-

由于具有废物产生量少、成本低、保护森林资源等优点,废纸回收利用是实现造纸工业环境友好型发展的有效途径[1]。不过,废纸制浆过程会产生大量的脱墨废水,其具有废水量大、有机物和总悬浮物固体(total suspended solid ,TSS)含量高、pH高、水质复杂等特点[2],且BOD5/COD很低,含具有生物毒性的化学品[3],故可生化性差。因此,经常规的二级生化处理后,该废水的有机物含量仍然比较高[4],须经深度处理才能达到我国相关排放标准或回用要求。

作为一种安全高效的废水深度处理技术[5],膜技术目前在处理造纸白水[6]、漂白废水[7]、 造纸黑液[8]以及废纸造纸产生的非脱墨废水和脱墨废水[9]等方面发挥了重要的作用,且微滤和超滤能够有效去除脱墨废水中的水基油墨,尤其是超滤的效果更好[10]。不过,膜污染仍是制约膜技术广泛应用于脱墨废水处理的关键[11]。

混凝是一种应用较广泛的膜污染控制技术[12-13],具有成本低廉、效果显著等优点[14]。而与传统混凝相比,强化混凝能显著提高废水中有机物的去除率[15]。本研究团队前期开发了强化混凝-平板折转错流膜分离工艺,发现聚合氯化铝(polyaluminum chloride ,PACl)在一定范围内的高投加量下的强化混凝可有效缓解平板折转错流超滤过程的膜污染,提高出水水质,且膜过滤总阻力随着PACl投加量的增加而减小[16]。但该工艺投入实际运行后的运行方式、清洗方式、运行稳定性等参数尚需优化和验证。因此,本研究以石家庄某造纸厂废纸脱墨废水的二级生化出水作为研究对象, 采用强化混凝-平板折转错流膜分离工艺开展了中试规模的实验研究,探索了该工艺在实际工况下的运行过程,并对相关操作参数进行了优化,以期为进一步的工程应用提供参考。

-

1)实验用水。本研究在河北省某家以废纸为原料生产高档新闻纸的企业内完成。实验所用原水是经厌氧生物法、射流曝气活性污泥法处理后的出水,水样浑浊,呈灰褐色,水质指标见表1。

2)混凝剂和实验用膜。根据前期研究[16],以市售粉末状PACl为混凝剂。其Al2O3 含量为30%,盐基度为48%。实验所用PACl质量浓度为100 g·L−1。实验分别采用圣万泉公司生产的PES 超滤膜和安德膜公司生产的PVDF 超滤膜,膜相关参数详见表2。

-

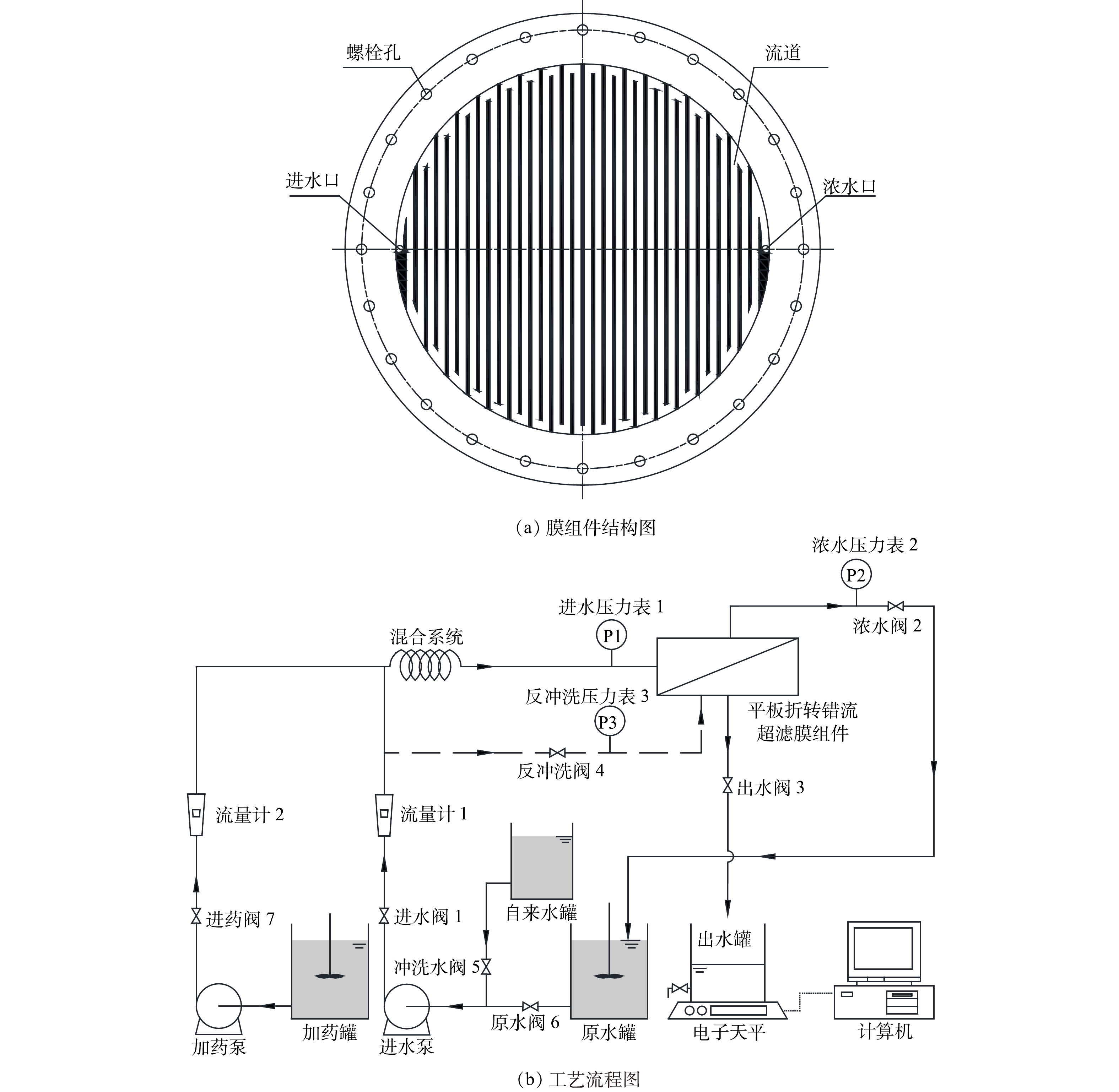

采用自主研发的带有折转错流过滤的平板膜分离装置(图1)。膜组件由2个外径为400 mm的圆盘组成,2个圆盘由螺栓固定,水平放置。上圆盘具有折转形流道,流道的宽度和深度均为8 mm;下圆盘为平面结构,中间凹槽内径为350 mm,圆盘中心设有出水孔,如图1(a)所示。超滤膜固定于2个圆盘之间,有效面积为0.091 m2。

实验装置及工艺流程如图1(b)所示。原水和PACl溶液分别经离心泵和计量泵由进水罐和加药罐输送至混合系统,进水流量为1 m3·h−1,膜表面流速为4 m·s−1。根据前期确定的最佳条件[16],PACl投加质量浓度为2 g·L−1。进水罐和加药罐均设有搅拌装置和液位控制系统,可根据液位情况自动进液。混合后的料液经上圆盘入口泵入膜组件,并沿着膜组件的折返流道在膜表面流动。滤液经下圆盘出水口排入出水罐,出水罐中的滤液量由电子天平每10 min测量1次,并由计算机自动记录,根据每10 min的滤出液重量增量和有效膜面积计算水通量。浓水经上圆盘出口排出后返回进水罐。膜组件进、出水口分别安装压力表1和2,2个压力表的平均值为跨膜压差(transmembrane pressure, TMP),实验过程中TMP保持恒定。实验过程中定时采集样品,测量浊度、COD和色度等。实验分别采用连续运行、间歇比8∶2 (运行8 min,间歇2 min)和间歇比6∶4 (运行6 min,间歇4 min) 3种方式运行,以考察运行方式对膜过滤性能的影响。运行结束后分别采用正向冲洗、正反同步冲洗的方式对污染的超滤膜进行清洗,以考察不同清洗方式的清洗效果。其中,正向清洗时,膜表面流速为4.0 m·s−1,TMP为0.05 MPa;正反同步冲洗时,膜表面流速控制在5.0 m·s−1,正向压力0.1 MPa,反冲洗压力为0.1~0.15 MPa,清洗时间为30 min。

-

1)水质分析方法。COD采用COD快速测试仪(5B-2A,北京连华科技)测定;浊度及色度通过台式浊度仪(2100AN,Turbidimeter,美国HACH)测定;pH采用精密pH计(Orion5 star,美国Thermo)测定;膜表面及孔径内部污染形态通过扫描电子显微镜(Hitachi-570,日本日立)表征;膜材料亲疏水性通过接触角测量仪(DSA 100,德国KRUSS)测定。

2)膜过滤阻力分析方法。错流条件下混凝-膜分离工艺的过滤阻力可通过实验测试和达西定律来计算。采用自来水测定膜纯水通量,记为J0,根据达西定律,得到式(1)。

式中:J0为纯水通量,L·(m2·h)−1;∆P为跨膜压差,Pa;µ为透过液粘度,Pa·s;Rm为膜自身固有阻力,m−1。

原水过滤实验结束时的水通量记为J1。随后将原水换为自来水,在其他条件不变的情况下测其纯水通量,记为J2。然后将污染的膜取出,利用绵花轻轻拭去其表面污泥层,而后在原条件下测定其纯水通量,记为J3。根据达西定律,可得式(2)~式(5)。

式中:R为膜总过滤阻力,m−1;Ra为膜吸附阻力,m−1;Rf为孔堵阻力,m−1;Rc为滤饼层阻力,m−1; Rg为浓差极化阻力,m−1;R、Ra、Rf、Rc和Rg可通过式(1)~式(5)计算得出。有研究[16]表明, Ra远小于其他阻力,且不随运行时间变化,故可忽略不计。

-

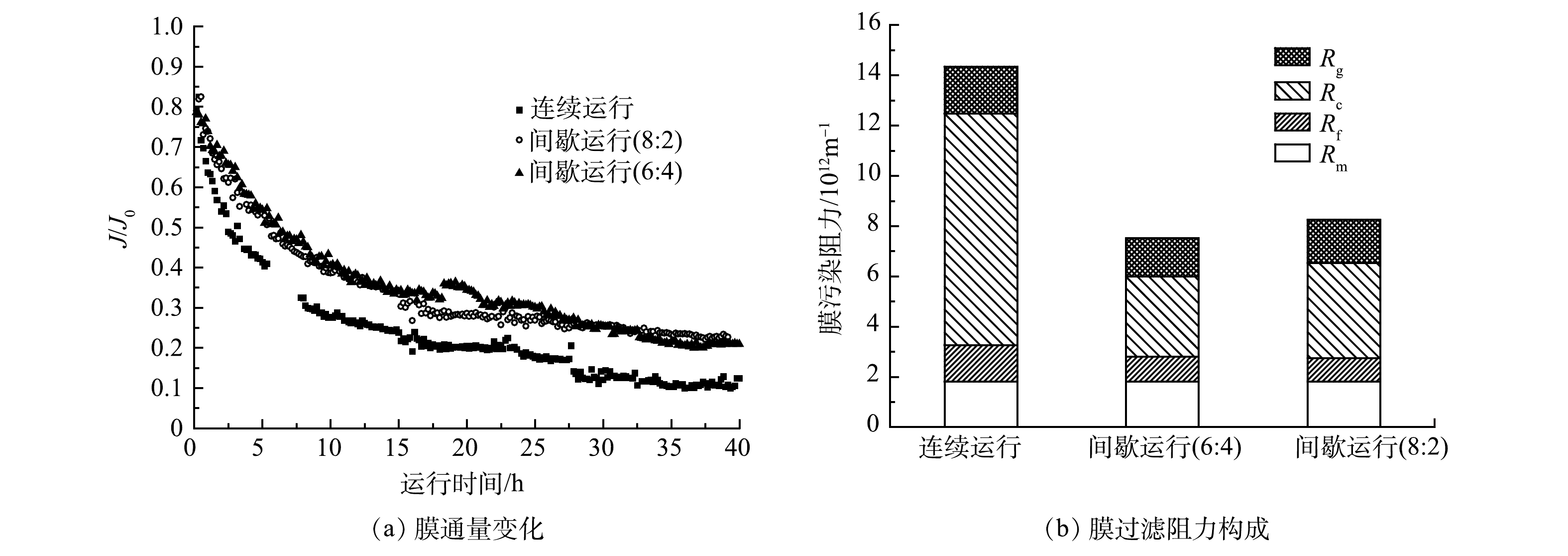

采用PES膜,在TMP为0.1 MPa的条件下,考察了运行方式对膜分离效果的影响,结果如图2所示。由图2(a)可见,无论是连续运行还是间歇运行,膜通量在运行初期均快速衰减,随后逐渐缓慢衰减,而间歇运行较连续运行能在一定程度上减缓通量下降趋势。由图2(b)可见,与连续运行相比,间歇运行的膜总阻力R大幅下降,其中以滤饼层阻力Rc下降最为明显。这是因为:一方面,运行中不断压缩的膜在停歇的时间里得到一定的缓解;另一方面,设备瞬间开启时料液的流速对膜表面形成了冲刷作用,使得Rc和Rg得以缓解。延长间歇时间可以增强Rc的缓解,但对Rf和Rg影响较小。从整体运行过程看,延长间歇时间对膜污染缓解作用不大。

由图3可以看出,间歇运行可以显著提高膜出水水质,但延长间歇时间对出水水质影响较小。间歇2 min时,浊度平均去除率可高达99.5%,比连续运行提高了0.89%,色度平均去除率可达88.7%,比连续运行提高了9.3%,COD平均去除率为33.0%,比连续运行时高出14.3%。这是由于间歇运行时,料液的冲刷作用降低了Rg,同时使膜表面形成的滤饼层更为疏松,加强了有机物的截留作用[17];而连续运行模式下,污染物在膜表面持续累积,浓差极化现象更严重,导致有机物截留率偏低[18]。

-

膜自身特性是影响膜污染的重要因素[19],通过实验室小试获知2种超滤膜优化参数(表3)。

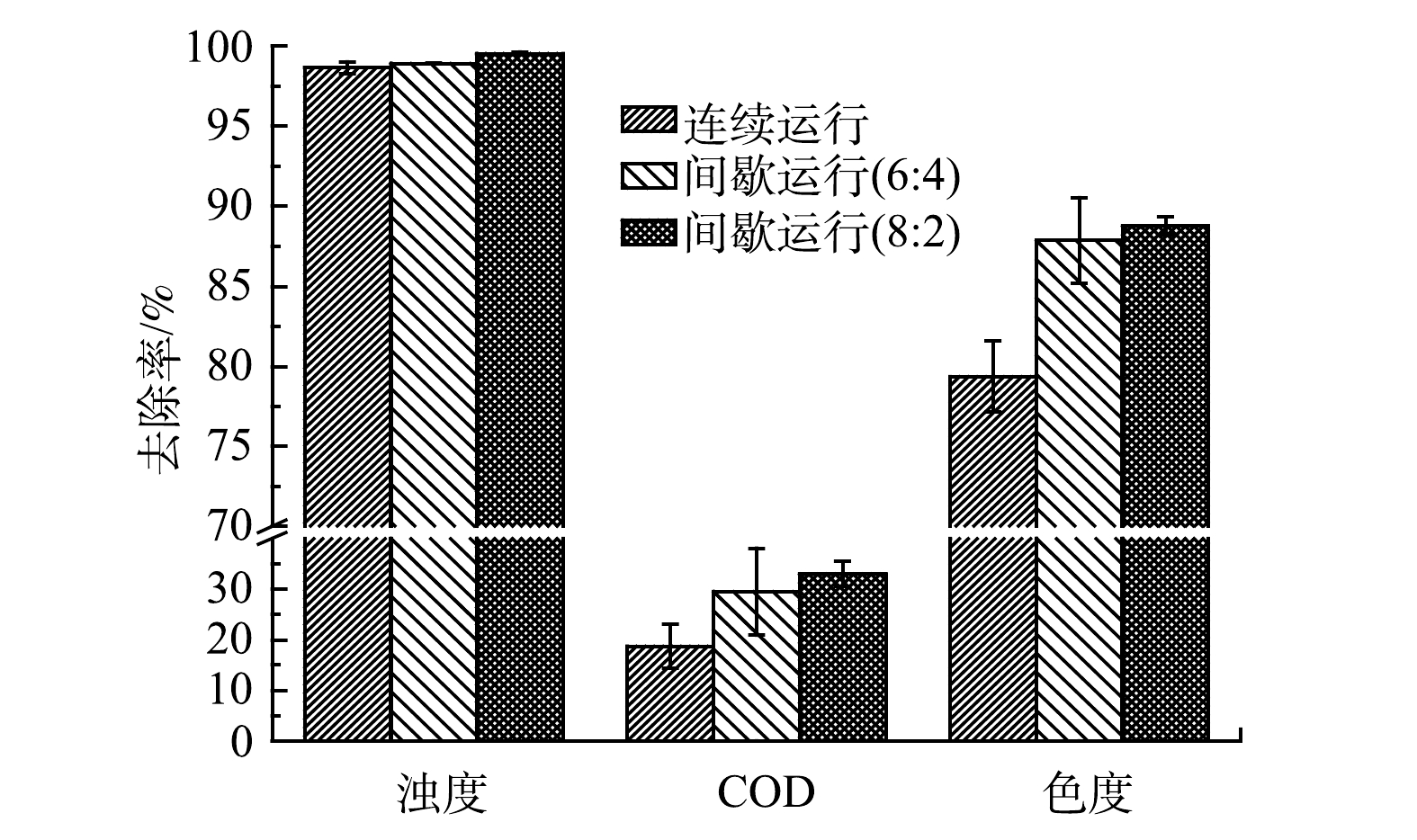

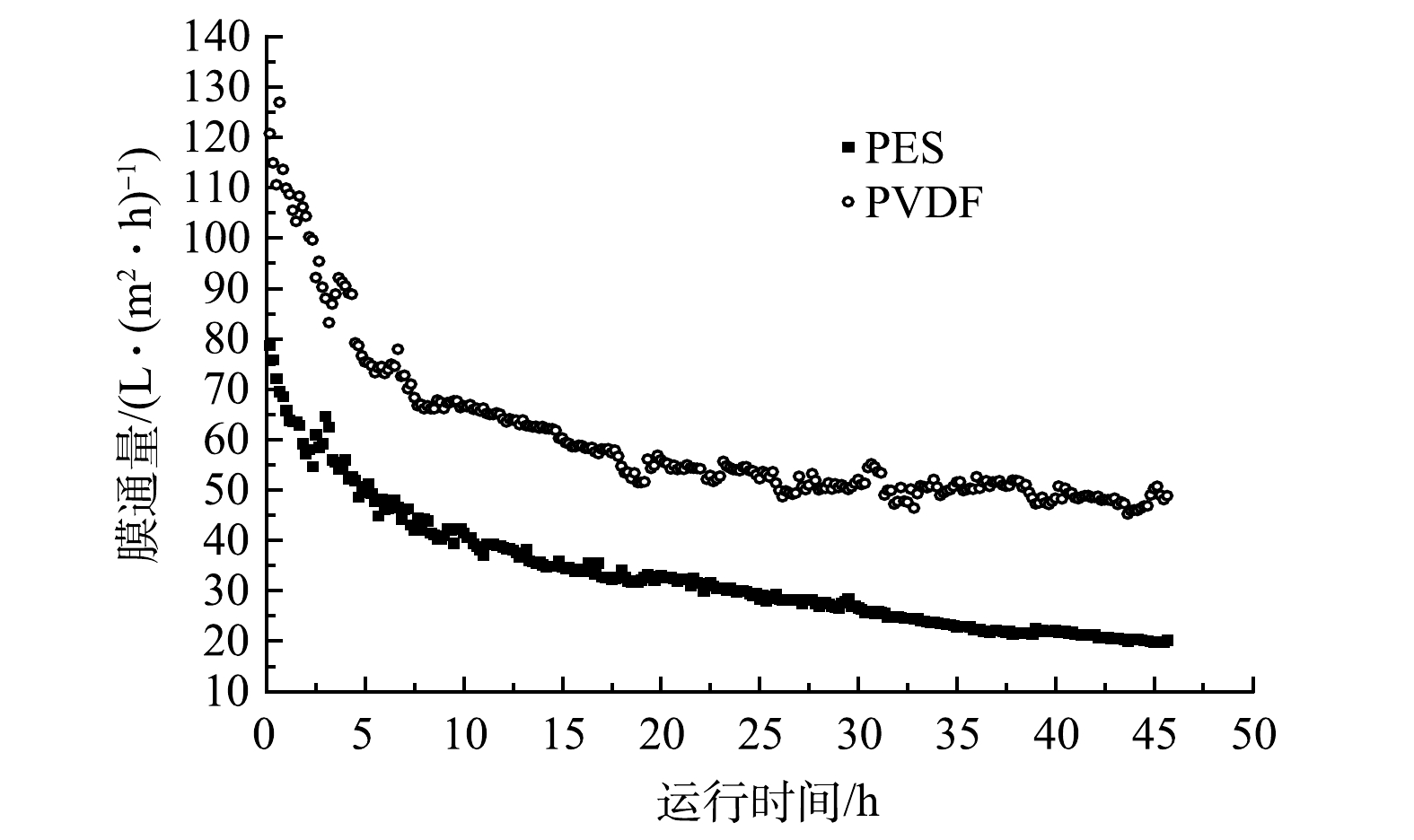

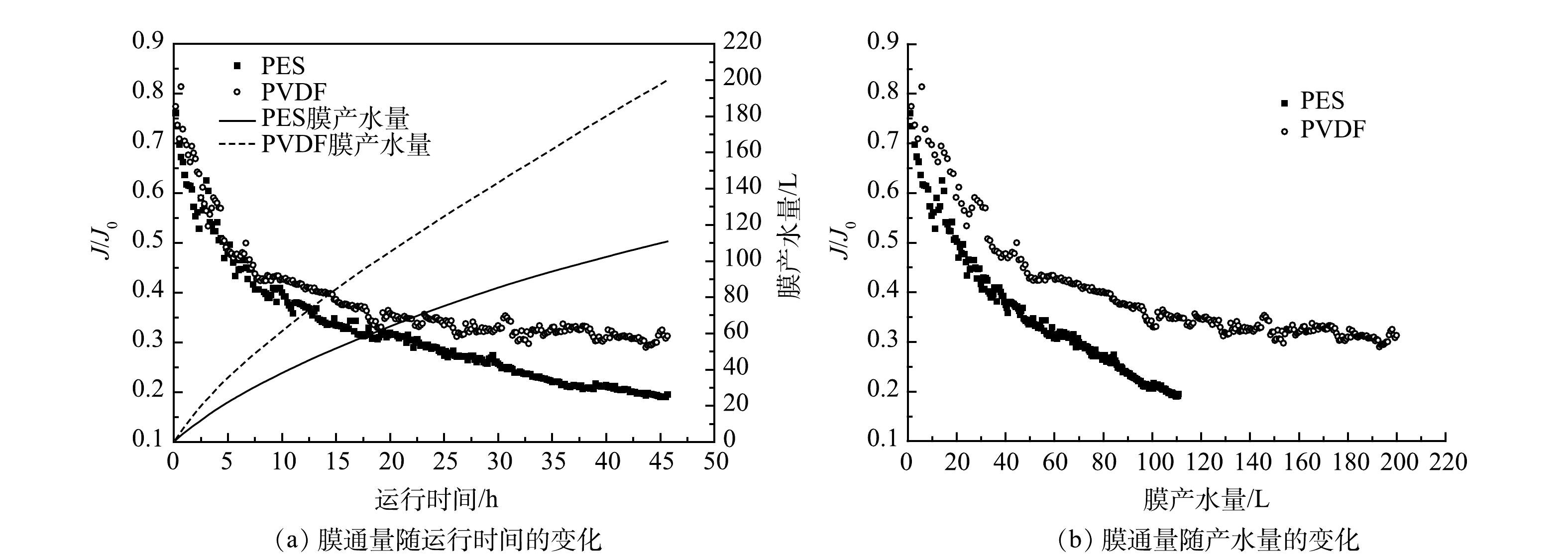

由图4可以看出,PVDF膜的水通量变化较大,即使其TMP明显低于PES膜,且在过滤过程中,前者膜通量始终优于后者。在运行48 h后,PVDF膜通量稳定在50 L·(m2·h)−1左右,是PES膜通量的2.5倍。这是由于PVDF膜亲水性强,截留分子质量大,因此,其过滤阻力更低,膜通量更大[20]。

图5更直观地反映了2种超滤膜在处理脱墨废水二沉出水时的抗污染性能。可见,亲水性更强的PVDF膜具有更好的抗污染性能,这与其他研究结果相一致[21]。如图5(a)所示,过滤初始8 h内,2种超滤膜通量均随运行时间的延长迅速下降,PVDF 膜通量下降趋势逐渐低于PES,且在运行20 h后趋于稳定,而PES膜通量扔持续下降。这种现象在膜通量随产水量变化时更为显著。由图5(b)可见, 相同产水量下,PVDF膜污染情况较轻,在相同运行时间内,产水量是PES膜的近2倍。

在对二沉水中有机物进行亲疏水性分析后发现,脱墨废水二级生化出水中疏水性有机物占总有机物的90.1%,其中强疏水物质占83.9%。由于PVDF 膜表面亲水性更强,易与水分子形成氢键,有序的水分子层结构在表面形成一层平衡水膜,水中疏水性有机物难以吸附到膜表面,提高了膜的抗污染性能[22]。而对于疏水性更强的PES膜来说,污染物更易在其表面累积[23],且其操作压力更大,使得膜表面滤饼层更为密实,孔堵情况更严重,因此膜污染现象更显著。

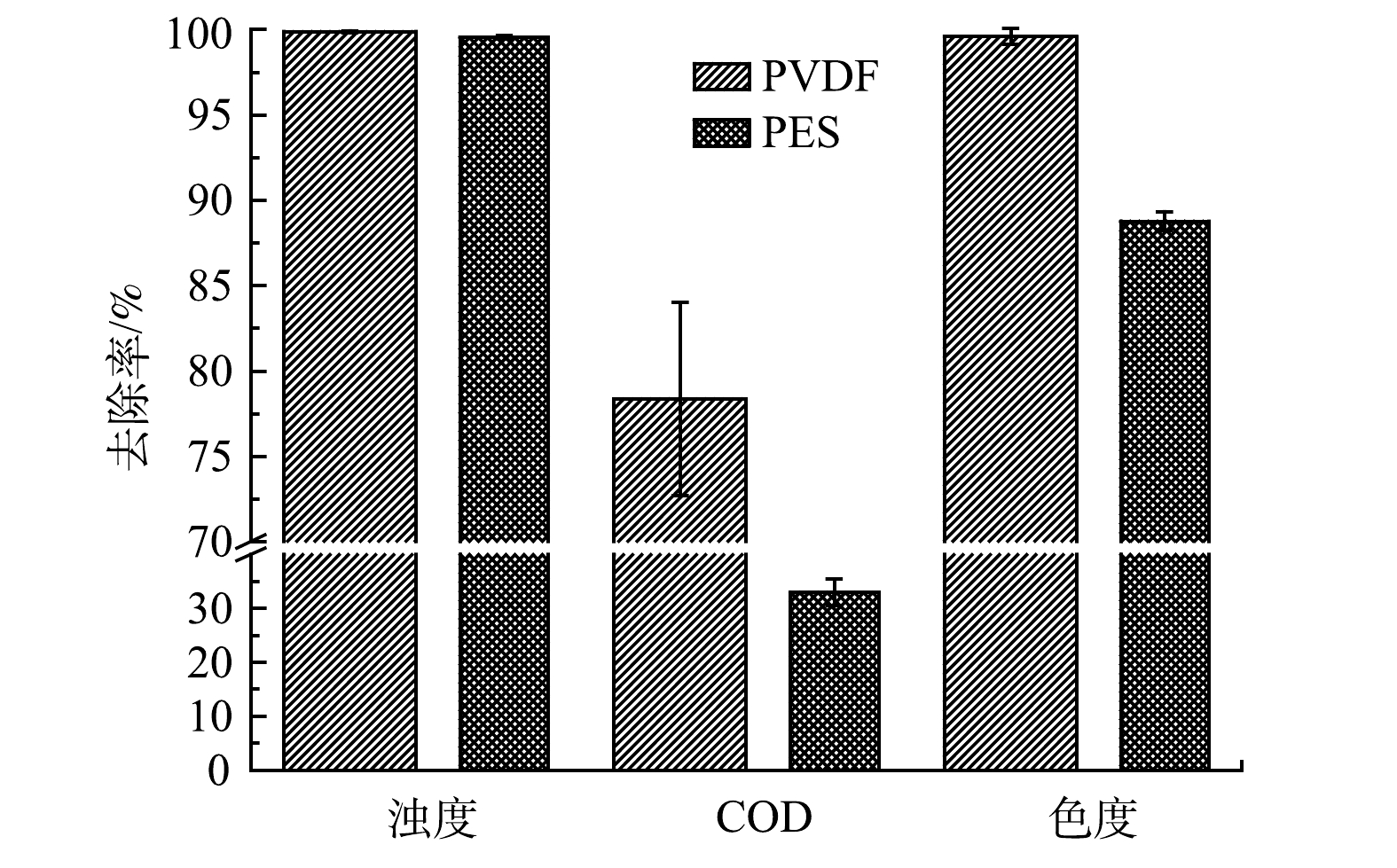

图6反映了不同超滤膜对脱墨废水二沉池出水的处理效果。由图6可以看出,2种超滤膜对浊度的去除率平均可达99.5%,其中PVDF 膜略优于PES。在色度及COD的去除方面,PVDF膜明显优于PES,其色度和COD去除率分别是PES的1.13倍和1.90倍。这是由于PVDF 膜表面呈亲水性,当料液与膜接触时,料液中的疏水性物质在错流过滤的作用下,不易黏附在膜面上,从而防止水中有机物透过膜影响出水水质。对2种超滤膜通量下降情况及出水水质进行比较后不难看出,亲水性更强,截留分子质量更大的PVDF膜更适宜脱墨废水二级生化出水的处理,因此,后续采用PVDF膜开展实验。

-

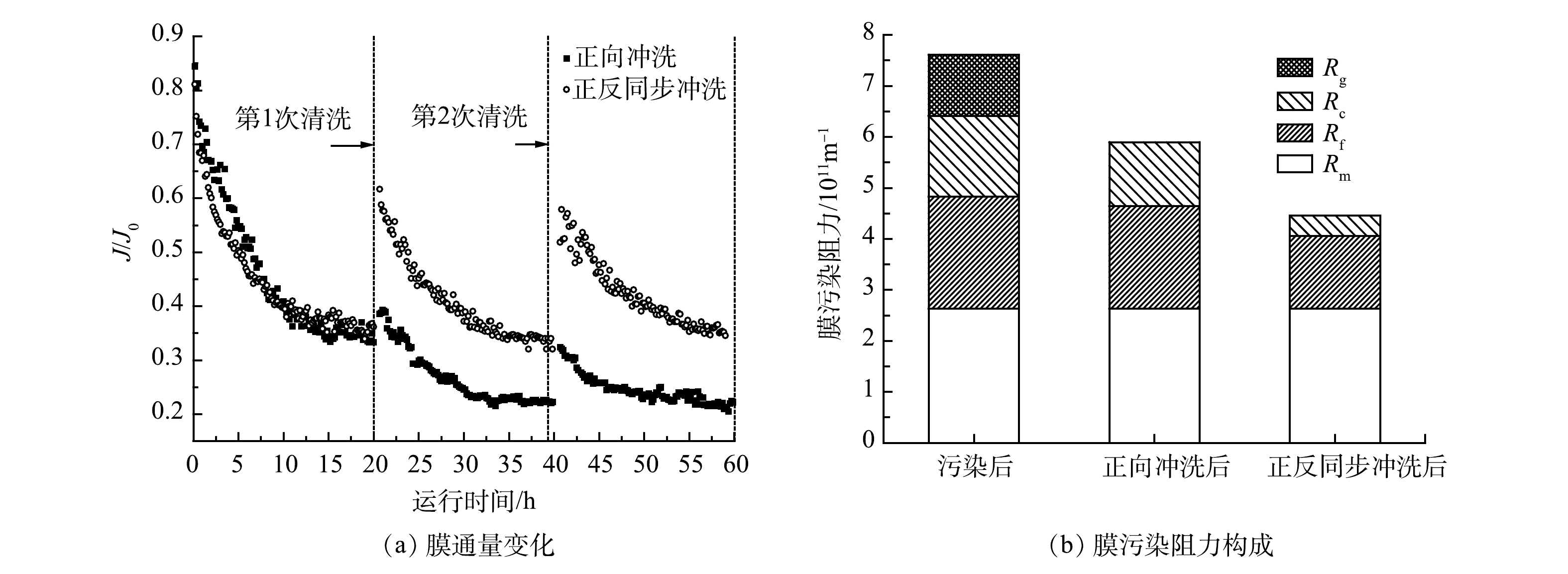

适宜的清洗方式可以延长膜的使用寿命[24]。实验采用PVDF膜,在TMP为0.025 MPa,间歇比为8∶2的运行方式下,分别采用正向冲洗和正反同步冲洗2种方式对连续运行的膜进行清洗。由图7(a)可见,正反同步冲洗效果显著优于正向冲洗,在2次清洗后通量恢复率分别可达76.0%和63.9%,比正向冲洗分别提高了30.3%和25.6%。由图7(b)可见,正向冲洗时,滤饼层阻力Rc和Rg在膜表面错流的高速冲刷下有所降低,但在正向跨膜压差作用下,膜孔内部的污染物无法得到有效清洗,Rf与污染前相比仅下降了8.1%,仍维持在较高水平,影响清洗效果。而正反同步冲洗,通过控制膜两侧压力平衡,缓解了这一现象,可实现膜表面和膜孔内部的同步清洗,从而有效降低了Rf、Rc和Rg。

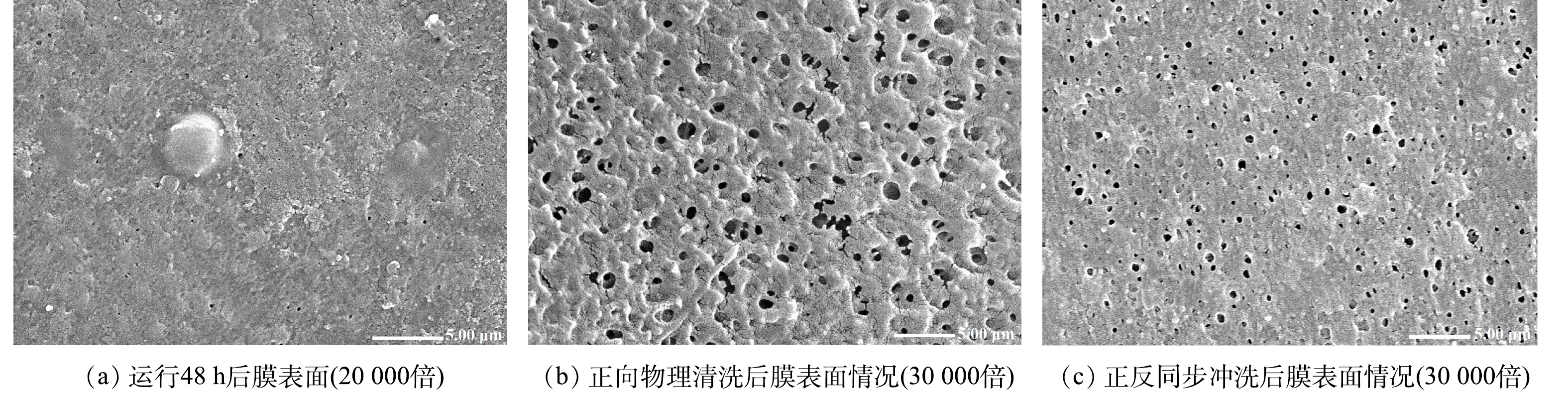

污染和清洗后超滤膜的扫描电镜结果如图8所示。由图8(a)可见,经过3个周期的连续运行,膜表面形成了较为致密的污泥层。正向清洗后(图8(b)),膜表面污染情况有所缓解,但仍有较薄的滤饼层存在;而经过正反同步冲洗后,膜表面较平整光滑,较高放大倍数下膜孔清晰可见。

-

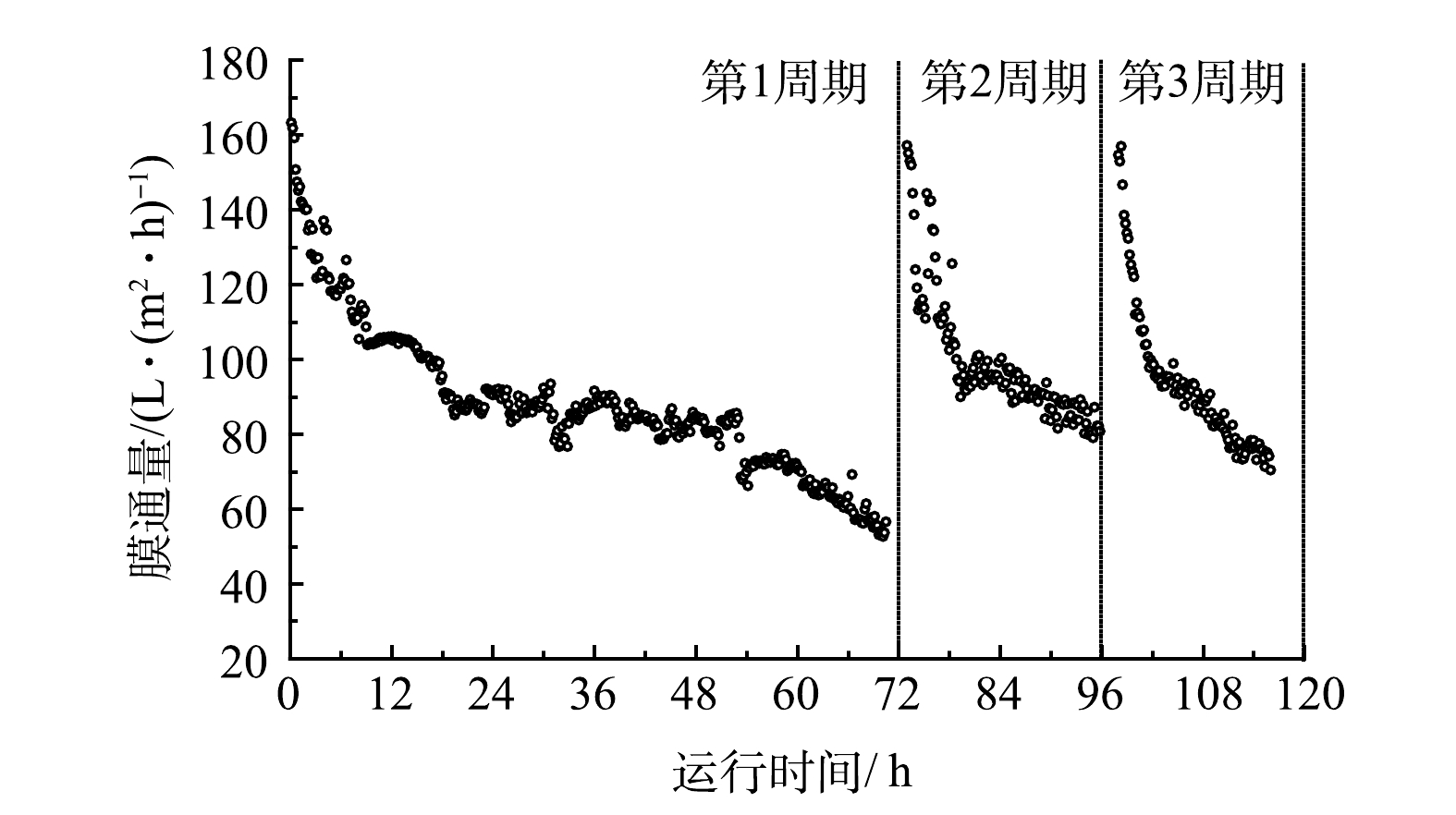

基于上述研究结果,采用PVDF 超滤膜,在TMP为0.025 MPa、PACl投加量为2 g·L−1条件下,采用运行8 min、停歇2 min运行方式,考察了该工艺连续长期运行的稳定性。每当膜通量低于70 L·(m2·h)−1时,采用自来水对膜进行正反同步冲洗。长期运行通量变化情况如图9所示。由图9可知,运行第1周期,膜通量先以较快速率下降,随后逐渐稳定,出水通量可在近50 h内稳定在80 L·(m2·h)−1。第1次清洗后,膜通量恢复率可达98%,但其保持高通量的时间明显下降,说明此时膜内部已造成一定的不可逆污染。第2次清洗后,膜通量恢复率依然在95%以上,但高通量稳定运行时间较前2周期有所缩短。

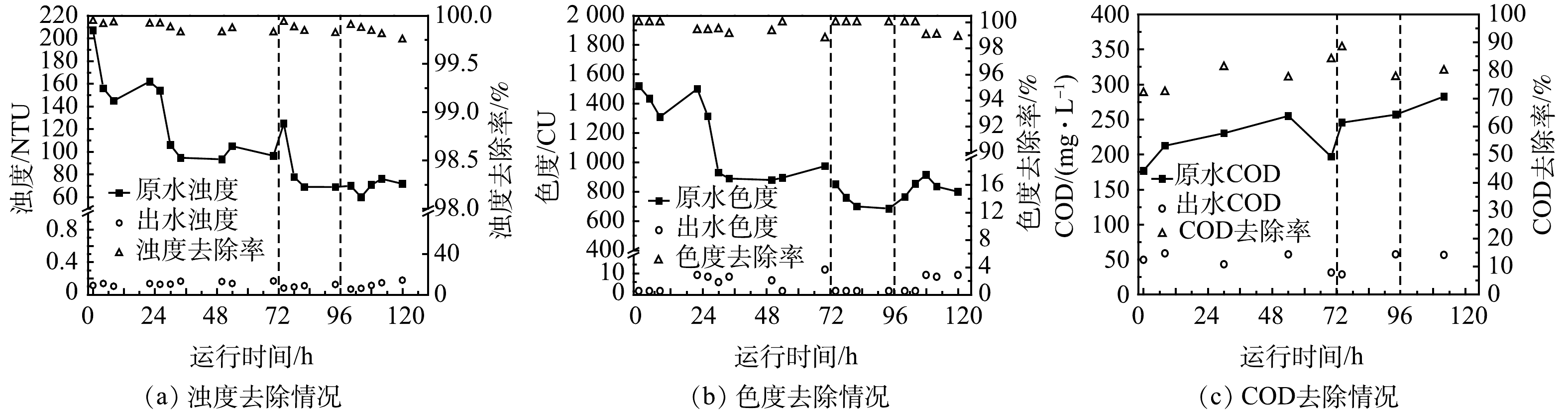

如图10所示,在3个运行周期中,出水浊度、色度及COD均比较稳定。其中浊度去除率稳定在99.5%以上,色度去除率稳定在99.0%以上,出水COD平均去除率可达79.1%,在运行期间始终稳定在60 mg·L−1以下。各项指标符合我国工业用水水质标准GB/T 1992-2005中相关水质要求,说明该工艺具有较好的稳定性。

-

1)与连续运行相比,间歇运行可有效缓解强化混凝-平板折转错流超滤过程中的膜污染,提高水通量和出水水质,特别对于滤饼层阻力Rc有显著的缓解作用。延长间歇时间无法进一步提高膜污染缓解效果。本研究中,间歇2 min,运行8 min的运行方式更佳。

2)膜片的亲疏水性对膜污染及出水水质影响显著,疏水性越强的膜,越容易造成膜污染。考虑到该实际脱墨废水中疏水性污染物占较大比重,故采用疏水性强的膜容易造成膜污染。因此,在本研究中亲水性更强的截留分子量为30 kDa的PVDF超滤膜过滤性能更佳。

3)采用正反同步冲洗的方式,可以有效清洗膜表面及膜孔内部,使Rc、Rf、Rg均显著降低,同时避免反向冲洗损伤膜表面功能材料。本研究中,控制正向压力为0.10 MPa,反冲洗压力为0.10~0.15 MPa,清洗30 min后的膜通量恢复率比0.05 MPa下正向水洗提高了30%以上。

4)采用截留分子质量为30 kDa的PVDF超滤膜,在跨膜压差为0.025 MPa,PACl投加量为2 g·L−1条件下,采用停歇2 min、运行8 min脉冲进水方式,可在膜通量不低于80 L·(m2·h)−1下稳定运行50 h。在运行的120 h内,出水主要指标符合我国《工业用水水质标准》(GB/T 19923-2005)中循环冷却水系统补水要求,且正反同步清洗后,通量恢复率可达95%以上,具有较好的稳定性。因此,该技术具有深度处理脱墨废水的应用潜力。

强化混凝-平板折转错流超滤工艺处理脱墨废水

Deinking wastewater treatment by a hybrid process of enhanced coagulation and flat-plate ultrafiltration in turn-around cross-flow mode

-

摘要: 采用强化混凝-平板折转错流膜分离技术对脱墨废水的二级生化出水进行了深度处理中试研究,从运行方式、超滤膜种类、清洗方式、长期运行稳定性等方面评估了工艺适用性。结果表明,间歇运行方式可有效降低滤饼层阻力(Rc)和浓差极化阻力(Rg),缓解膜污染,提高水通量和出水水质。亲水性强、截留分子质量(30 kDa)较大的聚偏氟乙烯(PVDF)超滤膜可以延缓膜污染,提高产水率和出水水质;比截留分子质量(8 kDa)较小的PES膜更适宜脱墨废水二级生化出水的处理。正反同步冲洗可有效清洗膜表面及膜孔内部,显著降低滤饼层阻力(Rc)、孔堵阻力(Rf)、浓差极化阻力(Rg),且可避免反冲洗损伤膜表面功能层。在跨膜压差为0.025 MPa、聚合氯化铝投加量为2 g·L−1条件下,采用停歇2 min、运行8 min操作方式,PVDF超滤膜可在膜通量为80 L·(m2·h)−1以上连续运行50 h,COD、浊度、色度的平均去除率分别可达79.1%、99.9%和99.4%,满足我国《工业用水水质标准》(GB/T 19923-2005)中循环冷却水系统补水要求,且清洗后水通量可恢复95%以上,表明该技术具有深度处理脱墨废水的应用潜力。Abstract: A pilot study on advanced treatment of the deinking wastewater from the secondary sedimentation tank in a paper mill was conducted using a hybrid process of enhanced coagulation at a high dosage of polyaluminum chloride (PACl) and flat-plate ultrafiltration in turn-around cross-flow mode. The applicability of the process was evaluated from some aspects including the operation mode, the membrane type, the cleaning mode, and the stability of long-term operation. The experimental results showed that an intermittent operation could effectively reduce the cake layer resistance (Rc) and the concentration polarization resistance (Rg), alleviate membrane fouling, and improve water flux and effluent quality. The PVDF membrane with hydrophilicity and higher molecular weight cut-off (30 kD) could alleviate membrane fouling and improve water yield and effluent quality, and consequently be more suitable for treating the deinking wastewater than the PES membrane with a MWCO of 8 kD. The simultaneous flushing along membrane surface and backwashing could effectively remove the foulants on membrane surface or in membrane pore, and significantly reduced Rc, Rg, and the pore blocking resistance (Rf). Furthermore, backwashing could avoid the damage to the active layer of membrane. The PVDF membrane could continuously run for 50 h at the PACl dosage of 2 g·L−1, with a flux of 80 L·m−2·h−1 or more under the TMP of 0.025 MPa. The average removal rates of COD, turbidity, and chroma could reach 79.1%, 99.9% and 99.4%, respectively, which can meet the requirements of The reuse of urban recycling water – Water quality standard for industrial use (GB/T 19923-2005). Moreover, the flux recovery rate could reach over 95% after cleaning. All these indicate the hybrid process is feasible for advanced treatment of the deinking wastewater.

-

颗粒物过滤技术在环境保护、职业卫生、医疗健康等领域具有广泛应用[1-4]。无论是在工业上用于处理废气的除尘滤袋,还是在劳动保护中用于净化空气的防尘口罩,纤维过滤材料在减少颗粒物排放及污染暴露中发挥着重要作用[5-7]。颗粒物过滤效果容易受到纤维材料的本身特性及外在环境条件的影响[8-9]。以往工程实践表明,环境相对湿度 (RH) 是影响颗粒物过滤效果的主要因素之一,影响程度的高低与湿度大小、粉尘成分、颗粒粒径、滤料性质等多方面的参数相关[10-12]。

在工业除尘领域,环境湿度过高往往容易引起过滤除尘效果出现衰减。王晓明[13]测试了袋式除尘器在水泥厂的实际应用情况,发现高湿度会导致粉尘黏附在滤料表面且无法通过脉冲清灰去除,严重时会导致除尘器效率显著降低、能耗大幅增加。KHIROUNI等[14]分析了冶金行业过滤除尘器的使用情况,发现环境湿度升高会引起金属氧化物颗粒沉积附着在滤料表面,造成除尘器压降显著升高。王辉[15]测试了不同相对湿度下过滤材料的强力特性变化,发现环境湿度升高会使滤料的断裂伸长率增加。BOUDHAN等[16]比较了滤袋在干燥空气和潮湿空气下的除尘效果,认为湿空气会引起清灰后残余粉尘量的大幅增加,从而减少了过滤元件有效使用寿命。以上学者虽然在应用实践中认识到环境湿度能够对粉尘过滤产生较大影响,但缺乏定量化的研究与系统化的分析,没有得出相对湿度对颗粒物过滤性能的精确影响规律。

在实验研究领域,由于忽视了颗粒物本身特性的影响,研究人员暂未得出较为一致的结论。RIBEYRE等[17]通过研究纳米颗粒在加载过程中的过滤阻力受相对湿度的影响情况,发现粉尘层的压降随着相对湿度的升高发生了增长,而 JOUBERT等[18]却发现暴露在湿空气下的粉尘层会发生压降和比阻力的下降;同样,关于环境湿度对过滤效率的影响,部分学者发现相对湿度对过滤效率的影响不明显,但湿度升高会使过滤效率出现增长[19-20]。因此,湿度对过滤效果的影响是复杂的、多因素的,应更深入地开展精确实验与定量分析以得出较为明确的规律。更为重要的是,除了在实验现象上进行描述之外,对于环境湿度影响颗粒物过滤性能的内在作用机理也需要进一步探究。

本研究主要通过实验方法测试不同湿度等级下加载粉尘颗粒物时纤维过滤材料的过滤效率及阻力变化特性。分别采用纳米和微米级的颗粒以比较不同颗粒尺寸产生的性质差异,并且引入吸湿性与非吸湿性颗粒来使结果更具有代表性。为明确环境相对湿度对颗粒物过滤效果的影响,测试不同环境湿度下颗粒物的过滤阻力、过滤效率和容尘效率的变化规律,以期为空气污染防治中颗粒物过滤技术的应用与改进提供参考。

1. 材料与方法

1.1 实验材料

选用了3种粉尘颗粒进行过滤测试,分别是纳米尺寸的氯化钠 (NaCl) 颗粒、纳米尺寸的氧化铝 (Al2O3) 颗粒,以及微米尺寸的氧化铝颗粒。其中,氯化钠颗粒是常见的吸湿性颗粒,能吸收空气中水蒸气,在湿空气中状态不稳定,相对湿度达到其自身潮解点 (约为75%) 之后会发生潮解液化的现象。而氧化铝颗粒是常见的非吸湿性颗粒,环境湿度变化对颗粒本身性质影响不明显。吸湿性和非吸湿性固体污染物均是空气中常见的粉尘物质,分别进行纳米与微米颗粒的测试则有助于揭示相对湿度对不同粒度粉尘颗粒物过滤性能的影响程度差异。

3种颗粒物的粒度分布如图1所示,其中测量纳米颗粒所用仪器为扫描电迁移率粒径谱仪 (型号:GRIMM 5416-based) ,微米颗粒测试仪器为激光粒度分析仪 (型号为Microtrac S3500) ,纳米氯化钠和氧化铝颗粒的粒径范围为10~1 000 nm。两者浓度峰值所处的粒径范围存在微小差异,微米氧化铝颗粒的中值粒径为2.87 μm。图2展示了这几种颗粒的微观形态。

实验中所用的过滤介质是常见的聚酯纤维滤料,其各项参数如表1所示。聚酯纤维滤料是使用最为广泛的过滤材料之一,常用于工业通风及空气净化系统,也是制造各类滤袋及滤筒的基础材料之一。为了更好地体现出过滤阻力与效率的变化规律,所选用的滤料过滤精度适中且透气性良好。

表 1 测试所用滤料的性能参数Table 1. Properties and parameters of the filter media项目 参数 滤料材质 聚酯纤维 厚度 0.75 mm 平均纤维直径 14.5 μm 滤料基重 208 g·m-2 过滤精度 0.3~2 μm 断裂强力 经向:750 N/5*20 cm纬向:980 N/5*20 cm 允许最高使用温度 150 ℃ 允许连续使用温度 120 ℃ 1.2 实验装置

图3展示了颗粒物过滤性能测试系统,主要包括颗粒发生与分散装置、含湿空气供给装置、滤料测试装置,以及浓度和压降检测装置等。其中,高效过滤器 (HEPA) 用来过滤进入系统的气体中的颗粒物,消除空气中的粉尘对实验结果的影响,调节阀用来调节各条支路上的气体流量。

系统涉及的主要仪器装置包括:气溶胶发生器 (德国Palas AGK-2000) ,用于产生粒径在0.005~15 µm范围内的颗粒物;粉尘颗粒扩散器 (德国Topas SAG-410) ,用于产生分散相的粉尘颗粒,颗粒粒径≤100 μm,气源供给压力≥0.6 MPa;气溶胶中和器 (德国GRIMM 5520) ,用于向电荷分布未知的气溶胶施加平衡电荷分布;差分电迁移率分析仪 (德国GRIMM 55-900) ,用于在线测量颗粒迁移率大小,筛分出具有特定粒径大小的颗粒,以测试滤料过滤效率随颗粒粒径大小的变化情况;凝结核颗粒计数器 (德国GRIMM 5416),用于测量颗粒物的浓度,其浓度检测上限为107 #·cm−3,粒径检测下限为4 nm,响应时间≤3 s;滤料夹用于固定过滤介质,同时提供压降和颗粒浓度的测量接口;真空泵 (中国上海SHZ-S) ,用于向实验系统提供负压与动力,其极限真空度为0.098 MPa,最大流量为90 L·min−1。

1.3 实验方法

过滤效率的测试包括初始过滤效率测试及容尘阶段过滤效率测试2个方面。初始过滤效率需要测量分级效率,即测量洁净滤料对于不同粒径粉尘颗粒的过滤效率。具体是通过差分电迁移率分析仪分别筛分出不同粒径的颗粒,然后用凝结核颗粒计数器分别测量过滤介质上下游的浓度,并根据式 (1) 计算出效率数值。

E(di)=1−Cdown(di)Cup(di) (1) 式中:

E(di) di Cdown(di) Cup(di) 实验中筛分出了6种不同粒径的颗粒,粒径分别为50、100、300、400、500、600 nm。测试时的过滤风速稳定在10 cm·s−1,在测试中设置了不同的环境湿度,用于研究初始过滤效率受环境湿度的影响程度。

容尘阶段过滤效率测试的是所有颗粒的总过滤效率,即是在粉尘沉积过程中测量过滤效率随滤料表面粉尘沉积量的变化情况,其测试方法与初始效率测试方法稍有区别,主要是颗粒供给支路上省去了差分电迁移率分析仪的筛分作用,并将其与颗粒计数器联用以测量上下游的粒谱变化情况。在实验测试中,气流温度始终稳定在20 ℃,并通过调整加湿器功率与气体流量,设置了4个不同的相对湿度等级,分别为20% (误差±2%) 、50% (误差±2%) 、80% (误差±2%) 、100% (误差-3%) 。在颗粒加载开始前和结束后,分别称量了测试滤料,以得到单位面积滤料表面的颗粒沉积质量,并通过式 (2) 计算在颗粒加载过程某一时刻的沉积质量[21]。

mi=∑ij=0(cup,j−cdown,j)×(tj−tj−1)∑nj=0(cup,j−ccon,j)×(tj−tj−1)⋅M (2) 式中:

mi cup,j cdown,j tj M 除了测量过滤效率之外,同时比较了不同湿度下颗粒在加载过程中过滤阻力的变化情况,其中滤料和粉尘层的总阻力可用式 (3) 表示[22]。

ΔP=R⋅μ⋅vf+Kc⋅μ⋅msSf⋅vf (3) 式中:

ΔP R μ vf Kc ms Sf 其中粉尘层的比阻系数

Kc Kc=180(1−ε)⋅ε−3⋅(ρPϕ2sds2)−1 (4) 式中:

ε ρP ϕs ds 2. 结果与讨论

2.1 相对湿度对过滤阻力的影响

图4展示了滤料在10 cm·s−1的恒定过滤风速下加载不同颗粒时的压降变化情况。对于研究中任意颗粒物,滤料的压降始终都会随着粉尘沉积质量的增加而不断增长,只是相对湿度会对压降增长的变化率产生影响。对于氯化钠颗粒,在相对湿度为20%和50%时,滤料在颗粒加载过程中的压降基本上呈现线性增长的趋势。在较高的湿度环境下,压降增长更为缓慢。在20%的相对湿度下,滤料单位表面的颗粒沉积质量浓度为18.15 g·m−2时,滤料的压降增长到391 Pa,而在相对湿度提升至50%后,处于相近的压降水平 (387 Pa) ,滤料单位表面的颗粒沉积质量浓度达到了37.73 g·m−2。由此可见,相对湿度对于氯化钠颗粒加载过程的压降变化产生的影响较为显著。

而在相对湿度为80%和100%的环境下,压降增长的趋势却发生了明显改变,不再具有线性增长的趋势。在一段时间的颗粒沉积过后,压降突然出现大幅提升,且增长速率十分迅速。其原因是由于氯化钠颗粒本身作为吸湿性粉尘,在环境相对湿度超过其自身潮解点之后,会发生潮解现象,不再保持完整的固体颗粒状态。因此,压降的大幅增加是由于在高湿度情况下,过滤状态由固体气溶胶的过滤转换成了液体过滤所导致的,原本沉积在滤料表面的颗粒潮解后转化为小液滴覆盖在滤料纤维表面并逐渐形成了液膜。另外,滤料在初始阶段依然经历了一段时间的线性增长,这可能是由于部分氯化钠颗粒尚未完全潮解,或者是颗粒潮解量不足,还没有引起纤维之间液膜的完全形成。

纳米氧化铝颗粒作为非吸湿性粉尘,在颗粒加载过程中没有出现颗粒物潮解或形变的情况,整体的压降增长速率变化也不明显,但是在不同相对湿度下还是能看出一定程度的区分。在3种相对湿度 (20%、50%和80%) 下,压降增长的速率随着相对湿度的增高而逐渐降低,但是相差的并不是很大,滤料单位表面颗粒沉积质量浓度分别为19.07、19.53和20.29 mg·m−2时,压降分别为327、302和299 Pa,三者之间的差距不足30 Pa。因此,相对于吸湿性的氯化钠颗粒而言,非吸湿性的纳米氧化铝颗粒受相对湿度的影响要小的多。然而,在相对湿度达到100%后,滤料压降的增长速率并未出现预料中的继续下降,反而出现了一定程度的增加,同样的现象也出现在了微米氧化铝颗粒的加载过程中。如图4 (c) 所示,饱和湿度下的压降增长率明显高于其余湿度等级下的增长率。此外,对比微米级和纳米级氧化铝颗粒加载过程中的压降增长特征发现,微米级氧化铝颗粒的压降增长更为平缓,且除饱和湿度外,其余测试湿度环境下的压降增长几乎没有明显区别,增长速率也十分接近。由此推测,相对湿度对于纳米氧化铝颗粒的影响比微米氧化铝颗粒更为显著。

由式 (4) 可知,粉尘层比阻系数与粉尘层的孔隙率密切相关,且比阻系数越高,代表孔隙率越低。因此,从以上比阻系数的计算结果可得出:除去饱和湿度这一特殊情况,对于纳米颗粒构成的粉尘层,无论颗粒是吸湿性或者非吸湿性,粉尘层的孔隙率均随着相对湿度的升高而升高。但在本研究中,对于微米级颗粒形成的粉尘层,其孔隙率受相对湿度影响不明显,且微米级颗粒粉尘层的孔隙率要明显大于纳米级颗粒粉尘层的孔隙率。这也意味着尺寸更大的微米级颗粒在滤料表面沉积的过程中,形成的粉尘层更加疏松、透气性更好。然而,在100%相对湿度的环境下,微米和纳米氧化铝颗粒层均出现了孔隙率突然下降的现象,实际上如果将氯化钠颗粒潮解,形成液膜后压降骤然上升的情况考虑在内,孔隙率在高湿度的环境下也同样是下降的。因此,推测高湿度必然会影响颗粒在滤料表面的沉积方式和沉积形态,进而导致粉尘层孔隙率发生改变。

为进一步探究相对湿度对于颗粒物加载特征的影响,根据公式 (3) 计算不同相对湿度下各颗粒物构成的粉尘层比阻系数,结果如图5所示。对于氯化钠颗粒 (注:因为该状态下不属于严格意义上的颗粒层,未将高湿度下液膜形成后的结果包括在内,即非线性增长阶段的数据) ,粉尘层比阻系数随着相对湿度的增长在不断下降。同样,对于纳米氧化铝颗粒,除了饱和湿度外,比阻系数也是随着相对湿度增加在降低,而对于微米氧化铝颗粒,比阻系数变化却不明显,但在饱和湿度下同样出现了显著增长。

图6对比了低湿度 (RH20%) 和高湿度 (RH100%) 环境下滤料表面颗粒沉积的表面形貌。低湿度下氯化钠颗粒以树枝状团簇的形态附着在滤料纤维上,虽然颗粒簇交叉在一起,缩小了纤维之间的孔隙,但滤料依然具有一定通气孔道,保持着良好的透气性。并且,低湿度下吸湿性氯化钠颗粒与非吸湿性氧化铝颗粒两者在滤料表面沉积状态的差异也不明显。这与实验测量的数据情况基本上是吻合的,两者在低湿度下的压降上升曲线也具有一定程度相似性。而在高湿度情况下,沉积在纤维表面的氯化钠因为潮解已转化为了液滴状,并且随着颗粒的不断积累,在后期已形成了覆盖在滤料表层的液膜,完全堵塞住了纤维之间的孔隙。因此,在颗粒沉积后期,监测到压降突然升高亦为正常现象。

值得注意的是,对于氧化铝颗粒,滤料表面同样也出现了部分液膜,且还夹杂着部分粉尘颗粒的团聚体。这一情况可能与饱和湿度下水蒸汽的凝结有关。在湿度达到或者接近100%时,空气中的水蒸气会处于一种不稳定的状态,湿空气在流经纤维间的孔隙时,由于发生气流扰动,水蒸气本身便容易发生凝结和液化,并且滤料纤维和纤维上的沉积颗粒在一定程度上能充当凝结核的作用,促进凝结作用的形成以降低空气中的饱和度。PEI等[23]指出,颗粒沉积在过滤介质表面后,相邻颗粒间形成的间隙是水蒸气发生凝结的理想场所,即便在低湿度的环境下,也会发生一定程度的蒸汽凝结现象。而这些以颗粒为中心凝结成的液滴随即会附着在颗粒表面,并随着沉积颗粒和凝结液滴的增多,最终颗粒的团聚体和铺展开来的液滴将会混合在一起覆盖在滤料表层,堵塞住表面的网孔。这一过程也是滤料压降快速提升的阶段。

上文已经阐述,在较高相对湿度下,尤其是在接近饱和湿度后,水蒸气凝结形成的液膜是影响滤料阻力特性的一个重要因素,而对于其他未达到饱和状态下的湿度等级,滤料的孔隙率会随着相对湿度的增加而增加,从而延缓阻力增长的速度。这一现象可从颗粒间液桥力作用的角度进行分析,液桥力是颗粒间重要作用力之一。液桥力会随着相对湿度的增加而变得更加显著,从而增大颗粒间粘附作用,因此在较高湿度下,被捕集的颗粒倾向于粘附在已沉积的颗粒上,形成结构更加开放的颗粒层,而不是滑移至纤维间的孔隙造成严重的堵塞,但这一作用对于微米级及以上尺寸颗粒的影响不明显[20, 24];另一方面,纤维上沉积的颗粒团聚形态在湿度升高后也会发生明显转变 (图7) ,树枝状的团簇会发生结构收缩,进一步粘附在介质纤维的表面,减少了颗粒团聚体的表面积,也产生了更加通畅的风流通道。这一过程也被MONTGOMERY等[25]通过荧光显微镜观察到,并在颗粒迁移率测试中得到证实。总之,相对湿度的升高改变了微观上的颗粒沉积模式,并导致加载过程中压降增长率发生变化。这一过程根据颗粒尺寸和环境相对湿度的不同,造成的影响程度也不尽相同。

2.2 相对湿度对初始过滤效率的影响

首先测试了不同相对湿度下滤料的初始过滤效率值,所用的测试气溶胶分别为吸湿性的氯化钠颗粒和非吸湿性的纳米氧化铝颗粒,测试结果如图8所示。不同相对湿度下的过滤效率随颗粒粒径的变化曲线并未发生显著变化。不仅如此,同一粒径大小的氯化钠颗粒和氧化铝颗粒测得的过滤效率值也非常接近。这说明初始过滤效率对环境中相对湿度的变化不敏感,也不会受到颗粒吸湿性能差别的影响。由于初始效率的测试时间较为短暂,滤料表面尚未形成有效的颗粒沉积,且在较短时间内颗粒本身也无法发生潮解,因此在本研究中,初始效率只受到了滤料自身结构和颗粒粒径大小的影响,并且随着粒径的增大呈现出先下降后升高的趋势。在粒径大小为100 nm时,所测得过滤效率达到了最低值,约为 (0.665±0.01) 。这一规律也与机械过滤机制相吻合,对于粒径较小的颗粒,扩散效应起到主导作用,而随着粒径的不断增大,扩散效应会逐渐减弱,惯性碰撞和拦截筛分等作用机制会逐渐增强。而其中存在一段粒径范围,扩散效应已经明显减弱,惯性碰撞和拦截筛分作用尚未有效增强,从而导致过滤效率发生一定程度下降。尽管对于不同的机械过滤材料,其过滤效率出现下降时所处的粒径范围存在一定差别,但该规律与之前学者的研究结果也基本一致[26-27] 。

2.3 相对湿度对容尘过滤效率的影响

相比于初始过滤效率,氯化钠颗粒在沉积过程中过滤效率的变化体现出较大的差异性 (图9)。在相对湿度低于其自身潮解点时,过滤效率呈现出缓慢但持续增加的趋势。这表明颗粒物在滤料纤维上的堆积,进一步减小了纤维之间的孔隙,增强了对微小颗粒的捕集作用,并且20%相对湿度下过滤效率的增长要高于50%相对湿度下的增长速率。这可能是由于较低湿度下形成的颗粒层孔隙率更低,对各项过滤机制作用效果的提升也更加显著。而对于相对湿度超过氯化钠潮解点的情况,过滤效率则展现出了截然相反的变化趋势,随着颗粒沉积在不断下降。这一现象明显区别于固体颗粒物的过滤机制,却与液体过滤的情况相吻合。在氯化钠颗粒完全潮解后,会转变为液滴附着在纤维表面;在液膜还未完全成型之前,液滴会在自身毛细力的作用下润湿整个纤维,造成纤维的实际直径增大。而纤维直径是影响滤料过滤效率的重要因素,纤维直径的增大通常会使过滤效率发生下降[21]。此外,由于颗粒液化后更容易随风流穿透滤料,过滤效率下降的原因也可能与部分液滴逃逸至过滤器下游有关。

对于非吸湿性的纳米氧化铝颗粒,相对湿度对其过滤效率所造成的影响并不明显,整体过滤效率缓慢增长的趋势也符合机械过滤的机制,如图9 (b) 所示。尽管效率增长差异比较小,但仍可发现在不同相对湿度下存在细微区分。对于20%、50%和80% 3个湿度等级,过滤效率的增长率随着湿度的增加在不断下降,在颗粒沉积初期时 (约在沉积质量浓度达到15 g·m−2之前) ,100%相对湿度下的效率增长也符合这一规律。但是在此之后,饱和湿度下效率增长的速度开始快速提升,效率值逐渐超过了其他湿度下的数值。结合压降增长曲线可发现,压降值快速升高的阶段也同样出现在这一时期。由此可推测,该时期滤料纤维或者颗粒层的孔隙产生了堵塞加剧情况,导致压降和过滤效率都出现了一定程度的升高。

微米氧化铝颗粒也出现了类似的情况,饱和湿度下的效率增长较为显著,而其余湿度等级下的效率增长曲线不存在明显的区分度 (如图9 (c) 所示) 。事实上,在颗粒沉积的后期,对微米颗粒的过滤效率已接近了100%,这或许也是无法看出区分度的一个实验因素。但可确定的是,对于非吸湿性颗粒,过高的湿度 (尤其是在接近饱和时) 在一定程度上加快了颗粒沉积过程中过滤效率的提升。当然这种提升效果也相对有限。

3. 结论

1) 吸湿性颗粒与非吸湿性颗粒加载过程中的阻力增长特性受相对湿度的影响程度不同。对于吸湿性颗粒,相对湿度为20%和50%时,压降呈现线性增长趋势,相对湿度升高至颗粒潮解点后,压降增长速度大幅提升。非吸湿性颗粒受相对湿度影响较小,压降增长速率变化不明显,在3种相对湿度 (20%、50%和80%) 下,颗粒沉积质量浓度为19.07、19.53和20.29 mg·m−2时,对应压降分别达到327、302和299 Pa。

2) 滤料初始过滤效率对环境中相对湿度的变化不敏感,也不会受到颗粒吸湿性能差别的影响,同一粒径大小的氯化钠颗粒和氧化铝颗粒在不同湿度下测得的过滤效率值较为接近;并且滤料初始效率会随着粒径的增大呈现出先下降后升高的趋势,在粒径大小为100 nm时,实验测得的过滤效率达到最低值,为 (0.665±0.01) 。

3) 吸湿性颗粒在沉积过程中过滤效率的变化受相对湿度影响较大。在湿度低于其自身潮解点时,过滤效率缓慢持续的增加;在湿度超过潮解点后,过滤效率会随着颗粒沉积不断下降。对于非吸湿性颗粒,不同相对湿度下其容尘过滤效率呈现缓慢增长趋势。在颗粒沉积质量浓度达到15 g·m−2后,100%相对湿度下的效率增长速度出现了较大提升。

-

表 1 实验用水水质特征

Table 1. Characteristics of the raw water from the secondary clarifier

统计值 浊度/NTU pH 色度/CU COD/(mg·L-1) 范围值 108~1969 6.94~8.22 323~1980 214~650 平均值 177.8 7.45 981.3 412.4 表 2 超滤膜参数

Table 2. Parameters of ultrafiltration membranes

实验用膜 材质 截留分子质量/Da 接触角/(°) PVDF 聚偏氟乙烯 30 000 62 PES 聚醚砜 8 000 92 表 3 不同超滤膜操作条件

Table 3. Different ultrafiltration membrane operating conditions

实验用膜 跨膜压差/MPa 纯水通量/L·(m2·h)−1 膜固有阻力/m−1 药剂及投加量 运行方式 PVDF 0.025 177.39±13.96 (2.64±0.21)×1011 2 g·L−1 PACl 运行8 min,停歇2 min,运行期间不清洗 PES 0.1 103.89 ±7.96 (1.80±0.14)×1012 -

[1] LIU Y, SHEN W H, MAN Y, et al. Optimal scheduling ratio of recycling waste paper with NSGAII based on deinked-pulp properties prediction[J]. Computers & Industrial Engineering, 2019, 132: 74-83. [2] KUMAR A, SRIVASTAVA N K, GERA P. Removal of color from pulp and paper mill wastewater- methods and techniques- A review[J]. Journal of Environmental Management, 2021, 298: 1-12. [3] KUMAR A, CHANDRA R. Biodegradation and toxicity reduction of pulp paper mill wastewater by isolated laccase producing Bacillus cereus AKRC03[J]. Cleaner Engineering and Technology, 2021, 4: 1-10. [4] KAMALI M, ALAVI-BORAZJANI S A, KHODAPARAST Z, et al. Additive and additive-free treatment technologies for pulp and paper mill effluents: Advances, challenges and opportunities[J]. Water Resources and Industry, 2019, 21: 1-22. [5] TIAN J Y, WU C W, YU H R. Applying ultraviolet/persulfate (UV/PS) pre-oxidation for controlling ultrafiltration membrane fouling by natural organic matter (NOM) in surface water[J]. Water Research, 2018, 132: 190-199. doi: 10.1016/j.watres.2018.01.005 [6] KAYA Y, CONDER Z B, VERGILI I, et al. The effect of transmembrane pressure and pH on treatment of paper machine process waters by using a two-step nanofiltration process: Flux decline analysis[J]. Desalination, 2010, 250: 150-157. doi: 10.1016/j.desal.2009.06.034 [7] SHUKLA S K, KUMAR V, MUDGAL M. , et al. Utilization of concentrate of membrane filtration of bleach plant effluent in brick production[J]. Journal of Hazardous Materials, 2010, 184: 585-590. doi: 10.1016/j.jhazmat.2010.08.075 [8] ARKELL A, OLSSON J, WALLBERG O. Process performance in lignin separation from softwood black liquor by membrane filtration[J]. Chemical Engineering Research and Design, 2014, 92: 1792-1800. doi: 10.1016/j.cherd.2013.12.018 [9] 李泓, 梁晴晴, 张玉忠. 膜分离技术处理造纸废水的研究进展[J]. 山东化工, 2020, 49(2): 69-70. doi: 10.3969/j.issn.1008-021X.2020.02.025 [10] UPTON B H, CULLINAN H T, ABUBAKR S, et al. Effects of operating variables on ultrafiltration of flexographic pigments from wash deinking filtrate[J]. Appita Journal, 1997, 50: 113-120. [11] 唐吴晓, 李卫星, 邢卫红. MBR处理造纸废水时膜污染的缓解因素[J]. 膜科学与技术, 2016, 36(2): 102-107. [12] YAN M J, SHEN X, GAO B Y, et al. Coagulation-ultrafiltration integrated process for membrane fouling control: Influence of Al species and SUVA values of water[J]. Science of the Total Environment, 2021, 793: 1-10. [13] MA B W, XUE W J, BAI Y H, et al. Enhanced alleviation of ultrafiltration membrane fouling by regulating cake layer thickness with pre-coagulation during drinking water treatment[J]. Journal of Membrane Science, 2020, 596: 1-11. [14] YU W Z, XU L, QU J H, et al. Investigation of pre-coagulation and powder activate carbon adsorption on ultrafiltration membrane fouling[J]. Journal of Membrane Science, 2014, 459: 157-168. doi: 10.1016/j.memsci.2014.02.005 [15] SILLANPAA M, NCIBI M C, MATILAINEN A, et al. Removal of natural organic matter in drinking water treatment by coagulation: A comprehensive review[J]. Chemosphere, 2018, 190: 54-71. doi: 10.1016/j.chemosphere.2017.09.113 [16] WU Y, ZHANG Z G, HE P R, et al. Membrane fouling in a hybrid process of enhanced coagulation at high coagulant dosage and cross-flow ultrafiltration for deinking wastewater tertiary treatment[J]. Journal of Cleaner Production, 2019, 230: 1027-1035. doi: 10.1016/j.jclepro.2019.05.139 [17] 杨海洋. 混凝/超滤处理为污染地表水及滤饼调控去除污染物研究[D]. 哈尔滨: 哈尔滨工业大学, 2017. [18] 黄韵清, 孙傅, 曾思育, 等. 污水深度处理中超滤工艺对有机物的截留模型[J]. 中国环境科学, 2015, 35(2): 420-426. [19] 孙丽华, 刘烨辉, 吕静静, 等. 不同超滤膜处理二级出水的膜污染机制研究[J]. 应用化工, 2020, 49(8): 1883-1887. doi: 10.3969/j.issn.1671-3206.2020.08.004 [20] TAVAKOLMOGHADAM M, MONHAMMAD T, HEMMATI M, et al. Surface modification of PVDF membranes by sputtered TiO2: Fouling reduction potential in membrane bioreactors[J]. Desalination Water Treatment, 2014, 57(8): 3328-3338. [21] ZHAO S F, LIAO Z P, FANE A, et al. Engineering antifouling reverse osmosis membranes: A review[J]. Desalination, 2021, 499: 114857. doi: 10.1016/j.desal.2020.114857 [22] ZHANG M, LIAO B Q, ZHOU X, et al. Effects of hydrophilicity/hydrophobicity of membrane on membrane fouling in a submerged membrane bioreactor[J]. Bioresource Technology, 2015, 175: 59-67. doi: 10.1016/j.biortech.2014.10.058 [23] 刘彦伶, 李天玉, 王小, 等. 高压膜表面性质对膜污染的影响机制[J]. 环境工程, 2021, 39(7): 46-53. [24] NINOMIYA Y, KIMURA K, SATO T, et al. High-flux operation of MBRs with ceramic flat-sheet membranes made possible by intensive membrane cleaning: Tests with real domestic wastewater under low-temperature conditions[J]. Water Research, 2020, 181: 1-9. -

下载:

下载: