-

近年来,随着养殖业的规模化与集约化发展,满足了人们日常生活的需要,但产生的养殖废水所造成的环境问题,也越来越引起人们的重视[1]。调查显示,猪场废水中有机物、氨态氮和磷的成分非常高,且采用不同的清粪方式对废水的水质有很大影响。有研究表明,采用水冲式清理粪污,废水中悬浮物的浓度是干清粪的2倍,这主要来源于猪粪和饲料。此外,猪场废水还具有其他特点,如废水的固液混合造成了粘度增大,冲圈时间的集中对废水处理工艺造成较大的冲击负荷等[2-3]。因此,开发经济高效的猪场废水处理工艺,对推动猪场废水无害化处理与资源化利用具有重要意义[4]。

厌氧膜生物反应器(anaerobic membrane bioreactor, AnMBR)是一种结合了厌氧消化工艺和膜分离技术的新型污水处理工艺[5]。利用膜组件的拦截作用,实现了污泥停留时间和水力停留时间完全分离,避免了厌氧消化过程中污泥流失,使系统保持较高的污泥浓度,提高了厌氧消化的效率和稳定性[6]。目前,对于AnMBR处理猪场养殖废水的研究相对较少,且多为实验室研究,工程应用可借鉴的经验、参数相对缺乏[7]。本研究采用中试规模外部浸没式平板膜生物反应器在中温厌氧条件下处理猪场养殖废水,研究其长期连续运行性能和污染物降解能力,为AnMBR处理猪场养殖废水的实际应用和优化控制等提供参考。

-

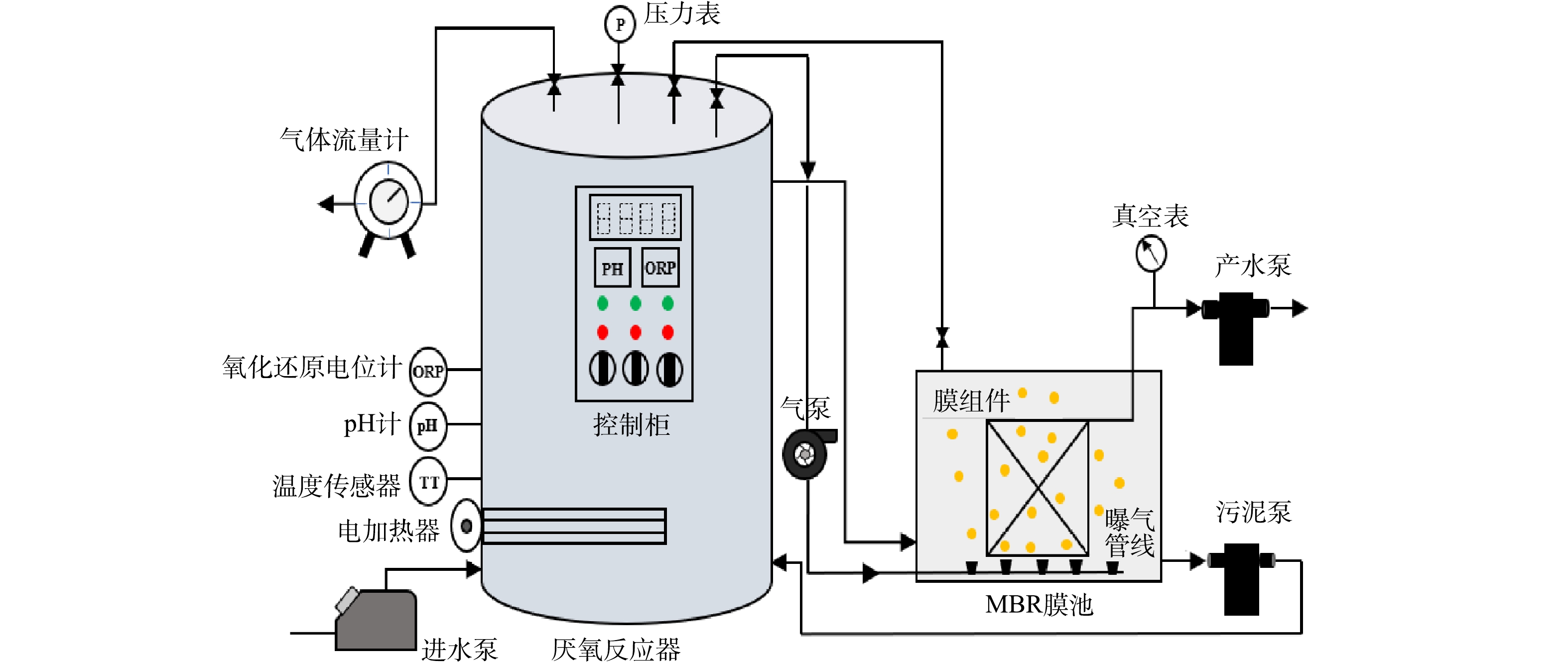

实验装置AnMBR位于河南省某养猪场污水处理单元,其结构及流程如图1所示。该装置主要由厌氧反应器、MBR膜池、控制系统3部分组成。其中厌氧反应器有效容积为1 m3,设有氧化还原电位计(ORP)、pH计(研华分析501型)、温度传感器及电加热器等;MBR膜池采用浸没式平板膜组件,该膜组件由江苏沛尔膜业提供,膜面积5 m2,平均孔径0.2 μm,材质为聚四氟乙烯,设定初始膜通量为5 L·(m2·h)−1。通过控制系统内设定的温度程序,将温度传感器与电加热器联锁,使厌氧消化温度在(37±2) ℃,由MBR膜池内设置的液位联锁,控制产水泵启停。

具体运行过程如下:废水通过蠕动泵(Kamoer Uip)连续进入厌氧反应器,初始HRT为8 d,后续逐步提高处理负荷,将HRT缩短为5 d和3 d。厌氧消化产生的沼气一部分由气泵(森森ACO电磁式空气泵)抽至MBR膜池内,经膜组件底部曝气管道对膜表面进行冲刷,气泵流量为200~300 L·min−1,膜池内回曝的沼气由管线再回流至厌氧反应器,最终通过湿式气体流量计(助科LML-1)排出。厌氧消化后的沼液自流进入膜池,通过产水泵(雷士泰电动隔膜泵30 W)将沼液透过膜组件抽出,产水泵按抽8 min停2 min的方式连续运行,由设定的液位高低联锁控制产水泵启停。产水泵前安装真空表(上海联力)监测运行过程跨膜压差变化。MBR膜池底部设有污泥管线,通过污泥泵(雷士泰电动隔膜泵30 W)将膜截留下来的污泥回流或外排。

-

该猪场养殖废水采用水冲粪工艺,废水中含有高浓度有机污染物和悬浮固体,经测算,其平均TCOD为45.9 g·L−1,BOD5为9.6 g·L−1,SS为23.2 g·L−1。废水颜色呈灰黑色,散发恶臭,为浆状,且含有明显大颗粒杂质。由于猪场收集的废水原水B/C<0.35,可生化性差,直接进行厌氧生化处理难度大,加上大颗粒杂质会堵塞管路,增大处理难度。为避免对厌氧膜生物反应器系统造成影响,实验用水来自厂区固液分离后经气浮沉淀预处理后的废水,接种污泥取自现场厌氧罐。实验废水与接种污泥性质如表1所示。

-

AnMBR运行过程分为3个阶段:第Ⅰ阶段为启动调试期(0~40 d),接种污泥取自现场处理废水的厌氧罐,接种污泥量为0.8 m³。该污泥对废水有良好的适应性,可使反应器在低负荷0.5~1.88 kg·(m3·d)−1(以TCOD计)下运行。在此期间,进水量逐步提高至125 L·d−1,HRT=8 d,温度保持在中温条件下;第Ⅱ阶段为负荷提升期(41~100 d),在系统运行稳定的情况下,通过提升进水量的方式来提高处理负荷,使有机负荷上升至3 kg·(m3·d)−1左右,HRT缩短为5 d,处理水量为200 L·d−1,并使反应器稳定运行;第Ⅲ阶段继续提升处理负荷(101~120 d),使负荷提高至5 kg·(m3·d)−1,HRT缩短至3 d,废水处理量增加至340 L·d−1,研究反应器在较高负荷下的运行性能。在整个过程中SRT为30 d,消化环境始终维持在中温,ORP小于-350 mV条件下运行。

-

雷磁便携式pH计测定pH;SS、VSS测定采用标准重量法,COD、NH3-N、TN、TP、挥发性脂肪酸(VFA)、总碱度(ALK)(以CaCO3计)均采用Hach(DR900)多参数检测仪,消解器采用Hach(DRB200),其中COD用高量程快速预制试剂,其余指标用高量程标准预制试剂。沼气产量由湿式气体流量计统计,ORP采用研华501型在线ORP计。污染物去除率根据式(1)进行计算。

式中:

$ {Q}_{\mathrm{m}} $ 为污染物$ \mathrm{m} $ 的去除率,%;$ {I}_{\mathrm{m}} $ 为进水中污染物$ m $ 的质量浓度,mg·L−1;$ {O}_{\mathrm{m}} $ 为产水中污染物$ \mathrm{m} $ 的质量浓度,mg·L−1。 -

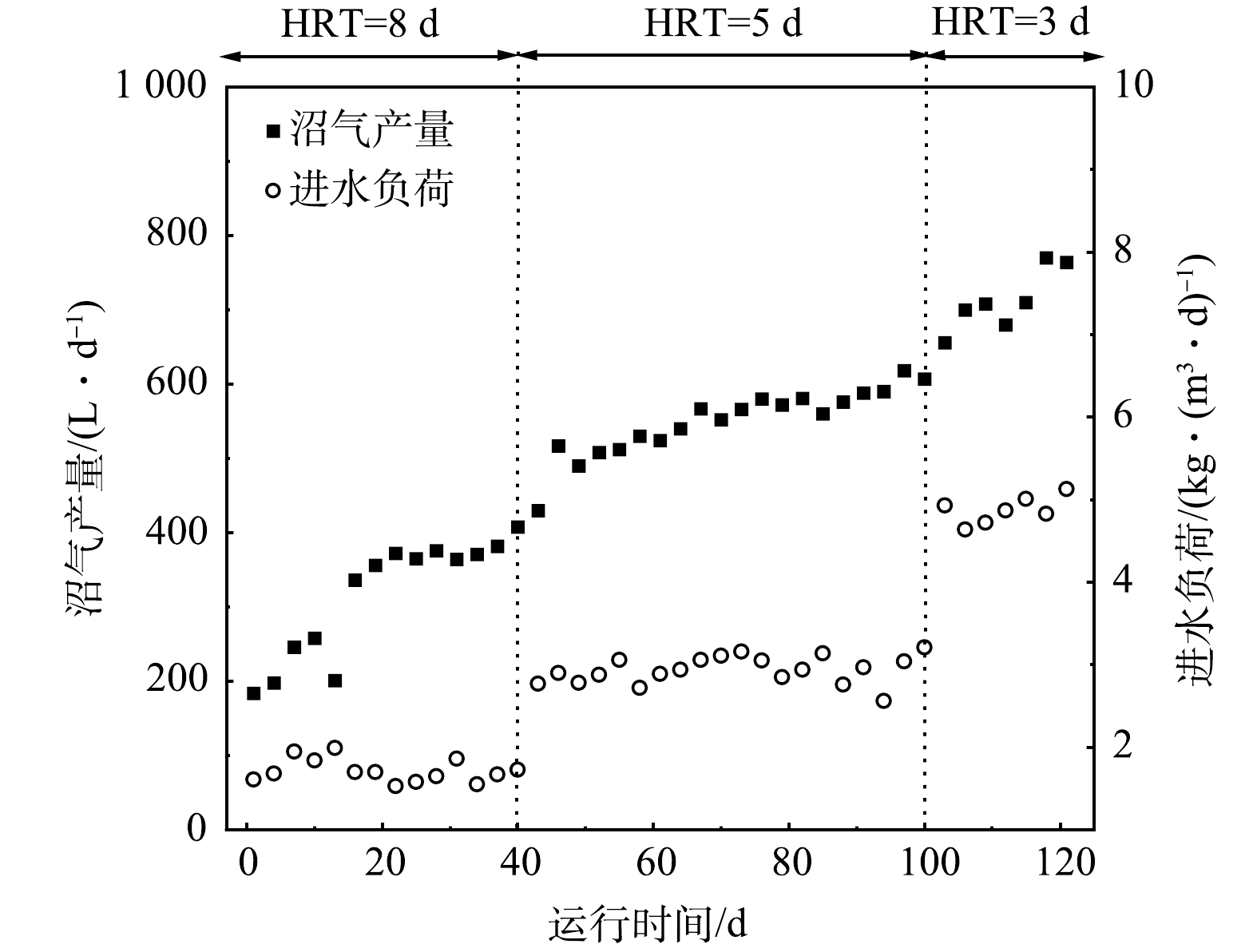

猪场养殖废水中含有高浓度有机污染物,通过厌氧消化作用,可以转化为沼气作为能源回收利用。实验通过湿试气体流量计对每天产气量进行记录。图2反映了系统运行期间日产气量随进水负荷的变化。由图2可见,在系统运行过程中随着HRT缩短,进水负荷由1.88 kg·(m3·d)−1提高至5 kg·(m3·d)−1,日产气量由184 L增加至764 L,沼气产率在0.38~0.45 m³·kg−1(以TCOD计)。此研究结果与LEE等[8]研究的浸没式AnMBR处理养猪废水产气性能类似。系统运行至10~13 d时,由于产气管漏气造成气体产量统计数据偏低,更换后恢复原有水平。有研究表明[9],当氨氮质量浓度为1 000 mg·L−1时,会对厌氧消化产气性能有所抑制。本实验进水中氨氮高于此抑制水平,但沼气产量良好,表明AnMBR有着较好的适应性,对抑制性因素抗受能力强。

-

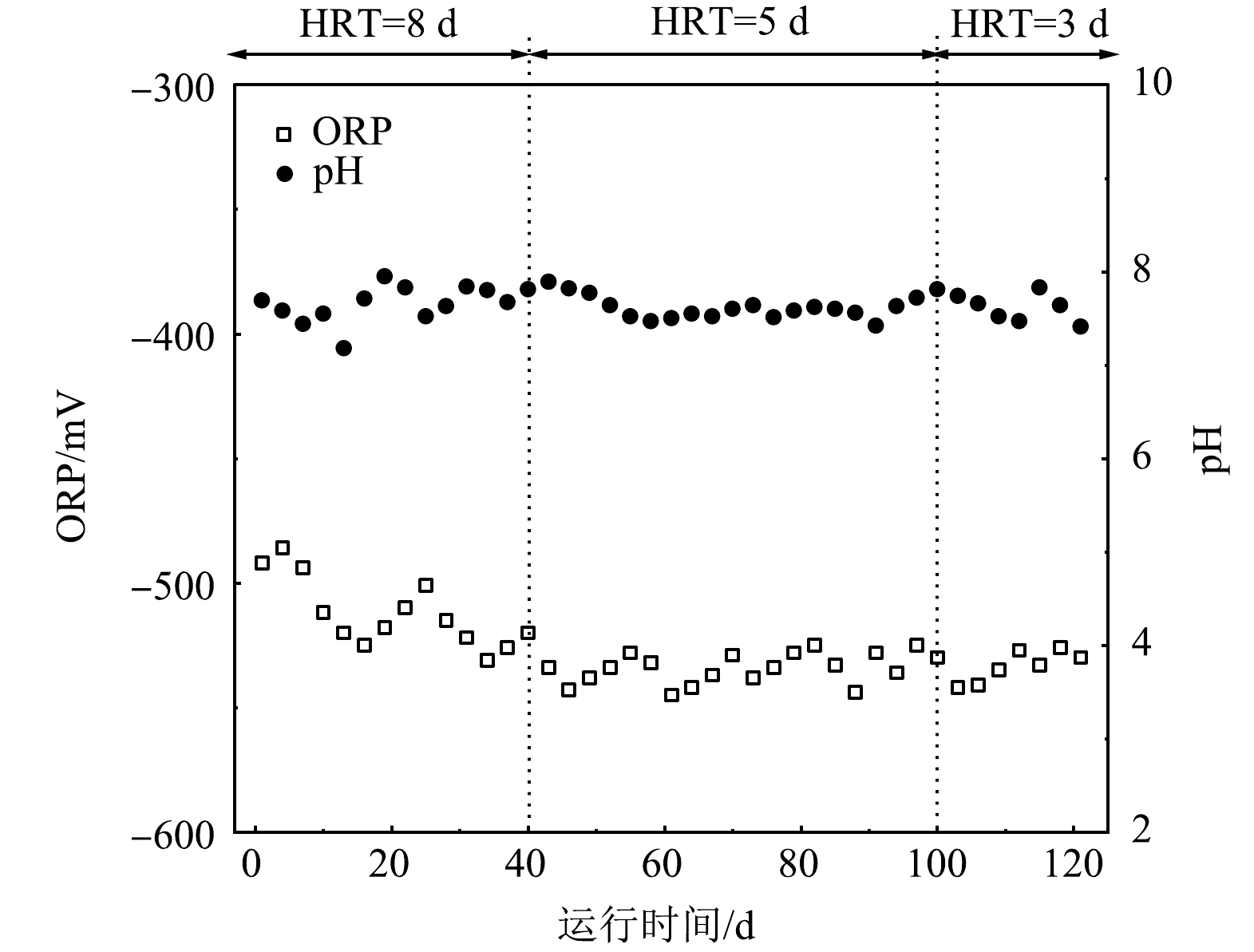

1) pH及ORP变化。本研究利用温度传感器与电加热联锁,有效控制厌氧消化在中温(35~40 ℃)条件下进行,考察了反应器在运行过程中ORP、pH的变化,结果如图3所示。ORP值可反映系统所处厌氧环境中的含氧量,一般情况下,中温厌氧消化系统要求的ORP值应小于−300 mV[10]。本研究运行初期ORP值较大,这是由于反应器内原本残留的空气以及进料过程废水中溶解氧所导致的,但其数值低于−300 mV,系统运行稳定后,ORP低于−500 mV,消化过程始终处于良好的厌氧环境。随着反应的进行,pH由起初的7.7下降至7.1,而后又逐渐上升最终稳定在7.5~7.8。造成前期pH下降的原因是由于甲烷菌的活性低,无法及时将系统内的有机酸转化,酸类物质的积累导致pH降低。本研究中甲烷菌的活性受到以下2方面原因的影响:一是由于实验装置接种的污泥来自现场厌氧罐,而现场厌氧罐长期未排泥,且停运很长一段时间,造成接种的污泥中微生物活性低,需要一定的适应期;二是因为实验初期ORP较高,对甲烷菌活性造成抑制。随着系统内厌氧环境逐渐优化,甲烷菌恢复功能将积累的有机酸转化为甲烷,酸类物质的消耗使pH升高并趋于稳定。有研究表明,在厌氧消化过程中,甲烷菌对pH比较敏感,最适pH在6.5~7.8,但水解酸化菌对pH有着较大的适应范围[11]。

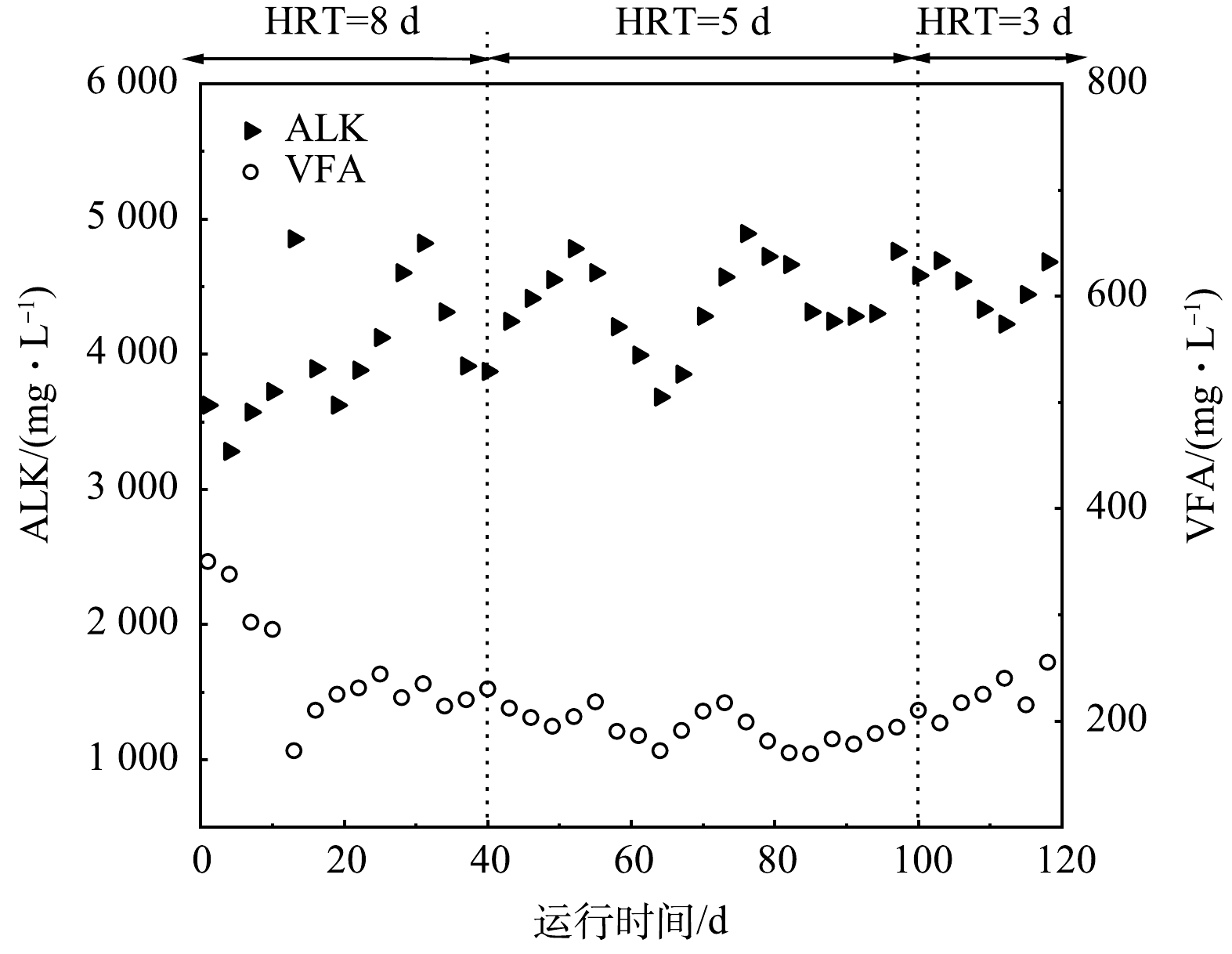

2) ALK与VFA变化。VFA与ALK可作为厌氧发酵过程中运行稳定性的关键指标,通过对其监测跟踪可以及时判断系统运行情况,从而做出相应的调节,防止系统出现酸化,保证反应器的正常运行[12]。如图4所示,ALK在运行期间波动较大,第Ⅰ阶段最低3 200 mg·L−1,最高可达4 850 mg·L−1,后期随着反应器运行逐步稳定,ALK在3 900~4 600 mg·L−1。VFA在169~350 mg·L−1,前期VFA值较高,大于300 mg·L−1,表明存在有机酸积累的现象,这与pH在前期下降情况相似,是甲烷菌活性低造成的。在装置运行稳定后,VFA也逐渐降低并稳定。有研究表明,当VFA/ALK的值大于0.4时,表明系统处于不稳定状态[13]。本研究运行的3个阶段,比值始终小于0.1,远小于失稳值0.4,说明系统运行稳定性较强。

-

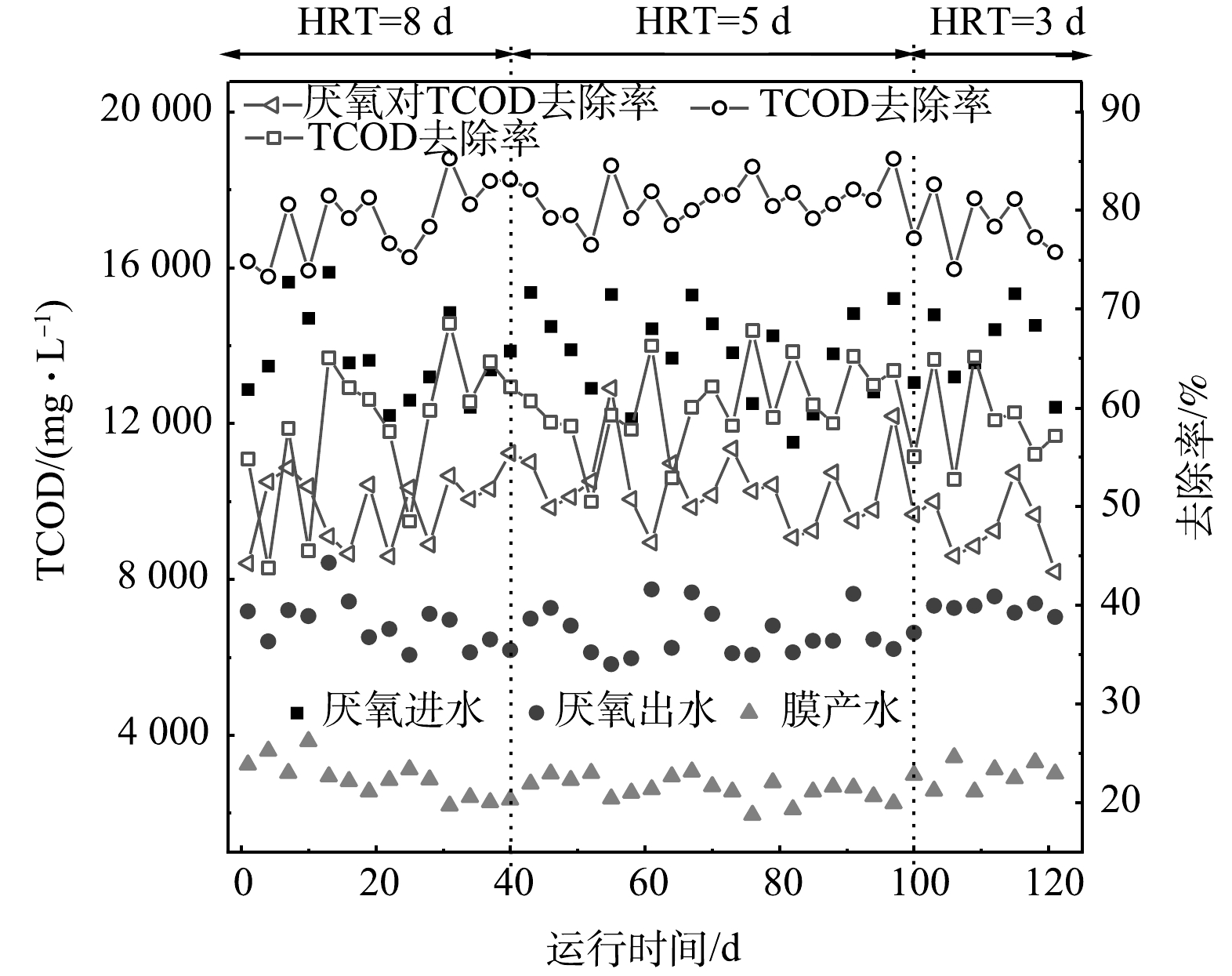

1)进出水TCOD变化。图5反映了AnMBR运行各阶段TCOD的变化及其去除率。厌氧反应器进水TCOD波动较大,在11 520~15 880 mg·L−1,厌氧出水TCOD为5 820~8 660 mg·L−1,整个运行过程厌氧消化对TCOD去除率为(53.2±8)%,在HRT为5 d时去除率最高可达61.2%。理论上,厌氧消化工艺能够大幅度去除废水中COD,如王亮等[14]采用UASB反应器在容积负荷为0.3~0.5 kg·(m3·d)−1时,COD去除率在77%~84%。本研究厌氧消化处理效果相对较差,是由于废水前端预处理过程对SS去除不充分所引起。有研究表明,厌氧发酵对猪场废水中溶解性有机质去除效果较好,而附着在悬浮物中的颗粒态有机物大多是惰性的难以水解,且消化时间对这部分物质的水解特性影响不大,因此会增大生化处理压力[15-16]。

厌氧出水经膜过滤,TCOD得到进一步去除,膜产水TCOD值为1 950~3 840 mg·L−1,故整个AnMBR对TCOD的去除率为(80±6)%。通过膜的拦截作用将厌氧出水中SS去除,此过程对TCOD的去除率为44%~66%,占AnMBR工艺TCOD去除率的(37±9)%。LEE等[8]采用浸没式AnMBR处理猪场养殖废水,结果表明,COD的去除率达80%。JIANG等[17]的研究也表明了不同HRT的情况下,利用AnMBR对COD的去除率均在82%以上。

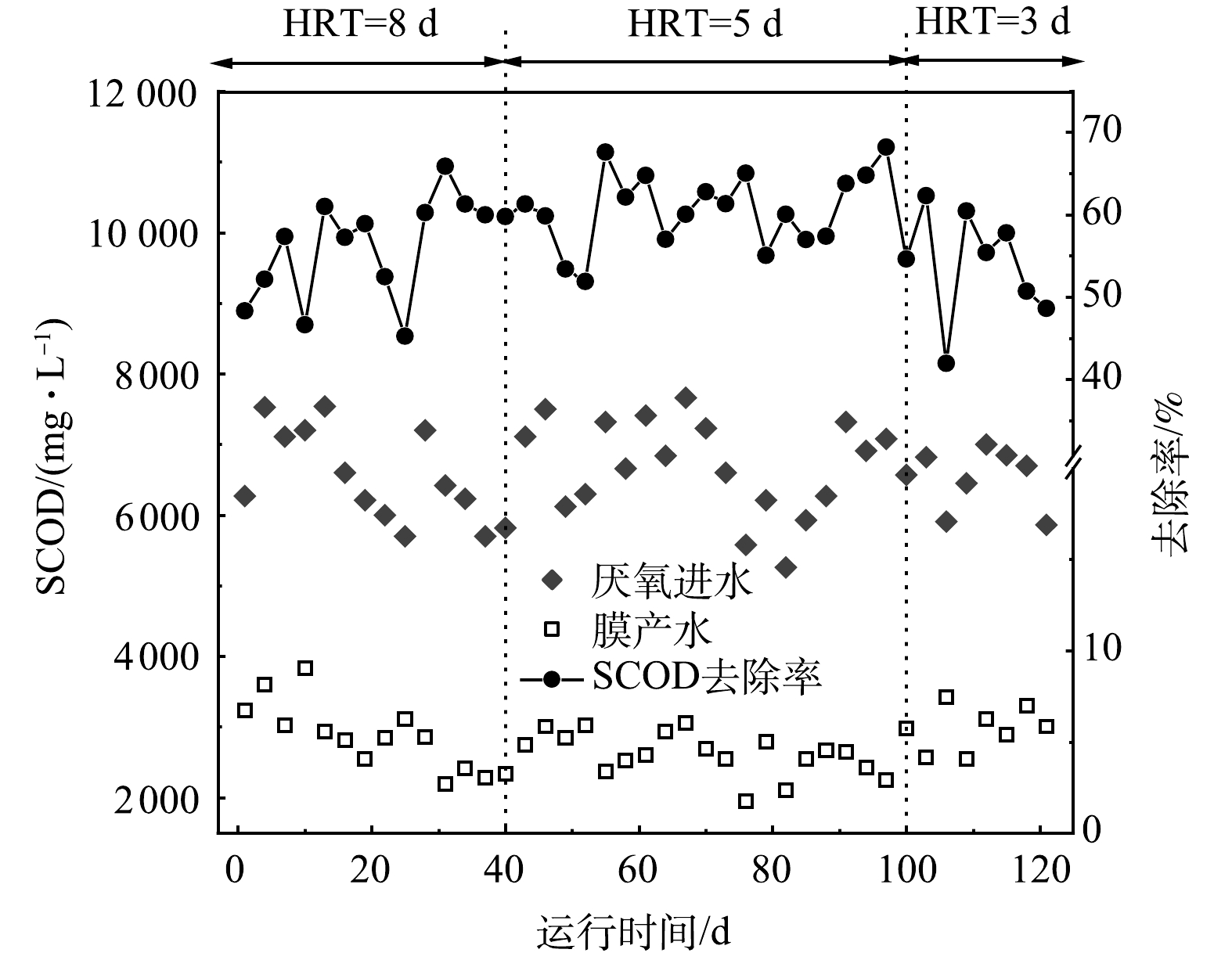

2)进出水SCOD变化。将厌氧进水通过滤纸(0.45 μm孔径)抽滤,得到滤液,测出溶解性COD(SCOD)值。图6反映了厌氧进水SCOD质量浓度及其在厌氧进水TCOD中的占比。厌氧进水中SCOD为5 700~7 660 mg·L−1,约占厌氧进水TCOD的42%~56%。图7反映了厌氧消化对SCOD去除效果。可见,系统运行期间,膜产水SCOD值为1 950~3 840 mg·L−1,SCOD去除率为(58±10)%,约占AnMBR进出水TCOD去除率的55%。这表明厌氧消化过程主要去除的是SCOD,而对由SS产生的惰性COD去除较少。本研究废水来自水冲粪和水泡粪,原水中含有大量的颗粒物,前端预处理难以有效固液分离。有研究表明微生物对污水中呈颗粒态污染物降解速度慢,呈液态的更容易被微生物利用,且颗粒物浓度过高会抑制微生物代谢[18]。若将清粪方式改为干清粪水冲洗,强化预处理固液分离,可有效减少颗粒态污染物进入厌氧消化,提高处理效果。当前该猪场厌氧消化工艺对COD平均去除率在35%左右,与其相比AnMBR有着更好的处理效果。

-

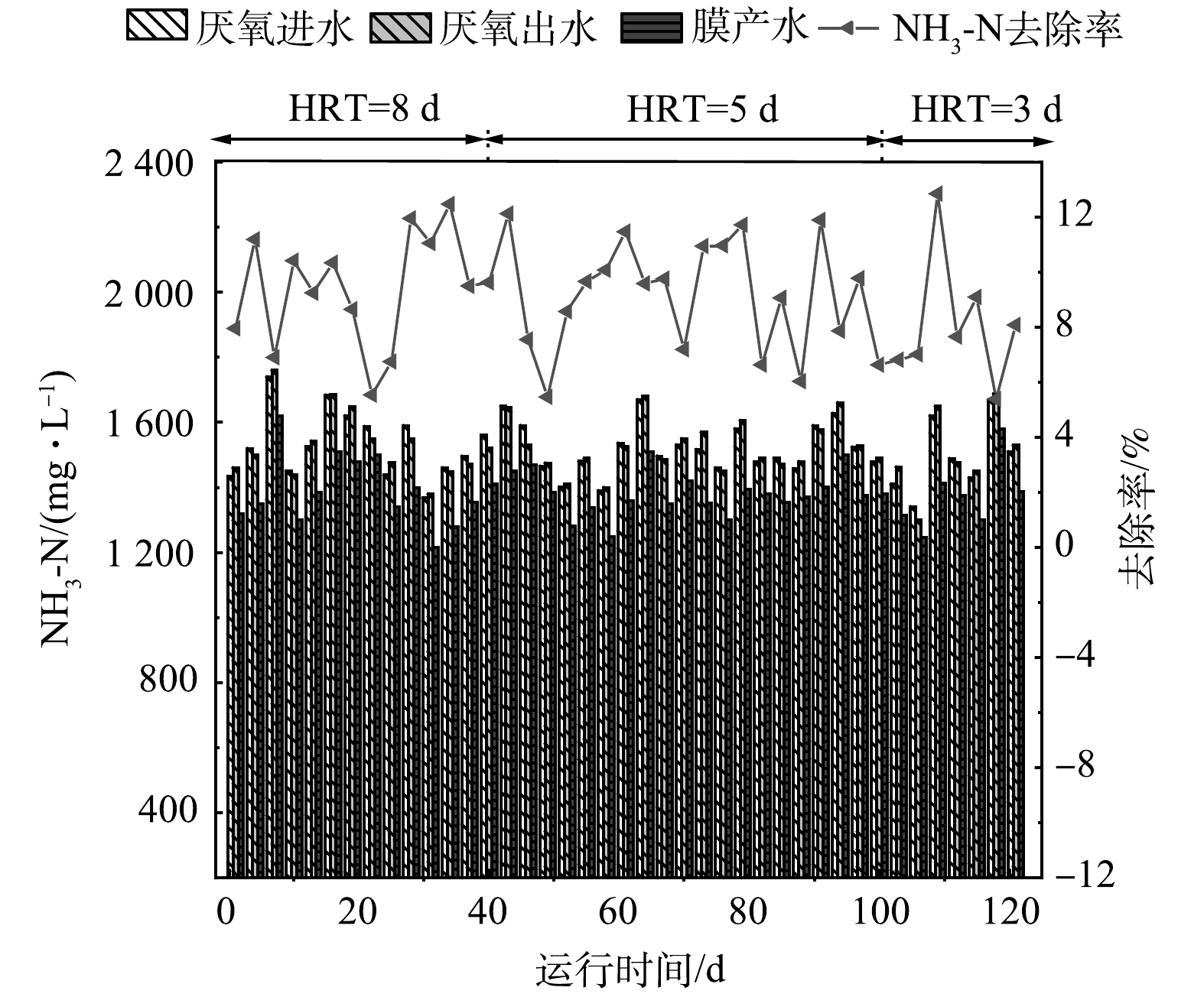

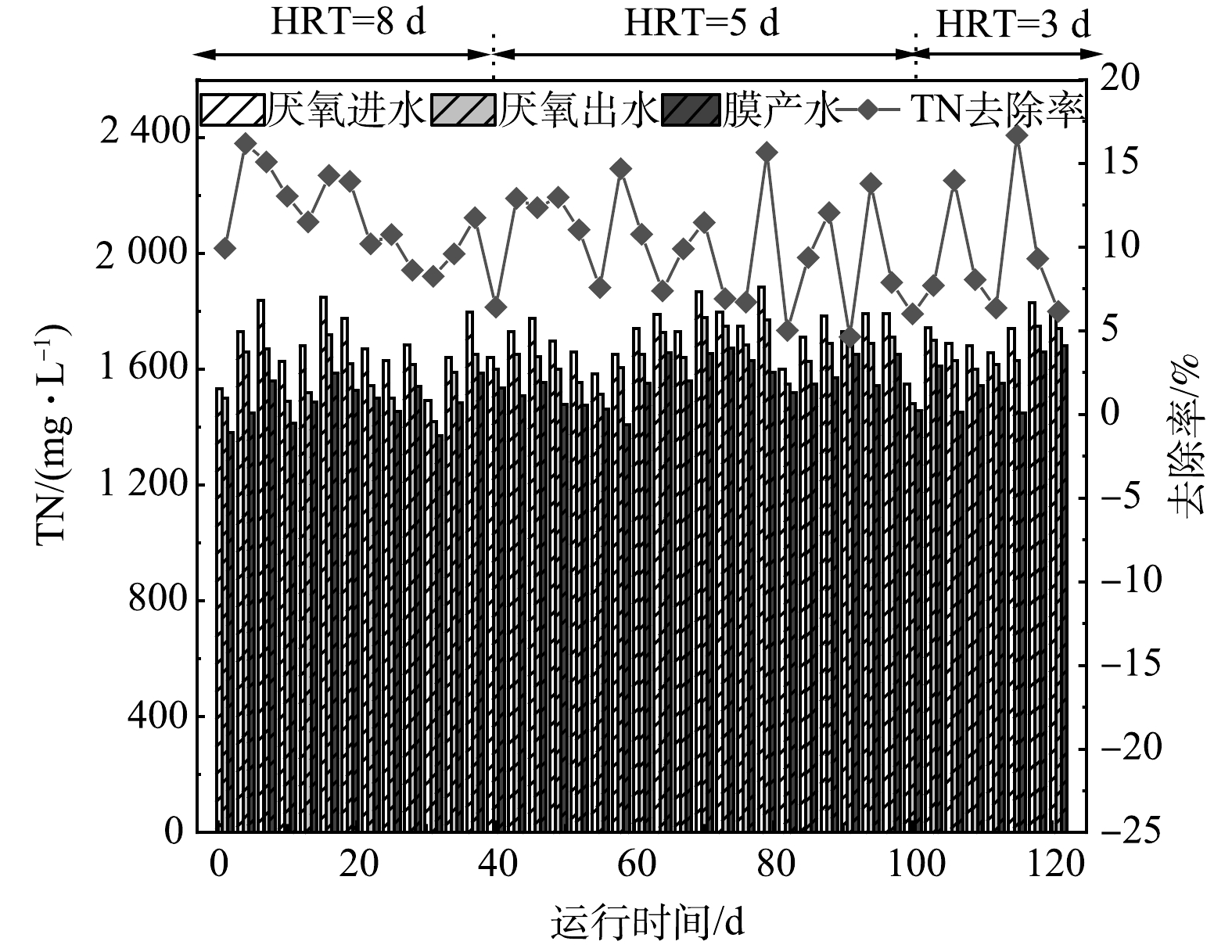

1)进出水NH3-N、TN的变化。采用水冲粪的养殖场粪污废水氨氮含量较高,可达到1 000 mg·L−1以上,致使废水中散发出强烈刺鼻的氨恶臭气味[19]。如图8和图9所示,该猪场废水经预处理进入AnMBR前NH3-N、TN质量浓度分别高达1 300~1 660 mg·L−1、1 480~1 770 mg·L−1。经过厌氧消化后NH3-N、TN分别为1 310~1 760 mg·L−1、1 420~1 778 mg·L−1,厌氧消化对NH3-N、TN去除效果不明显。厌氧产水经膜分离处理后,废水中NH3-N质量浓度下降到1 200~1 620 mg·L−1,去除率在7%~12.8%。膜分离出水TN为1 370~1 680 mg·L−1,去除率为4.6%~16.7%,波动较大。由于厌氧消化的局限性,对NH3-N、TN的去除率并不高。相关研究也说明了,AnMBR对TN的去除小于10%[20]。闫林涛等[9]采用AnMBR处理高浓度有机废水时发现进出水氨氮浓度相差不大,对氨氮的去除效果不明显。本研究对NH3-N、TN的去除可能是由于厌氧出水中颗粒性氮源被膜截留,也可能是部分氮源被微生物代谢利用固定在污泥中。有研究[21]表明,在中温条件下,高氨氮、弱碱环境容易造成游离氨以气体的方式逸散。此外,有研究[22]也表明,废水中游离氨的浓度会对厌氧消化产生影响,当其质量浓度大于50 mg·L−1时会有抑制作用。唐崇俭等[23]研究表明,对猪场废水进行厌氧处理时,当游离氨质量浓度为(180±40) mg·L−1时,COD去除率小于20%。本实验参考文献[24-25]中的公式对氨氮换算,得出废水中游离氨质量浓度可达68.4~83.6 mg·L−1,大于抑制浓度,所以会对厌氧消化中污染物的去除造成不利影响。

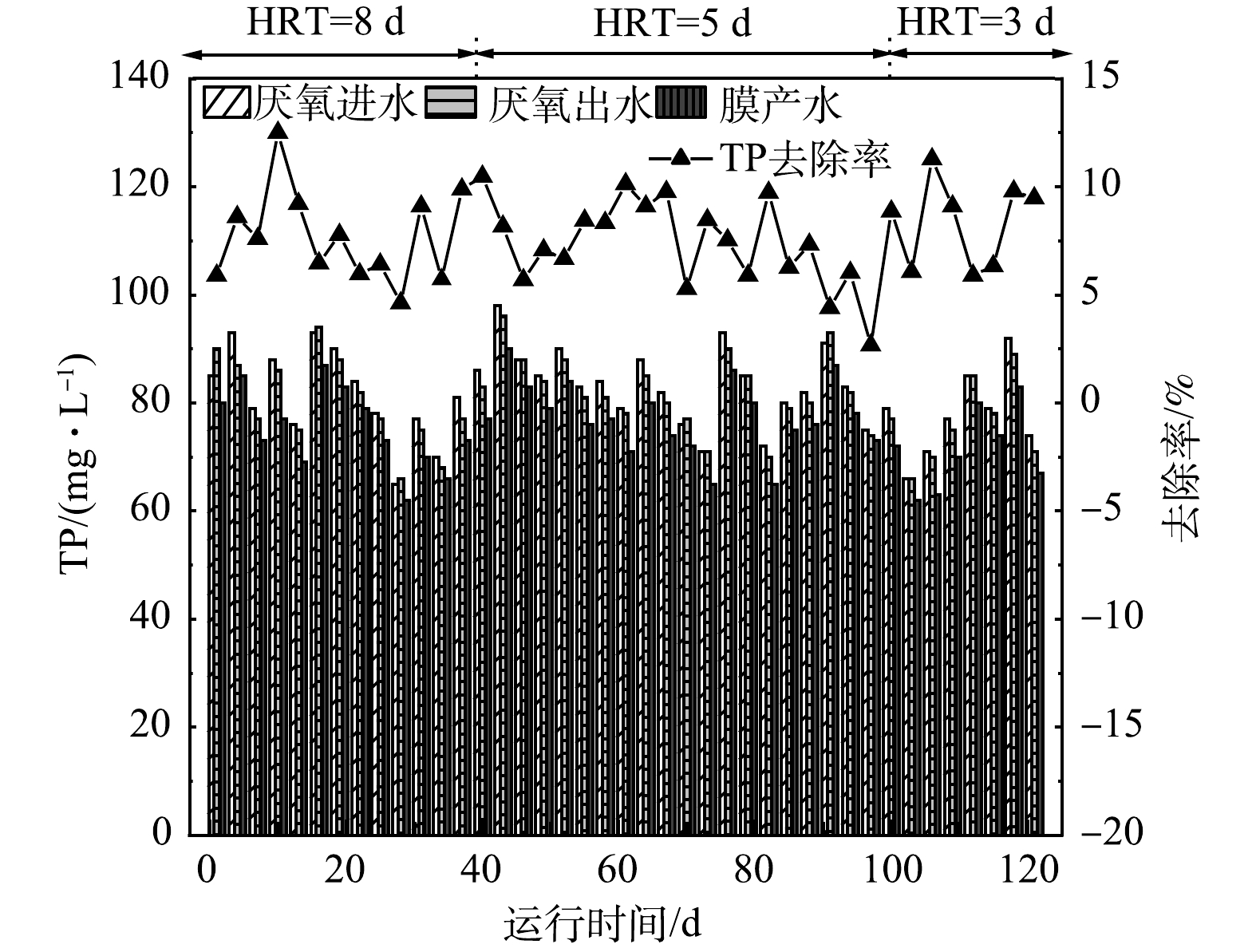

2)进出水TP变化。猪场废水中除了含有大量的有机物和氮外,还含有较高浓度的磷。图10反映了AnMBR进出水TP的变化。废水经固液分离预处理后,AnMBR进水中TP质量浓度在65~98 mg·L−1,膜产水中TP为62~91 mg·L−1,平均去除率在5%左右。AnMBR主要是通过膜的拦截作用去除附着在消化污泥上的磷。宁建凤等[26]在10个规模化养猪场厌氧发酵系统对氮磷处理效果的研究中发现,硝态和亚硝态氮去除效果较好,TN、TP和氨氮发酵后浓度有所升高,去除效果差。经AnMBR处理后的猪场废水还达不到排放要求,但富含养分的废水可用于还田。根据农田灌溉水质标准(GB 5084-2005),养殖废水用作农田灌溉时对氮磷未作具体要求,因此,废水后续处理主要针对COD的去除。通过AnMBR处理后的废水可大大降低后续处理负荷,减少处理成本。

-

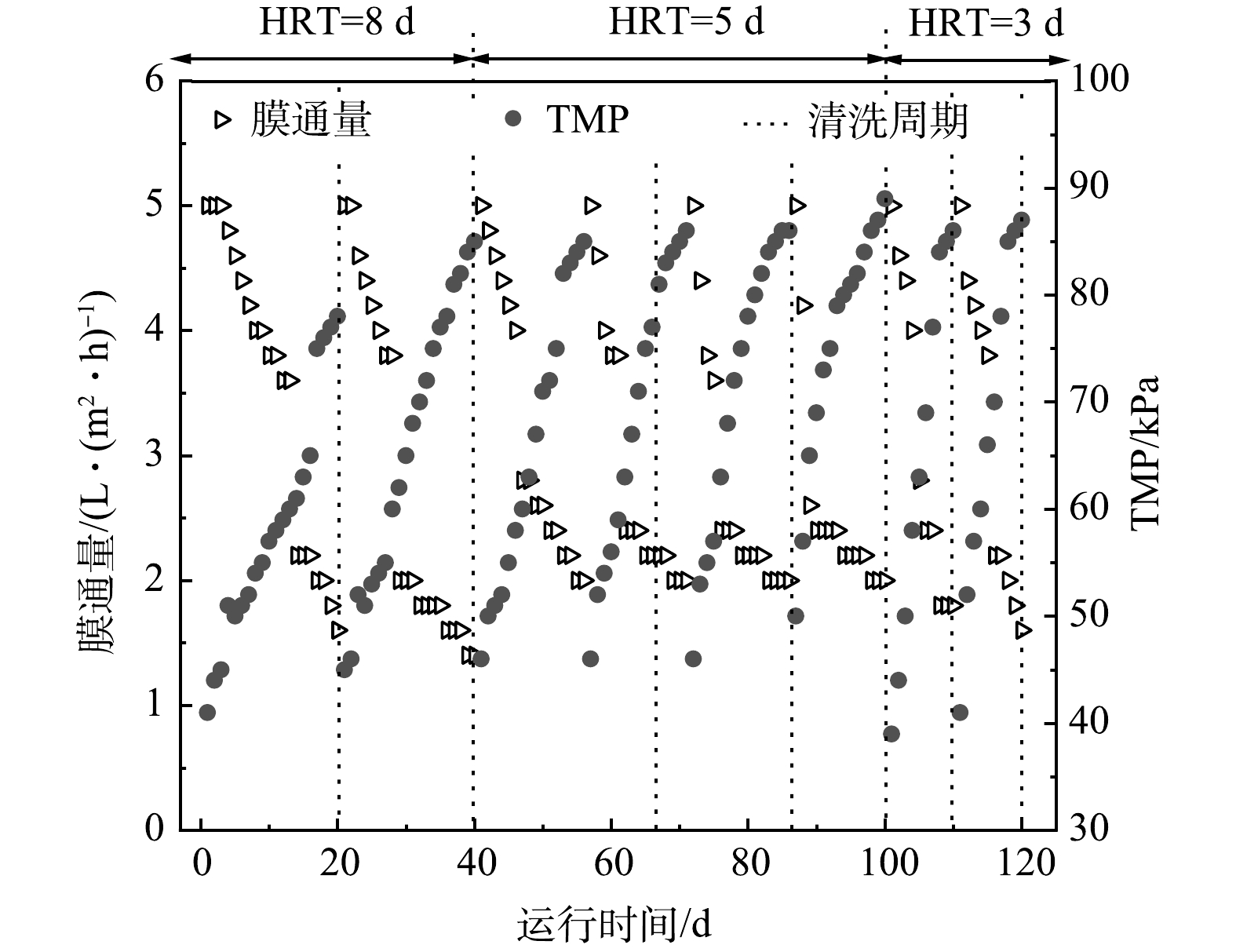

1)膜组件性能分析。膜组件运行性能是评价AnMBR运行效能的重要参数,可以通过对膜组件运行过程中膜通量、跨膜压差(TMP)及清洗周期的监测可以判断膜污染情况以及膜组件运行是否正常。系统运行期间内,膜初始通量为5 L·(m2·h)−1,产水泵抽吸按抽8 min停2 min方式运行。由图11可知,在AnMBR运行第Ⅰ阶段(HRT=8 d)时,膜组件运行14 d,TMP由最初41 kPa增大至61 kPa,膜通量出现跨越式下降,由5 L·(m2·h)−1降低至2.2 L·(m2·h)−1。继续运行6 d,TMP上升到78 kPa,膜通量仅为1.6 L·(m2·h)−1,此时需对膜组件清洗。在HRT=8 d阶段,清洗周期为20 d。运行第Ⅱ阶段HRT为5 d时,装置在第47 d时TMP增大至60 kPa,膜通量跨越式下降至2.8 L·(m2·h)−1,随后继续运行9 d,TMP上升到85 kPa,需对膜组件进行清洗。在运行阶段为HRT=5 d时,清洗周期下降至16、15、14 d。当HRT进一步缩短至3 d,TMP增长速度显著加快,运行10 d就达到了86 kPa,膜通量降至1.8 L·(m2·h)−1,清洗周期也降低至10 d。清洗周期的缩短与膜污染相关,有实验表明,随着HRT缩短,OLR也随之升高,微生物代谢活动受到影响,使代谢产物(EPS和SMP)的含量和污泥粒径增加,产生严重膜污染现象,造成清洗周期缩短[27]。此外,颗粒物、胶体、可溶性有机物、无机物等沉积在膜表面、孔隙和孔隙内壁,使得膜孔径变小或者堵塞,从而造成TMP升高和产水量下降[28]。本实验TMP与其他研究相比较大,主要是因为废水中颗粒物具有粘性,以及处理水量、悬浮物浓度及粒径等因素相关。KORNBOONRAKSA和许美兰等[29-30]在处理猪场废水时发现,与其他性质的污泥相比,猪场废水中污泥粒径和浓度对膜的过滤性能影响明显,污泥粒径减小和浓度提高更容易加剧膜污染。

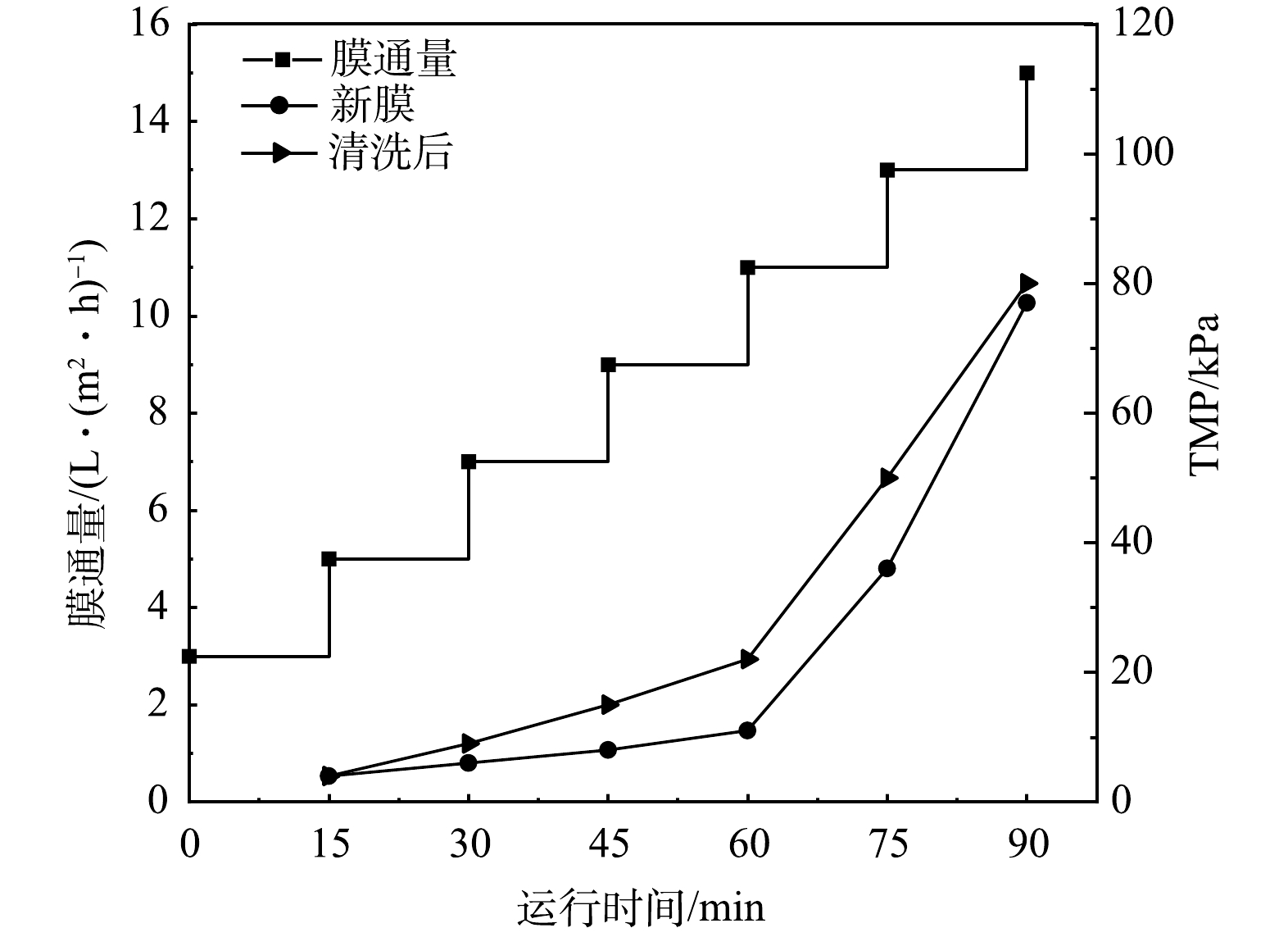

2)膜污染控制。当膜污染物主要为生物性有机污染时,采用碱洗的方法进行控制;为无机污染时,采用酸洗的方法进行控制。本研究对污染的膜组件采用水冲洗加化学清洗的方式将膜表面附着的污染物去除。首先通过水冲洗将膜表面黏泥层剥离,再分别进行碱洗、酸洗。碱洗时所用药剂为次氯酸钠,质量浓度为3~5 g·L−1,浸泡5 h;酸洗所用药剂为柠檬酸,质量浓度为3~5 g·L−1,浸泡3 h。清洗后采用通量阶梯递增法对膜组件临界通量测定并与新膜进行比较。临界通量测定时的环境温度为25~30 ℃,污泥来自实验厌氧罐,质量浓度为15.3~18.5 g·L−1,pH为7.5±0.3,设定起始通量为3 L·(m2·h)−1,通量阶梯设置为2 L·(m2·h)−1,维持各通量下恒定运行15 min,测试结果如图12所示。可以发现,在起始通量为3 L·(m2·h)−1时运行15 min,新膜与清洗后的膜TMP均为4 kPa。在膜通量小于9 L·(m2·h)−1,运行过程中TMP增长缓慢,当通量达到11 L·(m2·h)−1时,TMP增涨迅速,此时新膜与清洗后膜的TMP分别为36 kPa和50 kPa,继续增大膜通量后,TMP的增长速率也迅速提高。当通量达到13 L·(m2·h)−1时,新膜和清洗后膜的TMP分别为77 kPa和80 kPa。由此可见,该膜的临界通量为9~11 L·(m2·h)−1,故膜组件稳定运行时通量控制为2~5 L·(m2·h)−1。通过水冲洗结合碱洗加酸洗浸泡的方式,可有效去除膜污染,恢复膜的过滤性能。乔玮等[31]利用平板膜处理猪场废水时,经0.1%次氯酸钠和柠檬酸浸泡后,膜的过滤性能得到明显恢复。

-

1)在中温条件下,采用外部浸没式AnMBR处理猪场养殖废水,分别在HRT为8、5、3 d 3个阶段连续运行120 d,装置运行稳定。系统去除COD效果良好,抗冲击负荷能力强。在HRT为5 d时,厌氧消化对TCOD去除率最高可达61.2%,经膜拦截后,TCOD去除率达(80±6)%。溶解性COD去除效果明显,占TCOD去除的55%。

2)系统运行期间,随着进水负荷提高,沼气产量逐渐增加,产率在0.38~0.45 m3·kg−1,具有较高的资源利用价值。

3)膜组件运行过程中,有机与无机污染物在膜表面沉积,导致膜孔堵塞,形成膜污染。随着处理负荷的增大,清洗周期不断缩短。通过水冲洗与化学清洗的方式可有效去除污染物,恢复膜通量。但清洗周期过于频繁,会增加运行成本,降低膜组件使用寿命。

中试厌氧膜生物反应器处理养猪废水

Performance of a pilot anaerobic membrane bioreactor treating swine wastewater

-

摘要: 猪场养殖废水是一类有机污染物浓度高、悬浮物多、性质复杂的废水,在传统厌氧处理中存在消化污泥流失及处理效率低等问题。本研究采用中试规模外部浸没式厌氧膜生物反应器处理猪场实际废水,设计处理水量为1 m3·d−1,在HRT分别为8、5、3 d的3个阶段连续运行4个多月,考察了厌氧膜生物反应器的沼气产量、运行稳定性、污染物去除效果及膜组件运行性能和清洗效果。结果表明,系统运行期间ORP在−486~−545 mV;随着HRT缩短,有机负荷由0.5~1.88 kg·(m3·d)−1升高到5 kg·(m3·d)−1,沼气产量逐渐增大,产率为0.38~0.45 m3·kg−1。在整个运行过程中,VFA/ALK始终小于0.1,系统运行稳定。对TCOD、溶解性COD、氨氮、TN、TP去除率分别达到74%~86%、48%~68%、7%~12.8%、4.6%~16.7%、5%,其中溶解性COD去除率占总COD去除率的55%左右。系统运行期间初始膜通量设定为5 L·(m2·h)−1,在HRT=8 d时,清洗周期为20 d,随后不断缩短,当HRT为3 d时,清洗周期仅为10 d。通过水冲洗与化学清洗相结合的方式可有效缓解膜污染,进而恢复膜通量。以上研究结果可以为厌氧膜生物反应器处理猪场养殖废水工程应用提供参考。Abstract: Swine wastewater is a kind of wastewater with high concentration of organic pollutants, suspended solids and complex properties. Traditional anaerobic treatment has some problems such as loss of digested sludge, low efficiency and so on. In this study, a pilot-scale external submerged anaerobic membrane bioreactor was used to treat the actual wastewater from a pig farm. The designed water treatment capacity was 1 m3·d−1. In three stages of HRT=8 d, 5 d, and 3 d, the bioreactor was operated continuously for more than 4 months. The biogas production of anaerobic membrane bioreactor, operation stability, pollutant removal efficiency, as well as membrane module operation performance and cleaning efficiency were investigated. The results showed that the ORP was between −486 mV and −545 mV during the system operation. With the shortening of HRT, the organic load increased from 0.5~1.88 kg·(m3·d)−1 to 5 kg·(m3·d)−1, and the biogas production increased gradually, the yield was between 0.38 to 0.45 m3 kg−1. The VFA/ALK was always less than 0.1 during the whole process, the system maintained a stable running. The removal efficiencies of TCOD, SCOD, NH3-N, TN, and TP were 74%~86%, 48%~68%, 7%~12.8%, 4.6%~16.7%, and 5%, respectively. The removal efficiency of SCOD accounted for about 55% of TCOD. During the system operation, the initial membrane flux was set to 5L·(m2·h)−1. At HRT of 8 d, the cleaning period was 20 d, and then it was reduced continuously. At HRT of 3 d, the cleaning period was only 10 d. The combination of water washing and chemical cleaning could effectively alleviate membrane fouling and restore membrane flux. The above research results can provide a reference for the engineering application of anaerobic membrane bioreactor to treat swine wastewater.

-

-

表 1 实验废水与接种污泥基本性质

Table 1. Basic properties of test wastewater and inoculated sludge

g·L−1 项目 氨氮等污染物质量浓度/( g·L−1) pH TCOD SCOD BOD5 SS NH3-N TN TP 实验废水 12.1~15.8 5.1~7.6 4.8~6.2 1.8~3.4 1.3~1.7 1.4~1.8 0.06~0.09 7.2~8.2 接种污泥 14.7~16.9 — — 18.1~20.2 1.4~1.9 1.5~2.1 0.07~0.10 7.1~7.6 -

[1] 吴晓梅, 叶美锋, 吴飞龙. 我国规模化养猪场废水处理技术研究进展[J]. 福建农业科技, 2018(1): 36-40. doi: 10.13651/j.cnki.fjnykj.2018.01.012 [2] 周营, 俞捷径, 戴睿智. 规模化养猪场养殖废水处理案例分析[J]. 中国资源综合利用, 2020, 38(5): 199-201. doi: 10.3969/j.issn.1008-9500.2020.05.061 [3] 单晓明. 猪场养殖废水的工艺案例及探讨[J]. 广东化工, 2019, 46(9): 179-180. doi: 10.3969/j.issn.1007-1865.2019.09.083 [4] 张慧风, 王雅茜. 规模化养猪场废水处理分析及污染治理对策[J]. 中国资源综合利用, 2021, 39(4): 183-185. doi: 10.3969/j.issn.1008-9500.2021.04.055 [5] 孙凯, 陆晓峰, 周保昌. 厌氧膜生物反应器(AnMBR)处理高浓度豆制品废水的研究[J]. 膜科学与技术, 2011, 31(4): 65-69. doi: 10.3969/j.issn.1007-8924.2011.04.013 [6] 白玲, 蓝伟光, 严滨. 废水处理中膜生物反应器的研究进展[J]. 膜科学与技术, 2008, 28(1): 91-96. doi: 10.3969/j.issn.1007-8924.2008.01.019 [7] 刘婉岑, 李赟, 袁京. 厌氧膜生物反应器在畜禽养殖废水处理领域的应用机遇与挑战[J]. 中国沼气, 2020, 38(6): 3-13. doi: 10.3969/j.issn.1000-1166.2020.06.002 [8] LEE S M, JUNG J Y, CHUNG Y C. Novel method for enhancing permeate flux of submerged membrane system in two-phase anaerobic reactor[J]. Water Research, 2001, 35(2): 471-477. doi: 10.1016/S0043-1354(00)00255-4 [9] 闫林涛, 黄振兴, 肖小兰. 厌氧膜生物反应器处理高浓度有机废水的中试研究[J]. 食品与生物技术学报, 2015, 34(12): 1248-1255. doi: 10.3969/j.issn.1673-1689.2015.12.003 [10] 董良飞, 周凯迪. 新型厌氧膜生物反应器城市污泥消化研究[J]. 常州大学学报(自然科学版), 2018, 30(1): 1-8. [11] S. S M, EUGENIO G G, F. H R. Monitoring of the anaerobic methane fermentation process[J]. Enzyme and Microbial Technology, 1990, 12(10): 722-730. doi: 10.1016/0141-0229(90)90142-D [12] 亓金鹏, 肖小兰, 张瑞娜. AnMBR处理高盐榨菜废水的运行效能及膜污染特性[J]. 环境工程学报, 2021, 15(2): 553-562. doi: 10.12030/j.cjee.202004134 [13] XU, RUI, YANG, et al. Anaerobic co-digestion of municipal wastewater sludge with food waste with different fat, oil, and grease contents: study of reactor performance and extracellular polymeric substances[J]. RSC Advances, 2015, 5(125): 103547-103556. doi: 10.1039/C5RA21459A [14] 王亮. 规模化猪场养殖废水高效脱氮除磷技术探究[D]. 杭州: 浙江大学, 2013. [15] 韩伟铖, 颜成, 周立祥. 规模化猪场废水常规生化处理的效果及原因剖析[J]. 农业环境科学学报, 2017, 36(5): 989-995. doi: 10.11654/jaes.2016-1508 [16] 邵一奇, 王电站, 颜成. 厌氧消化对猪场废水中溶解性和颗粒态有机物的组成与性质的影响[J]. 南京农业大学学报, 2019, 42(4): 713-720. doi: 10.7685/jnau.201810031 [17] JIANG M, WESTERHOLM M, QIAO W, et al. High rate anaerobic digestion of swine wastewater in an anaerobic membrane bioreactor[J]. Energy, 2020, 193(C): 116783. [18] 金鹏康, 刘柯君, 王先宝. 慢速可生物降解有机物的转化特性及利用[J]. 环境工程学报, 2016, 10(5): 2168-2174. doi: 10.12030/j.cjee.201412209 [19] 李扬, 乔亮. 现代化养殖场粪污废水处理技术探讨[J]. 北京农业, 2014(30): 297. doi: 10.3969/j.issn.1000-6966.2014.30.232 [20] DAI W, XU X, LIU B, et al. Toward energy-neutral wastewater treatment: A membrane combined process of anaerobic digestion and nitritation–anammox for biogas recovery and nitrogen removal[J]. Chemical Engineering Journal, 2015, 279: 725-734. doi: 10.1016/j.cej.2015.05.036 [21] 田林, 吴冰, 戴晓虎. 中温厌氧膜生物反应器处理高浓度有机废水的启动特性研究[J]. 中国科技信息, 2016(Z1): 20-22,14. doi: 10.3969/j.issn.1001-8972.2016.03.003 [22] KATHERINE S, MANUEL A, ESTRELLA A, et al. Effect of ammonia on the methanogenic activity of methylaminotrophic methane producing archaea enriched biofilm[J]. Anaerobe, 2004, 10(1): 13-18. doi: 10.1016/j.anaerobe.2003.10.004 [23] 唐崇俭, 郑平, 金仁村. 猪场废水厌氧生物处理FAN抑制及其调控对策的研究[J]. 高校化学工程学报, 2008, 22(4): 697-702. doi: 10.3321/j.issn:1003-9015.2008.04.027 [24] 张树军, 彭永臻, 曾薇. 高氮城市生活垃圾渗滤液短程生物脱氮[J]. 环境科学学报, 2006, 26(5): 751-756. doi: 10.3321/j.issn:0253-2468.2006.05.009 [25] NIU Q, HOJO T, QIAO W, et al. Characterization of methanogenesis, acidogenesis and hydrolysis in thermophilic methane fermentation of chicken manure[J]. Chemical Engineering Journal, 2014, 244: 587-596. doi: 10.1016/j.cej.2013.11.074 [26] 宁建凤, 陈家欢, 李盟军. 规模化猪场新建厌氧发酵系统对废水氮、磷养分的处理效应[J]. 广东农业科学, 2015, 42(23): 5-11. doi: 10.3969/j.issn.1004-874X.2015.23.002 [27] 慕银银, 郭新超, 王小林. HRT对厌氧膜生物反应器混合液性质和膜污染的影响[J]. 水处理技术, 2016, 42(1): 110-114. doi: 10.16796/j.cnki.1000-3770.2016.01.024 [28] 牛承鑫, 潘阳, 陆雪琴. 厌氧膜生物反应器(AnMBR)膜污染过程及控制方法研究进展[J]. 环境化学, 2019, 38(12): 2851-2859. doi: 10.7524/j.issn.0254-6108.2019010802 [29] KORNBOONRAKSA T, LEE S H. Factors affecting the performance of membrane bioreactor for piggery wastewater treatment[J]. Bioresource Technology, 2009, 100(12): 2926-2932. doi: 10.1016/j.biortech.2009.01.048 [30] 许美兰, 李元高, 叶茜. 厌氧旋转膜生物反应器处理畜禽养殖废水[J]. 中国给水排水, 2018, 34(23): 91-95. doi: 10.19853/j.zgjsps.1000-4602.2018.23.018 [31] 乔玮, 姜萌萌, SM W. 厌氧平板膜生物反应器连续处理猪场废水研究[J]. 中国环境科学, 2018, 38(12): 4502-4508. doi: 10.3969/j.issn.1000-6923.2018.12.013 -

下载:

下载: