-

涉重危废指含重金属的危险废物,其危险特性源于重金属的毒性,分为材料源危废和工业源危废[1-2]。涉重危废是危险废物中最为独特且极为重要的类别之一,也是《巴塞尔公约》[3]和国际社会优先关注和严格监管的大类危废类别。我国《国家危险废物名录》(2021年版)[4]包含46大类危废,其中涉重危废就有18大类。重金属的不可降解性决定了涉重危废的环境风险不能完全消除;而重金属的广泛应用及其基础材料地位又决定了涉重危废具有显著的资源属性和循环利用价值。从涉及的金属类型来看,包括铬、钼、锌、铅、锡、镉、镍、金、银、铜、钯、铍、砷、硒、碲、锑、汞、铊等各种金属,这些金属同时属于有毒、剧毒、高价、稀有、稀散、稀贵、战略储备(类)金属。从产排行业来看,包括金属冶炼生产、金属制品生产、金属加工处理、重金属基功能材料失效和废弃等全产业链。从形成机制来看,包括金属基材料/产品功能丧失的废旧和失效材料、金属生产/加工过程产生的废渣和废料以及环境污染控制生成的污泥和飞灰等。总之,涉重危废具有量大、面广、源多、物杂的产排特性[1-2]。

当前,从涉重危废中提取回收各种昂贵、高价和有价金属既是从源头控制重金属环境污染的现实需要,又是实现金属资源循环利用和保障金属资源安全供给的发展需要。涉重危废的资源化利用代表了其处理处置技术的发展方向,已得到全球固废处置与资源化领域产业界和学术界的广泛关注。面对数量巨大、结构复杂多变、环境风险突出、资源属性各异的涉重危废,怎样才能实现其科学、合理、高效、高质、高值的资源化利用?解析涉重危废产排规律和本质特性,提出金属分离提取的科学原理和工艺技术的优选原则,构建资源化利用的理论体系是实现这一目标的首要前提。

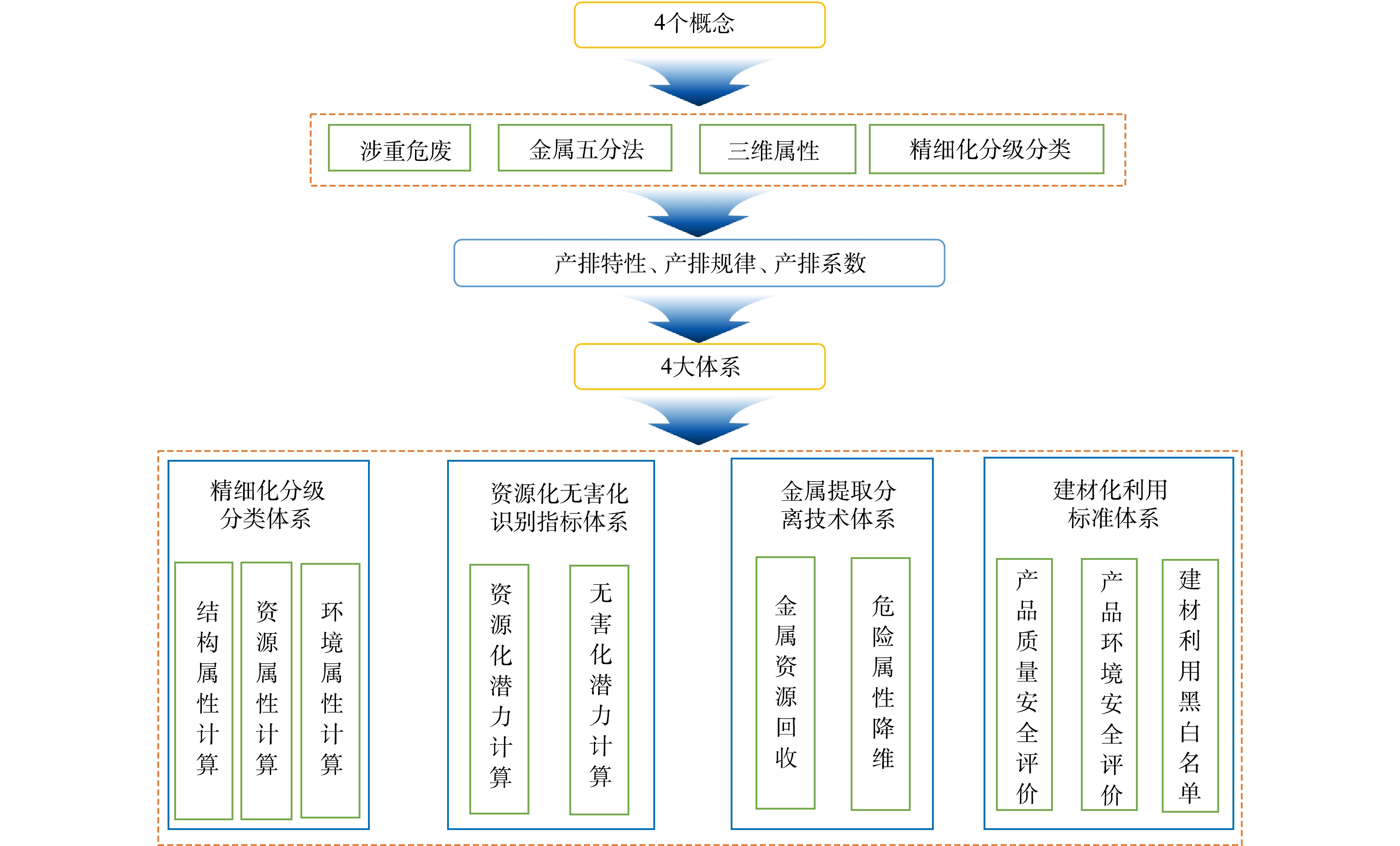

前期工作已完成涉重危废的概念创制、提出了涉重危废资源化利用的实现路径,论证了三维属性(污染、资源和结构属性)量化描述涉重危废特性的科学性,阐述了建立基于三维属性精细化分级分类体系的重要性[1-2]。但这些前期的理论创制、概念提出和制度设计仍是孤立的、离散的、局部的、单维度的,并没有形成系统化的完整理论体系,不能科学地回答涉重危废高效、高质、高值资源化利用的问题。完整的理论体系既要有基础性概念又要有多维度体系化设计,既要解决金属提取回收技术原理问题又要解决金属提取后二次残渣利用方式和污染控制问题,既要关注掌握不同类型涉重危废产排规律又要研究建立其科学分级分类及精细化管理问题。

涉重危废资源化理论体系包括涉重危废概念、来源及其资源化利用内涵和路径;不同行业和来源涉重危废的产排系数、产排特性和产排规律;不同行业和来源涉重危废资源属性、污染属性和结构属性及基于三维属性的精细化分级分类体系;不同类型涉重危废无害化处置和资源化利用的边际识别及其三维属性指标体系;不同类型涉重危废有价金属提取的技术原理和技术体系;脱毒“脱帽”残渣建材化利用路径选择及其产品安全和环境风险评价体系。该理论体系的构建、发展和成熟将使涉重危废处理处置这一重要细分领域由孤立的个体研究和感性经验上升到系统的科学理论,并为涉重危废资源化利用提供支撑。

-

涉重危废具有突出的危害特性和独有的资源属性。涉重危废概念的创制对于该类别危废更具针对性的分类精准监管、高效处置和高值利用至关重要,对于全球重金属污染防控和金属资源安全供给意义重大,是构成本理论体系的重要基础概念之一。涉重危废指含重金属的危险废物,其危险特性源于重金属毒性。这一创制概念首次将含重金属的危险废物与其他类别危废的边际进行了科学界定,形成了涉重危废这一危险废物的重要细分领域[1]。

涉重危废概念的提出,覆盖并联通了从金属冶炼生产、金属制品加工、金属表面处理、金属产品废弃到金属循环再生的产排全过程,既凸显了这一危险废物重要细分领域的共有特性也明确了其外延。按外延性质,又可进一步将涉重危废分为材料源危废和工业源危废2类。前者指重金属基功能材料或产品失效或废弃后演变而成的危废,如废旧电池和废催化剂等[5-6];后者指重金属生产、加工、利用或环境治理过程产生的涉重危废,如电镀污泥和冶炼废渣等[7-8]。

-

作为危险废物的重要细分领域,涉重危废显示出相当突出的资源-环境二元属性。因此,既要对涉重危废中的有毒金属进行固化稳定化甚至脱除以消除其危害特性,又要对涉重危废中的有价金属进行提取回收以实现其资源化利用。长期以来,有价金属定义的泛化和边界不明,尤其是有价金属和有毒金属之间的复杂交错,极大地困扰着涉重危废资源-环境二元属性的精确量化评价,及对涉重危废的精准监管、高效处置和资源化利用。

为了更精准地指导涉重危废中有价金属的回收利用及有毒金属的污染控制,本理论体系将金属/重金属进行了五分法分类[1],即:1)昂贵金属,单价100×104 元·t−1以上,包括金、银、钯、鉑、铑等;2)高价金属,单价(5~100)×104 元·t−1(以铜价为下限),包括铜、镍、钴、钼、钒等;3)低价金属,包括锌、锰、铝等;4)高毒金属,包括汞、砷、镉、铬、铅;5)无毒金属,包括钙、镁、铁、钠、钾等。金属五分法为精确反映和评价各类金属/重金属的资源回收价值和环境污染风险提供了分类学支撑,构成了本理论体系的第2个重要基础概念。

-

涉重危废的资源化利用从本质上讲就是通过调节调控不同金属在溶液-残渣两相中的分配行为(湿法)或在飞灰-熔体-渣体三相中的分配行为(火法)实现目标金属的分离、提取和回收,但不同类别金属需要采取不同的分离提取策略。金属五分法为涉重危废科学合理的资源化利用奠定了分类学基础。涉重危废全量资源化利用的总体原则和实现路径为:提取回收昂贵和高价金属,脱除有毒和高毒金属,保留低价和无毒金属的脱毒残渣进行建材利用。昂贵和高价金属的提取回收实现涉重危废的高值化资源利用,脱毒残渣的建材消纳实现低价和无毒金属的低值化资源利用,有毒和高毒金属的脱除及浓缩实现涉重危废的风险集中管控。

-

产排系数是指在正常技术经济和管理条件下,生产单位产品所产生或排放的污染物数量的统计平均值。产污系数是指生产单位产品所产生的原始污染物的量;排污系数是指经污染控制措施消减后排放到环境中的污染物的量。产排系数与产品类型、生产工艺、生产规模、原辅料使用、设备技术水平及污染控制措施等有关,通过现场实测、物料衡算或理论计算取得。产排系数是污染物统计、环境管理和污染治理的基础性数据[9-10]。

当前,产排系数在我国水污染和大气污染管理和防治中已发挥重要作用,但危险废物和涉重废物的产排规律、产排特性和产排系数研究基础却十分薄弱。实际上,产排系数对于危险废物和涉重危废产排总量的精确统计、涉重危废的精细管理和精准处理处置更为重要。我国的危险废物日常数据收集是采取产废单位主动申报制度,但由于危险废物高昂的处置费用和严格的管理要求,产废单位的申报数据往往存在少报、瞒报、漏报的现象,因而导致危险废物的真实产排数量难以掌握。借助科学的产排系数推算可有效甄别上报数据的真伪,有助于危险废物和涉重危废排放总量的精确掌握,从而为危险废物和涉重危废的规范管理和合理处置利用提供可靠的数据支持。

-

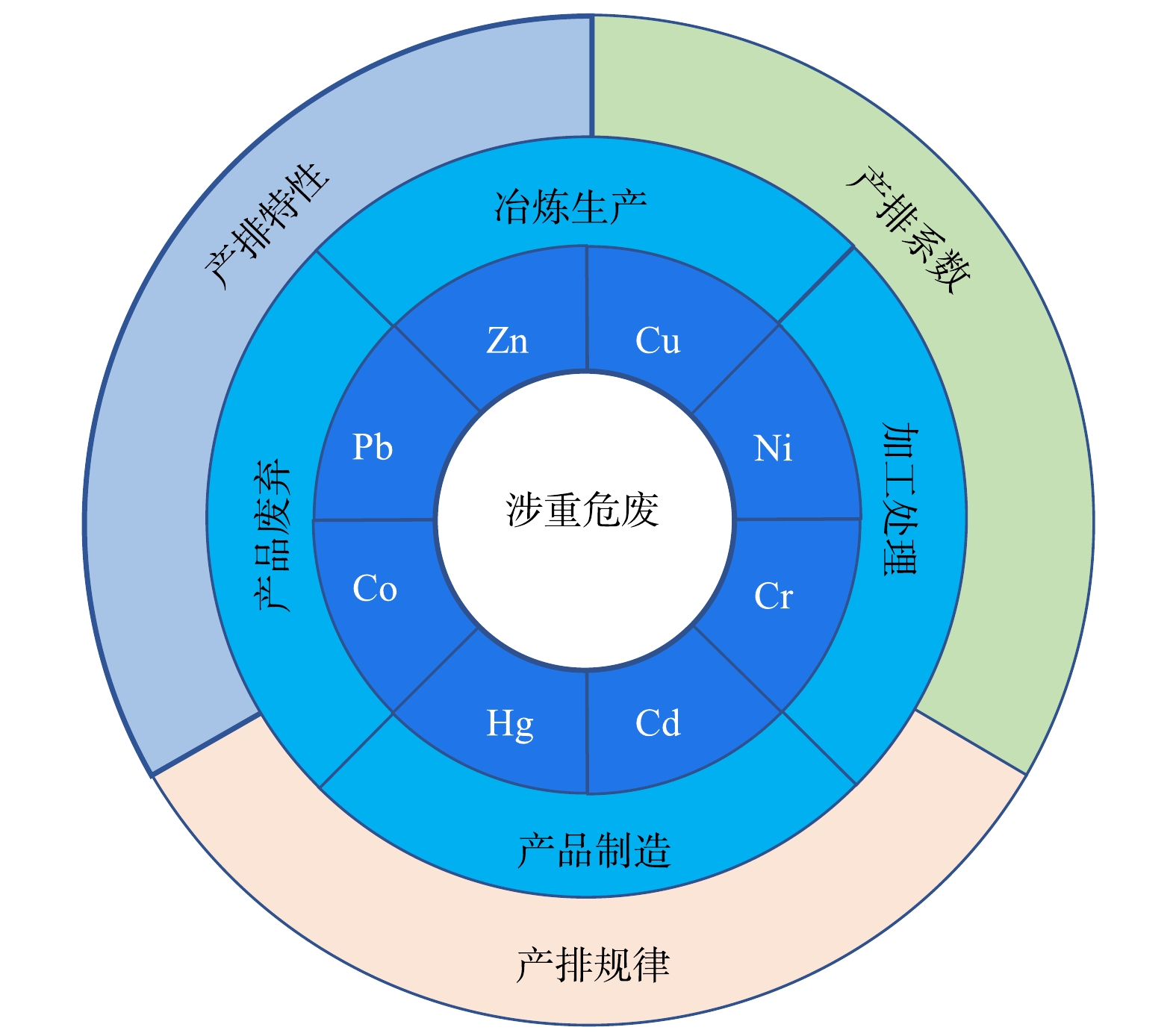

涉重危废这一概念覆盖并联通了重金属冶炼生产、重金属制品制造、重金属加工处理、重金属基产品使用、失效及废弃等上中下游涉重全产业链条。涉重危废涉及行业众多、金属类型多样,危废形成的过程和机制也各不相同,因此,不同行业、不同类型、不同过程涉重危废的产排特性和产排系数存在很大差异。从全产业链过程分析,针对铅、锌、铜、镍、铬、镉、汞、钴、钒等重要有毒重金属,系统研究其从冶炼生产、产品制造、加工处理、失效废弃、到再生循环等不同环节的产排规律、产排特性和产排系数,对于加强涉重危废科学管理、推进涉重危废精准处置利用具有重要意义(图1)。

涉重危废的危险特性源于重金属毒性。与有毒有机物相比,重金属不能降解、分解和矿化消失,只有形态转变、价态转化和空间位移。基于重金属的这一性质,通过质量平衡计算(物料衡算法)即可全面了解目标/有毒金属在产物、飞灰、底渣、浸出渣、净化渣、污泥等各相的分布及排入环境的量,并由此表征涉重危废的产排特性和产排系数。在此基础上,进一步研究飞灰、底渣、浸出渣、净化渣、污泥等各类固废/危废中金属赋存形态、液相溶解行为、高温挥发行为及其环境释放行为,从而为涉重危废的风险鉴别及分级分类、无害化处置和资源化利用提供理论依据[11-13]。

涉重危废的有毒金属产排系数计算公式见式(1)至式(4)。

式中:E产生是有毒金属污染产生量;Q原料是原辅料中金属总量;Q产品是产品或出品中的金属利用量;E排放是金属污染排放量;Wi是固废/危废i的排放量;Ci是固废/危废i中有毒金属含量;e产生系数是金属污染产生系数;e排放系数是金属污染排放系数;P是产品(出品)总量。

在现有严格的有毒金属污染排放控制标准下,无论一次危废还是二次危废中有毒金属的污染产生总量和排放总量大致相等,但不同排放途径和来源的有毒金属之环境行为、污染特性和危害强度存在显著差异,因而需要针对典型涉重危废产生、处置和利用全过程加强研究,以识别全产业链环境风险点并研发控制阻隔技术,引导目标金属向高资源利用和低环境风险的循环利用技术工艺和产业发展方式转变。

-

涉重危废具有鲜明的资源-环境二元属性,但目前对于该类别危废二元属性的表征都是粗略说明和定性描述,缺乏量化指标和计算公式。这显然对于涉重危废的精细化管理、无害化处置和资源化利用都极为不利。另一方面,涉重危废产排涉及行业众多、金属类型多样、形成过程机制各不相同,以致其组分多变、结构复杂、种类繁多。不同产业链位阶、不同来源、不同行业、不同类型的涉重危废不仅在资源属性和污染属性上差异巨大,在组成和结构方面也千差万别。复杂多变的结构无论对于有毒/高毒金属的环境释放行为还是昂贵/高价金属的分离提取效能都会产生严重影响和干扰。因此,只有三维(资源、污染、结构)属性才能更加客观、准确、全面地反映涉重危废的固有本质特性。三维属性及其量化计算构成本理论体系的第3个基础概念。涉重危废之结构属性、资源属性和污染属性的量化计算公式和方法参考文献[2]。

-

在固体废物/危险废物环境管理中,分级分类聚焦于环境风险管控,只关注固体废物/危险废物的污染属性。为了解决危险废物监管压力和效率之间日益增长的矛盾,新修订的《固体废物污染环境防治法》[14]专门提出危险废物要进行分级分类管理。目前,我国《国家危险废物名录》[4]中并没有体现明确的分级分类管理思路,只是通过豁免管理清单和排除管理清单作为辅助和并行管理措施;而美国等国家针对危险废物小微产生源的分级管理措施基本属于名录管理的补充和完善,并不是严格意义上的分级分类,更没有形成完整体系[15]。

本研究提出的精细化分级分类体系是基于涉重危废三维属性的综合性分级分类,构成本理论体系的第4个基础概念。精细化分级分类体系从环境危害程度,资源利用潜力和物料结构特性3个维度对涉重危废进行定量描述。在三维属性量化计算的基础上进行5级(极高、高、中、低、极低)分级,再基于定量分级进行综合分类。该体系将突破不同行业领域的传统边界划分,完全按照三维属性量化指标进行分级分类。基于行业领域和危害特性定性分类的《国家危险废物名录》[4]和基于三维属性的精细化分级分类体系呈相辅相成的互补关系。前者是国家危险废物监管的依据和基础,后者是前者的辅助和补充,共同为涉重危废的高效精准监管、切实无害化处置和合理资源化利用提供科学可靠的理论基础。

-

涉重危废的资源-环境二元属性决定了无害化处置和资源化利用并举是涉重危废处置利用的基本原则,但无害化处置和资源化利用是两种完全不同的路径选择。前者为了消除涉重危废的污染特性,凸显了环境效益;而后者为了提取回收稀缺的二次金属资源,体现了经济效益。无害化处置和资源化利用的路径选择显著依赖涉重危废的三维属性。

涉重危废的资源化利用潜力不但取决于其所含昂贵/高价金属的浓度、类型、价格、赋存形态以及金属提取的技术经济性,而且与有毒/剧毒金属的含量、种类、赋存形态以及低价/安全金属等干扰离子的种类及浓度都有密切关系。具有高资源属性、低污染属性、低结构属性的涉重危废适宜资源化利用;而具有低资源属性、高污染属性、高结构属性的涉重危废适宜无害化处置。因此,需要在全面分析涉重危废三维属性基础上,确立可满足不同类型涉重危废无害化处置和资源化利用边际识别的三维属性指标体系,才能确保涉重危废科学、合理、可持续地资源化利用。涉重危废资源化利用潜力和无害化处置潜力归一化指标计算公式参考文献[2]。

-

涉重危废具有的资源-环境二元属性,决定了其资源化利用的核心内涵是潜在资源价值的最大化回收和环境危害特性的最大化降低,其中的关键诉求是昂贵/高价金属的深度提取以实现最大的经济效益和剧毒/高毒金属的深度脱除以实现残渣的危险属性降级。但无论昂贵/高价金属的提取回收还是剧毒/高毒金属的脱除分离,都需要适宜的技术工艺以及相应的处置成本,工艺选择和费用投入与涉重危废的三维属性存在紧密关系[16]。基于不同类型涉重危废无害化处置和资源化利用的边际识别,对于资源化利用潜力较高的涉重危废则实现资源化利用,对于资源化利用价值较低的涉重危废则实行无害化处置。

-

火法冶金、湿法冶金和生物沥浸在涉重危废有价金属提取和危险属性降级中各具优劣。总体来讲,火法冶金适宜高浓度、大批量、单一金属的分离提取和危险属性降维,尤其是低沸点、易挥发金属的烟化或挥发提取;湿法工艺适宜中高浓度、中小批量、多金属的同步提取回收;生物沥浸-循环富集适宜低浓度、小批量、多金属深度浸提和危险属性降级[17-18]。3种金属提取工艺存在较高的互补性和协同性,因此,只有科学合理的工艺组合才能保证有价金属提取和危险属性降级两大诉求的有效达成。例如:火法工艺还原融熔所产的合金或富氧侧吹所产的冰铜、冰镍等富集物料必须借助湿法工艺才能进一步获得高纯度单质态金属或金属盐;湿法工艺所产浸出渣需要借助生物沥浸-循环富集工艺以实现金属的深度提取、液相富集和危险属性降级;生物沥浸工艺有时需要火法或湿法工艺作为前(预)处理,如石化废催化剂需要低温煅烧去除包覆的油类物质后,才能确保生物沥浸高效进行,高浓度电镀污泥则需要前置硫酸浸提再串以生物沥浸才能使其处理规模提高、浸提富集成本减低。

目前,涉重危废中昂贵/高价等目标金属的提取回收技术工艺选择大多依靠孤立的离散实验和研究者的感性经验。由于缺乏系统完整的科学原理指导以及基于定量分析的优选理论支持,现有的涉重危废金属提取工艺普遍存在设计不合理、标准不统一、技术不规范、路径选择随意性大的问题,加之涉重危废结构复杂多变的特性有时甚至出现技术工艺难以运行的严重状况。这是因为,金属提取工艺选择不但与金属类型性质有关,而且与其含量及赋存形态也存在很大关系,甚至与共存的其他低价、高毒和无毒金属以及处理规模、电价水价、物料配伍等都存在密切关系。所以,需要在三维属性精细化分级分类基础上,深入探究涉重危废三维属性及其分级分类与金属提取优化工艺及其组合之间的内在关联和响应关系,阐明不同分级分类物料提取工艺优选的一般规律和总体原则,构建涉重危废金属提取回收技术优选的多目标多参数定量精准决策体系。

-

涉重危废金属提取过程需要在特定反应介质中进行,反应介质中的外加物料会以各种方式进入残渣之中,并改变残渣的元素组成、物相结构、金属含量及其赋存形态。不同的金属提取工艺或工艺组合可实现涉重危废的危险属性降级,但脱毒残渣中各类金属和其他有害组分、含量、赋存形态及环境风险差异较大,其建材化利用方式、途径和使用方向也各不相同[19]。因此,需要系统分析不同三维属性涉重危废脱毒残渣的物相、结构和组成,识别关联产品安全和环境安全的有害元素和离子,评估脱毒残渣建材化利用的产品安全和环境风险并进行分级分类,建立建材化利用的黑/白名单,进而提出涉重危废脱毒残渣建材化利用的技术规范和标准体系。

基于产品安全的离子/元素限值按式(5)计算;基于环境安全的离子/元素限值按式(6)计算。

式中:M指脱毒残渣中关联产品安全的离子/元素含量;L指建材产品安全要求限值;S1指脱毒残渣在建材产品中的掺和比。

式中:N指脱毒残渣中关联环境安全的离子/元素含量;K指建材环境安全要求限值;S2指脱毒残渣在建材产品中的掺和比。

脱毒残渣在建材产品中的掺和比S取S1和S2二者中的最小值。当S≤10%,则说明该消纳途径风险大,可列入黑名单;当S≥30%,则说明该消纳途径风险小,可列入白名单。通过黑/白名单的管理,使脱毒残渣是否采用或采用何种建材化利用的路径判别更加便利。

-

涉重危废产排贯穿金属冶炼生产、金属加工处理、金属基材料制备、废弃和再利用等全产业链。金属作为现代生活和工业生产的基础性原材料,其生产、消耗和废弃正以前所未有的规模在全球进行,因此,涉重危废的产生也以前所未有的速度在全球发生。据估算,世界上涉重危废的年产量在1×108 t左右,我国涉重危废年产量在3 000×104~3 500×104 t[1]。涉重危废的长期任意排放是全球环境重金属污染的主因之一,而重金属不能降解的特性又使得重金属污染显示出累积性、持久性和高危害性。但另一方面,涉重危废含有以各种形式存在的多种金属元素,而金属不可再生的特性又赋予了涉重危废独有的二次资源价值。有毒/高毒/剧毒金属赋予涉重危废污染属性,昂贵/高价/有价金属赋予涉重危废资源属性,金属激发的污染属性和资源属性并存是涉重危废最显著的特点。从涉重危废中提取回收有价金属不但能够从源头消除涉重危废的环境危害,而且还可实现稀缺金属资源的循环永续利用,是固体废物处理处置学科及资源再生学科领域的热点课题。

作为危险废物的重要细分领域,涉重危废资源化利用已是国内外经济社会发展的必然趋势,而我国作为世界制造大国,更是面临涉重危废产排量不断增长和金属资源愈加短缺的双重困境,涉重危废的资源化利用更加紧迫。然而,涉重危废固有的高污染属性给其资源化利用带来很大困扰,在分级分类、提取工艺、风险管控、政策法律等许多方面都面临巨大挑战[20-21]。目前,针对不同类型涉重危废,世界各国学者在技术层面广泛研究了有价金属高效提取的火法冶炼、湿法冶炼和生物沥浸的工艺优化、过程控制和溶释机理,但基本都是基于特定单一危废物料的孤立个案研究,未见针对涉重危废三维属性的量化分析及精细化分级分类,亦未见无害化处置和资源化利用的边界识别研究,更未见有价金属深度提取和危险属性降级的技术原理探究和技术工艺优选,以及脱毒残渣建材化利用的方式、工艺和标准研究。涉重危废量大、面广、源多、物杂的产排特性,给其高效、高质、高值的资源化利用带来很大挑战。构建基于精细化分级分类的涉重危废资源化利用理论体系是实现这一目标的根本保证,是指导涉重危废资源化利用健康、科学、可持续发展的必然要求,是涉重危废资源化利用从经验数据积累到完整学科形成的必然要求。

涉重危废资源化利用的理论框架以涉重危废、金属五分法、涉重危废三维属性及精细化分级分类4组概念为基础,以涉重危废精细化分级分类体系、涉重危废无害化处置和资源化利用边际识别指标体系、涉重危废有价金属提取和危险属性降级技术体系、涉重危废脱毒残渣建材化利用标准体系4大体系建设为核心,以涉重危废产排系数计算、涉重危废三维属性定量描述、涉重危废资源化利用和无害化处置潜力归一化指数计算、涉重危废脱毒残渣建材化利用风险控制和黑白名单管理4个重要问题为抓手和工具(总体框架见图2)。该理论体系全面系统地回答了涉重危废全量高值化资源利用所涉及的关键问题和重大困扰,有力保障了其资源化利用的过程安全、产品安全和环境安全。该理论体系的构建、发展和成熟将使得涉重危废这一重要细分领域由孤立的个体研究上升到系统的科学理论,并为涉重危废的精细化监管、精准化风险管控和高质化资源利用提供全周期全方位全流程的理论指导。

-

1)从涉重危废中提取有价回收金属促进其污染属性向资源属性的定向转化,虽然可从源头消除涉重危废的环境污染而且实现金属资源的循环利用,但其危险属性对资源化利用构成了极大困扰。为了确保涉重危废的科学、合理、健康、可持续、高值化利用,构建了涉重危废资源化利用的理论体系。

2)涉重危废资源化利用的理论体系框架由4组概念和4大体系组成。4组概念包括涉重危废、金属五分法、涉重危废三维属性及精细化分级分类;4大体系包括涉重危废精细化分级分类体系、涉重危废无害化处置和资源化利用边际识别指标体系、涉重危废有价金属提取和危险属性降级技术体系、涉重危废脱毒残渣建材化利用标准体系。

3)该理论体系以4组概念为基础、以4大体系建设为核心,以系统化数学公式和定量计算为工具。该理论体系的提出、发展和成熟将使得涉重危废这一重要细分领域由孤立的个体研究和感性经验上升到系统的科学理论,为涉重危废的精细化监管、精准化风险管控和高质化资源利用提供全周期全方位的理论指导。

涉重危废资源化利用理论体系

Theoretical system of resource utilization of hazardous wastes containing heavy metals

-

摘要: 涉重危废是危险废物中污染属性和资源属性都极为突出的大类类别。从涉重危废中提取昂贵/高价/有价金属不但可从源头上阻断重金属进入环境,而且可实现稀缺金属资源的永续利用,因而成为环境和资源领域的热点课题。当前,涉重危废中金属提取回收工艺研究及工程实践大都基于离散物料的孤立个案和技术人员的个人经验,缺乏系统完整科学的理论指导,难以适应涉重危废高效、高值、高质的资源化利用需求。为此,以涉重危废、金属五分法、重金属三维属性及涉重危废精细化分级分类4组创制概念为基础,阐述了涉重危废精细化分级分类体系、涉重危废无害化处置和资源化利用边际识别指标体系、涉重危废金属提取和危险属性降级技术体系、涉重危废脱毒残渣建材化利用标准体系4大体系建设必要性及建设内容,构建了涉重危废资源化利用的理论体系。本研究结果可为涉重危废的资源化利用提供理论支撑。Abstract: Hazardous wastes containing heavy metals have both serious environmental threats and high recycling value, which result in global contamination of heavy metals and fierce metals resource loss if discarded without proper treatment. The recovery of valuable metals from hazardous wastes containing heavy metals not only eliminates the pollution of heavy metals at the sources but also recycles the non-renewable metals resources, representing a hot issue in both environmental sciences and metals smelting. However, the works concerning hazardous wastes containing heavy metals are discrete, scattered, individual studies and do not form complete and systematic theory to guide the scientific, efficient and sustainable resource utilization of heavy metals-containing hazardous wastes. In the current work, four important fundamental concepts covering hazardous wastes containing heavy metals, five classification methods of metals, three-dimension properties and precise grading and classification were established, and four important branch systems including precise grading and classification system, harmless disposal and resource utilization boundary identification system, metals extraction/separation technology system and detoxification residue-used building materials quality control standard system were reviewed. Based on the four important fundamental concepts and the four important branch systems, the theoretical system of resource utilization of hazardous wastes containing heavy metals was put forward for the first time.

-

在饮用水处理过程中,氯因其持久氧化性及经济性是目前最为常用的氧化剂和消毒剂。然而,氯与有机物反应会生成多种具有致畸性、致癌性消毒副产物(disinfection by-products,DBPs)。我国《生活饮用水卫生标准》(GB 5749-2022)对三卤甲烷(trihalomethanes,THMs)和卤乙酸(haloacetic acid,HAAs)进行了明确管控。除了已知的包括THMs、HAAs、卤代苯酚、亚硝铵等多种DBPs之外,饮用水中还存在着大量具有较高潜在毒性风险的未知DBPs。

活性炭(activated carbon,AC)作为一种高效、经济的吸附剂广泛应用于饮用水厂和家用净水过滤系统中[1]。在预处理阶段,粉末活性炭常用于解决突发性微量污染物问题[2]。在净水过滤器中,AC可以作为其吸附剂的主要组分[3]。因此,在预处理阶段或者家用净水器端,AC不可避免的会与氯接触。之前的研究发现[4],AC本身也可与氯反应生成毒性更强的DBPs。且由于AC的催化作用,其可催化次氯酸产生氯自由基(Cl·),导致不同的氯化产物。BULMAN等[5]发现,氯光解过程中形成的多种活性氧化剂会诱导形成新兴的氯化DBPs。VOUDRIAS等[6]也发现AC会促进游离氯氧化酚类物质形成新的副产物。此外,AC作为优良的吸附剂既可以吸附溶解性天然有机物(dissolved organic matter,DOM),也可以吸附生成的DBPs,导致其对DOM氯化过程中DBPs的生成具有复杂的影响效应。因此,深入探究AC对DOM氯化过程中产生DBPs释放风险的影响具有重要意义。

傅立叶变换离子回旋共振质谱(fourier transform ion cyclotron resonance mass spectrometry,FTICR-MS)是一种高分辨率质谱仪器。为了分析的精确性,其采用较长的采集时间和上百次的谱图叠加[7],用于检测DOM中的分子结构,也可鉴定高分子质量的有机化合物[8-9]。FTICR-MS可通过分子式的元素比率和芳香度信息来分析DOM的组分特征,从而研究DOM与生物、自然介质之间的关系[10]。ZHANG等[11]通过FTICR-MS对不同分子质量DOM馏分的光学和分子特征进行了研究,发现高度不饱和的芳香族物质富含电子,其与次氯酸表现出高反应性。AC氯化后会生成分子质量为1 000~10 000 Da的副产物,但具体的种类及AC对DOM氯化的影响机制还尚未明确。

因此,本研究通过以是否在氯化过程中投加AC为变量,达到以下目的:1)研究AC对DOM氯化过程中产生已知DBPs的影响,并评价其出水产物毒性;2)通过FTICR-MS技术识别并明确AC对DOM氯化过程中产生的氯化产物种类的影响;3)通过FTICR-MS技术阐明AC对氯化过程中DOM特性转化的影响。

1. 材料与方法

1.1 试剂与材料

本研究中使用的DBPs标准品为色谱纯,购自Accu Standard公司(美国);甲基叔丁基醚(methyl tert-butyl ether,MTBE)为色谱纯,购自北京百灵威科技有限公司;无水硫酸钠(Na2SO4)、碳酸氢钠(NaHCO3)、浓硫酸(H2SO4)、硫代硫酸钠(NaS2O3)和次氯酸钠(NaClO)均为分析纯,购自国药集团化学试剂有限公司;AC购自宁夏光华活性炭有限公司,选取椰壳炭的物理性质包括碘值1 030 mg·g−1,比表面积1 114 m2·g−1,平均孔径3.61 nm,总孔隙体积0.78 m2·g−1,微孔和介孔体积分别为0.3 m2·g−1和0.46 m2·g−1;其表面官能团结构包括碱性、酸性、酚醛、羧基和内酯基团的含量为0.58、0.50、0.11、0.38和0.02 mmoL·g−1。AC均用去离子水洗涤至滤液pH呈中性,在115 ℃下干燥12 h后,将其制备成1 g·L−1的悬浊液。原水(raw water,RW)取自中国北京京密引水渠,本研究所用的实验水样参数:pH=8.27,浊度为1.28 NTU,以CaCO3计的碱度和硬度分别为83.38 mg·L−1和111.00 mg·L−1,UV254为0.023 cm−1,溶解性有机碳(dissolved organic carbon,DOC)为2.21 mg·L−1。

1.2 实验方法

将AC悬浊液超声后加入到1 L 0.1 mmol·L−1 NaClO的超纯水和RW中,AC质量浓度为10 mg·L−1,使用10 mmol·L−1磷酸盐缓冲液将溶液的pH调整为7.5,同时设计另一组实验,先使用AC对RW中的DOM进行吸附,再加氯进行反应。磁力搅拌24 h,检测反应0.5、1、2、24 h后水样中THMs和HAAs的浓度,同时对反应24 h的样品进行FTICR-MS分析,使用Na2S2O3淬灭余氯并利用0.45 μm的膜过滤去除AC,滤后水中加入5 g无水Na2SO4,使用MTBE作为萃取剂提取水样,HAAs还需甲醇酸化处理,使其衍化为卤乙酸甲酯,测定DBPs以及其他指标。

1.3 分析方法

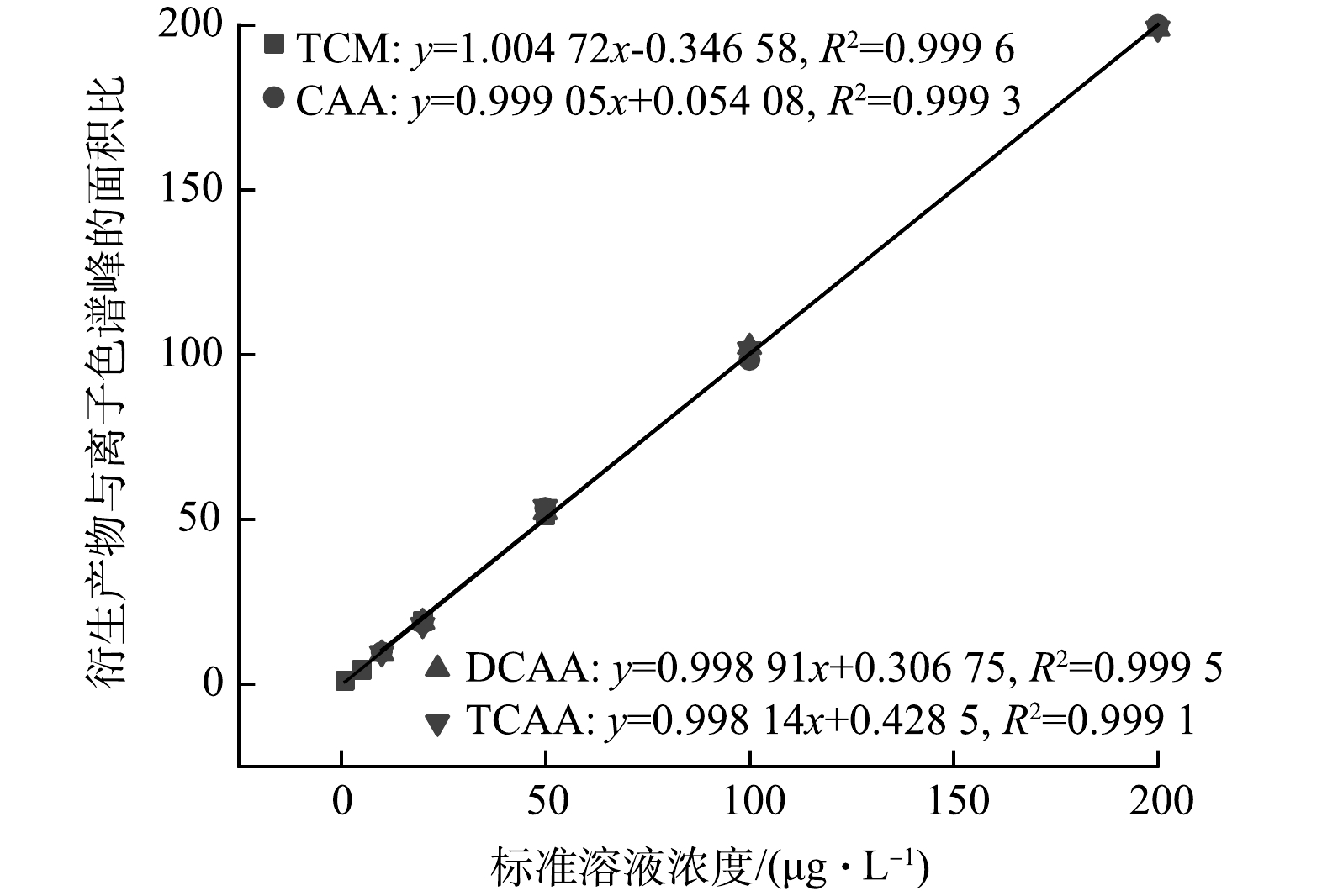

THMs和HAAs的测定参考美国环境保护署标准方法(USEPA Standard Methods 551.1和552.3),THMs和HAAs的回归曲线如图1所示。测定的4种DBPs(TCM、CAA、DCAA、TCAA)采用配备电子捕获检测器(Agilent Technologies,Santa Clara,CA,USA)的气相色谱仪(Agilent 7 890,Santa Clara,USA)进行分析[12]。气相色谱柱为HP-5型的熔融石英毛细管柱(30 mm×0.25 mm内径,薄膜厚度为0.25 mm)。氯化反应开始前的溶液使用pH计(HACHHQ 40 d,Loveland Colorado,USA)校准成中性。余氯使用N,N-二乙基对苯二胺(DPD)方法进行测定,结果以mg·L−1的Cl2表示(HACH Pocket ColorimeterII,Loveland Colorado,USA)。总有机碳分析仪(total organic carbon,TOC,Elementar公司,德国)测定AC滤后水中DOC的浓度。溶液中的有机物含量使用紫外分光光度计(UV-6 100型,中国上海)进行测定。在5,5-二甲基-1-吡咯啉-N-氧化物(DMPO)作为捕获剂的条件下,采用电子自旋共振波谱仪(electron spin resonance,ESR,A300-10/12型Bruker公司,德国)检测自由基。

1.4 FTICR-MS分析

仪器参数与操作步骤使用配备有15.0 T超导磁体和电喷雾电离源的FTICR-MS(Bruker Solari X型)对样品的分子组成进行分析。样品在负离子模式下进行测试,进样方式为连续进样,进样速度为150 μL·h−1,毛细管入口电压为4 kV,离子累积时间为0.08 s,相对分子质量采集范围为100~1 000 Da,采样点数为4 ppm,时域信号叠加300次以提高信噪比.上机测试前用10 mmol·L−1甲酸钠对仪器进行校正,样品检测完成后用可溶性有机质(已知分子式)进行内标校正。经过校正后,检测的质量误差均小于1 ppm。样品检测时取原水样品200 μL,过0.22 μm滤膜以去除颗粒物等杂质,然后用甲酸酸化水样,逐滴加入甲酸直至水样pH调节至2。然后对水样中的DOM进行SPE固相萃取(萃取柱型号为Agilent Bond Elut PPL(1.0 g,6 mL)。H/Cw、O/Cw和碳归一化双键当量(DBE/Cw)等分子式参数根据每个样品中指定分子式的相对强度加权平均值计算得出[13]。数据采用DOM中已知的CHO类化合物进行内标校准,如对应多个分子式,采用同系物规则和最小杂原子个数规则进行正确分子式筛选。

2. 结果与讨论

2.1 AC对氯与有机物反应生成已知DBPs的影响

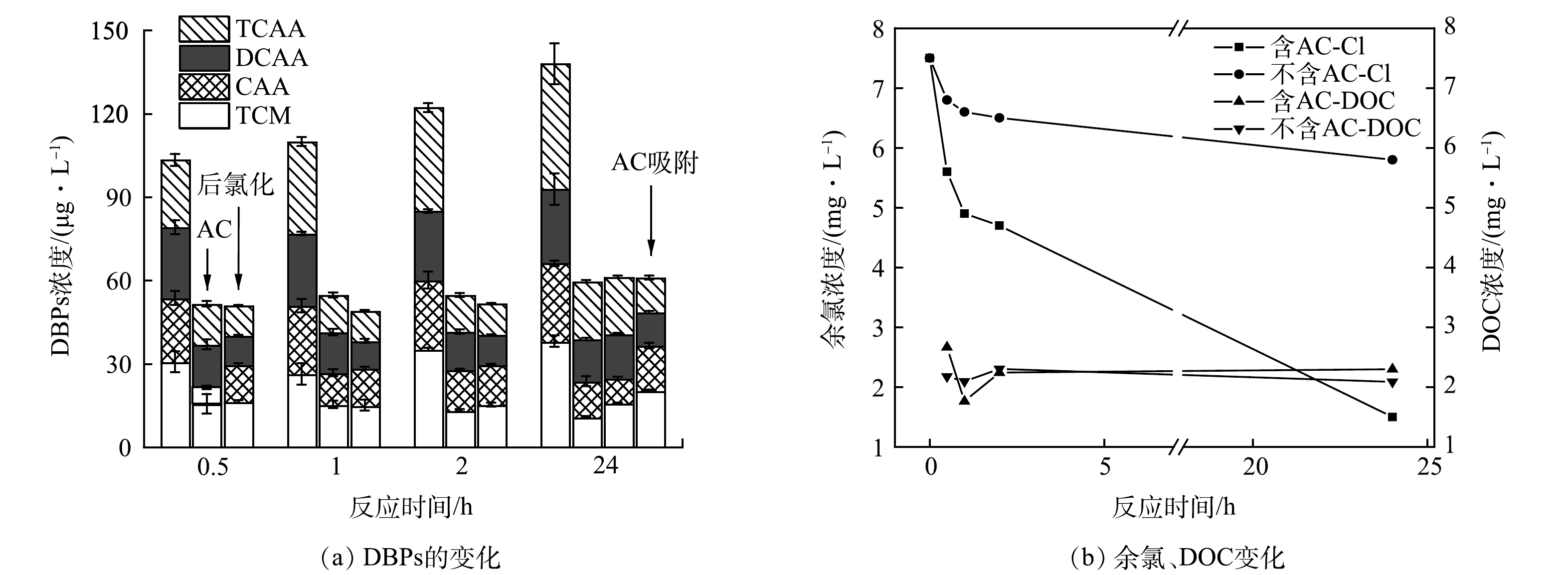

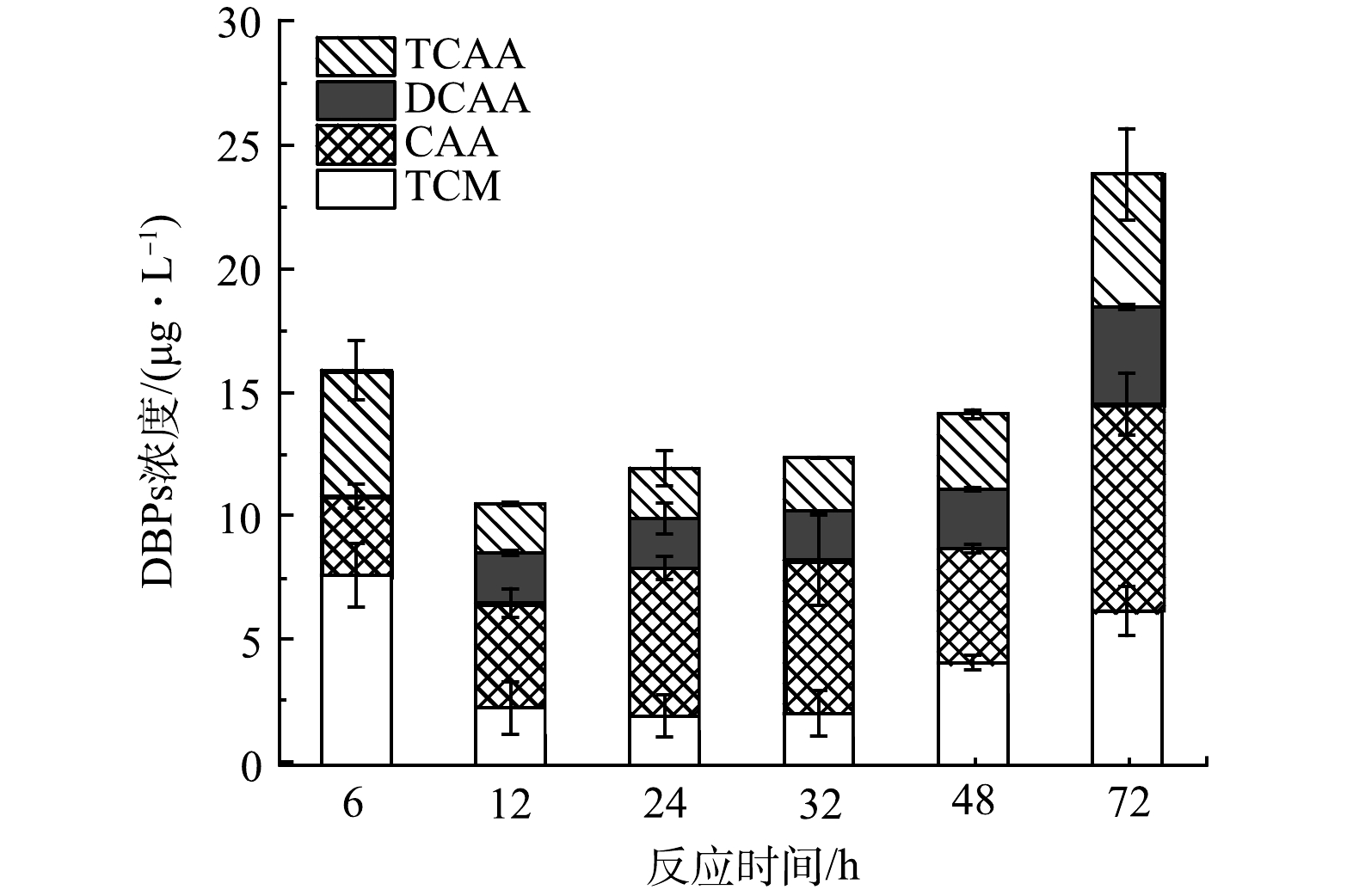

如图2所示,比较了AC是否存在和不同氯化方式对RW氯化过程中DBPs的释放情况。图2(a)所示为测定的DBPs浓度随时间变化规律,可以看到无论是否在RW中加入AC,DBPs浓度均随时间的延长升高,DBPs的总浓度在反应初始时可忽略不计。AC存在与不存在时DBPs的浓度分别从0.5 h的51.29 μg·L−1和103.19 μg·L−1上升至24 h的59.34 μg·L−1和137.87 μg·L−1,并且在2 h时达到较高水平,说明AC与0.1 mmol·L−1 NaClO在开始的2 h内剧烈反应生成大量DBPs。但加入AC的水样随着反应时间的增加,DBPs的变化并不明显,可能是由于部分DBPs及其前体物被AC快速吸附以及自由氯被大量消耗后导致反应速率下降。此外,进一步对比了在RW氯化过程中不同活性炭加入方式对DBPs生成释放的影响,结果如图2(a)所示。发现过滤掉AC后氯化方式产生的DBPs与AC一直存在的结果基本一致,说明AC在此过程中虽然可以吸附THMs、HAAs及其前体物,并且可以催化氯产生自由基,但对释放到水中THMs及HAAs影响较小。如图2(b)所示,在AC存在时,氯的衰减率明显增加,但释放到水体的目标DBPs浓度较未加入AC时更低。AC存在时余氯衰减快,测得DBPs较少。一方面是由于生成的DBPs被AC吸附,另一方面具有较强还原性的AC本身也会快速消耗自由氯。如图2(a)所示,单独在24 h时测定AC吸附的DBPs,发现即使将吸附反应后的AC经有机溶剂丙酮浸泡,并超声处理释放DBPs,测定的4种TCM、CAA、DCAA、TCAA的质量浓度分别为19.85、16.29、12.08、12.50 μg·L−1,可以发现加入AC组的DBPs总质量浓度(120.05 μg·L−1)仍低于不加入AC组(147.87 μg·L−1)。此外,如图3所示,还测定了在纯水中AC与过量氯反应产生的DBPs。发现THMs及HAAs的浓度先下降后上升。这是由于AC前期吸附性较强,后期吸附能力下降,生成的DBPs逐渐释放到水中。同时对水中的DOC进行测定,前2 h的DOC浓度均为先下降后上升,但随着反应时间的继续增加,加入AC组的DOC浓度继续上升,而未加入AC组却呈现下降趋势。这一现象说明AC影响了DOM的氯化过程,导致其结构被破坏且生成了其他副产物。VOUDRIAS等[14]发现AC会导致一系列自由基连锁反应的发生。HUANG等[4]研究了THMs和HAAs在AC存在下的含量变化,但没有研究其单独氯化DOM的情况,而且AC存在时溶液的细胞毒性也有所增强。因此,还需进一步探究AC存在时的氯化副产物的变化。

2.2 FTICR-MS分析氯化副产物

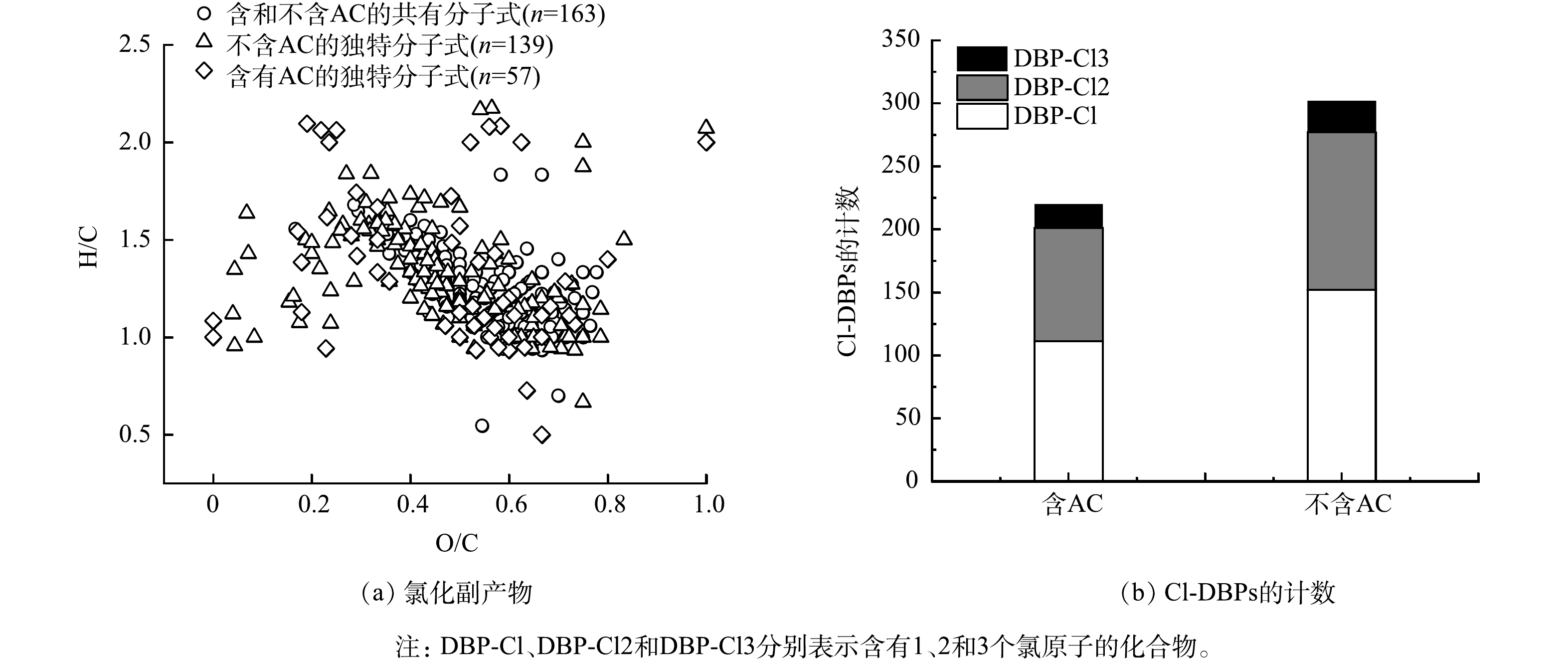

如图4所示,通过FTICR-MS探究了AC对氯化副产物的影响。由图4(a)可以看到,在RW氯化过程中,其产物匹配了302个氯化分子式,而AC存在时的氯化产物中,可对应220个氯化分子式。进一步分析302种氯化产物,其中163种分子式与AC存在时相同,因此AC存在时的氯化会导致部分氯化产物减少,但也生成了新的氯化产物包括57种在内的独特分子式,其中CHOCl、CHONCl、CHOSCl、CHNSCl、CHNOSCl分子式各生成了42、5、5、2、3种。如图4(b)所示,在有AC存在的氯化过程中,氯化副产物产生的含有2个和3个氯原子的DBPs相对较少。在AC存在的氯化水样中,生成含有2个和3个Cl原子的分子式分别为90个和19个;而在RW氯化过程中,生成含有2个和3个Cl原子的分子式为125个和25个。此外,如表1所示,经对比发现,AC存在时,CHOCl、CHONCl、CHONSCl分子式的数量减少,而CHOSCl的分子式增加,并且CHOCl、CHONCl以及CHOSCl和CHONSCl分子式的H/Cw值均低于RW的氯化过程,相反的是O/Cw均高于RW氯化。有研究[15]表明,与传统的暗氯化生成副产物的生成机制不同,活性氯物种(reactive chlorine species,RCS)与有机物的主要反应机理是氯加成、单电子转移和氢抽取反应。BEN等[16]和SUN等[17]发现氯可以通过自由基链式反应发生降解,从而减少自身与其他物质的接触时间。RCS和DOM结合也会影响靶向DBPs的生成,诱导形成新型的DBPs[5],这可能是AC存在时有Cl·的生成,从而发生的后续自由基反应导致H/Cw值较低、O/Cw较高。

表 1 RW氯化过程中的氯化产物分子式分子指数的强度加权平均值Table 1. Intensity-weighted average of molecular indices of molecular formulae for chlorination products during the RW chlorination process分子式 水样 H/CW O/CW DBEW AImod,w 总强度 相对丰度/% CHOCl 不含AC 1.29 0.50 6.98 0.22 4.60×109 93.77 含AC 1.23 0.54 7.24 0.25 2.8×109 94.38 CHONCl 不含AC 1.42 0.28 8.84 0.17 1.48×108 3.41 含AC 1.33 0.33 9.22 0.24 7.52×107 2.54 CHOSCl 不含AC 1.68 0.21 7.28 0.03 6.8×107 1.37 含AC 1.67 0.51 3.69 -0.31 6.15×107 2.07 CHONSCl 不含AC 1.6 0.30 7.02 -0.14 7.2×107 1.45 含AC 0.49 0.13 0.65 -0.12 4.02×107 1.01 2.3 溶解有机物的转化

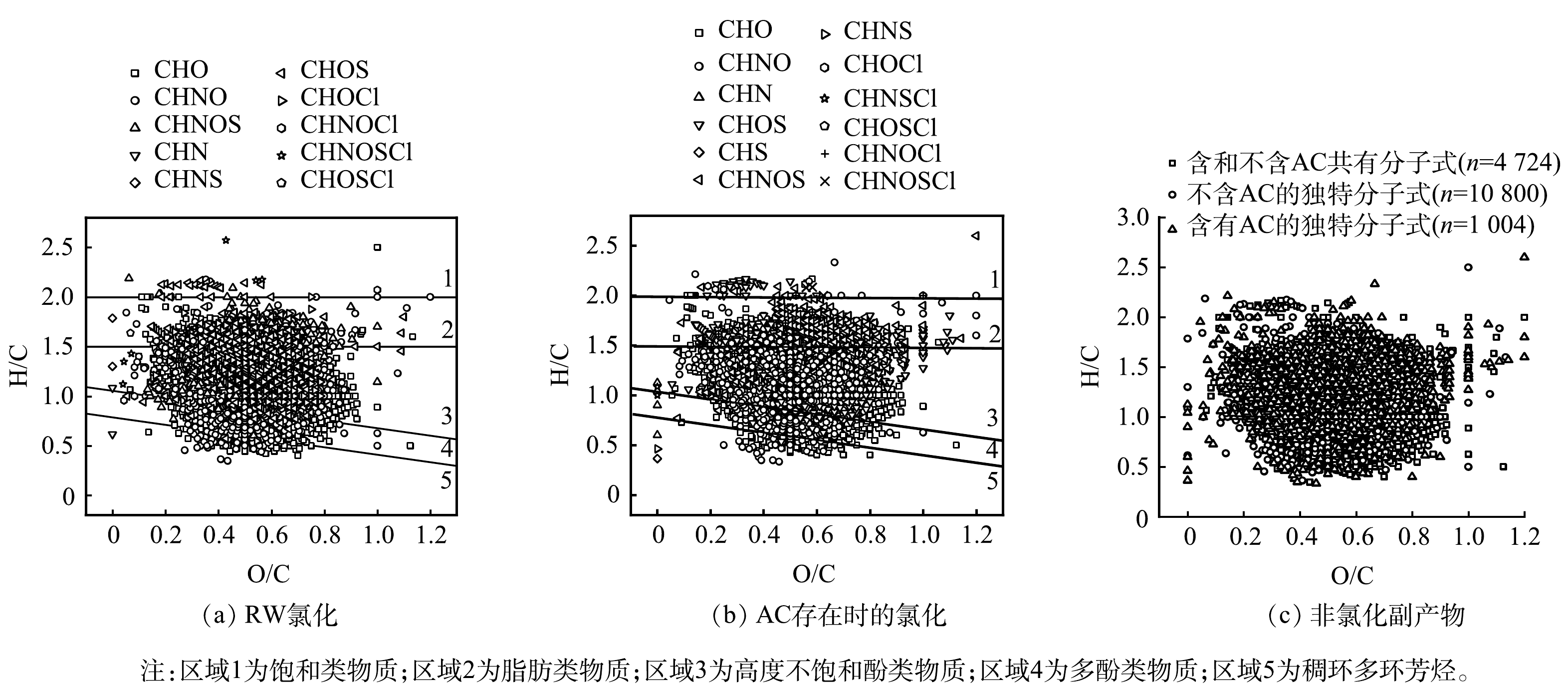

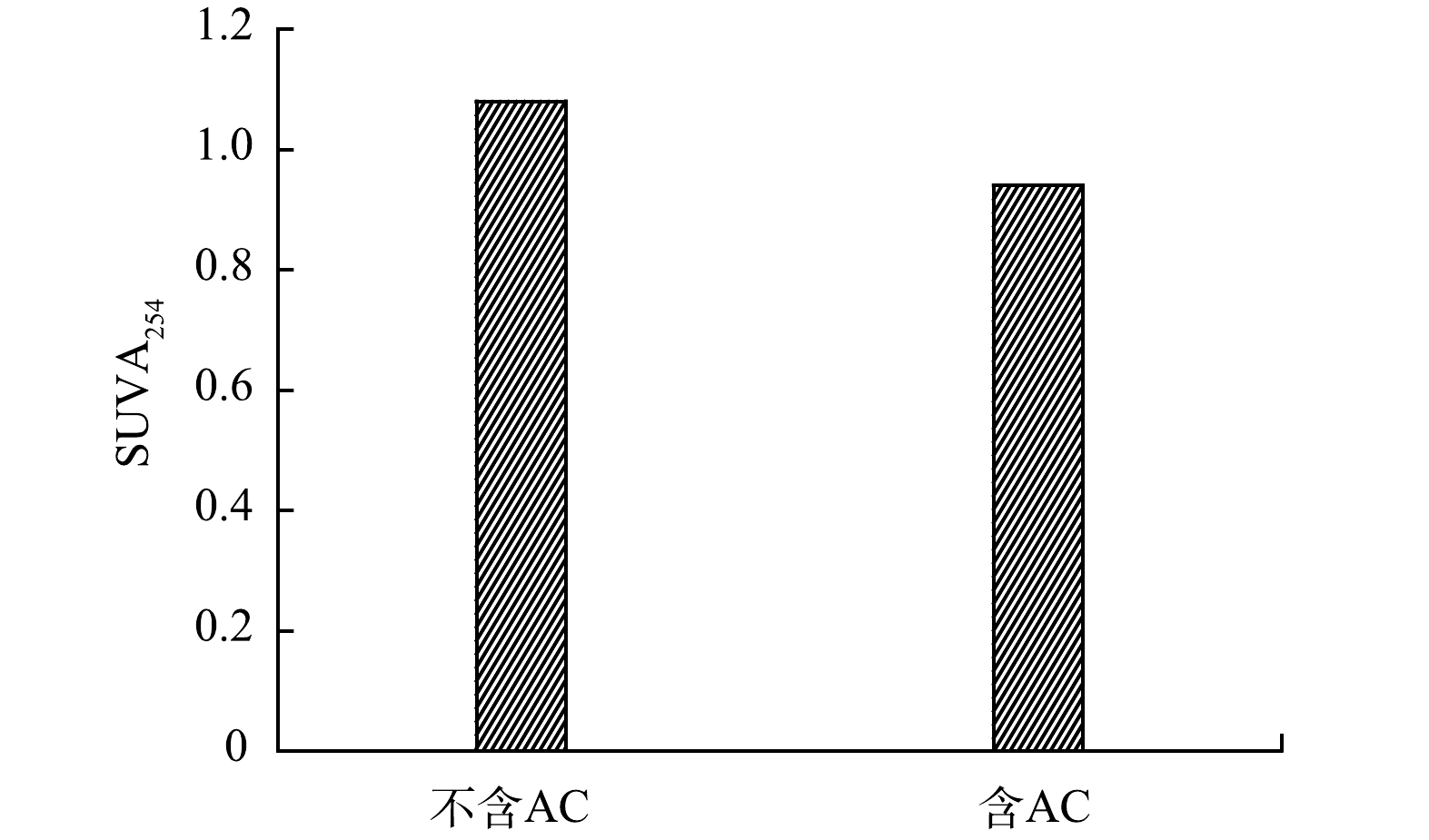

DOM的成分也会影响AC对氯的反应特性。因此,探究了AC存在时RW氯化过程中DOM的转化情况。基于修正后的芳香指数和H/C将溶解性有机质分为5类[18]:稠环多环芳烃(AImod>0.66)、多酚类物质(0.5<AImod≤0.66)、高度不饱和酚类物质(AImod≤0.5且H/C≤1.5)、脂肪类物质(AImod≤0.5和1.5<H/C≤2)和饱和类物质(H/C>2)[19]。如图5(a)和图5(b)所示,绝大部分有机物属于脂肪类物质、高度不饱和酚类物质和多酚类物质。此外,SUVA254(即UV254/DOC)可用来比较不同样品中的芳香族化合物的含量(即芳香度)[20]。芳香度与反应性有关,有机物的反应性反映了通过凝聚去除该有机物的难易程度,以及有机物与氯反应产生DBPs的可能性。如图6所示,对比了氯化后RW中是否存在AC时SUVA254的变化,THMs和HAAs的浓度随SUVA254的增加而增加[21]。图5显示AC存在时的SUVA254低于不含AC的水样,与上述结果保持一致。含AC和不含AC的RW中DOC在氯化前后仅有轻微变化,这表明DOM未发生矿化作用。SUVA254还可以表征有机物中不饱和键数量(芳香特征),氯化后的RW中,加入AC组后的SUVA254较低,因此其芳香性低,DOM转化的较多。在两种氯化过程后,SUVA254均有所下降,尤其是AC存在时,BULMAN等[5]的研究也得到了类似的结果,这表明SUVA254的大幅下降可能是由于含有芳香族DOM分子,富含芳香族结构的化合物可以提供更强的疏水作用、离子相互作用和键合作用。

利用FTICR-MS对有无AC存在的2种情况下的无氯分子式进行比较。如图5(c)所示,2种条件下,相同分子式的比例(约70%)显著高于氯化分子式的比例。如表2所示,CHO、CHON、CHOS和CHONS分子式的H/Cw和O/Cw相似。不含AC氯化条件下CHO、CHON、CHOS和CHONS分子式的DBEw均大于AC存在时氯化条件下的DBEw。较低的DBEw表明产生的DOM平均脂肪族含量更高,与SUVA254结果相一致。有研究[15, 22]表明,AC可与氧气反应生成过氧自由基,过氧自由基经过双分子衰变或单分子衰变生成醇或醛。因此,较低的DBEw可能是由于过氧自由基在AC和氧的活化下产生了部分醇。

表 2 RW氯化过程后的非氯化产物分子式分子指数的强度加权平均值Table 2. Intensity-weighted average of molecular indices of molecular formulae for non-chlorinated products after the RW chlorination process分子式 水样 H/CW O/CW DBEW AImod,w 总强度 相对丰度/% CHO 不含AC 1.23 0.52 9.54 0.24 1.79×1011 80.56 含AC 1.23 0.52 9.35 0.23 1.79×1011 78.06 CHON 不含AC 1.20 0.52 9.99 0.23 3.21×1010 14.45 含AC 1.20 0.52 9.88 0.23 3.11×1010 13.56 CHOS 不含AC 1.40 0.49 6.45 0.07 8.5×109 3.83 含AC 1.42 0.53 6.40 0.03 1.54×1010 6.71 CHONS 不含AC 1.51 0.55 7.81 -0.14 2.58×109 1.16 含AC 1.55 0.60 7.12 -0.22 3.82×109 1.67 2.4 自由基的表征

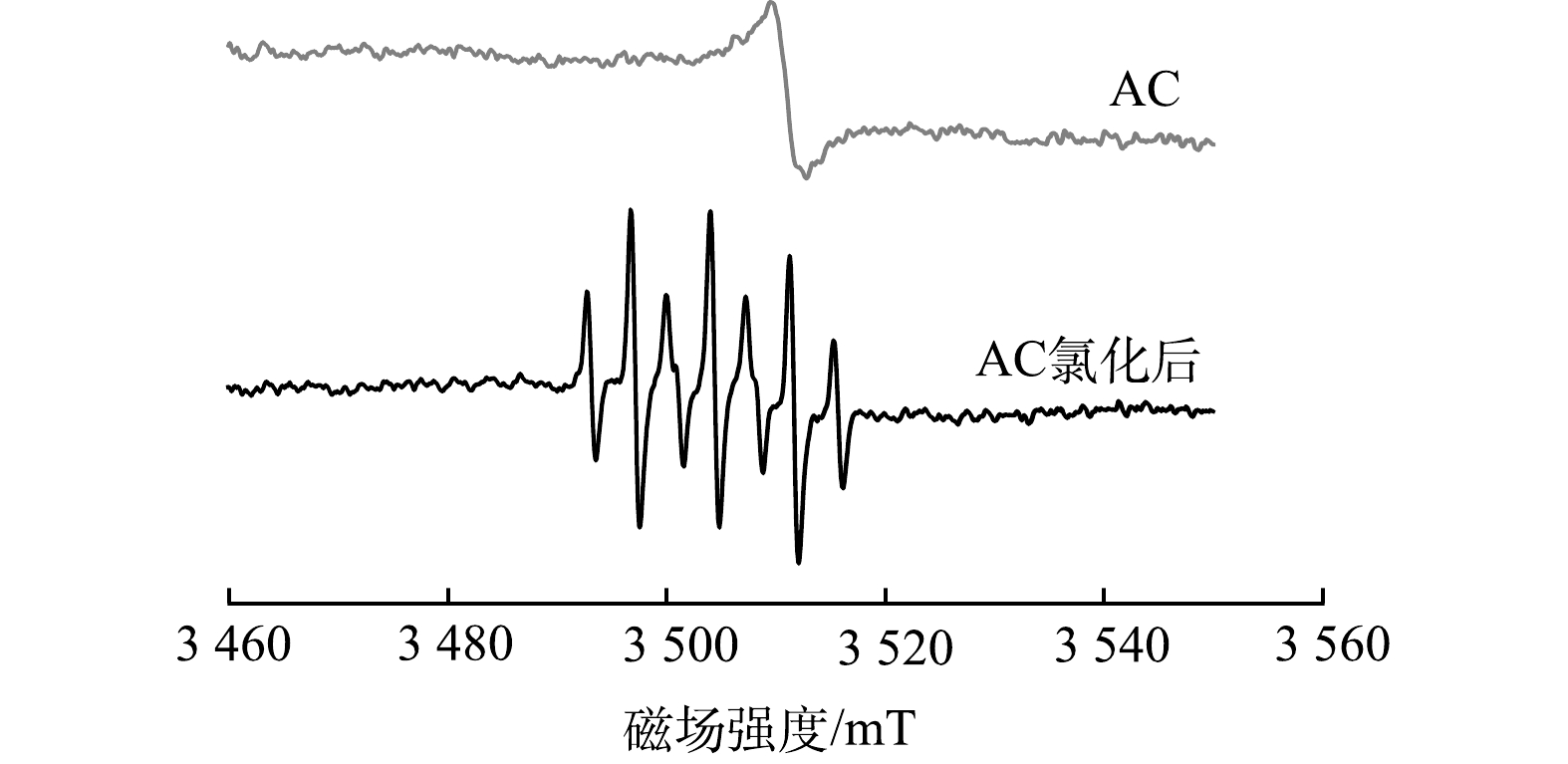

采用ESR技术对AC氯化前后产生的自由基进行检测分析。如图7所示,在只含AC时,可检测到活性炭表面的持久性自由基。在AC氯化后发现了多重峰的存在,DMPO-H2O体系中的七重峰对应·Cl/DMPO加合物,表明在此过程中产生了Cl·[23],Cl·是一种对有机化合物具有较强选择性的自由基,易发生取代反应。由于Cl·具有很强的活性,因此,能够促进DBPs的生成,诱导某些有毒副产物的形成。ESR的结果表明,AC表面持久性自由基可催化次氯酸产生Cl·,在自由基的作用下,DOM与RCS之间会产生氯化副产物,尤其是亲核反应在其中发挥着很大作用,并且DOM的芳香性变强也有助于总有机氯的形成[24]。因此,氯化过程中AC会促进自由基的产生进而诱导其他类型DBPs的生成。

3. 结论

AC作为一种优良吸附剂被广泛应用于水处理工艺和终端净水过滤;同时,氯也是一种常见的预氧化剂和消毒剂。本文阐述了AC对RW氯化过程DBPs生成及DOM转化的影响,主要结果如下。

1)虽然AC存在时余氯下降较为迅速,但生成的THMs及HAAs较少,这是由于AC优良的吸附性能以及还原性AC快速消耗氯生成其他DBPs,DOC的变化也可说明了这一变化趋势。

2) FTICR-MS检测结果表明,AC存在时含氯物质的数量减少,Cl-DBPs的种类由302种减少到220种,其中有57种特异性氯代产物,CHOSCl化合物生成较多,其他CHOCl、CHONCl、CHONSCl化合物的数量减少。

3) FTICR-MS的结果显示,AC存在时可鉴定的化合物数量呈下降趋势,其是否存在的两种情况,生成的化合物有较大区别,但大部分化合物均属于脂肪类物质、高度不饱和类及酚类物质和多酚类物质。AC存在时,SUVA254的大幅降低表明含有芳香性的DOM被转化,而未加入AC组没有发生矿化反应。

4) AC表面持久性自由基催化次氯酸产生Cl·,Cl·引发的自由基反应是造成氯化产物及有机物形态改变的主要原因。

-

-

[1] 辛宝平, 王佳. 涉重危废概念的提出及其资源化利用[J]. 环境工程学报, 2022, 16(1): 1-9. doi: 10.12030/j.cjee.202111146 [2] 辛宝平, 王佳. 涉重危废三维属性及其精细化分级分类体系[J]. 环境工程学报, 2022, 16(2): 355-362. doi: 10.12030/j.cjee.202112159 [3] 联合国环境署. 巴塞尔公约(中文)[EB/OL] 0-08-17]. http://bcrc.tsinghua.edu.cn/atm/7/20200817215215207.pdf.

[4] 生态环境部, 国家发展和改革委员会, 公安部, 等. 国家危险废物名录(2021年版)[EB/OL]. [2020-11-25].https://www.mee.gov.cn/xxgk2018/xxgk/xxgk02/202011/t20201127_810202.html. [5] GAUSTAD G, WILLIAMS E, LEADER A. Rare earth metals from secondary sources: Review of potential supply from waste and byproducts[J]. Resources, Conservation and Recycling, 2021, 167: 105213. doi: 10.1016/j.resconrec.2020.105213 [6] KRISHNAN S, ZULKAPLI N S, KAMYAB H, et al. Current technologies for recovery of metals from industrial wastes: An overview[J]. Environmental Technology and Innovation. 2021, 22: 105525. [7] GU T Y, RASTEGAR S O, MOUSAVI S M, et al. Advances in bioleaching for recovery of metals and bioremediation of fuel ash and sewage sludge (review)[J]. Bioresource Technology, 2018, 261: 428-440. doi: 10.1016/j.biortech.2018.04.033 [8] FUNARI V, BRAGA R, BOKHARI S, et al. Solid residues from Italian municipal solid waste incinerators: a source for “critical” raw materials[J]. Waste Management, 2015, 45: 206-216. doi: 10.1016/j.wasman.2014.11.005 [9] DING Y J, ZHANG S G, LIU B, et al. Recovery of precious metals from electronic waste and spent catalysts: A review[J]. Resources, Conservation and Recycling, 2019, 141: 284-298. doi: 10.1016/j.resconrec.2018.10.041 [10] HAO J J, WANG Y S, WU Y F, et al. Metal recovery from waste printed circuit boards: A review for current status and perspectives[J]. Resources, Conservation and Recycling, 2020, 157: 104787. doi: 10.1016/j.resconrec.2020.104787 [11] LI H, EKSTEEN J, ORABY E. Hydrometallurgical recovery of metals from waste printed circuit boards (WPCBs): Current status and perspectives: A review[J]. Resources, Conservation and Recycling, 2018, 139: 122-139. doi: 10.1016/j.resconrec.2018.08.007 [12] ZENG X L, GONG R Y, CHEN W Q, et al. Uncovering the recycling potential of “new” WEEE in China[J]. Environmental Science and Technology, 2016, 50: 1347-1358. doi: 10.1021/acs.est.5b05446 [13] PATHAK A, KOTHARI R, VINOBA M, et al. Fungal bioleaching of metals from refinery spent catalysts: A critical review of current research, challenges, and future directions[J]. Journal of Environmental Management, 2021, 280: 111789. doi: 10.1016/j.jenvman.2020.111789 [14] 中华人民共和国全国人大常委会. 中华人民共和国固体废物污染环境防治法(2020年修订)[EB/OL]. [2020-04-29]. http://www.gov.cn/xinwen/2020-04/30/content_5507561.htm. [15] 胡华龙, 郑洋, 郭瑞. 发达国家和地区危险废物名录管理实践[J]. 中国环境管理, 2016, 8(4): 76-81. [16] NIU T Q, WANG J, CHU H C, et al. Deep removal of arsenic from regenerated products of spent V2O5-WO3/TiO2 SCR catalysts and its concurrent activation by bioleaching through a novel mechanism[J]. Chemical Engineering Journal, 2021, 65: 1103-1110. [17] 王海北. 我国二次资源循环利用技术现状与发展趋势[J]. 有色金属(冶炼部分), 2019, 9: 1-11. [18] DAHMUS J B, GUTOWSKI T G. What gets recycled: An information theory based model for product recycling[J]. Environmental Science and Technology. 2007, 41: 7543-7550. [19] ANCTIL A, FTHENAKIS V. Critical metals in strategic photovoltaic technologies: abundance versus recyclability[J]. Progress in Photovoltaics. 2013, 21: 1253-1259. [20] 生态环境部, 国家市场监督管理总局. 危险废物鉴别标准通则(GB 5085.7-2019)[EB/OL]. [2019-11-07].https://www.mee.gov.cn/xxgk2018/xxgk/xxgk01/201911/t20191114_742433.html. [21] MARTINEZ O V, BOOGAAR K G, LUNDSTROM M, et al. Statistical entropy analysis as tool for circular economy: Proof of concept by optimizing a lithium-ion battery waste sieving system[J]. Journal of Cleaner Production, 2019, 212: 1568-1579. doi: 10.1016/j.jclepro.2018.12.137 -

下载:

下载: