-

由于含有大量的重金属,不锈钢渣与铜渣中被许多国家归属为危险废物[1-4]。这些危险废物在雨水的淋滤过程中容易进入地下水系统和土壤中,从而对生态环境造成威胁。一般可通过二次回收和固化2种方式解决不锈钢渣与铜渣中的重金属污染问题[5-7]。仪桂兰[8]以粉煤灰和不锈钢渣为原料成功地制备了微晶玻璃为不锈钢渣资源化利用提供了新途径。卜金彪等[9]综合利用不锈钢渣、尾矿及废玻璃制备了主晶相为镁黄长石相微晶玻璃。SOHN等[10]通过改变不锈钢熔渣中Al2O3/SiO2比例,提高富铬尖晶石在熔渣中浸出率,减少熔渣中游离的Cr离子含量,提高了Cr离子的稳定性。MA等[11]以铜渣为原料添加ZnO制备微晶玻璃,研究发现Zn能够有效包裹在晶体结构中,降低了酸碱环境中重金属被浸出的风险。LIU等[12]利用钢渣与粉煤灰制备全固废基微晶玻璃,使Zn、Fe、Mn进入微晶相中对重金属离子进行固化。此外,DENG等[13]、DENG等[14]和DENG等[15]利用铬铁渣制备微晶玻璃使不锈钢渣中的多种重金属结晶为尖晶石,实现多种重金属协同固化。因此,以粉煤灰、不锈钢渣和铜渣制备微晶玻璃可以高值化利用固体废弃物,减少毒性物质的浸出。

微晶玻璃具有较高的机械强度、耐腐蚀性和耐磨性,可替代铸石和耐酸陶瓷板在煤炭、采矿、水泥、机械等工业部门应用。大部分微晶玻璃是通过非均匀形核制备获得,晶核剂是促进玻璃析晶和优化性能的重要物质[16]。DENG等[13]提出了在CaO-MgO-SiO2-Al2O3体系微晶玻璃中Cr2O3容易优先结晶形成尖晶石纳米晶粒作为晶核剂诱导辉石结晶。ZHANG等[17]研究发现Cr2O3能够诱导玻璃分相,降低析晶温度。魏海燕等[18]尝试以微波热处理技术制备微晶玻璃,探究Cr2O3和Fe2O3为晶核剂对微晶玻璃析晶行为的影响。Fe2O3是一种促进微晶玻璃析晶的重要晶核剂,铁离子能够弱化玻璃网络结构,增加非桥氧数量,降低玻璃析晶活化能,促进玻璃析晶[19-20]。因此,金属离子作为形核剂诱导硅酸盐玻璃析晶是制备微晶玻璃的一种优势选择。

目前,主要采用电阻加热方式对微晶玻璃进行热处理,该方法制备微晶玻璃能耗高、热能利用率低,不利于可持续发展。基于废弃物成分以SiO2、CaO、MgO、Al2O3以及Fe2O3为主,适合制备 CaO-MgO-SiO2-Al2O3-Fe2O3(CMASF)体系微晶玻璃。本研究以粉煤灰、不锈钢渣和铜渣为原料采用微波热处理制备矿渣微晶玻璃,拟探究微波热处理过程重金属迁移与固化机制,并分析Fe2O3对辉石微晶玻璃形成过程中的玻璃网络结构变化与结晶规律。

-

采用X荧光光谱仪测试确定粉煤灰、铜渣以及不锈钢渣的化学成分,其结果见表1。本实验中固体废弃物利用率达90%,其中粉煤灰与不锈钢渣的利用比例为55%~65%与15%~25%,铜渣的利用率为0%~25%。其他不满足实验配方成分采用石英砂、CaO、MgO和硼砂补充,实验配方与样品编号如表2所示。

将3种废弃物按配方设计比例称量,添加一定比例的石英砂、CaO、MgO和硼砂补充,混合搅拌1 h。然后将混合物放置在刚玉坩埚内在马弗炉中以1 500 °C熔制3 h,随后将玻璃熔液倒入模具中成型,并在650 °C退火1 h。少量玻璃熔液浇注在冷水中制备水淬渣,采用差示扫描量热法 (Differential scanning calorimeter, DSC) 确定玻璃的热力学参数。本实验采用2.45 GHz微波在1~4 Kw功率中对母相玻璃析晶热处理。微波处理方法为一步晶化法,参考DSC曲线将母相玻璃以3 °C·min−1升温到860 °C并保温1 h制备微晶玻璃样品。

-

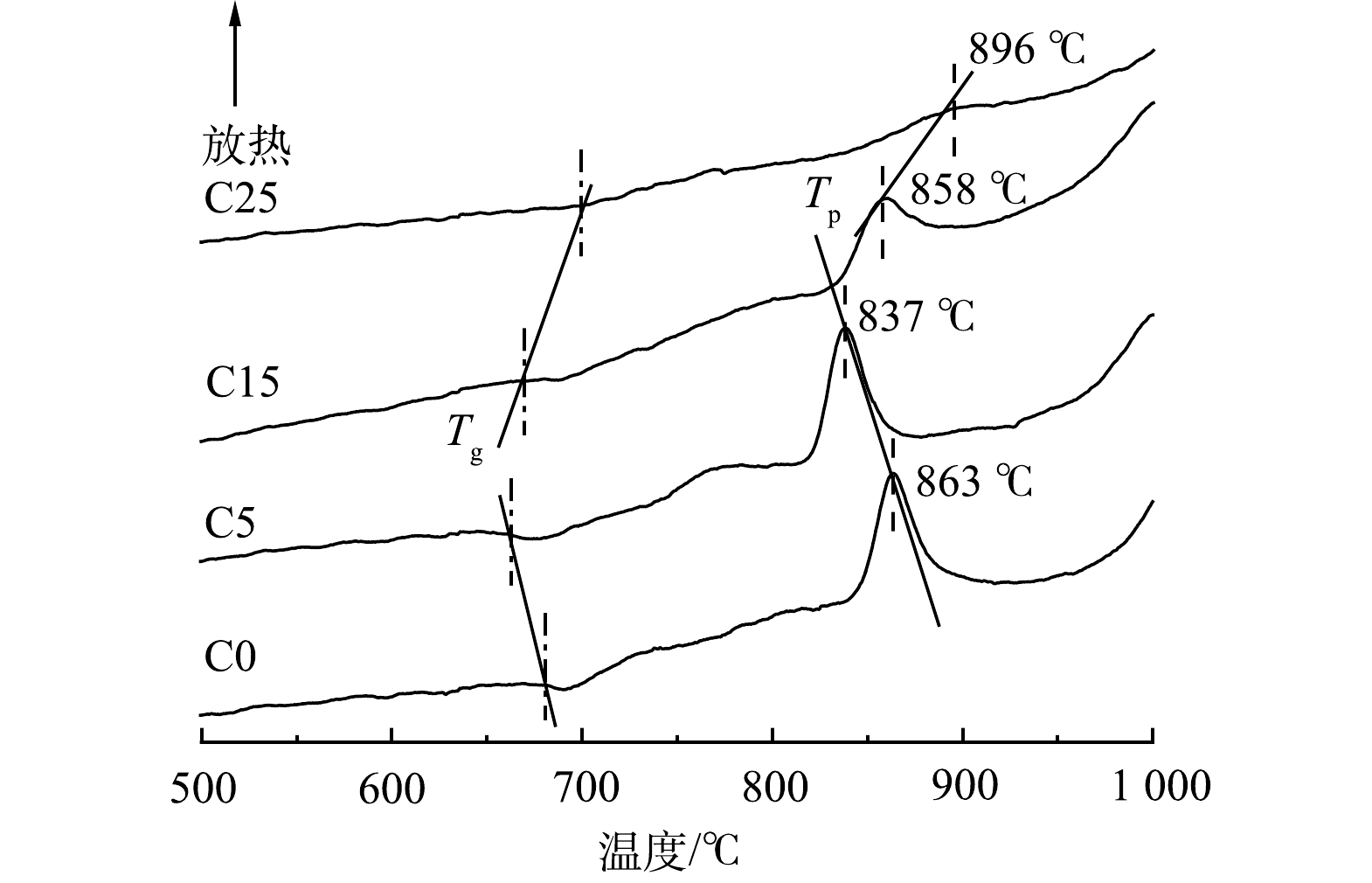

采用DSC差示扫描量热仪 (STA 449F3,耐驰,德国) 对水淬渣进行测试,获得微晶玻璃的玻璃转变温度 (Tg) 和析晶峰温度 (Tp) ;氩气气氛保护,升温速率为5 °C·min−1;试样测试温度范围为20~1 200 °C。

通过X射线衍射 (X-ray diffraction, XRD) 分析仪 (Rigku XRD MiniFlex,日本) 测试获得微晶玻璃的晶相结构信息;Cu靶激发X射线,扫描范围10°~90°。

利用傅里叶红外光谱 (Fourier transform infrared, FTIR) 仪 (Invenio,布鲁克,德国) 测试获得母相玻璃与微晶玻璃在400~4 000 cm−1的红外吸收峰。

通过场发射扫描电子显微镜 (Scanning electron microscope, SEM) (Suppra55,蔡司,德国) 在二次电子相模式中观察获得微晶玻璃的微观形貌,并利用能谱仪获得微晶玻璃样品元素分布。

-

采用DSC测试了水淬渣的结晶温度的变化,确定了母相玻璃的晶化处理温度。图1显示母相玻璃的转变温度 (Tg) 在650~700 °C,玻璃析晶温度 (Tp) 在830~900 °C。随铜渣质量分数的增加,铜渣中的Fe2O3对母相玻璃的析晶温度产生重要影响,Tg与Tp均呈现先降低后升高。前人研究发现,Fe2O3对玻璃结构有双重调控作用,当微晶玻璃中含有少量的Fe2O3主要以[FeO6]形式存在,其能够破坏Si-O网络结构,降低玻璃网络的连通性,使玻璃发生解聚促进玻璃析晶[19]。当玻璃中含有过多Fe2O3,形成[FeO4]结构单元对玻璃网络进行补充,增加玻璃聚合度抑制玻璃析晶[20]。可见,加入少量的铜渣时,Fe2O3以[FeO6]形式存在,扮演玻璃网络改性剂的角色,降低玻璃析晶温度。当铜渣添加量到15%时,玻璃基体中存在过多的Fe2O3,形成[FeO4]结构对玻璃进行补网,增加玻璃的聚合度,抑制玻璃的析晶。

玻璃的稳定性可以用△T (△T=TP−Tg) 表示,根据DSC测试结果获得的不同样品的玻璃稳定性变化情况列于表3。随着铜渣质量分数增加,△T由183 °C降低到176 °C,当铜渣质量分数为5%,△T值最低。当铜渣质量分数为15%,△T呈现增长趋势为190 °C,当铜渣质量分数为25%,△T为198 °C。△T值越大玻璃的稳定性越强,由此可知玻璃的稳定性先降低后升高。这与通过DSC曲线确定了微晶玻璃结晶温度先降低后升高的趋势一致。玻璃稳定性、结晶温度与玻璃网络聚合度有关,玻璃网络聚合度越高其稳定性越强,并且微晶玻璃析晶温度也会提高。因此,少量Fe离子以[FeO6]破坏玻璃网络连通性,过多的Fe离子以[FeO4]对玻璃进行补网,玻璃稳定性先降低后增加。

-

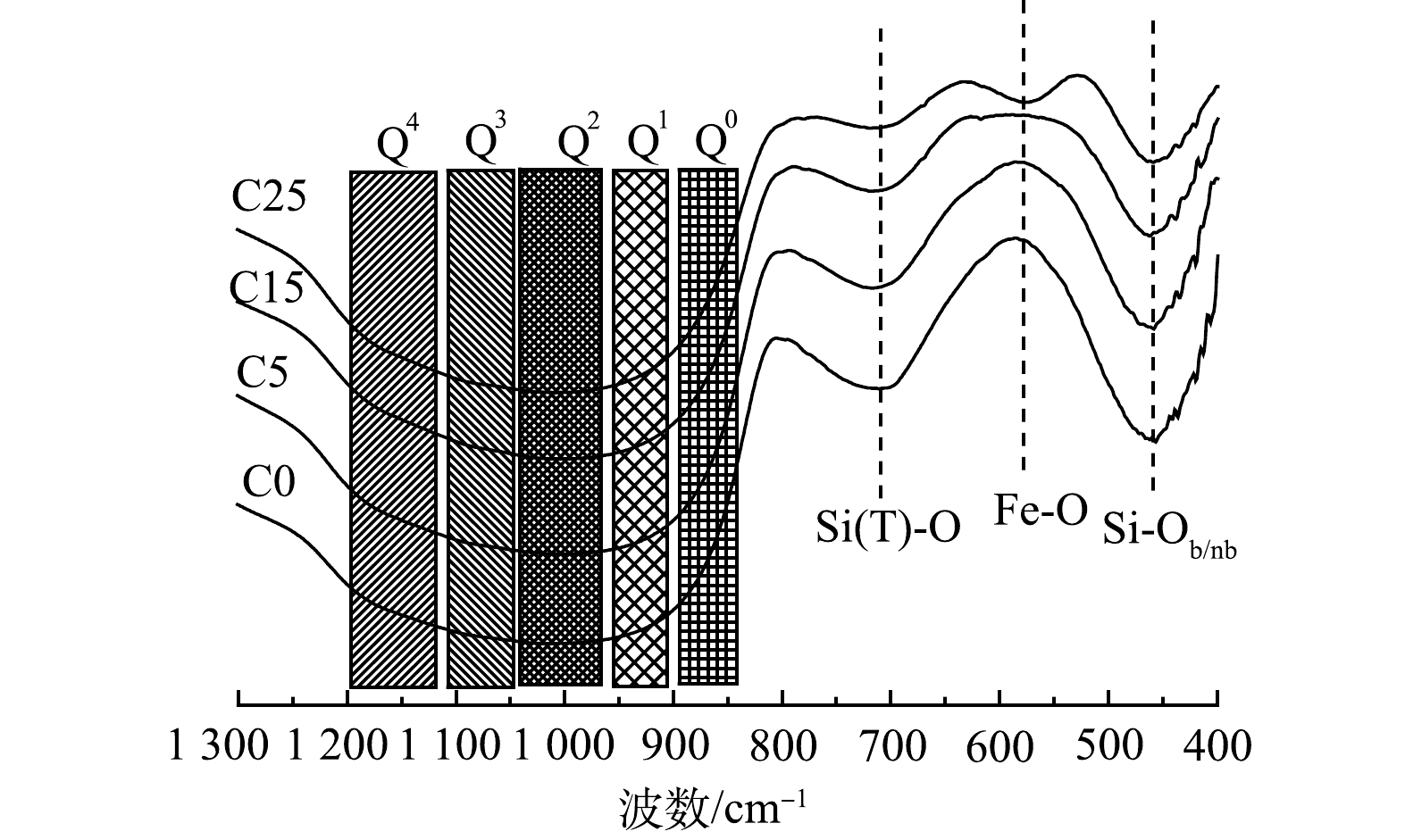

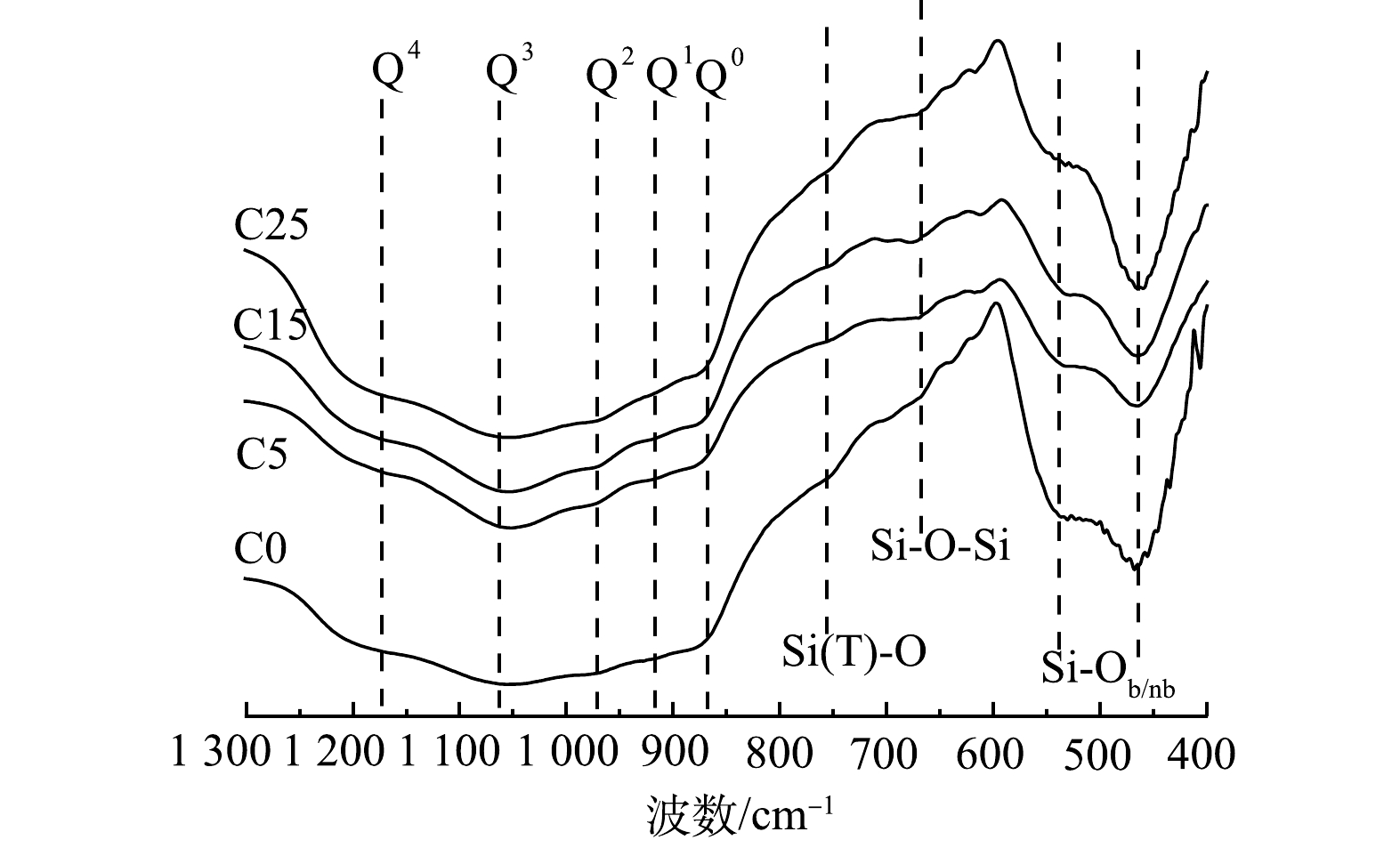

玻璃的结晶行为与玻璃的网络结构密切相关,因此采用红外光谱分析了不同样品的玻璃网络结构,其结果如图2所示。从图2可以看出,红外光谱显示3个典型特征吸收带,430~560 cm−1、600~760 cm−1和730~1 200 cm−1,分别代表了Si-O-Si、Si(T)-O键的弯曲振动和玻璃网络Qn结构单元的对称伸缩振动。随着铜渣质量分数增加到25%时,在580 cm−1形成1个独立的吸收峰,代表Fe-O键的振动。

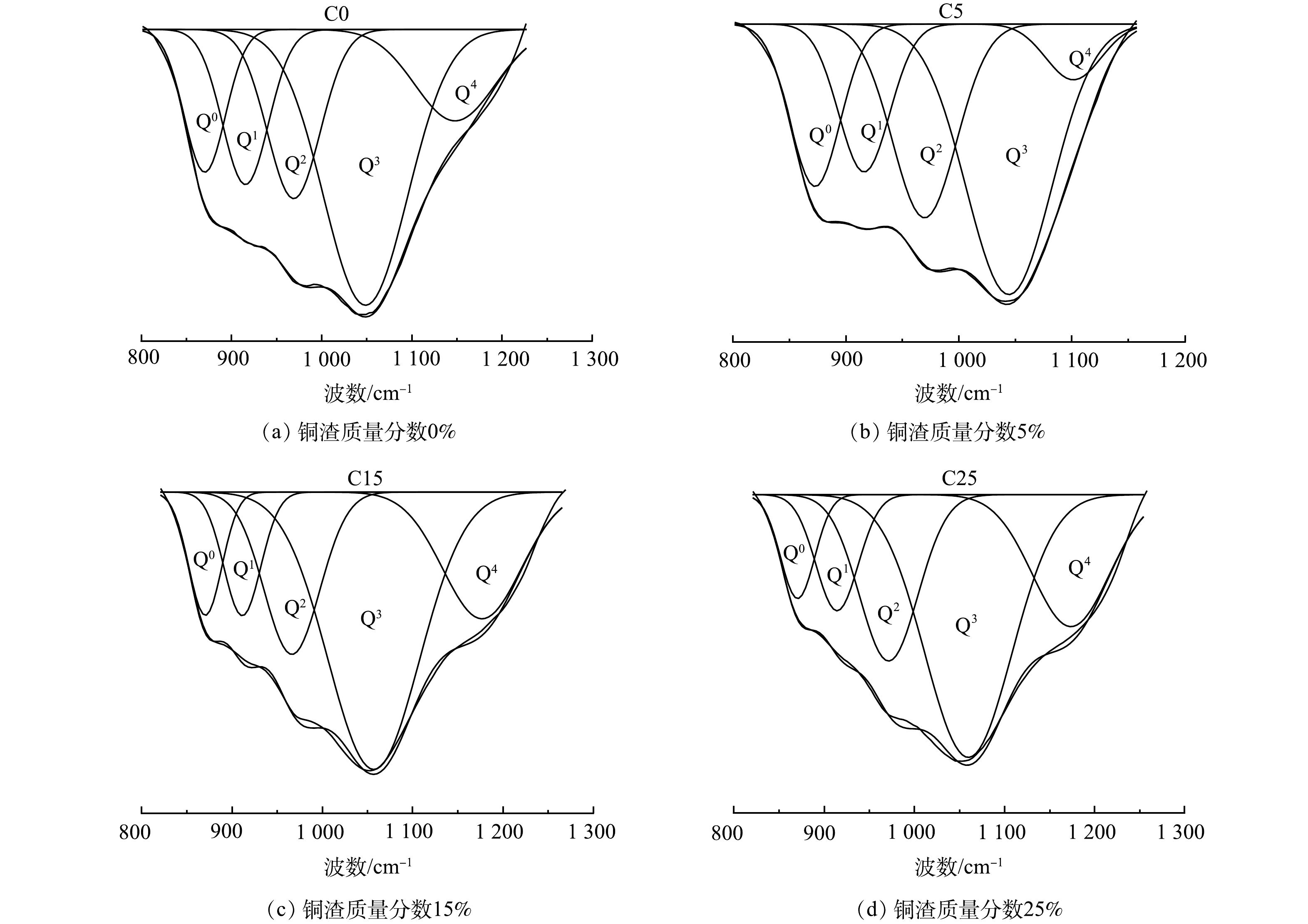

玻璃网络的聚合度反应了微晶玻璃的结晶趋势,通常用不同Qn的相对含量 (n,表示[SiO4]的桥接氧量) 来评价。其中,Q0 (SiO44−)、Q1 (Si2O76-) 、Q2 (Si2O64-) 、Q3 (Si2O52−) 、Q4 (SiO2) 结构单元的红外特征吸收峰分别出现在840~890 cm−1、900~950 cm−1、960~1 030 cm−1、1 050~1 100 cm−1和1 160~1 190 cm−1范围[21-22]。采用高斯微积分方法对800~1 200 cm−1的Qn的吸收峰进行解卷积,获得的不同Qn的吸收峰面积,如图3所示。通过玻璃中非桥氧键占总硅氧四面体结构的含量值可以反映玻璃网络的解聚度 (DOP) 。玻璃网络的解聚度由式DOP = 4×Q0+3×Q1+2×Q2+1×Q3+0×Q4计算获得,DOP值见表4。

从表4可看出,随着铜渣含量的增加,母相玻璃的DOP值先增大后减小。C5样品的DOP值最大是1.89。对比DOP值,可知C15、C25样品的玻璃网络聚合度明显高于C0和C5样品。此外,C15、C25样品中Q4的占比明显多于C0和C5样品,Q4代表了完全聚合的SiO2,其含量增加导致玻璃网络聚合度增强。由此可知,母相玻璃中含少量Fe2O3时,Fe离子能够破坏[SiO4]网络结构,降低玻璃粘度。当玻璃中Fe2O3含量过多时,样品中形成[FeO4]对玻璃补网,从而提高玻璃聚合度。

-

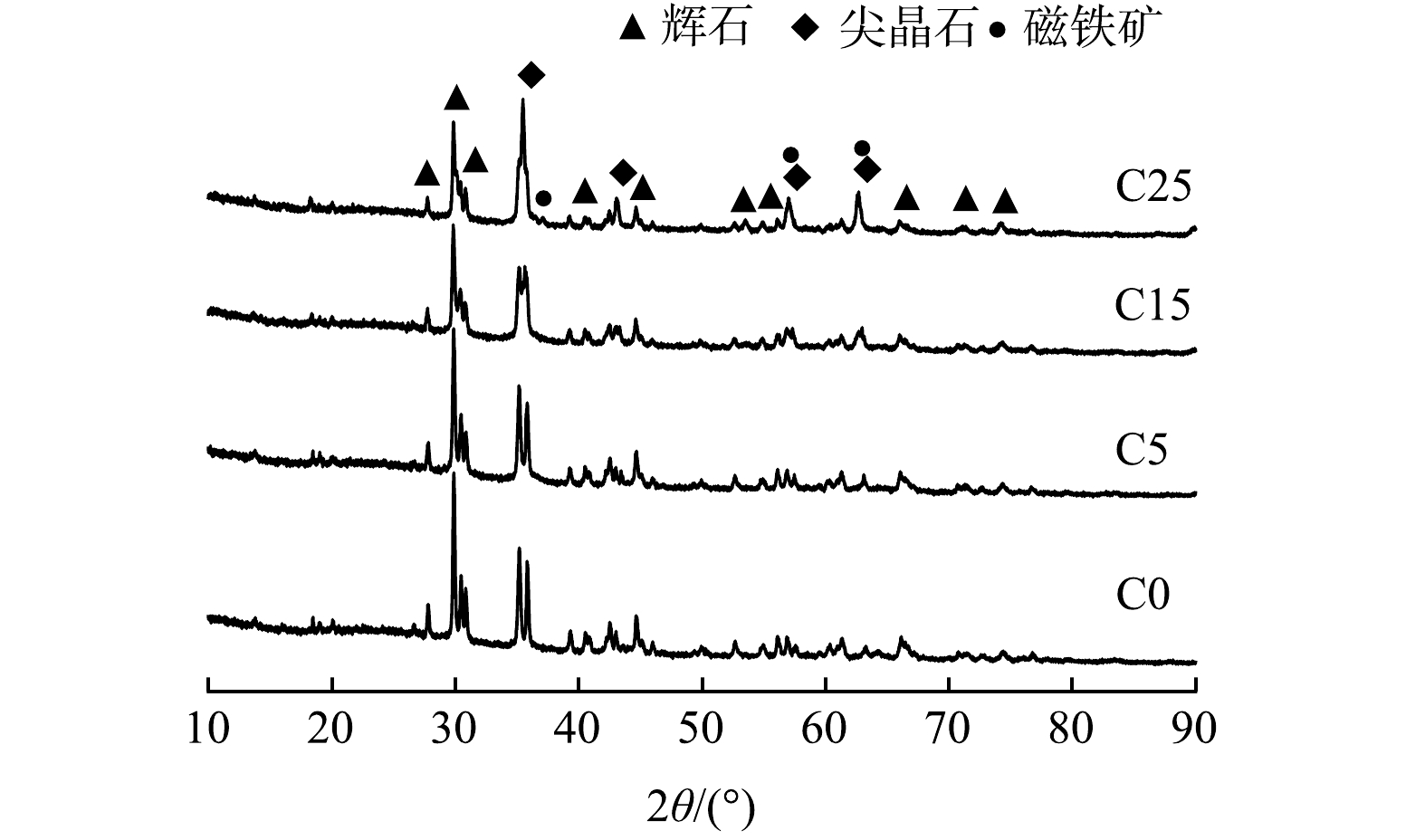

图4为微波晶化热处理获得微晶玻璃样品的XRD图。XRD图谱显示不同样品均出现明显的结晶峰,形成以辉石相(Mg,Fe,Al)(Ca,Mg,Fe)(Si,Al)2O6 (PDF:88-0856)为主晶相,磁铁矿Fe3O4 (PDF:89-0691)和尖晶石Fe(Cr,Mg)2O4 (PDF:89-2618)为副相的复合相微晶玻璃。随着铜渣质量分数提高,辉石相的衍射峰强度先增强后逐渐降低,并且磁铁矿与尖晶石相的衍射峰强度逐渐增强。由XRD图谱可看出,铜渣质量分数为5%时,其中的Fe2O3可以作为晶核剂促进辉石结晶。然而,随着铜渣质量分数增加,母相玻璃中含有较多的Fe离子,一部分Fe3+与Fe2+结合并结晶形成磁铁矿相,另一部分Fe3+与Mg2+、Cr3+、Zn2+耦合生成尖晶石析出。

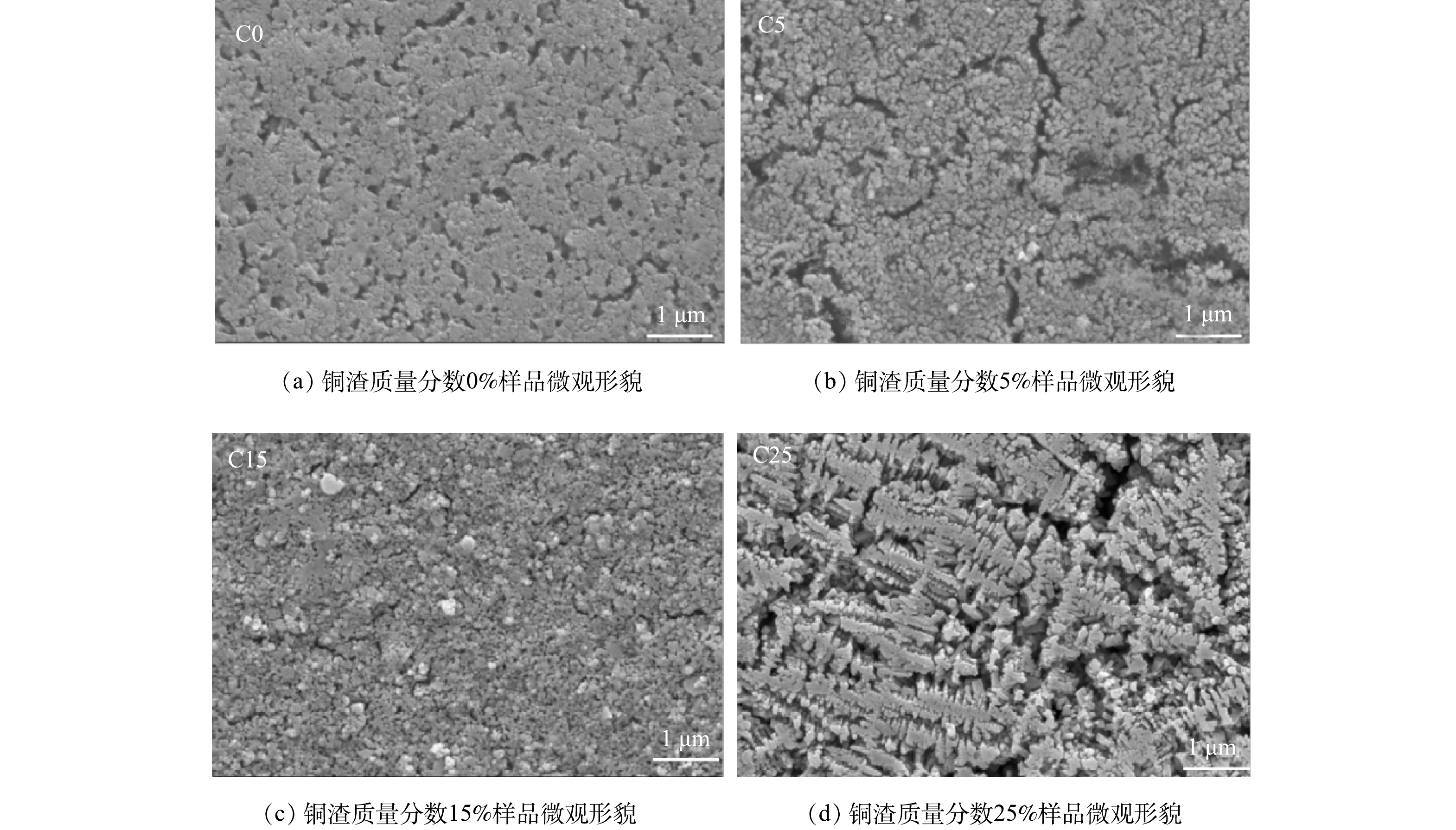

图5为微波晶化热处理微晶玻璃样品的微观形貌图。从图中观察到C0、C5、C15样品形成了均匀分布辉石粒状晶,且晶粒尺寸逐渐变小。由于Fe2O3质量分数增加使玻璃中形核质点增多,从而使辉石晶粒细化。此外,微波热处理具有均匀加热的特点,能够促使辉石均匀生长。相关微波法制备微晶玻璃研究表明,微波效应不仅降低了玻璃析晶活化能提高析晶效率,而且促使辉石晶粒均匀分布[23]。然而,C25样品中出现了大量磁铁矿枝状晶,这与玻璃中的铁含量增多有关。微晶玻璃中出现大量磁铁矿枝晶分布,一方面是因为磁铁矿具有较强的析晶能力与较低的结晶温度,能够在母相玻璃中优先析晶;另一方面,磁铁矿的析晶使玻璃中阳离子含量减少,增加玻璃粘度,使辉石的结晶受到抑制。

图6为微晶玻璃样品的红外光谱图。红外光谱中显示在400~600 cm−1、600~650 cm−1、760 cm−1和830~1 250 cm−1形成典型的吸收峰,分别代表Si-O结构的弯曲振动、Si-O-Si结构的对称弯曲振动、Si(T)-O对称伸缩振动以及各个不同Qn结构的伸缩振动[15, 19-20]。样品晶化热处理后,在465 cm−1与 538 cm−1形成强的Si-O-Fe比肩峰。760 cm−1处Si(T)-O结构单元的红外吸收峰减弱,结合XRD可认为,Fe3+在玻璃析晶过程逐渐从母相玻璃中偏析形成了磁铁矿与富铁相尖晶石,使玻璃中的Fe3+减少,导致Si(T)-O结构红外吸收峰强度减弱。另外,830~1 250 cm−1范围的Qn的红外吸收峰向低波数偏移,表明母相玻璃在微波辅助热处理过程发生了结构重组。

在CaO-MgO-SiO2-Al2O3-Fe2O3体系矿渣微晶玻璃结晶过程,铜渣中的氧化铁在高温下不稳定,容易以Fe2SiO4形式存在,破坏硅氧四面体网络连通性,降低玻璃粘度[24]。母相玻璃在结晶过程,铁离子迁移并分相成Fe3O4与Fe2O3,反应过程见式 (1)~式 (3) 。

根据实验结果可以推断,母相玻璃在结晶过程,少量的铁离子发生式 (1) 反应,生成Fe2O3。随着Fe2O3增加,其与玻璃中的MgO、CaO、SiO2耦合反应,发生式 (2) 反应生成辉石相。当铁离子含量过多时,式 (3) 反应优先于式子 (1) 反应生成Fe3O4,在微晶玻璃中结晶形成磁铁矿。

-

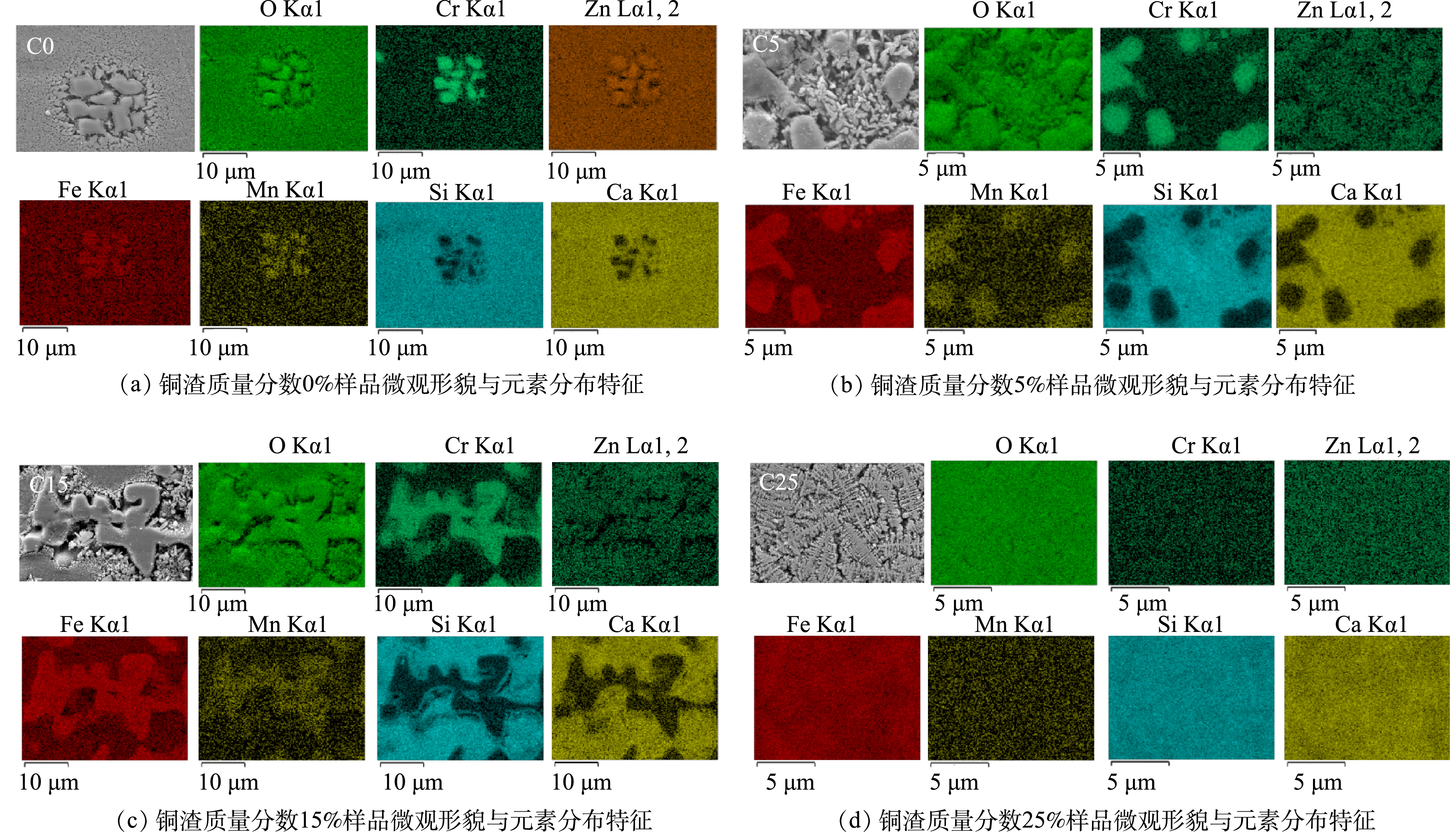

图7显示了微波处理微晶玻璃中尖晶石相的微观形貌与元素分布。从图中可看出,尖晶石在微晶玻璃中发生偏析,C0、C5、C15样品中尖晶石形成独立的结晶团聚体分布在辉石相与玻璃相之间。在能谱图中显示尖晶石存在区域,主要以O、Cr、Mn、Fe、Zn、Mg元素富集。由此可推断,不锈钢渣与铜渣中的重金属离子进入尖晶石相。然而,C25样品未发现尖晶石在微晶玻璃中偏析。结合能谱图分析可认为,过多的Fe、O离子富集形成了磁铁矿,而Cr、Mn、Zn、Mg以同构体的形式进入磁铁矿相。进一步观察发现,C0、C5、C15样品尖晶石富集区域出现了较大的辉石晶体。这说明,尖晶石结晶使离子扩散增加了玻璃中结构缺陷,降低玻璃内的局部析晶活化能促进辉石生长发育。

为研究重金属的迁移规律,进一步对重金属离子在微晶玻璃中离子迁移规律建立了模型,如图8所示。从图8 (a) 可见,尖晶石周围密集分布了一层不规则的细小辉石晶粒,辉石晶体依附尖晶石生长并对尖晶石形成了完全包裹状态。根据前人研究可知,在辉石微晶玻璃中添加Cr2O3容易结晶生成富Cr尖晶石相,尖晶石可为辉石析晶提供形核质点,使辉石外延尖晶石结晶[25-26]。在本研究中发现,尖晶石能够作为晶核剂促进辉石析晶。然而,以尖晶石为形核质点结晶的辉石晶粒都较为细小 (图7,C0、C5、C15) ,是由于大颗粒尖晶石的形成消耗了大量的阳离子 Cr3+、Mn4+、Fe3+等,尖晶石周边阳离子缺乏导致玻璃粘度增加,从而辉石晶体生长缓慢晶粒尺寸较小。此外,微波晶化热处理样品中尖晶石为无规则的形态,无规则的边缘提高了晶界结构缺陷程度,增加了辉石外延尖晶石结晶生长的几率。这导致了尖晶石被细小的辉石晶粒包裹,形成稳定的“核-壳”结构,结构模型如图8 (b) 所示。辉石微晶玻璃中重金属Cr、Mn进入尖晶石相被耐腐性优良的辉石包裹降低了重金属离子不易被浸出的效率[14]。本研究中,不锈钢渣与铜渣中的重金属离子迁移进入尖晶石相或磁铁矿,在微晶玻璃中尖晶石、磁铁矿晶体被辉石与玻璃包裹形成双重屏蔽,提高了重金属的固化效率。因此,通过微波热处理工艺制备微晶玻璃是有效的重金属固化方法。

-

1) 利用粉煤灰、不锈钢渣和铜渣制备辉石相矿渣微晶玻璃。其中,添加质量分数5%的铜渣降低玻璃聚合度,提高辉石析晶能力。然而,当铜渣质量分数超过15%,铁离子浓度过饱和,促进磁铁矿相结晶,辉石析晶受到抑制。同时,Zn、Mn对[FeO6]或Cr对[FeO4]中的Fe离子进行同构取代,形成(Mg, Fe, Zn, Mn)(Fe, Cr)2O4尖晶石。

2) 微波晶化热处理使不锈钢渣与铜渣中的Cr2O3、MnO2、ZnO、Fe2O3结晶形成尖晶石和磁铁矿。在矿渣微晶玻璃中尖晶石为辉石提供形核质点,诱导辉石外延尖晶石析晶形成“核-壳”结构,使重金属离子有效固化。

微波处理多种固废制备微晶玻璃

Microwave treatment of various solid wastes to prepare glass-ceramics

-

摘要: 以不锈钢渣、铜渣和粉煤灰为原料,通过熔铸法与微波晶化法相结合制备矿渣微晶玻璃,研究铜渣添加量 (Fe2O3) 对矿渣微晶玻璃结晶特性与重金属迁移规律。结果表明,铜渣中的Fe2O3对微晶玻璃结晶具有调控作用,5%的铜渣添加量会促进辉石结晶;当铜渣超过15%导致了磁铁矿的结晶,抑制辉石析晶。不锈钢渣与铜渣中的重金属Zn、Mn、Cr离子在玻璃结晶过程迁移进入尖晶石,尖晶石为辉石提供形核质点,诱导辉石外延尖晶石析晶。在矿渣微晶玻璃中辉石包裹尖晶石形成“核-壳”结构,对重金属离子有效固化。本研究结果可为高值化利用多种固废制备矿渣微晶玻璃及重金属固化研究提供参考。Abstract: Taking the fly ash and the slag of the stainless steel, the copper slag as raw materials, slag glass-ceramics was prepared through the combination of the method of casting and microwave heating, and the purpose of the paper was to study on the crystallization characteristics and the migration law for heavy metal existed in glass-ceramics made of slag by the addition of copper slag(Fe2O3). The results showed that Fe2O3 in copper slag had a regulatory effect on glass-ceramics crystallization while the addition of 5% copper slag would forward augite crystallization. However, over 15% that would lead to the crystallization of magnetite, and augite crystallization would be inhibited. The heavy metals Zn, Mn and Cr ions in the slag of the stainless steel and the copper slag would be transferred by migration into spinel during the glass crystallization process, while the spinel provides nucleation points for augite, which would induce the crystallization on epitaxial spinel for augite. Thru augite wrapping of the spinel to form a core-shell structure in slag glass-ceramics, it would lead to an effective curing of the heavy metal cation. The results of this study can provide a reference for highly preparing of the slag glass-ceramics and the curing for heavy metal from a variety of solid wastes.

-

Key words:

- Slag glass-ceramics /

- Microwave treatment /

- Augite /

- Spinel /

- Heavy metal curing

-

减少废水中的氮化合物是改善水环境和水质的重要措施之一[1]。与传统硝化/反硝化工艺相比,短程硝化/厌氧氨氧化(partial nitrification/anaerobic ammonia oxidation, PN/A)工艺可以将脱氮需氧量降低50%,有机碳需求量降低100%,污泥产量降低90%[2-3]。因此,PN/A工艺被认为是最经济、最有前景的脱氮工艺[4]。

反应器内生物质的保留能力对厌氧氨氧化(Anammox)工艺的启动周期有着重要影响[5]。据报道,颗粒和生物膜污泥都具备良好的生物质截留能力[6-7],但已知这两种污泥形式分别单独运行时都会存在较长的启动时间[8-9]。生物膜系统形成周期短,但长期运行后载体上太厚的生物膜会导致生物质脱落并被水流冲刷[7]。Anammox颗粒污泥的形成是一个漫长的过程,但可以有效地拦截污泥流失并保持较高的生物量[10]。因此,生物膜和颗粒污泥的组合应用可能最大程度上保留反应器内生物质,从而实现PN/A的快速启动和功能菌的高效富集。然而,将好氧生物膜和厌氧颗粒相结合来启动PN/A工艺目前尚未见报道。。

不同于传统的单阶段和两阶段PN/A反应器,在多级PN/A反应器中,交替的缺氧室和好氧室不仅为 (anaerobic ammonia oxidizing bacteria(AnAOB)和ammonia oxidizing bacteria(AOB)这2种功能细菌的同时生长和富集提供了空间条件,而且在缺氧区亚硝酸盐氮(NO2−-N)和氨氮(NH4+-N)共存的环境有利于厌氧氨氧化菌的自然富集[7-8]。此外,实现PN/A工艺的关键不仅需要同时富集AOB和AnAOB,还必须尽可能抑制亚硝酸盐氧化菌(nitrite oxidizing bacteria,NOB)活性[11]。据报道,间歇曝气和pH控制等策略可以有效控制PN/A工艺中不同菌群的活性(富集AnAOB和AOB,抑制NOB)[12]。然而,具有间歇曝气、pH控制、多级反应器和生物膜/颗粒污泥系统等优点的组合PN/A反应器的运行策略仍需要研究。

本研究构建了由3个好氧反应柱和3个厌氧反应柱组成的新型多级好氧生物膜/厌氧颗粒反应器(multistage aerobic-biofilm/anaerobic-granular sludge reacto, MOBAPR),以同时促进AnAOB和AOB的富集。本研究的主要目的为:拟通过MOBAPR实现PN/A工艺的快速启动和高效运行;考察MOBAPR各反应柱的氮转化过程;探索不同MOBAPR柱中功能菌丰度的变化和微生物群落结构的差异;通过优化气液比(gas/liquid ratio, G/L),进一步提高PN/A工艺的脱氮效率(nitrogen removal efficiency, NRE)。

1. 材料与方法

1.1 进水水质与接种污泥

接种物取自中国江西省赣州市白塔生活污水处理厂的剩余污泥(普通活性污泥)。在第1天分别向每个反应柱加入100 mL接种物,其活性污泥浓度(MLSS)大约为5 100 mg·L−1。

本研究采用模拟废水(含150 mg·L−1 NH4+-N),其改编自前人研究[13]。主要成分包括0.708 g·L−1 (NH4)2SO4,1.05 g·L−1 NaHCO3, 0.02 g·L−1 KH2PO4, 0.022 g·L−1 MgSO4,0.008 g·L−1 CaCl2,1.25 mg·L−1营养液I(5 g·L−1 EDTA、0.00625 g·L−1 FeSO4)和营养液II(15 g·L−1 EDTA、0.43 g·L−1 ZnSO4·7H2O、0.25 g·L−1 CuSO4·5H2O、0.19 g·L−1 NiCl2·6H2O、0.99 g·L−1 MnCl2·4H2O、0.24 g·L−1 CoCl2·6H2O、0.22 g·L−1 NaMoO4·2H2O、0.014 g·L−1 H3BO4)。

1.2 实验装置

MOBAPR的示意图如图1所示。该反应器由6个高30 cm、直径4.5 cm的有机玻璃柱相互串联构成,总有效容积为2.5 L。从进水到出水的6个反应柱(reaction column, Rc)分别标记为 Rc1、Rc2、Rc3、Rc4、Rc5和Rc6(隔室数量可根据出水水质增减)。在好氧反应柱(Rc1、Rc3和Rc5)中添加无纺布作为填料,并采用间歇曝气。厌氧隔室(Rc2、Rc4和Rc6)采用低速搅拌装置。当PN工艺成功启动后停止搅拌。曝气量由玻璃转子流量计调节,并采用自动断电定时器电路实现间歇曝气。根据之前的报道[14],由蠕动泵(Langer,BT101L,UK)、pH 控制器(WEIPRO,pH-2010B,China)和NaOH溶液组成的pH控制系统将MOBAPR中的pH保持在8.2~8.5。在每次曝气15 min后开始检测DO(dissolved oxygen)质量浓度。

1.3 运行条件

本研究在MOBAPR中依次启动PN和PN/A工艺。第I阶段(1~7 d),为快速恢复硝化细菌(AOB和NOB)的活性,在好氧区((Rc1、Rc3和Rc5)中连续曝气,并在厌氧区(Rc2、Rc4和Rc6)连续搅拌。此外,此阶段由于污泥处于悬浮状态,会随着进水流动,因此,启动污泥回流以保证反应器内充足的生物质含量。第II阶段(8~15 d)为抑制NOB,在好氧区中使用间歇曝气。第III阶段(16~60 d)好氧区微生物已成功挂膜生长,基本没有污泥流失,停止回流。此外,为进一步抑制NOB,第29天水力停留时间(hydraulic residence time, HRT)降低至8 h(16~28 d的HRT为12 h)。第IV阶段(61~86 d)为避免搅拌影响厌氧区AnAOB富集,厌氧区停止搅拌。第V阶段(87~110 d),调整曝气量以保证反应器内充足的NO2−-N。各阶段运行参数详见表1。在第VI阶段(111~162 d),在进水NH4+-N为150 mg·L−1和好氧/厌氧时间为90 min/30 min条件下,分别调节曝气量和HRT来探讨不同G/L对NRE的影响。

表 1 实验条件及操作参数Table 1. Experimental conditions and operating parameters时期 阶段 时间/d HRT/h 曝气量/(L·min−1) 好氧(厌氧)时间/min 好氧区DO/(mg·L−1) 回流比/% 适应期 I 1~7 24 0.02 好氧 — 200 PN 启动期 II 8~15 12 0.05 80/40 0.5±0.2 100 PN运行期 III 16~60 12/8 0.05 80/40 0.5±0.2 0 PN/A 启动期 IV 61~86 8 0.08 90/30 0.0±0.2 0 PN/A运行期 V 87~110 6 0.10 90/30 0.0±0.1 0 气液调控期 VI 111~162 — — 90/30 — 0 注:表中曝气量和DO值均为好氧区(Rc1、Rc3和Rc5)的平均值;“—”表示无法检测。 1.4 分析方法

实验中反应器内NH4+-N、NO2−-N、NO3−-N的检测分析均根据《水和废水检验标准方法》中制定的方案,使用实验室规模的紫外/可见分光光度计(SQ2800,意大利UNICO)进行测定,包括纳氏试剂分光光度法(NH4+-N)(1-萘基)-乙二胺分光光度法(NO2−-N)和氨基磺酸紫外分光光度法(NO3−-N)。此外,为了更好地揭示MOBAPR中PN/A过程的氮转化机理,每天对各反应柱的氮质量浓度进行检测,并分析其亚硝酸盐积累率(nitrite accumulation rate, NAR)、氨氮去除率(ammonia nitrogen removal rate, ANR)、氮去除率(NRE)、氮负荷率(nitrogen load rate, NLR)和氮去除负荷(nitrogen removal load rate, NRR)[13-14]。

1.5 16S rRNA基因测序与微生物菌群分析

为探索MOBAPR中不同阶段微生物群落的演变,阐明连续多阶段PN/A过程中所涉及的生物学机制,分别对接种物、第56天(阶段III)和第110天(阶段V)的泥样进行微生物功能菌群分析。接种物命名为A0,第III阶段在Rc1~Rc6收集的污泥样品分别命名为A1、A2、A3、A4、A5和A6,第V阶段分别命名为B1、B2、B3、B4、B5和B6。这些样本保存在−20 ℃,直到提取DNA结束。

在成功提取样本内微生物的DNA后,使用16S rRNA基因的通用扩增引物进行PCR扩增,并且PCR产物使用 AxyPrep™ DNA凝胶提取试剂盒(Axygen Biosciences,Union City,USA)按照制造商的说明进行纯化。然后通过Illumina MiSeq测序平台(PE300)对样品高通量测序,并得到原始测序序列。为了解样本测序结果中的菌种、菌属、物种功能等信息,将在Miseq测序得到的原始序列数据利用cutadapt(version 1.18)和PRINSEQ(version 0.20.4)软件进行去除引物接头序列、拼接、识别的处理以得到各样本的有效数据。然后利用Usearch(version 11.0.667)按照97%相似性对非重复序列(不含单序列)进行OTU聚类。然后利用RDP classifier(version 2.12)等软件进行OTU物种分类,并根据得到的OTU序列进行微生物菌群分析与功能预测。

1.6 优化MOBAPR操作

由于在第V阶段DO值较低,MOBAPR的性能无法通过DO来进行控制。因此,在第VI(111~162 d),阶段,为了代替DO控制(当DO低至无法控制),本研究提出了一种新型控制参数—气液比(式(1))。分别在2、4、6和8 h的HRT条件下调控曝气量(0.05、0.1、0.15和0.2 L·min−1),从而得到G/L比为2.4、4.8、7.2、9.6、4.4、19.2、21.6、28.8和38.4。并且在每次操作条件调整后,MOBAPR连续运行3~4 d。此外,利用高斯模型预测了G/L与NRE之间的相关性(式(1))。

q=60tvV (1) 式中:q为G/L值;t为HRT,h;v为曝气速率,L·min−1;V为MOBAPR的总有效容积,L。

2. 结果与讨论

2.1 MOBAPR中PN/A工艺的脱氮性能

1)接种物驯化。阶段I(1~7 d)在进水NH4+-N为150 mg·L−1、曝气速率为0.02 L·min−1、DO为2~4 mg·L−1和HRT 24 h的条件下运行MOBAPR。如图2所示,出水NO3−-N由64.03 mg·L−1增加到122.71 mg·L−1。这说明在被重新接种后,硝化细菌(AOB和NOB)的活性在高DO水平下得到了快速恢复。此外,在阶段I中NRE大多低于零(图2(c))。这可能是一些细菌(主要是异养菌)不能适应无碳源下的MOBAPR,细菌死亡后细胞溶解释放出额外的氮源到反应器内。

2) PN工艺的启动。在阶段II(8~15 d),MOBAPR的pH为8.3,好氧区平均溶解氧为0.5 mg·L−1,间歇曝气(好氧/厌氧时间为80 min /40 min)。结果表明,NO2−-N由0 mg·L−1增加到106.89 mg·L−1(图2(b)),NO3−-N由122.71 mg·L−1减少到20.92 mg·L−1(图2(d)),这表明NOB被有效抑制的同时AOB成功富集。因此,此阶段PN工艺在MOBAPR成功启动。此外,PN工艺中的NO2−-N稳定供应是实现Anammox工艺的前提[15],其关键是高效稳定地抑制反应器中的NOB 活性[14]。有研究表明,控制pH和间歇曝气是抑制NOB活性的重要手段[13]。因此,将以上2种抑制策略的结合是实现PN过程快速启动的关键。

在阶段III(16~60 d),出水NO3−-N逐渐增加,第16~28天处于较高水平(30~46 mg·L−1)。因此,要实现PN过程的稳定运行,需要对控制条件进行调整。在第17天好氧区在已经形成稳定生物膜结构后,MOBAPR停止回流。结果NAR短暂升至81%,然后逐渐下降(图2(b))。在第20~28天,出水NO3−-N相对稳定(30~41 mg·L−1),说明综合控制策略仍能有效抑制NOB活性。第29天,HRT由12 h缩短到8 h,出水NO3−-N由29.2mg·L−1逐渐降至16.7 mg·L−1,NAR也增加到90%。因此,HRT是影响PN工艺稳定性的重要参数,HRT过长会产生额外的NO3−-N。

随着PN过程成功启动和AOB被富集积累[16-17],反应器中DO被AOB大量消耗,这导致厌氧区室中的DO质量浓度降低至0.2 mg·L−1左右,从而为厌氧菌提供了适宜的生长环境。由图2(c)可知,NRE由5.51%逐渐增加到25.52%。这表明AnAOB可能在此阶段自然富集。有研究表明,AOB是从微需氧甚至厌氧的祖先进化而来的,在亚硝酸氧化还原酶(NXR)和其他反射蛋白的形式上与AnAOB高度相似[18]。MIAO等的研究结果同样表明接种硝化污泥可以缩短Anammox的启动时间[19]。因此,基于PN工艺,AnAOB可能更容易富集。此外,高通量测序结果表明阶段III中AnAOB的增加。

3)PN/A工艺的启动与运行。有研究[20]表明,较大污泥絮凝物中的AnAOB具有更高的活性。厌氧区中污泥絮体的生长可能会受到搅拌的限制,从而抑制AnAOB的活性[20]。因此,在阶段IV(61~86 d)停止搅拌以增加AnAOB的活性。并且有研究表明,NO2−-N质量浓度越高越有利于Anammox的积累[21]。因此,延长好氧区的相对曝气时间以进一步增加反应器中NO2−-N质量浓度。在第IV阶段,厌氧区中停止搅拌,并且好氧区中好氧/厌氧时间从80 min/40 min变为90 min/30 min。在第61天后,MOBAPR的TN质量浓度逐渐下降,由126.96 mg·L−1(第61天)降低至(32.79±6.21) mg·L−1(77~86 d),NRE也从21.5%迅速增加到(78.86±4.6)%(图2(c))。这表明在本研究采用的操作策略下,61 d内成功实现PN/A工艺的快速启动。

此外,随着AnAOB成功富集,MOBAPR中脱氮速率增加,导致进水中大部分的NH4+-N在Rc1~Rc4中已经被去除,而Rc5和Rc6中功能微生物缺乏营养物质。因此,有必要适当缩短HRT以保证MOBAPR中功能微生物的进一步富集。在阶段V(87~110 d),HRT由8 h缩短至6 h。此阶段反应稳定后(102~110 d),出水NO2−-N、NO3−-N和NH4+-N质量浓度分别为(0.63±0.50)、(16.72±1.78)和(8.29±6.65) mg·L−1。其中,出水NO3−-N质量浓度(NO3−-N产生/NH4+-N去除=0.12)与Anammox的NO3−-N理论产生值(NO3−-N产生/NH4+-N去除=0.11)接近,这表明NOB被稳定抑制[21]。此外,PN/A工艺的NRE、ANR和NRR分别为(83.41±2.45)%、(97±3.61)%和(0.41±0.09) kg·(m3·d)−1(图2)。这表明该操作策略可用于MOBAPR,以实现PN/A过程的长期高效稳定运行。

有趣的是,在第IV和第V阶段(曝气量分别为0.08 L·min−1和0.10 L·min−1),所测得DO质量浓度接近0。有研究[14]表明,当AOB的耗氧速率高于曝气效率,反应器曝气后的DO质量浓度仍会保持在较低水平。因此,在MOBAPR中非曝气后,好氧区的曝气会被AOB等好氧细菌及时转化,从而维持反应器内低DO水平。此外,在MOBAPR中,AOB的富集是AnAOB快速启动的关键。AOB不仅可以为AnAOB创造环境,还提供营养物质。然而AOB主要在好氧区活性较高。因此,在整个启动期间,基本不对厌氧区进行直接调控(搅拌停止后)。

2.2 各阶段微生物群落演替分析

为了探索MOBAPR中微生物群落的变化规律,对接种物、第56天(第III阶段末期)和第110天(第V阶段)末期采集的污泥样品进行微生物群落进行分析。其中PA1为接种物A0,PA2为第III阶段各反应柱(A1、A2、A3、A4、A5和A6)内微生物丰度的平均值,PA3为第V阶段(B1、B2、B3、B4、B5和B6)微生物丰度的平均值。高通量测序得到的优质细菌序列被划分为不同的分类类别(门和属),结果如图3(a)和图3(b)所示。Proteobacteria包括具有硝化反硝化功能的细菌[16],是门水平上的主要细菌(图3(a))。Proteobacteria在接种物中的丰度为68.15%,而在阶段III和阶段V后分别下降到44.68%和40.39%(图3(a))。这表明在变形菌门中许多异养硝化或反硝化细菌由于有机物的缺乏而被淘汰。有研究表明,Planctomycete门中不仅拥有一些专性好氧菌,还包含了所有已知的AnAOB[2]。接种物(PA1)中的Planctomycete相对丰度接近第III阶段(PA2),分别为4.07%和3.71%。而到了第V阶段(PA3),Planctomycete丰度达到10.85%,这表明Planctomycete主要在第III阶段后被富集。此外,在属水平上PA1的Candidatus Kuenenia的相对丰度极低,约0.05%(图3(b))。这表明在接种物中几乎不含AnAOB。与接种物(PA1)相比,PA2和PA3中Armmonadetes和Chloroflexi的丰度显著增加(图3(a))。有研究表明,在Armarmadetes和Chloroflexi中的许多细菌含有与氮代谢相关的功能基因(Nar、NirK或Nos)[22]。因此,Armatimonadetes和Chloroflexi可能含有多种AOB和AnAOB协同细菌,为PN/A工艺的启动和运行做出了贡献。

图3(b)反映了PN/A工艺中所有样品在属水平上的微生物群落。在第III阶段Nitrosomonas的丰度由1.49%增加到28.20%(图3(b)),证实了该操作策略可以成功富集AOB。并且,16s结果表明Candidatus Kuenenia是MOBAPR中主要的AnAOB,其由接种物PA1(0.05%)增长到2.97%。这表明随着PN工艺的长期运行,此阶段(第56天)AnAOB开始富集。在第V阶段,PN/A工艺启动成功并长期运行后,Nitrosomonas (27.09%)和Candidatus Kuenenia(9.99%)的丰度得到了较高程度富集,这表明AOB和AnAOB在MOBAPR中可以同时富集。因此,通过第IV和第V阶段的综合运行策略,AOB和AnAOB作为优势菌被富集,并形成细菌协同关系完成脱氮。此外,NOB的主要菌属Nitrobacter、Nitrospira和Nitrospina等可能由于含量太低(<0.1),均未被检测到。

2.3 不同阶段各反应柱内的氮转化途径

1)氮转化途径分析。为了更深入地了解MOBAPR各反应柱内PN/A工艺的氮转化过程,对PN (阶段III)和PN/A 工艺(阶段V)长期运行阶段分别进行测试分析,结果如图4所示。在第III阶段,出水NO2−-N质量浓度从Rc1到Rc6逐渐增加,NH4+-N相应降低(图4(a))。这表明各反应柱内均参与到氨氧化过程中。每个反应柱内都含有NH4+-N和NO2−-N (图4(a)),这为AnAOB的富集提供了必要条件。并且由于氨氧化过程需要氧气参与,好氧区(Rc1、Rc3和Rc5)内的ANR显著高于厌氧区(Rc2、Rc4和Rc6)(图4(c))。此外,NO3−-N浓度一直处于较低水平(<10 mg·L−1)(图4(a)),这表明通过本研究采用的操作策略,NOB活性长期受到有效抑制。在这一阶段,MOBAPR的平均氮损失约为30 mg·L−1(图4(a)),证实了反硝化细菌或AnAOB的增加。特别是Rc1、Rc3和Rc5中NRE的增加也显著高于Rc2、Rc4和Rc6(图4(e)),说明好氧区内氮损失主要是反硝化细菌或AnAOB造成的。

在第V阶段,由于进水中的氨(150 mg·L−1)通过前4个反应柱被PN/A完全转化,最后2个反应柱(Rc5和Rc6)在此阶段被废弃。模拟废水在流经Rc4后被排出。如图4(b)所示,在此阶段出水NH4+-N降至较低水平。这表明经过长期运行,PN/A工艺的NRE有所提高。此外,由图4(d)可以看出,大部分氨氧化过程基本在Rc1完成,而在Rc4之后脱氮量达到最高(图4(f))。此外,在第V阶段各反应柱内NO2−-N含量低于阶段III(图4(a)),这表明由AOB产生的NO2−-N被AnAOB快速利用,即AnAOB与AOB之间形成了良好的协同脱氮效果。Rc1和Rc3中NRE和ANR均显著增加(图4(f)),因此,PN和Anammox过程主要在好氧室中进行。这是由于在好氧区内形成了内层为AnAOB和外层AOB的微生物生物膜协同脱氮系统。依赖于外部的AOB提供的NO2−-N,内部的厌氧微生物将剩余的氨转化为氮。其中,由图4(f)可知,厌氧区(Rc2和Rc4)中NRE的增加远低于好氧区(Rc1和Rc3),并且厌氧区的出水NO2−-N几乎为0(图4(b))。因此,NO2−-N的缺乏可能限制了厌氧区的NRE。此外,在MOBAPR的好氧室中添加填料形成生物膜系统,不仅有效避免了DO对AnAOB的抑制,而且还有利于AnAOB的富集。在此阶段稳定的生物膜和颗粒污泥系统分别在好氧区和厌氧区形成。一方面,在好氧区的生物膜系统中形成了分层分布的好氧外层和厌氧内层。AnAOB在厌氧环境的生物膜内层得到富集,并与外层AOB协同脱氮。另一方面,AOB产生的大部分NO2−-N被生物膜内层的AnAOB利用,剩余少量NO2−-N流出并被位于厌氧区的AnAOB颗粒污泥消耗。此阶段在好氧区的脱氮方式与单阶段PN/A工艺相似,而厌氧区脱氮方式与两阶段PN/A工艺相似。因此,生物膜和颗粒污泥结构成功将单阶段与两阶段PN/A工艺的优势结合在一起,不仅具备两阶段PN/A更快的启动速度,还具备单阶段PN/A的更高效的反应速率。

2)各反应柱中AOB和AnAOB的动态分析。为了探究在PN工艺和PN/A工艺长期运行过程中,MOBAPR中不同反应柱内微生物群落的差异,对接种污泥、阶段III和阶段V获得的污泥样品进行高通量测序。其中,接种污泥样品命名为A0,在第56天(阶段III)Rc1、Rc2、Rc3、Rc4、Rc5和Rc6采集的样品分别命名为A1、A2、A3、A4、A5和A6,在第110天(阶段V)采集的样品命名为B1、B2、B3、B4、B5和B6。高通量测序得到的相关参数如表2所示。厌氧区中的Simpson指数明显低于好氧区(表2),这说明好氧区的物种富集程度是高于厌氧区的,Shannon指数也得到了类似的结论。每个污泥样品的覆盖率超过99.70%(表2),说明高通量测序基本代表了污泥样品的实际微生物群落结构。

表 2 微生物多样性分析Table 2. Microbial diversity analysis阶段 样品 序列数 丰富度 OTU数 多样性 覆盖率/% Ace指数 Chao1指数 Simpson指数 Shannon指数 I A0 52 844 913.5 933.6 841 0.07 4.27 99.8 III A1 57 036 886 863 724 0.11 3.48 99.7 A2 64 451 1 006.4 1 024.1 877 0.05 4.13 99.7 A3 70 746 891 932.1 751 0.16 3.05 99.7 A4 54 252 949.5 953.5 801 0.08 3.78 99.7 A5 59 513 899.5 902.3 786 0.18 3.13 99.7 A6 52 884 962.5 1 003.1 842 0.07 3.99 99.7 V B1 61 553 844.7 837.2 666 0.12 3.21 99.7 B2 64 627 892.2 896.5 742 0.09 3.57 99.7 B3 75 032 845.7 863.1 692 0.11 3.2 99.8 B4 62 284 900.8 909.7 764 0.06 3.86 99.7 B5 62 838 853.3 852 703 0.21 2.84 99.7 B6 59 777 984.9 1 014.6 851 0.13 3.64 99.7 注:A1、A3、A5、B1、B3和B5是来自好氧区的污泥样品;A2、A4、A6、B2、B4和B6是来自厌氧区的污泥样品。 为深入了解好氧生物膜/厌氧颗粒污泥的微生物分布情况,在阶段III和阶段V,从MOBAPR中的6个反应柱中获得的污泥样品进行了微生物群落分析。PN工艺启动并长期运行后,A1、A3和A5中亚硝基单胞菌(Nitrosomonas)的相对丰度分别从1.49%提高到30.99%、39.77%和40.74%,A2、A4和A6中亚硝基单胞菌的相对丰度分别从1.49%提高到11.42%、22.25%和22.15%(图5(c)),这证实了AOB在每个隔间中都被富集。厌氧区中AOB的富集与好氧区出水的DO有关。因此,厌氧区的AOB丰度明显低于好氧区(图5(c))。此外,在A1、A2、A3、A4、A5和A6中,AnAOB(Candidatus Kuenenia)的丰度分别由0.05%提高到0.16%、5.25%、0.56%、5.87%、0.39%和5.06%(图5(c)),这表明AnAOB已经开始富集。AOB不仅通过消耗溶解氧为AnAOB创造厌氧环境还为AnAOB提供必需的基质(NO2−-N)。因此,此阶段Nitrosomonas富集可能为Anammox的启动奠定了基础。

在PN/A工艺成功启动和运行后(第V阶段),B1、B2、B3和B4中Candidatus Kuenenia的丰度分别增加到12.67%、19.07%、12.41%和11.43%(图5(a))。由于Rc5和Rc6中NO2−-N的缺乏,B5和B6中Candidatus Kuenenia的丰度较低(分别为0.24%和2.29%)。在各反应柱中,Nitrosomonas和Candidatus Kuenenia都得到了较高水平的积累(图5(b))。这证实了微生物之间协同脱氮系统的存在。有趣的是,Candidatus Kuenenia不仅被富集在厌氧区,而且在好氧区中也有较高的丰度,这表明好氧区已形成分层分布的生物膜系统。此外,在PN/A工艺的长期运行阶段,未分类菌数量较多(图5(c))。有研究表明,PN/A工艺微生物群落由各种功能菌和协作菌共同组成的[14]。因此,在演替过程中会出现一些未分类协作菌以促进功能菌更好的富集。

2.4 G/L对NRE的影响

在第V阶段,MOBAPR中的DO值接近于零。一方面,不能通过控制DO值来进一步优化反应器性能;另一方面,不能人为直接调控DO值,即只能通过曝气量或流量等来间接调控DO值。因此,在PN/A工艺在运行过程中,DO控制会存在一定的滞后性。此外,在此阶段发现曝气速率越高,厌氧菌活性会降低;而曝气速率越低,厌氧菌的氮转化性能同样会将低。因此,在MOBAPR中提供合适的曝气量非常重要。

第2.1节和2.2节中的结果表明可通过缩短HRT将MOBAPR的NRE进一步提高,但好氧区中AOB的需氧量随着进水氨氮浓度的增加而增加。因此,本研究通过控制G/L,一方面可以为MOBAPR中的功能微生物提供稳定适宜的NO2−-N/NH4+-N,从而促进MOBAPR的总氮去除率;另一方面,直接调控反应器参数(代替DO控制),从而简化操作。为探讨G/L对总氮去除率的影响,通过调节曝气量和HRT,在进水NH4+-N为150 mg·L−1,好氧/厌氧时间为90 min/30 min条件下,G/L参数分别设置为2.4、4.8、7.2、9.6、14.4、19.2、21.6、28.8和38.4。用高斯模型对得到的NRE和相应的G/L进行拟合(极点拟合)以得出最适G/L,拟合结果如图6所示。可以看出,PN/A工艺的NRE在G/L为0~19.2时增大,而在G/L为21.6~38.4时减小。高斯模型的相关系数(R2)为0.992 2(图6(b)),说明该模型较好地描述了NRE与G/L之间的关系。模型拟合结果表明,当G/L比值参数为20~30时,NRE可达到较高水平。

3. 结论

1)本研究构建了厌氧和好氧区共存、悬浮污泥系统与生物膜系统相结合的MOBAPR。

2)在MOBAPR中15天内成功启动PN工艺,PN/A工艺在61天内成功启动。在运行阶段,PN工艺的NAR为(87.35±2.7)%,PN/A工艺的NRE为(83.41±2.45)%。

3)高通量测序结果表明,Nitrosomonas(27.09%)和Candidatus Kuenenia(9.99%)在厌氧区和好氧区被同时富集。在长期运行阶段,PN工艺的NAR为(87.35±2.7)%,PN/A工艺的NRE为(83.41±2.45)%。

4)在DO低至无法控制时,G/L可能是一种可以代替DO控制的重要策略,并且高斯模型拟合结果表明,当G/L比值参数为20~30时,NRE可达到较高水平。

-

表 1 固体废弃物成分

Table 1. Composition of waste residues

% (质量分数) 成分 粉煤灰 铜渣 不锈钢渣 SiO2 53.34 22.59 37.76 Al2O3 18.18 3.91 13.16 CaO 11.53 2.41 3.68 MgO 3.33 0.68 23.10 Fe2O3 10.83 66.36 6.37 K2O 1.23 0.67 0.20 Na2O 0.56 0.69 0.35 ZnO — 1.00 0.05 Cr2O3 — — 2.90 其他 1.00 1.69 2.41 表 2 基础玻璃的主要化学成分

Table 2. The main chemical composition of glasses

样品编号 粉煤灰添加质量/g 铜渣添加质量/g 不锈钢渣添加质量/g SiO2添加质量/g CaO添加质量/g MgO添加质量/g B2O5添加质量/g C0 126.72 0 31.68 8.25 9.9 1.65 9.90 C5 120.37 10.00 30.10 7.84 9.41 1.57 9.41 C15 107.69 30.00 26.93 7.01 8.41 1.40 8.41 C25 94.98 50.00 23.76 6.19 7.43 1.23 7.43 表 3 玻璃的稳定性特征

Table 3. Stability characteristics of glass

温度/ ℃ C0 C5 C15 C25 Tg 680 661 668 698 Tp 863 837 858 896 △T 183 176 190 198 表 4 Qn的含量与DOP计算结果

Table 4. Qncontent and DOP calculation results

样品编号 Q0/% Q1/% Q2/% Q3/% Q4/% DOP R2 C0 11.25 13.67 17.16 44.43 13.49 1.65 0.996 C5 14.93 13.91 22.91 42.63 5.62 1.89 0.994 C15 6.92 9.62 17.12 44.92 19.37 1.40 0.994 C25 7.70 8.66 19.16 48.06 18.46 1.39 0.996 -

[1] AHMAD S, MAHMOUD M M, SEIFERT H J. Crystallization of two rare-earth aluminosilicate glass-ceramics using conventional and microwave heat-Treatments[J]. Journal of Alloys and Compounds, 2019, 797: 45-57. doi: 10.1016/j.jallcom.2019.05.100 [2] ZHANG J J, LIU B, ZHANG S G. A review of glass ceramic foams prepared from solid wastes: processing, heavy-metal solidification and volatilization, applications[J]. Science of the Total Environment, 2021, 781: 146727. doi: 10.1016/j.scitotenv.2021.146727 [3] ZHAO S Z, WEN Q, ZHANG X Y, et al. Migration, transformation and solidification/stabilization mechanisms of heavy metals in glass-ceramics made from MSWI fly ash and pickling sludge[J]. Ceramics International, 2021, 47: 21599-21609. doi: 10.1016/j.ceramint.2021.04.172 [4] WANG X X, ZHU K Y, ZHANG L, et al. Preparation of high-quality glass-ceramics entirely derived from fly ash of municipal solid waste incineration and coal enhanced with pressure pretreatment[J]. Journal of Cleaner Production, 2021, 324: 129021. doi: 10.1016/j.jclepro.2021.129021 [5] YU Y, WANG H, HU J H. Co-treatment of electroplating sludge, copper slag, and spent cathode carbon for recovering and solidifying heavy metals[J]. Journal of Hazardous Materials, 2021, 417: 126020. doi: 10.1016/j.jhazmat.2021.126020 [6] GU F Q, ZHANG Y B, SU Z J, et al. Recovery of chromium from chromium-bearing slags produced in the stainless-steel smelting: A review[J]. Journal of Cleaner Production, 2021, 296: 126467. doi: 10.1016/j.jclepro.2021.126467 [7] 王光瑜, 杜永胜, 张红霞, 等. 共伴生多金属尾矿中重金属的高温固化研究进展[J]. 中国陶瓷, 2021, 57(9): 1-6. doi: 10.16521/j.cnki.issn.1001-9642.2021.09.001 [8] 仪桂兰. 利用不锈钢尾渣、粉煤灰制备微晶玻璃[J]. 中国资源综合利用, 2010, 28(10): 32-34. doi: 10.3969/j.issn.1008-9500.2010.10.007 [9] 吴春丽, 杨键, 卜金彪, 等. 晶化温度对不锈钢渣微晶玻璃析晶及性能影响[J]. 硅酸盐通报, 2015, 34(6): 1638-1643. doi: 10.16552/j.cnki.issn1001-1625.2015.06.037 [10] WANG Z J, SOHN I. Understanding the solidification and leaching behavior of synthesized Cr-containing stainless steel slags with varying Al2O3/SiO2 mass ratios[J]. Ceramics International, 2021, 47: 10918-10926. doi: 10.1016/j.ceramint.2020.12.211 [11] LI Z, MA G J, ZHENG D G, et al. Effect of ZnO on the crystallization behavior and properties of SiO2-CaO-Al2O3-Fe2O3 glass-ceramics prepared from simulated secondary slag after reduction of copper clag[J]. Ceramics International, 2022, 48: 21245-21257. doi: 10.1016/j.ceramint.2022.04.045 [12] LIU L D, LIU J L, LIU T Y, et al. Preparation, crystallization kinetics and stabilization behavior of the heavy metal ions of all-solid waste-based glass-ceramics from steel slag and coal gangue[J]. Journal of Non-Crystalline Solids, 2022, 592: 121750. doi: 10.1016/j.jnoncrysol.2022.121750 [13] DENG L B, LU W W, ZHANG Z, et al. Crystallization behavior and structure of CaO-MgO-Al2O3-SiO2 glass ceramics prepared from Cr-bearing slag[J]. Materials Chemistry and Physics, 2021, 261: 124249. doi: 10.1016/j.matchemphys.2021.124249 [14] DENG L B, YAO B, LU W W, et al. Effect of SiO2/Al2O3 ratio on the crystallization and heavy metal immobilization of glass ceramics derived from stainless steel slag[J]. Journal of Non-Crystalline Solids, 2022, 593: 121770. doi: 10.1016/j.jnoncrysol.2022.121770 [15] DENG L B, YUN F, JIA R D, et al. Effect of SiO2/MgO ratio on the crystallization behavior, structure, and properties of wollastonite-augite glass-ceramics derived from stainless steel slag[J]. Materials Chemistry and Physics, 2020, 239: 122039. doi: 10.1016/j.matchemphys.2019.122039 [16] GUO X Z, CAI X B, SONG J, et al. Crystallization and microstructure of CaO-MgO-Al2O3-SiO2 glass-ceramics containing complex nucleation agents[J]. Journal of Non-Crystalline Solids, 2014, 405: 63-67. doi: 10.1016/j.jnoncrysol.2014.08.048 [17] ZHANG J J, ZHANG S G, LIU B. Degradation technologies and mechanisms of dioxins in municipal solid waste incineration fly ash: A review[J]. Journal of Cleaner Production, 2020, 250: 119507. doi: 10.1016/j.jclepro.2019.119507 [18] 张雪峰, 魏海燕, 欧阳顺利, 等. 微波法热处理制备CaO-MgO-Al2O3-SiO2系微晶玻璃的研究[J]. 人工晶体学报, 2016, 45(9): 227-2231. [19] ZHAO M Z, CAO J W, WANG Z, et al. Insight into the dual effect of Fe2O3 addition on the crystallization of CaO-MgO-Al2O3-SiO2 glass-ceramics[J]. Journal of Non-Crystalline Solids, 2019, 513: 144-151. doi: 10.1016/j.jnoncrysol.2019.03.021 [20] ZHAO S Z, LIU B, DING Y J, et al. Study on glass-ceramics made from MSWI fly ash, pickling sludge and waste glass by one-step process[J]. Journal of Cleaner Production, 2020, 271: 122674. doi: 10.1016/j.jclepro.2020.122674 [21] ZHANG S, ZHANG Y L, GAO J T, et al. Effects of Cr2O3 and CaF2 on the structure, crystal growth behavior, and properties of augite-based glass ceramics[J]. Journal of the European Ceramic Society, 2019, 39: 4283-4291. doi: 10.1016/j.jeurceramsoc.2019.05.060 [22] MCLEOD R L. Preliminary observations of kaolinite in a volcanogenic massive sulphide deposit of permian age[J]. Tschermaks Minerlogischeund Petrographische Mitteilungen, 1985, 34: 261-269. doi: 10.1007/BF01082965 [23] LI H X, LI B W, DENG L B, et al. Evidence for non-thermal microwave effect in processing of tailing-based glass-ceramics[J]. Journal of the European Ceramic Society, 2019, 39: 1389-1396. doi: 10.1016/j.jeurceramsoc.2018.12.056 [24] TAE S K, JOO H P. Viscosity-structure relationship of CaO-Al2O3-FetO-SiO2-MgO ruhrstahl-heraeus(RH) refining slags[J]. ISIJ International, 2021, 61(3): 724-733. doi: 10.2355/isijinternational.ISIJINT-2020-482 [25] SHI Y, SONG X W, HAN X X. Catalytic mechanism of iron oxide doping on the crystallization process of Cr2O3-containg glass ceramics[J]. Journal of Non-Crystalline Solids, 2021, 570: 121002. doi: 10.1016/j.jnoncrysol.2021.121002 [26] LI H R, LIU S Y, XU W C, et al. The mechanism of the crystalline characteristics of spinel-induced epitaxial growth of diopside in CMAS glass-ceramics[J]. Journal of the European Ceramic Society, 2021, 41: 1603-1612. doi: 10.1016/j.jeurceramsoc.2020.09.037 期刊类型引用(2)

1. 李东,林则全,赵贵州. 旋风炉解毒不锈钢渣与熔渣调质制备矿渣棉的研究. 钢铁研究学报. 2024(02): 265-274 .  百度学术

百度学术

2. 唐勇发,张作良,曹宇,苗昇暄,王成鑫,冷芳宇. 复合固废制备微晶玻璃性能研究. 辽宁科技学院学报. 2024(03): 10-13+21 .  百度学术

百度学术

其他类型引用(2)

-

下载:

下载: