排液浓缩液污染物在这些技术工艺中的去除效能和机理是返排液高效回用目标下的重要研究方向。

-

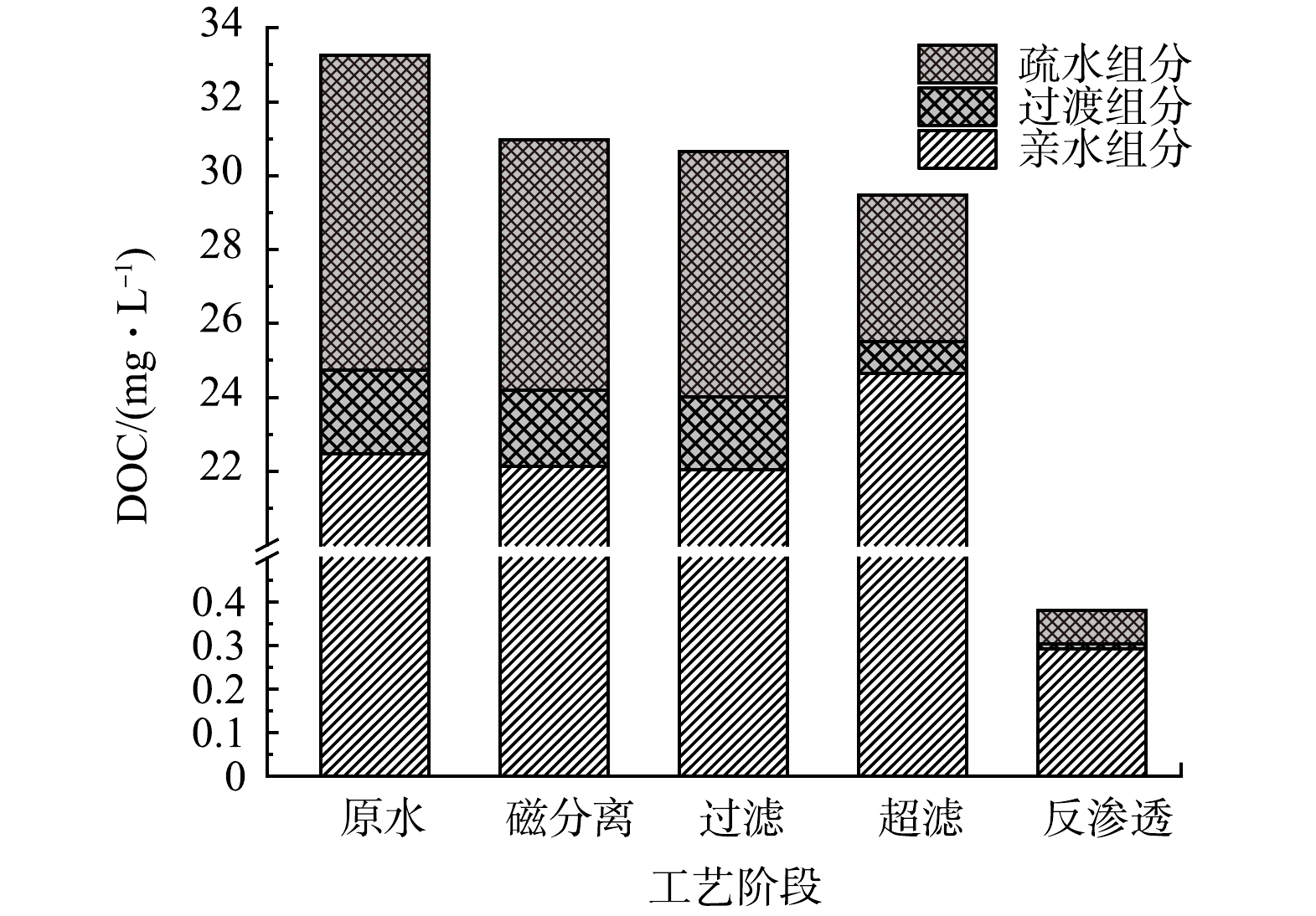

为研究工艺不同阶段出水中亲疏水性有机物的变化规律,使用XAD树脂对亲疏水化合物进行了分离。由图2可以看出,返排液原水中含有较高比例的亲水性有机物组分(67.6%),疏水组分占25.7%,过渡组分占6.7%,这与之前的研究结果一致[31]。

经磁分离工艺处理,疏水类有机物去除率达到20.5%,而亲水类有机物仅去除1.6%,疏水有机物去除占总有机物去除的76.4%。这是由于疏水性有机物更易于吸附在混凝过程中产生的絮凝体上,随着絮凝体一起沉淀,因此,混凝工艺对疏水性有机物有较好的去除效果。精细过滤主要是通过简单的物理截留和疏水吸附,进一步去除返排液中的悬浮颗粒和胶体,对溶解性有机物的去除率较低,因此,亲疏水性有机物组分及其含量变化并不明显。值得注意的是,经过超滤处理后,疏水类有机物较原水去除率达到53.5%,而亲水类有机物却略有增加(9.7%)。经超滤(ultrafiltration,UF)后亲水类有机物的增加可能主要与进水浓缩以及微生物活动有关,这将在下一节荧光有机物分析中进行详细解释。最后,由于反渗透膜的较小孔径以及空间位阻效应,DTRO工艺能够去除大部分的疏水和过渡有机物,去除率(相较于原水)分别达到98.1%和98.8%。另外,本研究中反渗透膜表面带有负电荷,而亲水性有机物在结构中通常包含更多的羧基、羟基等基团[25],这些基团在水中易于电离而使化合物也带负电,从而增大有机物分子与膜表面间静电斥力。因此,在空间位阻与静电排斥等效应的共同作用下,DTRO对亲水性有机物也有较好的去除效果(98.8%)。DTRO出水中仍然是以亲水性有机物为主(77.1%),有研究表明,可能主要是由于吸附/扩散机制[32],导致亲水性有机物相对更容易透过膜表面聚酰胺层,从而到达膜的出水一侧。

-

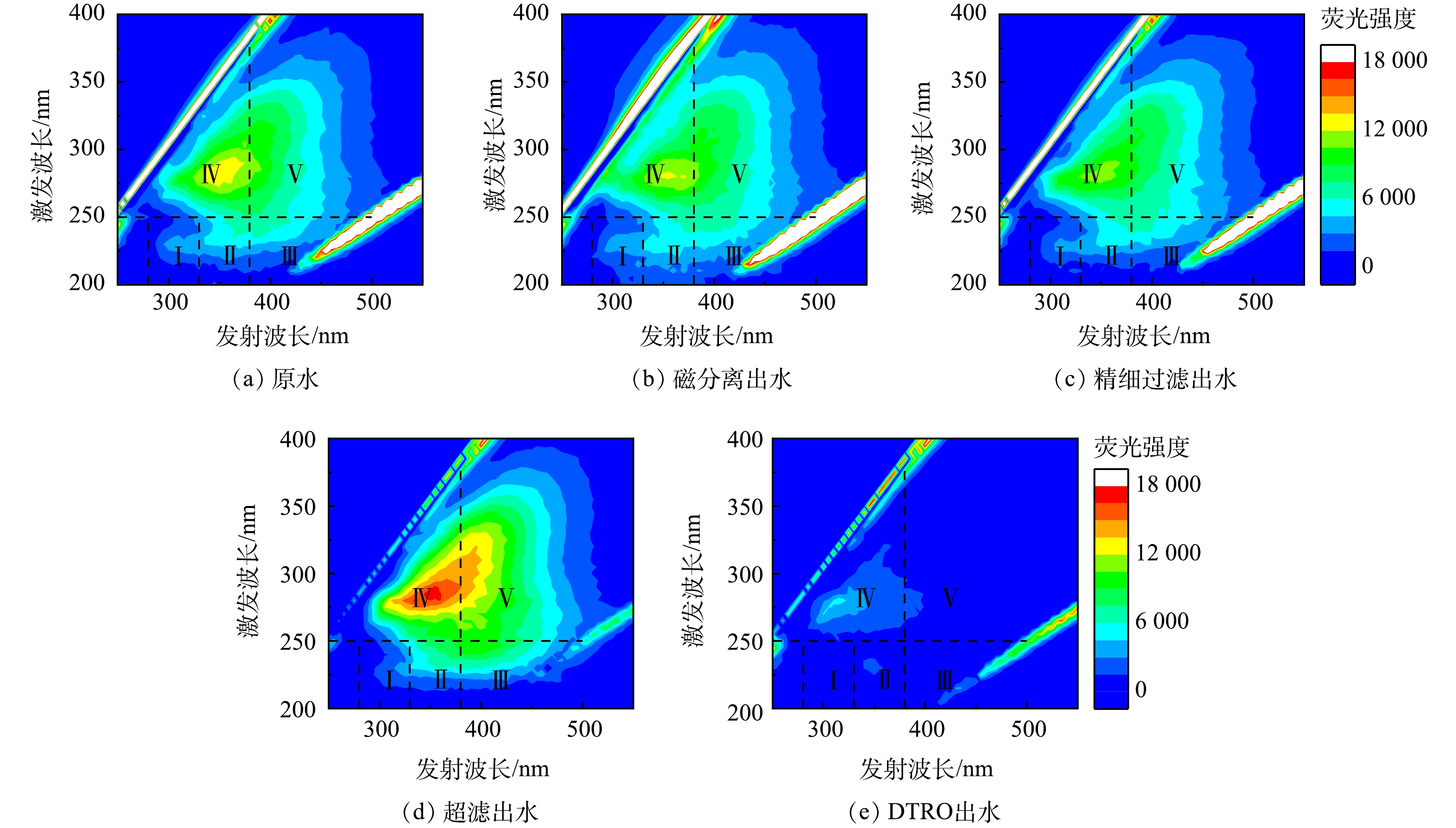

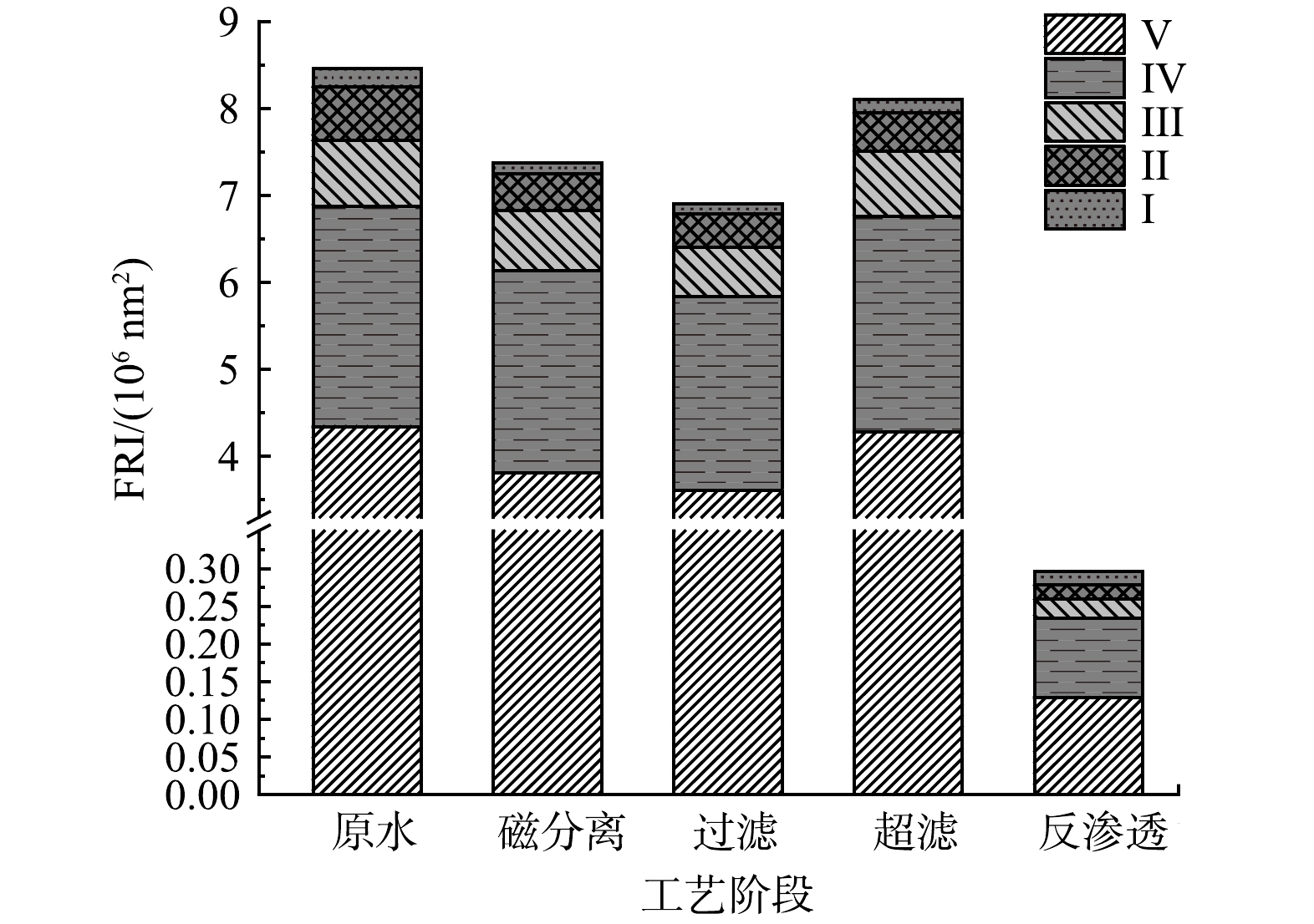

不同工艺阶段样品荧光激发-发射矩阵(EEM)光谱如图3所示。采用荧光区域积分(FRI)将EEM光谱划分为5个区域:Ⅰ区为酪氨酸蛋白类物质(Ex/Em=220~250 nm /280~330 nm);Ⅱ区为色氨酸蛋白类物质(Ex/Em=220~250 nm /330~380 nm);Ⅲ区为富里酸类物质(Ex/Em=220~250 nm/380~480 nm);Ⅳ区为可溶性微生物副产物(Ex/Em=250~440 nm /280~380 nm);Ⅴ区为腐殖酸类物质(Ex/Em=250~440 nm/380~540 nm)[33-34]。根据EEM光谱,对每个区域对应的体积积分,可以定量分析返排液样品中荧光有机物的去除率,FRI结果如图4所示。页岩气压裂返排液原水中各区域荧光有机物占比情况:Ⅰ区为2.5%,Ⅱ区为7.3%,Ⅲ区为8.9%,Ⅳ区为30.0%,Ⅴ区为51.3%,主要荧光有机物是腐殖质类有机物质以及可溶性微生物代谢产物类(主要由多糖、蛋白质、核酸等物质组成)。

磁分离工艺共去除了12.8%荧光类有机物(Ⅰ区为39.0%,Ⅱ区为31.2%,Ⅲ区为8.3%,Ⅳ区为8.4%,Ⅴ区为12.3%),各区荧光去除占总荧光去除比例为Ⅴ(49.2%)>Ⅳ(19.7%)>Ⅱ(17.7%)>Ⅰ(7.7%)>Ⅲ(5.7%)。有研究表明,磁分离主要通过电性中和与疏水吸附机理去除废水中溶解性有机物[35]。而区域 V(腐植酸类物质)处荧光主要与疏水性有机酸有关[25],此类有机物更易于与阳离子混凝剂、絮凝剂发生电性中和,或吸附聚集到絮凝体上,从而通过沉淀去除,因此,磁分离对区域 V处荧光有较好的去除效果,该结果也与磁分离过程中大量疏水性组分的去除相一致。过滤工艺进一步去除返排液中的细小悬浮颗粒、胶体及其吸附的有机物,进而实现对一部分荧光有机物的去除,总荧光去除率为(相较于磁分离出水):6.37%,各区域去除占总荧光去除比例分别为Ⅴ(43.5%)>Ⅲ(27.8%)>Ⅳ(19.2%)>Ⅱ(6.5%)>Ⅰ(3.0%)。由表1可见,UF处理后总有机物(DOC、COD等指标)浓度降低。这可能是由于超滤膜对大分子有机物(高分子质量腐殖质和生物聚合物)的物理截留导致的。然而UF出水后荧光有机物浓度却有一定程度的增加(各区域增加比例分别为:Ⅰ区为31.9%,Ⅱ区为12.6%,Ⅲ区为34.2%,Ⅳ区为11.0%,Ⅴ区为18.7%,总荧光强度增加17.4%)。事实上,UF处理返排液后荧光有机物浓度升高这一现象在之前的研究中已经有广泛的报道[36-37]。一方面,已有研究表明,返排液中存在大量的微生物活动[38],而UF可以有效截留这些微生物,使其在进水侧生长繁殖。因此,微生物代谢对高分子量有机物的降解和低分子量微生物产物透过超滤膜可能是导致本研究中UF出水荧光有机物浓度增加的原因。这也与UF出水中可溶性微生物副产物(区域IV)的荧光信号明显增强以及亲水性组分增加的实验结果相一致。另一方面,在死端过滤的模式下,由于超滤膜的作用,部分污染物也被截留在反应器中,进水浓缩也可能导致UF出水中荧光有机物浓度增加。最后,DTRO工艺几乎去除了所有的荧光有机物,较UF出水各区截留率分别为:Ⅰ区为88.1%,Ⅱ区为95.8%,Ⅲ区为96.6%,Ⅳ区为95.8%,Ⅴ区为97.0%,总荧光截留率为96.3%。DTRO出水中荧光有机物占比为Ⅰ区6.2%,Ⅱ区6.3%,Ⅲ区8.7%,Ⅳ区35.3%,Ⅴ区43.5%,未截留荧光物质主要分布在Ⅳ区和Ⅴ区,可能包括部分微生物代谢产生的小分子有机酸。

-

为对本工艺装备进行经济分析,表3反映了该装备的运行成本,主要包括电费、药剂费、膜元件替换费等。经计算可得,本装备处理返排液的运行成本为18.92 元·m−3。其中,超滤工艺使用一套一体化平板陶瓷膜组件,组件单价为4.0×104元·套−1,使用寿命以5 a计,处理水量为24 m3·d−1,折算耗膜元件费用为0.91 元·m−3;DTRO工艺中膜元件单价为2.0 ×104元·支−1,共使用4支,则更换一次膜元件费用为8.0×104元,DTRO膜元件使用寿命以3 a计,则折算耗膜元件费用为3.04 元·m−3。此外,超滤和DTRO工艺中使用到的化学药剂主要包括酸碱清洗剂、阻垢剂、杀菌剂等。

除运行成本外,设备运维需2人,且年薪以7.0×104元·人−1计算,人工成本为15.98 元·m−3,则直接处理成本合计34.90 元·m−3。设备投资400×104元,10 a折旧,检测维修费按投资3%计算,设备折旧及检测维修费为59.36 元·m−3,则综合处理成本合计94.26 元·m−3。上述经济分析是以深度除盐成套设备(UF-DTRO工艺)处理能力,即24 m3·d−1,为基础进行计算的,后续扩大工艺处理规模后,成本有望进一步减少。

生物降解被认为是最经济的水处理技术之一,然而由于页岩气返排液含盐量较高,不利于微生物生长繁殖,生物法处理返排液往往存在启动周期长、处理效果不佳等问题。罗臻等[39]构建了电絮凝-磁分离-电氧化工艺装备处理返排液,悬浮物和COD去除率均可达85%以上,装备出水可满足返排液内部回用的要求,综合处理成本为73.73 元·m−3,然而该工艺对返排液中高盐含量无明显去除效果。相比之下,本套工艺装备可在处理成本增加不大的情况下,同时去除返排液中的无机盐和有机污染物,实现返排液的外部回用。因此,本工艺装备处理回用页岩气压裂返排液兼具高效性和经济性。

-

1)磁分离-精细过滤-超滤(UF)-碟管式反渗透(DTRO)工艺装置对于实现页岩气压裂返排液高效回用具有巨大潜力。磁分离-精细过滤工艺可去除返排液中95.5%的浊度,出水经消毒后可以满足返排液内部回用要求;此外,DTRO工艺对返排液中各类污染物去除率均大于95%,DTRO出水指标满足《污水综合排放标准》(GB 8978-1996)和《农田灌溉水质标准》(GB 5084-2021)所规定限值,有望通过返排液外部回用(外排、农田灌溉)实现水资源的循环利用,缓解水资源短缺危机。

2)磁分离工艺主要通过电性中和疏水吸附机理去除返排液中的溶解性有机物,对于返排液中的疏水组分及腐殖酸类物质(荧光区域Ⅴ)有很高的去除效率;进水浓缩以及微生物活动将高分子质量有机物降解为低分子质量微生物产物从而透过超滤膜可能是超滤出水中亲水有机组分以及荧光强度增加的原因;DTRO出水的有机成分主要由亲水组分、可溶性微生物副产物(荧光区域Ⅳ)及腐殖酸类物质(荧光区域Ⅴ)组成。

3)本工艺装备处理返排液直接处理成本达34.90 元·m−3,综合处理成本达94.26 元·m−3。相较于生物、氧化等技术具有经济、高效等优势。

磁分离-精细过滤-超滤-碟管式反渗透耦合工艺高效回用页岩气压裂返排液

Magnetic separation-fine filter-ultrafiltration -disk tube-reverse osmosis coupling process to realize the efficient reuse of shale gas fracturing flowback fluid

-

摘要: 页岩气压裂返排液高效处理回用是页岩气开发中亟待解决的关键问题之一。本研究在某页岩气开采平台上,构建了“磁分离-精细过滤-超滤(UF)-碟管式反渗透(DTRO)”返排液处理工艺装备,进行现场实验研究并分析污染物去除效能和机理。在优化运行条件下,磁分离-精细过滤对浊度去除率达95.5%,精细过滤出水可内部回用于复配水力压裂液;DTRO工艺对TDS、DOC、总荧光强度去除率分别达99.9%、98.7%和96.3%,出水满足《污水综合排放标准》(GB 8978-1996)和《农田灌溉水质标准》(GB 5084-2021),有望通过外排和灌溉等方式进行外部回用。此外,装备运行直接处理成本约34.90元·m−3。相较其他技术,本工艺兼具高效性与经济性。因此,该工艺装备具有实现返排液高效回用的巨大应用潜力。

-

关键词:

- 压裂返排液 /

- 回用 /

- 磁分离 /

- 超滤 /

- 碟管式反渗透(DTRO)

Abstract: Efficient treatment and reuse of shale gas fracturing flowback fluid is one of the key problems to be solved in shale gas development. In this study, a flowback liquid treatment device with the magnetic separation-fine filter-ultrafiltration (UF) -disk tube-reverse osmosis (DTRO) coupling process was constructed on a shale gas mining platform, and field tests were conducted to study and analyze the pollutant removal efficiency and mechanism. Under the optimized operating conditions, the turbidity removal rate by magnetic separation-fine filtration process reached 95.5%, and the effluent from fine filtration could be reused internally for reconfiguring hydraulic fracturing fluid. The removal rates of TDS, DOC and total fluorescence intensity by DTRO could reach 99.9%, 98.7% and 96.3%, respectively, and the DTRO effluent could meet the limits stipulated in the Integrated Wastewater Discharge Standard (GB 8978-1996) and the Standard for Irrigation Water Quality (GB 5084-2021), which is expected to be reused externally through approaches including discharge and irrigation. In addition, the direct operating cost of the device was about 34.90 yuan·m−3. Compared with other technologies, this process presented higher efficiency and economy. Therefore, the process device had a great application potential for highly efficient reuse of flowback fluid.-

Key words:

- fracturing flowback fluid /

- reuse /

- magnetic separation /

- ultrafiltration /

- DTRO

-

大气环境颗粒物中的铬(Cr)主要以三价铬(Cr(Ⅲ))和六价铬(Cr(Ⅵ))2种价态存在。Cr(Ⅲ)是人体进行糖类和脂类等代谢活动必不可少的微量物质;Cr(Ⅵ)则是剧毒物质,具有致癌性。1990年,美国的《清洁空气法》将Cr(Ⅵ)化合物列入188种有害空气污染物,美国环境保护局也将其列入18种核心污染物[1]。我国的《环境空气质量标准》规定其年平均浓度限值为25 pg·m−3[2]。近年来,相关学者围绕Cr这种环境颗粒物中重要的有害过渡金属[3-5],展开了Cr的污染特征和来源解析、潜在生物危害和健康风险评估以及在环境中可能存在的化学作用等[6-9]方面的研究。

大气颗粒物产生化学过程往往只持续较短时间(大约几个小时)。切实模拟和研究其产生、传输、消耗的动态过程,需要在该时间精度内进行分析测定[10-11]。在高时空分辨率背景下,研究大气化学过程中过渡金属的污染特征,可为探索此类气溶胶的理化特性、并控制其潜在毒性提供重要见解。建立灵敏而可靠的测量方法需要解决3个问题:1)如何提高测量的灵敏度(达到更低的检测限);2)如何降低测量过程中的潜在干扰;3)如何在处理和测量过程中降低样品中待测物质的损失。目前,多数研究者倾向于使用原子吸收光谱技术测定样品中的总Cr,包括火焰原子吸收光谱法(FAAS)、石墨炉原子吸收光谱法、电热原子吸收光谱法(ET-AAS)等[12-13]。但是,此类方法的样品前处理较为繁琐,所需仪器设备造价昂贵。紫外/可见光分光光度法(UV/Vis)灵敏度很高,通过适当的显色试剂进行络合反应可在高吸收率条件下测量水溶性金属,常被用于溶液中金属浓度的高精度测量[14-15]。以此为基础,可通过配备长光液体波导毛细管来实现UV/Vis定量测定环境样品中的水溶性金属[16-17],结合测量系统的开发,还能有序测量环境颗粒物样品中的金属浓度[18-19]。

结合采样和前处理操作,设计并评估了一种基于分光光度法连续测量大气环境细颗粒物(PM2.5)中铬浓度的系统,以便于精确了解大气颗粒物中铬的污染水平及其来源,提供一种测量环境大气中水溶性痕量金属的思路,以期为开发实际监测技术奠定基础。

1. 材料与方法

1.1 试剂标准

实验所需化学药品纯度至少为光谱纯,配制的试剂和溶液使用由纯水机(Smart-DUV(F) SAIDE)生产(电阻率不低于18.2 MΩ)的超纯水和去离子水。用于试剂配制的实验器材和试剂保存的聚丙烯瓶在使用前均先用浓度为4 mol·L−1的HCl进行清洗,然后用超纯水反复冲洗干净后烘干置于干净环境中备用。

用于标定和校准的Cr(Ⅵ)标准溶液通过用重铬酸钾(K2Cr2O7,纯度为99.9%)和去离子水制备的100 μg·m−3母液稀释获得,在使用前取母液用去离子水稀释到需要的浓度梯度(0.5~8 ng·mL−1)。制备4 mol·L−1的HNO3和3 mol·L−1的NaOH用于酸化和调整溶液pH。用于前处理过程的0.1%的H2O2试剂通过用0.1 mol·L−1的NaOH溶液将0.044 mL 30%的H2O2水溶液定容稀释至1 L制备。将167 mg的二苯碳酰二肼(diphenylcarbazide,DPC)溶解于100 mL的丙酮(C3H6O,纯度为99.9%)中,再与1.67%的H2SO4溶液按照1∶1的体积比混合,制备用于光度法检测前络合反应的DPC试剂[16]。除Cr(Ⅵ)标准溶液,所有的试剂均不含铬。

1.2 样品采集与预处理

用中流量颗粒物采样器(XY-2200,青岛旭宇)通过石英膜(QMA-Whatman,20.3 cm

× 25.4 cm,Φ90 mm)采集环境大气细颗粒物(PM2.5),采样流速100 L·min−1。为降低膜上Cr的本底浓度并减少其在采样中的损失,在采样前将待采样的空白石英膜通过450 ℃高温烘烤6 h,再用2 g·L−1的NaHCO3溶液浸泡后置于清洁恒温箱内晾干密封。采样口距离地面150 cm,用除湿装置保证过程中采样器的环境干燥。样品膜用密封的聚丙烯袋封装并且在-10 ℃下低温保存。所有的样品在采样完成1 d内取回,在3 d内完成前处理和分析测定,以此减少采样过程中Cr的损失,减少测量误差。1.3 分光光度法检测系统及误差避免方法

分光光度检测系统由容量为112 μL、光程为50 cm的长光程流通池(liquid waveguide capillary cell,LWCC,LWCC-3050, World Precision Instruments, Inc., Sarasota, FL),钨灯光源(HL-2000-FHSA-LL,Ocean Optics, Inc., Dunedin, FL),光缆(QP450-1-XSR, Ocean Optics, Inc., Dunedin, FL)和光谱范围为200~900 nm的小型光谱仪(USB4000-UV-VIS,Ocean Optics, Inc., Dunedin, FL)组成。

分析过程中,Cr浓度由Cr(Ⅵ)与DPC反应产生的络合物在540 nm的吸光度进行测算。尽管DPC与大气环境中部分金属离子(Fe3+、Hg2+、Mo6+、Cu2+和V5+)会发生类似络合反应,但这些金属络合物的最大光吸收波长范围均不含540 nm,且相差较大[6]。因此,检测前加入DPC可保证结果基本不受其他金属离子干扰。设定光谱的积分时间为8 ms,每个样品平均次数为20次,光吸收谱图上800 nm处吸光度信号用于设定基线(即设定系统背景信号)。为去除检测仪器自身产生的背景吸光度,通过断开光源测得仪器的暗光谱,并在光谱分析软件中设定扣除暗光谱得到实测光谱数据,以便对系统进行自吸收校正。

1.4 系统运行流程

系统分为2个部分(见图1):石英膜采样和前处理操作的样品采集模块;以分光光度检测为基础的浓度分析模块。将采样后的石英膜用清洁陶瓷剪刀取样、剪碎,放入烧杯后加入20 mL的去离子水和1 mL浓度为4 mol·L−1的HNO3溶液。为尽可能溶解石英膜上采集的环境颗粒物,用磁力搅拌机将石英膜制成的酸化浆液加热(温度为50 ℃)搅拌40 min,分离出10 mL样品清液,装入棕色聚丙烯瓶中避光储存。每次测量后,用4 mol·L−1的HCl溶液清洗所有样品管路,再用超纯水洗净。

分光光度方法测定样品中的Cr浓度:1)络合反应。向样品溶液中加入0.1 mL 0.1%的H2O2试剂将样品溶液中的Cr(Ⅲ)转化为Cr(Ⅵ),同时加入0.1 mL的DPC试剂,静置10 min,待Cr络合物形成并稳定;2)样品注入。用带0.22 μm微孔滤膜(聚四氟乙烯,PTFE)的聚丙烯注射器将1 mL样品注入LWCC中;3)测定浓度。通入样品2~3 min后,待光谱稳定,得到光吸收谱图上540 nm处Cr络合物的最大吸收峰值,将该值扣减设定的800 nm基线值得出净峰高,并通过与标定结果的对比计算得出总Cr浓度。

1.5 采样点

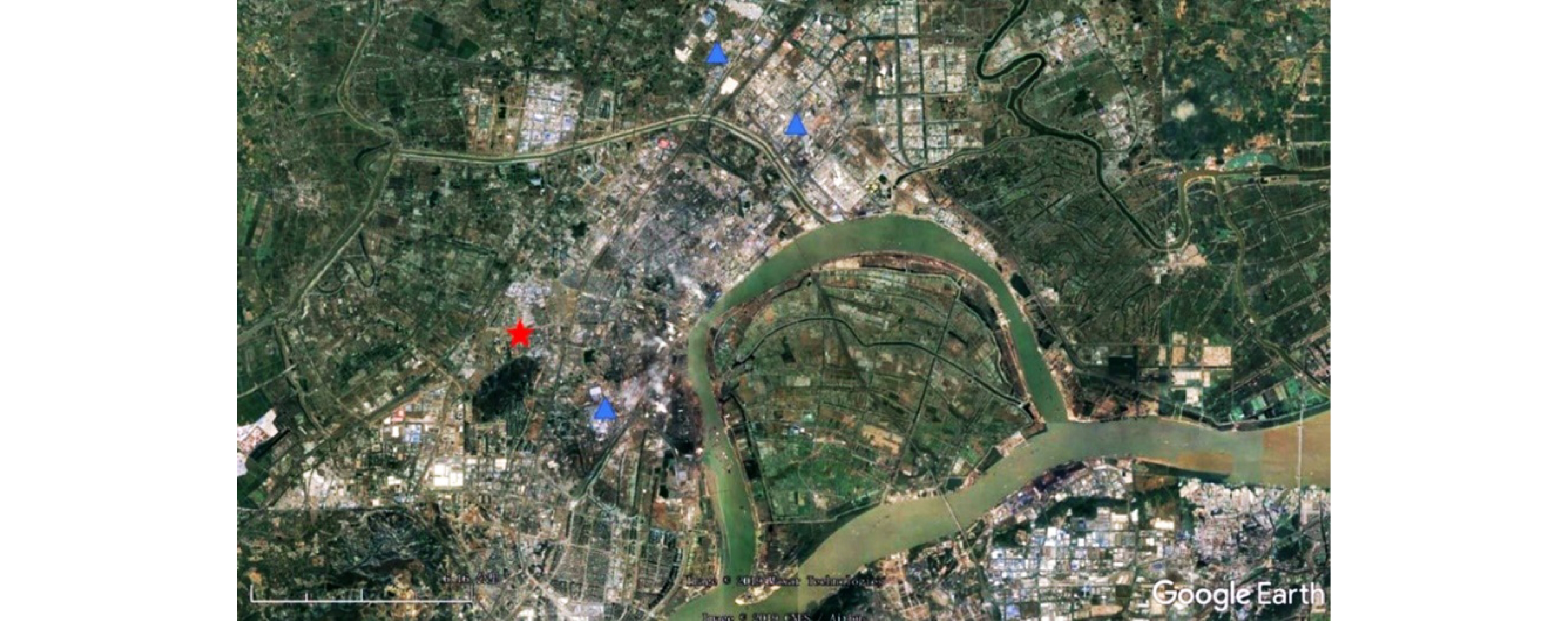

采样点设在南京信息工程大学气象观测场内,按12 h的时间间隔采集南京北郊大气颗粒物样品。设定样品采集的起始时间为每日6:30和18:30。采样点(红色星标)位于南京市中心以北大约15 km处,大型工业区(蓝色三角标)以西,靠近城区日常交通干道(见图2)。该地的PM2.5质量浓度数据由Met One Instruments公司的PM2.5在线监测仪进行实时在线监测,时间分辨率为1 h。

2. 结果与讨论

2.1 最佳样品测定条件的设定

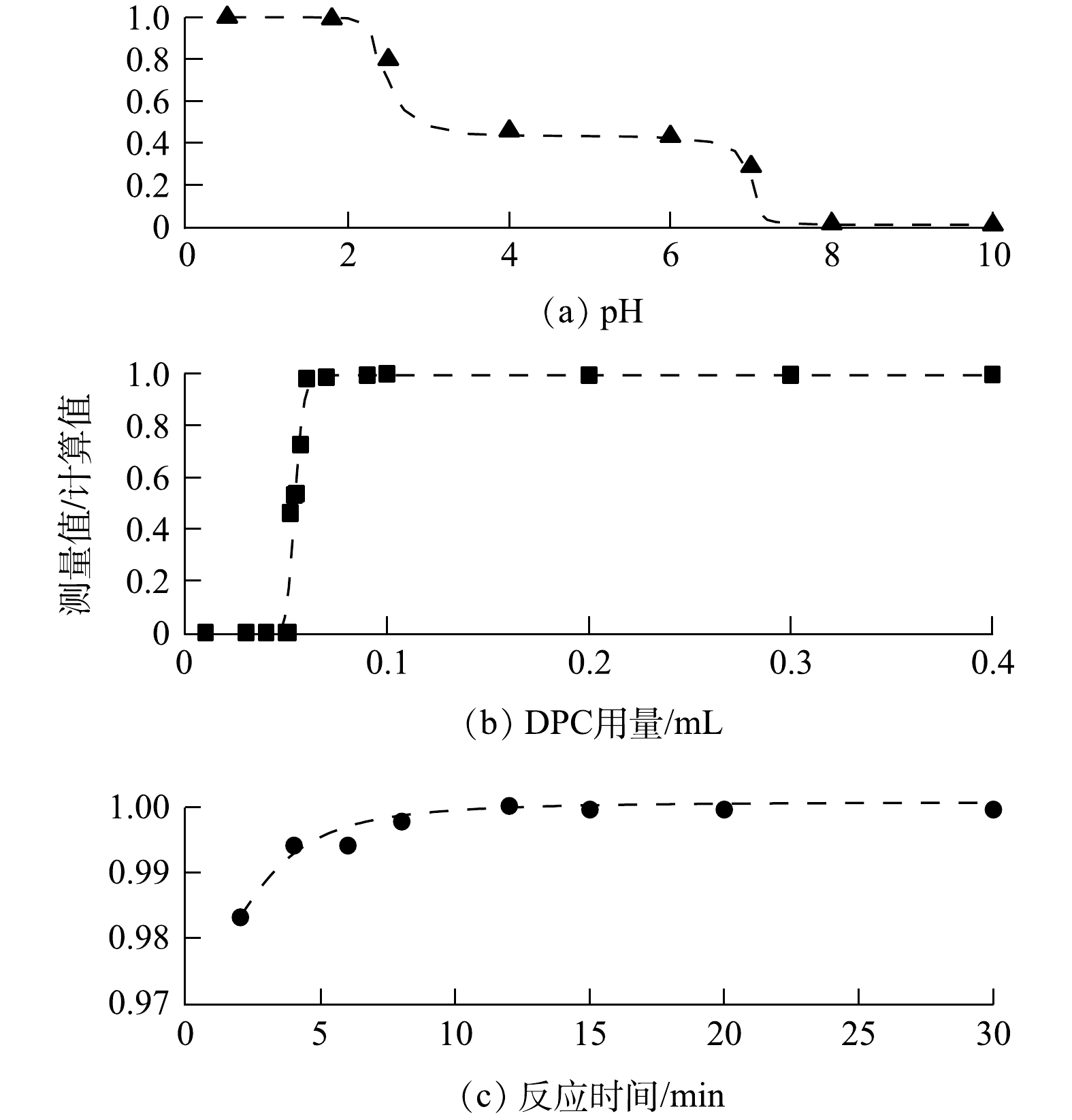

由于大气本底Cr浓度较低,每次取用10 mL浓度为5 ng·mL−1的Cr(Ⅵ)标准溶液进行条件实验。通过改变溶液的pH、DPC试剂的用量及预留的络合反应时间,根据条件实验结果来确定前述各项参数的最佳值或阈值。将仪器的测量值与标准样品浓度的计算值之比作为判别标准,比值越接近1,则结果对应的条件和参数更优。

在酸性环境下,Cr(Ⅵ)与DPC络合的效率随溶液pH的升高而降低,导致测定结果偏低;在碱性环境下,Cr(Ⅵ)无法发生络合反应。因此,需要对溶液体系进行酸化。按体积比加入去离子水和HNO3溶液,得到混合浆液的pH约为0.5。用3 mol·L−1 NaOH溶液调节混合浆液pH,结果如图3(a)所示。加入DPC的Cr络合物反应后溶液的最佳pH为0.5~1,故在前处理中无需调节溶液pH。溶液中过量的氧化剂H2O2将Cr(Ⅲ)氧化成Cr(Ⅵ)后,会优先和DPC发生反应,干扰Cr络合物的生成。DPC试剂的用量为0.1 mL时,可去除过量H2O2的干扰(见图3(b))。同时,所有试剂加入后静置10 min以保证溶液中的Cr络合物完全产生(见图3(c))。

2.2 标定曲线和检测限

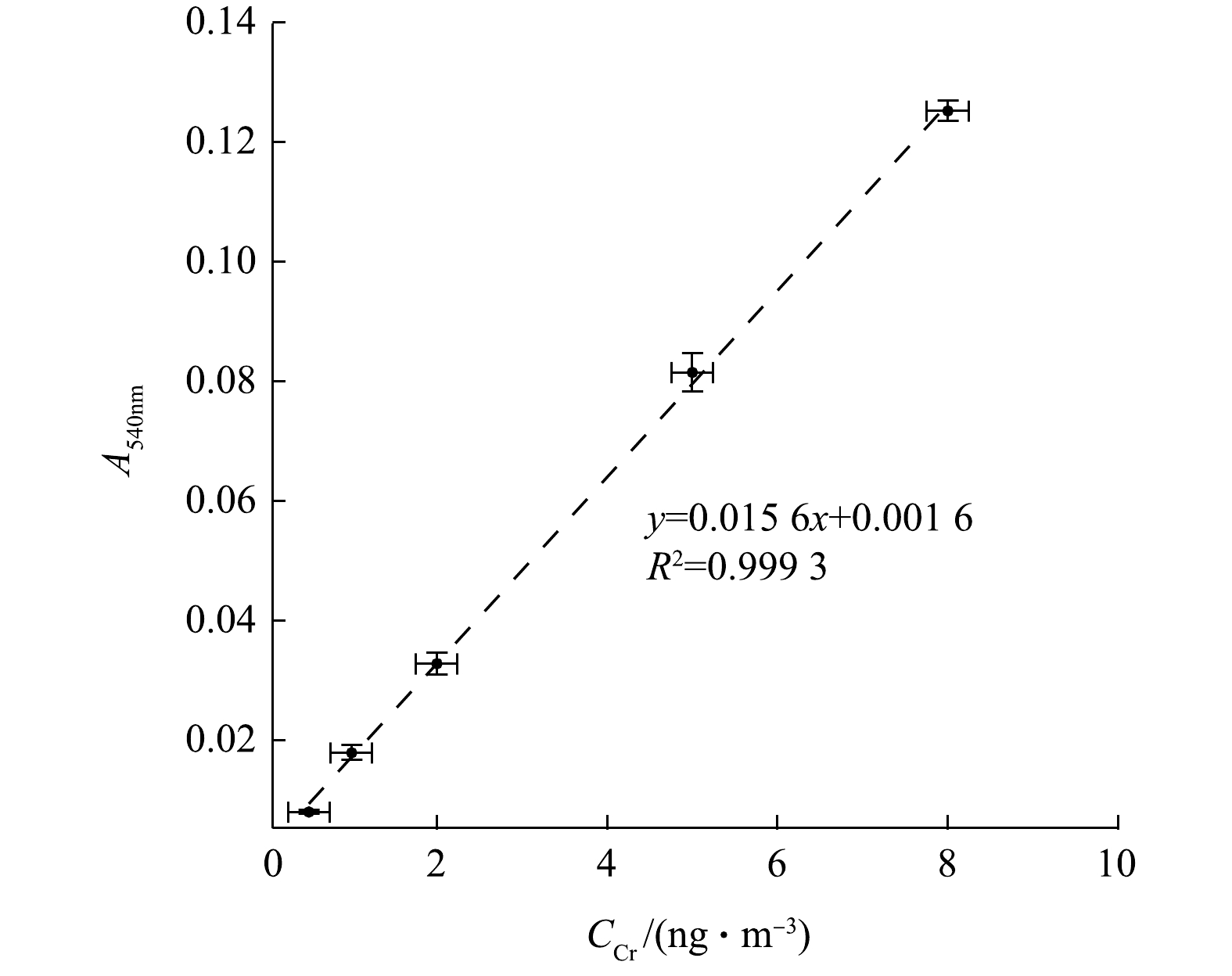

根据实际环境大气颗粒物中总Cr浓度,选择合适浓度梯度(0.5、1、2、5、8 ng·mL−1)的Cr(Ⅵ)标准溶液确定标准曲线。每次标定使用相同Cr(Ⅵ)母液,用去离子水稀释至所需浓度。图4为14 d内不同时间进行的5次标定结果的平均值,相同浓度的多次测定值范围以error bar形式在图中标出。几次标定得到的线性方程斜率在(0.015 6±0.000 2)mL·ng−1范围变化,并且所有标定曲线的R2均能达到0.99。系统分光光度测量的标定范围涵盖了一般环境大气颗粒物中Cr浓度范围。Cr浓度与其络合物的吸光度峰值呈稳定线性关系,多次标定反映出该结果重现性好。

根据空白样品吸光度峰值标准偏差的3倍来测算系统的检测限(limit of detection,LOD)。空白样品由空白石英膜按照样品的前处理过程制得。将加入DPC的空白样品通入LWCC测量吸光度峰值,LOD约为0.158 ng·mL−1,对应采样空气体积约为12 m−3。经过计算对应的环境颗粒物中Cr浓度为0.133 ng·m−3,大气颗粒物中Cr浓度至少比该LOD高一个数量级,故检测系统对Cr浓度的测定灵敏度较高,可满足大气监测需求。从上述空白样品的测定结果还表明,石英膜上Cr本底浓度极低,为(0.971±0.087)ng·g−1,不会干扰实际测量。

2.3 回收率实验

检测系统的回收率实验包括空白加标回收和样品加标回收两部分。空白样品的加标回收通过在空白石英膜上加入10 ng Cr(Ⅵ),再按照样品前处理步骤进行处理和分析测定,测定结果与理论值之比即空白加标回收率。用微升注射器(HAMILTON-7000)取用1 μL由相同Cr(Ⅵ)母液稀释所得浓度为10 μg·mL−1的Cr(Ⅵ)标液,直接加注在石英膜表面进行样品加标,以相同浓度的Cr(Ⅲ)标液(由纯度为99.99%的CrCI3·6H2O和去离子水制得)进行加标实验,通过加入0.1%的H2O2氧化Cr(Ⅲ)后,检测Cr(Ⅳ)浓度并与配置的Cr(Ⅲ)标液比较得到转化率。样品的加标回收则选用NIST商品化的城市颗粒物标准物质(NIST 1648 PM)作为样品。用清洁研钵将NIST样品磨碎,取2份(各5 mg)分别涂抹在空白石英膜上,其中1份加入10 ng Cr(Ⅵ)。将2份样品通过检测系统进行分析,2份样品测量的差值与加入标准Cr(Ⅵ)物质的理论值之比即加标回收率。上述实验均重复进行多次以减少偶然性误差。

由于使用高纯度的药品且系统测量受到干扰误差很小,Cr(Ⅵ) 空白加标回收率均值可达98%,标准偏差为2.4%(样品数为10);Cr(Ⅲ)的转化率为(95±2.6)%(样品数为10)。样品加标回收实验结果显示:在15个加标的标准环境样品中Cr(Ⅵ)回收率为(90.3±8.1)%;而对不加标的NIST标准样品中Cr浓度测定的误差范围为(9.6±3.3)%。ERG使用相同样品加标,通过碳酸盐缓冲液提取与离子色谱(IC)测得的回收率为((89.8±10)%, N=10)[20]。2组样品加标回收率经中位数检验并不存在统计上的显著差异,故该系统具有较好的采集和测量精度。

2.4 与ICP-MS方法的对比测试

ICP-MS是目前颗粒物中痕量金属的热门测定方法之一[21-22]。2014年,我国环境保护部将其确定为测量环境水样中多种痕量元素的标准方法(HJ 700-2014)。近年来,ICP-MS与各种分离技术联用已常见于Cr的相关研究中[23-25]。

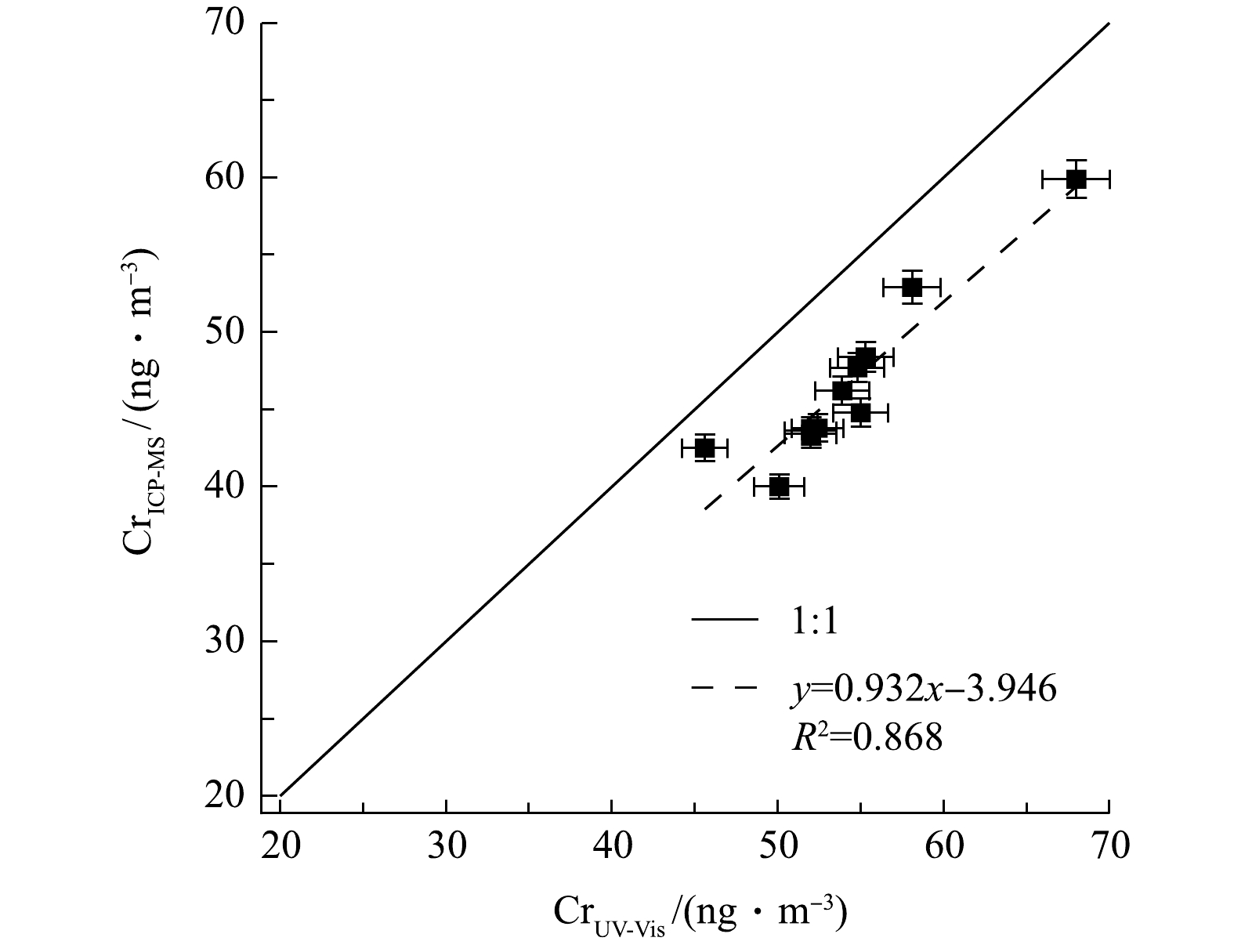

将2016-12-17—2016-12-27在福州三中地区(PM2.5>80 μg·m−3)采集的高浓度大气颗粒物石英膜样品(膜规格:QMA-Whatman, 1851-050, Φ50 mm;采样时长3 h;采样流速16.7 L·min−1),分别通过本系统和ICP-MS测量总Cr浓度。

在进行ICP-MS测定前,将膜样品做密闭微波消解前处理。取用与本系统分析等量样品置于Teflon-TFM消解罐中,再加入10 mL HNO3和HCl的混合液(体积比为1:1),摇匀浸湿样品膜后放入微波消解仪(XT-9900A,上海新拓)中消解8 h。待消解罐冷却至室温,将其中的混合物用0.45 μm的醋酸纤维素滤膜进行过滤。将得到滤液用去离子水稀释至50 mL,用ICP-MS(X-Series2, US Thermo fisher)进行分析。

2种方法测量结果的相关性如图5所示,表明结果呈线性关系(斜率为0.932,R2为0.868)。该结果表明本系统对环境颗粒物中总Cr浓度测定的准确性与稳定性较好,也进一步证明本系统的前处理操作(包括酸化、加热搅拌等)能基本确保样品中所有含铬组分充分溶解,以得到可靠的测量结果。同时也表明若颗粒物样品含Cr组分中耐酸且难溶物质较多,会影响系统测量结果。

2.5 大气PM2.5中Cr浓度的外场实测

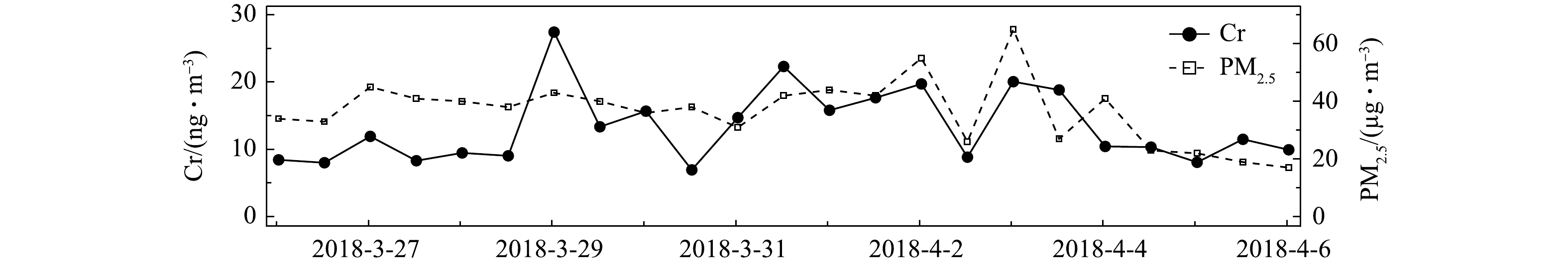

在2018-03-26—2018-04-06对环境大气PM2.5进行样品采集,每12 h采集1次,得到1周多的连续数据如图6所示。测得Cr浓度在采样期间出现了明显的变化,浓度为6.9~27.4 ng·m−3。该浓度水平与其他观测结果相似[27-28],Cr浓度的变化趋势与PM2.5的变化趋势基本一致。整个采样期间,Cr的日平均浓度为13.4 ng·m−3。而这段时间Cr浓度变化较大,这是由于春季空气污染过程频发,且受风向风速变化的影响较大。

分析Cr浓度的变化可发现,2018-03-28夜间到2018-03-29凌晨、2018-03-31白天、2018-04-01夜间到2018-04-02凌晨,以及2018-04-02夜间到2018-04-03凌晨这几个时段达到观测期间的峰值,平均值比日平均浓度高50%~67%;2018-03-30全天、2018-04-02白天Cr浓度降至观测期间日平均浓度的52%~60%;2018-04-04下午到2018-04-06凌晨,Cr浓度基本与采样期间的Cr日平均浓度持平。由于Cr被广泛用于工业生产,如冶金、铬镁耐火材料制造和电镀工艺等[29-31],交通工具的尾气排放和机械磨损[32]也会使环境大气颗粒物中含有这类过渡金属,Cr是地壳中的金属物质之一,故土壤粉尘和地面扬尘也为大气颗粒物中贡献了Cr[33-34]。结合采样点的地理位置分析可推断,大气颗粒物中的Cr主要来自早晚期间强烈的交通活动导致的直接排放和扬尘排放,以及偏东风带来的工业园区排放的污染气团。上述结果表明,本系统可对PM2.5中Cr浓度进行准确连续的测量。

3. 结语

1)设计并评估了一种基于分光光度法测量环境PM2.5中微量Cr的系统。系统通过膜采样经过前处理制成待测样品,再基于分光光度法测量样品中总Cr浓度。系统具有很好的灵敏度和重现性,采集效率较高,测量精度较好。用相同样品与ICP-MS测量结果的对比表明,系统可靠性和准确性均较好。外场采样观测的结果显示,系统具有足够的可靠性,在较少人工监管的情况下能够对环境细颗粒物中Cr进行较快速的连续测量。

2)设计中用到的通过替换金属络合试剂及对前处理步骤进行的优化方法,不仅能测定Cr的价态,还能帮助测定大气环境中部分金属浓度,为实现连续快捷地分析大气环境中水溶性金属离子的污染特征提供了参考。同时,根据大气颗粒物中Cr的来源可以判断,还应进一步研究不同季节大气中Cr的来源和日变化特征。

-

表 1 不同工艺阶段样品常规水质指标

Table 1. Conventional water quality indexes of samples at different process stages

样品 浊度/NTU pH TDS/(mg·L−1) EC/(mS·cm−1) UV254/cm−1 COD/(mg·L−1) DOC/(mg·L−1) TN/(mg·L−1) 原水 161 7.07 20 580 33.46 0.095 625.43 33.26 30.23 磁分离 14.33 6.98 19 450 31.84 0.092 613.96 30.97 28.75 过滤 7.25 7.19 19 635 32.12 0.092 609.47 30.65 28.24 超滤 0.28 7.43 19 610 32.07 0.102 605.86 29.48 28.63 反渗透 0.19 6.41 14.39 0.03 0.004 1.14 0.38 1.06 表 2 不同工艺阶段样品离子浓度

Table 2. Ions concentrations of samples at different process stages

mg·L−1 样品 Na+ K+ Mg2+ Ca2+ Sr2+ F− Cl− Br− SO42- 原水 8 617.8 134.4 75.91 414.6 51.25 1.58 11 469.5 79.54 7.45 磁分离 8 201.2 126.5 72.81 400.5 7.46 1.67 11 501.8 76.94 7.98 过滤 7 794.1 117.9 69.89 398.7 5.48 1.15 11 369.4 73.04 6.66 超滤 7 799.2 108.4 67.56 378.3 1.18 1.12 11 505.8 70.81 5.9 反渗透 5.79 0.33 BDLa BDL BDL BDL 3.62 0.034 0.39 注:a BDL:低于检测限 (0.01 mg·L−1)。 表 3 运行成本分析

Table 3. Analysis of operating cost

工艺段 项目 消耗量 单价 金额/(元·m−3) 磁分离 PAC 0.03 kg·m−3 2.4 元·kg−1 0.07 精制铁粉 0.01 kg·m−3 2 元·kg−1 0.02 PAM 0.001 kg·m−3 12 元·kg−1 0.01 污泥处置药剂 0.005 kg·m−3 12 元·kg−1 0.06 电耗 0.73 kWh·m−3 0.65 元·kWh−1 0.47 精细过滤 电耗 0.51 kWh·m−3 0.65 元·kWh−1 0.33 超滤 电耗 5.57 kWh·m−3 0.65 元·kWh−1 3.62 化学药剂 — — 0.70 超滤膜元件 — — 0.91 DTRO 电耗 11.21 kWh·m−3 0.65 元·kWh−1 7.29 化学药剂 — — 2.39 DTRO膜元件 — — 3.04 -

[1] SUN Y, WANG D, TSANG D C W, et al. A critical review of risks, characteristics, and treatment strategies for potentially toxic elements in wastewater from shale gas extraction[J]. Environment International, 2019, 125: 452-469. doi: 10.1016/j.envint.2019.02.019 [2] ZHONG C, ZOLFAGHARI A, HOU D, et al. Comparison of the hydraulic fracturing water cycle in China and North America: A critical review[J]. Environmental Science & Technology, 2021, 55(11): 7167-7185. [3] HOU D Y, LUO J, AL-TABBAA A. COMMENTARY: Shale gas can be a double-edged sword for climate change[J]. Nature Climate Change, 2012, 2(6): 385-387. doi: 10.1038/nclimate1500 [4] VIDIC R D, BRANTLEY S L, VANDENBOSSCHE J M, et al. Impact of shale gas development on regional water quality[J]. Science, 2013, 340(6134). [5] YU M, WEINTHAL E, PATINO-ECHEVERRI D, et al. Water availability for shale gas development in Sichuan Basin, China[J]. Environmental Science & Technology, 2016, 50(6): 2837-2845. [6] CHANG H, LI T, LIU B, et al. Potential and implemented membrane-based technologies for the treatment and reuse of flowback and produced water from shale gas and oil plays: A review[J]. Desalination, 2019, 455: 34-57. doi: 10.1016/j.desal.2019.01.001 [7] JI X, TIRAFERRI A, ZHANG X, et al. Dissolved organic matter in complex shale gas wastewater analyzed with ESI FT-ICR MS: Typical characteristics and potential of biological treatment[J]. Journal of Hazardous materials, 2023, 447: 130823. doi: 10.1016/j.jhazmat.2023.130823 [8] XIE W, TIAN L, TANG P, et al. Shale gas wastewater characterization: Comprehensive detection, evaluation of valuable metals, and environmental risks of heavy metals and radionuclides[J]. Water Research, 2022, 220: 118703. doi: 10.1016/j.watres.2022.118703 [9] ESTRADA J M, BHAMIDIMARRI R. A review of the issues and treatment options for wastewater from shale gas extraction by hydraulic fracturing[J]. Fuel, 2016, 182: 292-303. doi: 10.1016/j.fuel.2016.05.051 [10] SHANG W, TIRAFERRI A, HE Q, et al. Reuse of shale gas flowback and produced water: Effects of coagulation and adsorption on ultrafiltration, reverse osmosis combined process[J]. Science of the Total Environment, 2019, 689: 47-56. doi: 10.1016/j.scitotenv.2019.06.365 [11] LIU Y, TANG P, ZHU Y, et al. Green aerogel adsorbent for removal of organic compounds in shale gas wastewater: High-performance tuning and adsorption mechanism[J]. Chemical Engineering Journal, 2021, 416: 129100. doi: 10.1016/j.cej.2021.129100 [12] VINGE S L, ROSENBLUM J S, LINDEN Y S, et al. Assessment of UV disinfection and advanced oxidation processes for treatment and reuse of hydraulic fracturing produced water[J]. ACS ES& T Engineering, 2021, 1(3): 490-500. [13] TANG P, LIU B, ZHANG Y, et al. Sustainable reuse of shale gas wastewater by pre-ozonation with ultrafiltration-reverse osmosis[J]. Chemical Engineering Journal, 2020, 392: 123743. doi: 10.1016/j.cej.2019.123743 [14] 林雯杰, 王菁, 孟宣宇, 等. 电-Fenton法处理页岩气压裂返排液[J]. 环境工程学报, 2017, 11(2): 857-861. doi: 10.12030/j.cjee.201510035 [15] TANG P, XIE W, TIRAFERRI A, et al. Organics removal from shale gas wastewater by pre-oxidation combined with biologically active filtration[J]. Water Research, 2021, 196: 117041. doi: 10.1016/j.watres.2021.117041 [16] TANG P, XIE W, TIAN L, et al. Oxidation-biotreatment-membrane combined process for external reuse of shale gas wastewater[J]. Separation and Purification Technology, 2022, 291: 120920. doi: 10.1016/j.seppur.2022.120920 [17] TONG T Z, CARLSON K H, ROBBINS C A, et al. Membrane-based treatment of shale oil and gas wastewater: The current state of knowledge[J]. Frontiers of Environmental Science & Engineering, 2019, 13(4). [18] GUO C, CHANG H, LIU B, et al. A combined ultrafiltration-reverse osmosis process for external reuse of Weiyuan shale gas flowback and produced water[J]. Environmental Science-Water Research & Technology, 2018, 4(7): 942-955. [19] HE C, VIDIC R D. Application of microfiltration for the treatment of Marcellus Shale flowback water: Influence of floc breakage on membrane fouling[J]. Journal of Membrane Science, 2016, 510: 348-354. doi: 10.1016/j.memsci.2016.03.023 [20] HE C, WANG X, LIU W, et al. Microfiltration in recycling of Marcellus Shale flowback water: Solids removal and potential fouling of polymeric microfiltration membranes[J]. Journal of Membrane Science, 2014, 462: 88-95. doi: 10.1016/j.memsci.2014.03.035 [21] 刘宇程, 吴东海, 袁建梅, 等. 膜蒸馏处理页岩气井压裂返排液[J]. 环境工程学报, 2017, 11(1): 48-54. doi: 10.12030/j.cjee.201509096 [22] GETZINGER G J, O’CONNOR M P, HOELZER K, et al. Natural gas residual fluids: Sources, endpoints, and organic chemical composition after centralized waste treatment in Pennsylvania[J]. Environmental Science & Technology, 2015, 49(14): 8347-8355. [23] 骆欣. 含锶放射性废水的处理方法研究进展[J]. 华北科技学院学报, 2014, 11(3): 72-76. [24] NI Y, ZOU C, CUI H, et al. Origin of flowback and produced waters from Sichuan Basin, China[J]. Environmental Science & Technology, 2018, 52(24): 14519-14527. [25] ROSENBLUM J, THURMAN E M, FERRER I, et al. Organic chemical characterization and mass balance of a hydraulically fractured well: From fracturing fluid to produced water over 405 days[J]. Environmental Science & Technology, 2017, 51(23): 14006-14015. [26] BARBOT E, VIDIC N S, GREGORY K B, et al. Spatial and temporal correlation of water quality parameters of produced waters from devonian-age shale following hydraulic fracturing[J]. Environmental Science & Technology, 2013, 47(6): 2562-2569. [27] ZHOU S, LI Z, PENG S, et al. Combining eDNA and morphological approaches to reveal the impacts of long-term discharges of shale gas wastewaters on receiving waters[J]. Water Research, 2022, 222: 118869. doi: 10.1016/j.watres.2022.118869 [28] ZHOU S, LI Z, PENG S, et al. River water influenced by shale gas wastewater discharge for paddy irrigation has limited effects on soil properties and microbial communities[J]. Ecotoxicology and Environmental Safety, 2023, 251: 114552. doi: 10.1016/j.ecoenv.2023.114552 [29] PéREZ-GONZáLEZ A, URTIAGA A M, IBáñEZ R, et al. State of the art and review on the treatment technologies of water reverse osmosis concentrates[J]. Water Research, 2012, 46(2): 267-283. doi: 10.1016/j.watres.2011.10.046 [30] TONG T Z, ELIMELECH M. The global rise of zero liquid discharge for wastewater management: Drivers, technologies and future directions[J]. Environmental Science & Technology, 2016, 50(13): 6846-6855. [31] LIU Y, WU Q, CHEN C, et al. An efficient system of aerogel adsorbent combined with membranes for reuse of shale gas wastewater[J]. Desalination, 2022, 526: 115545. doi: 10.1016/j.desal.2021.115545 [32] LICONA K P M, GEAQUINTO L R D O, NICOLINI J V, et al. Assessing potential of nanofiltration and reverse osmosis for removal of toxic pharmaceuticals from water[J]. Journal of Water Process Engineering, 2018, 25: 195-204. doi: 10.1016/j.jwpe.2018.08.002 [33] CHEN W, WESTERHOFF P, LEENHEER J A, et al. Fluorescence excitation−emission matrix regional integration to quantify spectra for dissolved organic matter[J]. Environmental Science & Technology, 2003, 37(24): 5701-5710. [34] 姚璐璐, 涂响, 于会彬, 等. 三维荧光区域积分评估城市污水中溶解性有机物去除[J]. 环境工程学报, 2013, 7(2): 411-416. [35] HE Y, LIU J W, SONG P B, et al. Magnetic hybrid coagulant for rapid and efficient removal of nitrogen compounds from municipal wastewater and its mechanistic investigation[J]. Chemical Engineering Journal, 2021, 417. [36] LIU X, TANG P, LIU Y, et al. Efficient removal of organic compounds from shale gas wastewater by coupled ozonation and moving-bed-biofilm submerged membrane bioreactor[J]. Bioresource Technology, 2022, 344: 126191. doi: 10.1016/j.biortech.2021.126191 [37] TANG P, SHI M, LI X, et al. Can pre-ozonation be combined with gravity-driven membrane filtration to treat shale gas wastewater?[J]. Science of the Total Environment, 2021, 797: 149181. doi: 10.1016/j.scitotenv.2021.149181 [38] CLUFF M A, HARTSOCK A, MACRAE J D, et al. Temporal changes in microbial ecology and geochemistry in produced water from hydraulically fractured Marcellus shale gas wells[J]. Environmental Science & Technology, 2014, 48(11): 6508-6517. [39] 罗臻, 张晓飞, 张华, 等. 页岩气压裂返排液电化学处理现场试验研究[J]. 工业水处理, 2022, 42(10): 118-124. -

下载:

下载: