-

餐厨垃圾和污泥是两种常见的有机固体废物。其中,餐厨垃圾在城市生活垃圾中的占比高达20%~45%[1],污泥年产量已经突破6×107 t (80%含水率)[2],如此巨大数量的有机固废给环境治理带来了严峻挑战。餐厨垃圾和污泥都有着含水率高、有机质丰富和易腐败发臭等特点。此外,两者均含有有害物质,如病原菌和寄生虫卵等[3-4],若不加以处理可能会危害人群健康。目前,我国处理餐厨垃圾和污泥的方法有卫生填埋、焚烧和堆肥等[5]。其中,卫生填埋需要占用大量土地并可能产生渗滤液和温室气体[6];焚烧受制于餐厨垃圾和污泥的高含水率和低热值,而且还可能产生二恶英等废气。相比之下,好氧堆肥有着操作简单、设备投资少、工艺成熟等优点,在实现有机固废“减量化、无害化和资源化”方面得到了广泛应用。

好氧堆肥的原理是利用微生物的代谢活动快速分解底物中的有机成分,在底物减量的同时产热,致使堆体迅速升温杀死其中的寄生虫和病原菌,最终形成有机肥并用于调理土壤[7-9]。单独将餐厨垃圾进行堆肥得到的腐殖质因缺乏P和K等植物营养元素,导致肥效不佳;而污泥中含有丰富的P和K等元素[6],且污泥中还存在多种分解有机物的细菌和真菌。因此,用餐厨垃圾和污泥联合堆肥,不仅能够提高堆肥效率,还可以得到更有价值的腐熟产品,故有利于这两种固体废物的资源化利用。MA等[10]将餐厨垃圾和污泥以不同比例混合进行联合生物处理,证明了餐厨垃圾和污泥协同作用下有着更好的处理效果。ZHANG等[11]研究了不同比例下,餐厨垃圾和污泥联合堆肥情况,结果表明,1∶1湿重配比下得到的腐殖质肥效较单独污泥堆肥更佳。

微生物在好氧堆肥中起着重要作用,其功能是分解有机物。但是,在自然堆肥过程中存在的微生物生长周期长,难以在短时间内实现快速堆肥;而人工筛选的微生物菌剂或腐熟堆肥因具有特定的细菌或真菌,能够有针对性地分解堆体内的有机成分,最终达到提高效率、增强肥效的目的。周营等[5]向餐厨垃圾堆肥中投加复配微生物菌剂,降低了氮素损失;JURADO等[12]发现,接种菌剂后堆体内难分解的半纤维素、纤维素和木质素的降解率分别提高了28%、21%和25%。腐熟堆肥是餐厨垃圾、污泥或粪便等的堆肥腐熟产品,具有多孔结构、含水率低等特点,并且富含微生物,将其添加至堆体中也能对堆肥起到促进作用。马强等[13]发现,在生活垃圾好氧发酵时投加腐熟污泥堆肥能够有效减少氮素损失;YANG等[6]采取覆盖和混合两种方式将腐熟堆肥加入到餐厨垃圾堆肥中,结果表明,混合添加的腐熟堆肥在减少温室气体排放和提高肥效方面有着更显著的作用。由此可见,微生物菌剂和腐熟堆肥的添加能够对好氧堆肥起到很好的促进作用。

目前,大多数研究集中在向单一堆肥组分中添加微生物菌剂或腐熟堆肥,如单独餐厨垃圾堆肥[6]、单独污泥堆肥[14]、单独猪粪堆肥[15]等,向餐厨垃圾和污泥联合好氧堆肥中投加外源菌剂或腐熟堆肥的报道较少,且其理化性质的变化尚不清楚。因此,本实验选用微生物菌剂和腐熟堆肥作为添加剂,以不添加任何外源物作为对照,并以废木屑作为膨胀剂调节C/N、含水率及孔隙率,通过测定相关理化指标和营养元素的变化,并结合腐熟指标,探究这两种添加剂对餐厨垃圾和污泥联合堆肥的影响,以期为联合堆肥研究提供参考。

-

堆肥所用餐厨垃圾收集于北京市某高校食堂,人工去除骨头等杂物后经清水冲洗掉油和盐,再用粉碎机将其粉碎至糊状。脱水污泥取自北京市某污水处理厂。废木屑收集于北京市某家具城,其粒径为1~2 cm。微生物菌剂购买于山东某生物公司,主要菌种为放线菌、芽孢杆菌、酵母菌和乳酸菌等。其中,放线菌和酵母菌是嗜热菌,能够分解复杂有机物,芽孢杆菌和乳酸菌对堆肥过程中氮素转化有重要影响[16-17]。腐熟堆肥为餐厨垃圾堆肥实验所得的腐熟产物。

实验装置为圆柱桶型,有效容积为5 L,反应器周围用20 mm厚的保温材料减少热量散失,中间有搅拌桨用于搅匀物料,底部设置曝气装置进行通风供氧,采用间歇曝气方式,每12 h通风1次,通风速率为0.4 L·min−1。

-

本实验以餐厨垃圾和污泥湿重1∶1混合作为联合堆肥底物,以分别添加底物总重15%(湿重)的微生物菌剂和腐熟堆肥为处理组1 (T 1)和处理组2 (T 2),没有任何外源剂投加的为对照组(CK)。3个反应堆体均加入底物总重30%(湿重)的废木屑,将原料调节到合适的含水率和C/N,各堆体的原始理化性质如表1所示。堆肥时间设计为15 d,从实验开始每隔3 d进行1次翻堆,翻堆后分别从各堆体的上、中、下位置多点取相同量的样品,混合均匀后取适量样品将其制备成浸提液用于理化指标的测定。浸提液的制备方法为新鲜样品与去离子水按1∶10配比后在26 ℃恒温震荡器中震荡2 h,随后以3 000 r∙min−1速率离心10 min,过0.45 μm的滤膜后取上清液进行理化指标的测定。

-

温度采用插入式感应测温仪每24 h测量1次;pH采用pH计测定浸提液确定;含水率采用重量法测定;氧化还原电位(Oxidation Reduction Potential,ORP)采用氧化还原电极头测定;电导率(Electrical Conductivity,EC)采用CT−20 型便携电导率仪测定;挥发性固体含量(Volatile Solids,VS)采用灼烧法确定。

总有机碳(Total Organic Carbon,TOC)采用《土壤检测标准》(NY/T 1121.6—2006)[18]提供的方法测定;总氮(Total Nitrogen,TN)采用元素分析仪测定;C/N为总有机碳量/总氮量。

腐殖酸光学特性E4/E6(即浸提液在465 nm和665 nm波长处的UV−Vis吸光度比值)的值采用HACH DR600型紫外可见光分光光度计测定;种子发芽指数(Germination Index,GI)的测定参考文献[19],计算方法见式(1)。

-

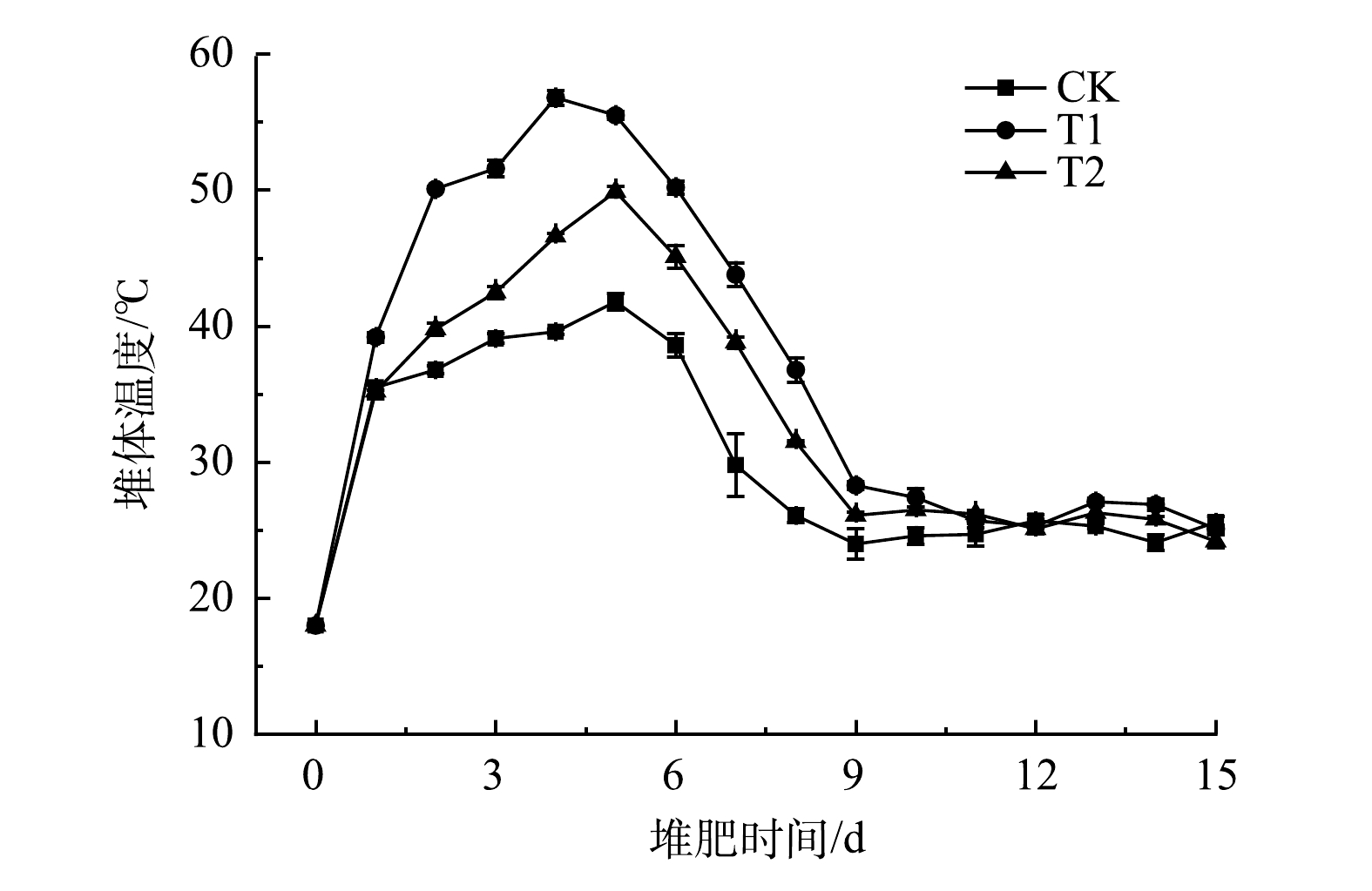

温度是好氧堆肥的重要参数之一,其变化可以反映出堆体内微生物的代谢活动强弱和堆肥效率[20]。好氧堆肥通常经历3个温度变化阶段:升温期→高温期→降温期。图1所示为本实验3个堆体的温度变化曲线。T1、T2和CK都经历了先快速升温到达最高值后逐渐下降到接近室温的稳定水平。3个堆体的温度分别在第5 d、第4 d和第5 d达到最高值41.8、56.8和49.9 ℃。T1处理的峰值温度和升温速率明显高于T2和CK组,且高温期(>50 ℃)持续了5 d,满足堆肥安全卫生标准[21]。微生物利用堆体内丰富的有机物进行代谢和繁殖,并产生了大量的热,致使堆肥温度在前期迅速升高,之后随着易降解有机质的消耗,堆体温度随之逐渐下降。相比之下,虽然添加微生物菌剂和腐熟堆肥均能提高堆肥温度,但是在延长高温期持续时间方面菌剂效果更好。T1处理组添加的微生物菌剂中含有放线菌,这是一种典型的嗜热细菌[17],能够在高温条件下生长并降解复杂有机物。这可能是T1能够长期保持高温状态的原因。

-

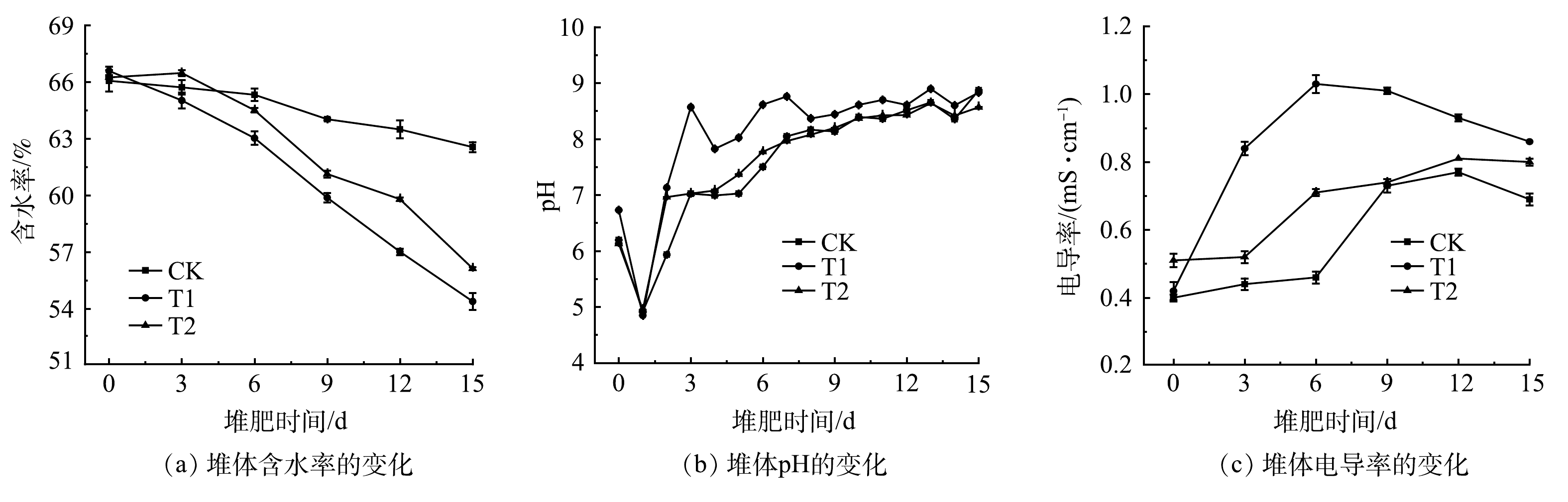

1)含水率、pH和电导率。含水率是保证堆肥正常进行的重要条件,含水率过高或过低都会影响微生物的代谢活动[8]。因此,在本研究中,初始含水率都被调到65%左右以保证堆肥正常进行。如图2(a)所示,随着堆肥进行,3个堆体含水率都呈现出下降的趋势,堆肥结束时,T1、T2和CK的含水率分别为56.15%、54.40%和62.56%。在堆肥初期,适宜的含水率和大量易降解有机质利于微生物快速代谢和增殖,促进体系内温度快速升高(图1)。其中,水分一部分用于微生物生长,一部分被蒸发,两者共同作用导致含水率的下降[22]。在堆肥至第9 d后,3个堆体的温度没有出现太大的变化(图1),而含水率持续下降。由此可推测堆肥后期水分蒸发是含水率降低的主要原因。从含水率变化来看,投加菌剂可以更好地提高微生物活性,微生物分解有机物产生热量造成了更多的水分蒸发损失。这一点和温度的变化是一致的(图1)。

pH是堆肥过程中一个重要参数,其变化能够影响到微生物的活性,适当控制pH可以促进堆肥有机物的降解[8,23]。图2(b)为3个不同处理堆体的pH变化曲线,总体呈现出逐渐增加的趋势。到堆肥结束时,T1、T2和CK组的pH分别稳定在8.83、8.57和8.87。这与之前的相关研究结果一致[24]。在堆肥前期,所有堆体的pH均出现了下降,并在第24 h时达到最低值。这可能是堆肥前期易降解的有机质被微生物利用时产生了部分有机酸[25]。随着堆肥的进行,pH都逐渐增加并最终稳定在弱碱性范围内。究其原因,一方面是温度升高导致有机酸挥发,另一方面是在微生物作用下有机氮发生矿化生成了氨氮,两者共同作用下造成了pH的变化[6]。综合3个处理来看,添加微生物菌剂的T1有着最剧烈的pH变化,T2和CK组的pH变化没有太大的差异。这说明腐熟堆肥的添加对pH的影响效果不如微生物菌剂。

电导率(EC)可以反映出堆肥产品的含盐量,高含盐量会抑制植物生长[26]。3个堆体EC的变化如图2(c)所示,T1和CK组的变化均为先升高后降低,T2则一直呈现轻微的上升趋势。反应结束时,3个堆体EC值分别为0.86、0.80和0.69 mS·cm−1,均有了一定程度的增加。一般认为,只要电导率的阈值不超过4 mS·cm−1就不会对植物生长产生毒性[11],故本实验最终堆肥产品均符合安全堆肥的标准。在T1堆肥前期,由于易降解有机物的矿化作用生成了铵盐和磷酸盐,再加之堆体体积的减少,堆体电导率增加[8];随着小分子有机成分的消耗,电导率逐渐下降。这一点和SONG等[21]的研究结果一致。此外,根据MA等[14]的研究结果,添加腐熟堆肥能够增加降温期脲酶的含量,有利于尿素转化为铵盐,导致T2处理组EC值不断上升。总体来看,添加微生物菌剂的T1处理组有着最剧烈的EC变化。这说明菌剂的加入有利于联合堆肥过程中有机物矿化生成盐类物质。

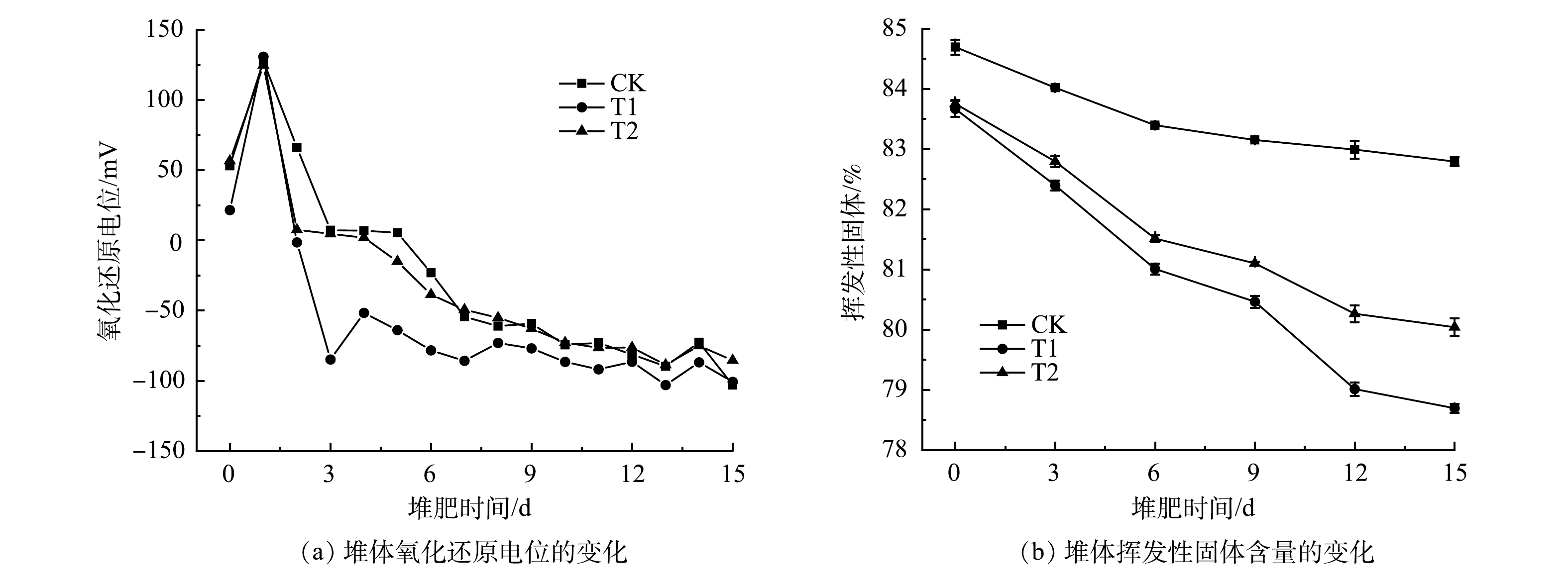

2)氧化还原电位、挥发性固体含量。堆体内氧化还原电位(ORP)的变化可以反映出微生物活性及其对养分的利用情况。由图3(a)可知,3个处理的ORP均呈现出前期升高再逐渐降低,后趋于稳定的趋势。在堆肥最初的24 h里,3个堆体的ORP都达到了最大值,分别为130.8、127.6和124.7 mV。此时,微生物以氧气作为电子受体,利用有机物进行代谢的速率达到最大。随着反应的进行,堆体内的氧气逐渐被消耗,体系内的ORP逐渐降为负值,到反应结束时,3个堆体的ORP分别为−100.8、−85.5和−103.1 mV。整体来看,添加微生物菌剂的T1处理明显低于另外2组。这可能是菌剂中微生物在分解有机物时快速消耗体系内的氧气,而添加腐熟堆肥的T2处理效果不明显,这表明菌剂的加入利于提高微生物活性及其对养分的利用。值得一提的是,从图2(b)和3(a)对比来看,pH和ORP似乎有着相反的变化趋势,即pH越高,所对应的氧化还原电位越低。这和KHALIL等[27]的研究结果一致,而且他们认为,ORP可以作为监测堆肥腐熟的指标。

挥发性固体(VS)的变化如图3(b)所示,3个堆体均呈现出下降趋势。在堆肥结束时,3个堆体的VS都降到最低,分别为78.69%、80.04%和82.79%,分别下跌了5.95%、4.43%和2.24%。以上实验结果表明,T1的VS减少量最多。这可以归因于微生物菌剂的加入增强了细菌和真菌的代谢活动,有机物被快速降解利用。相比于T1和T2处理组,没有任何接种的CK组VS减少量最低。其可能的原因是:CK组缺乏必要的微生物,很难更彻底地分解挥发性有机物。有报道[17]称,放线菌能够在高温条件下生存,其具有降解纤维素和木质素的功能。添加微生物菌剂的T1处理温度高且高温期持续时间长(图1),放线菌分解纤维素和木质素导致T1处理的VS含量减少最多。此外,腐熟堆肥的添加也能促进纤维素和木质素的降解。这是因为,腐熟堆肥中可能存在放线菌,但相较于人工筛选含有放线菌的菌剂,T2的放线菌需要一段时间繁殖才能发挥作用,故T2的VS降解效果不如T1。

-

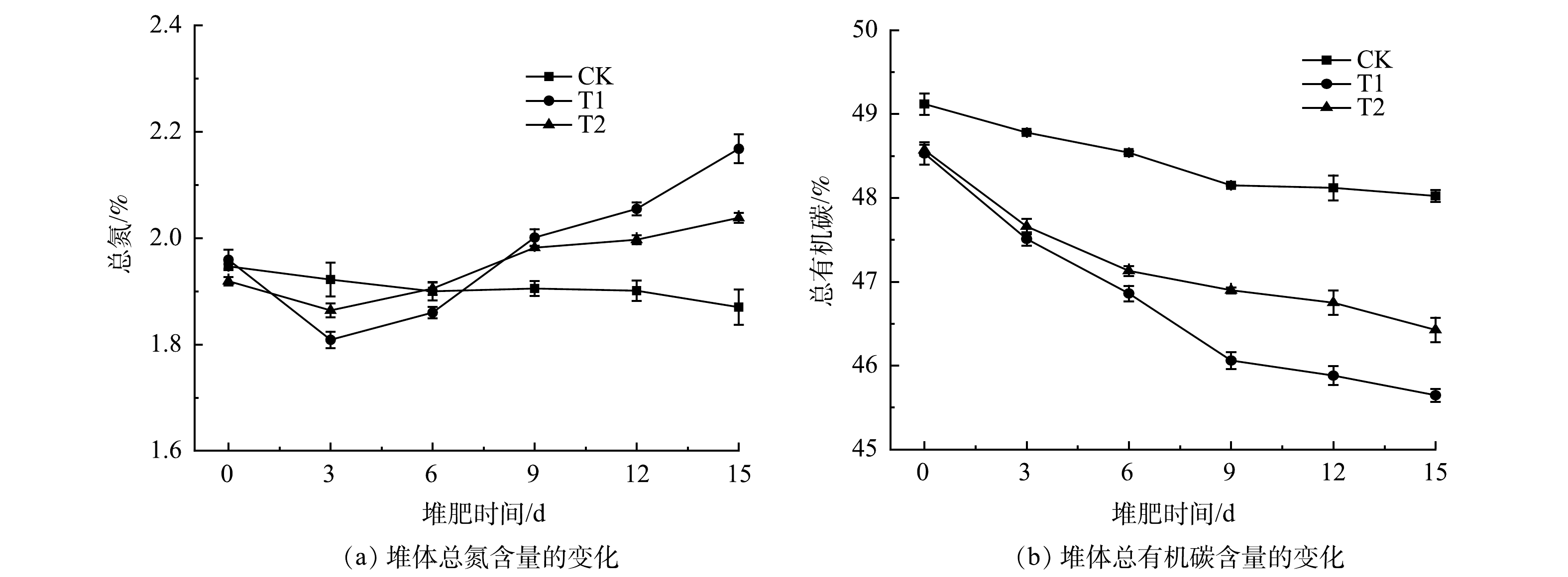

1)总氮(TN)变化。氮(N)是对植物生长起重要作用的元素之一,能够反映出堆肥产品的肥效。3个堆体的TN变化情况如图4(a)所示,T1和T2呈现出先降低后升高的规律,CK组则一直降低。堆肥初期,微生物活性大,堆体快速升温导致氨气挥发。高温能抑制硝化细菌将铵态氮转化为硝态氮的反应,反硝化细菌消耗硝态氮生成氮气加速了氮的损失[13]。随着微生物活动变弱,堆体温度逐渐降低,氮素损失速率低于堆体体积减少速率,造成TN浓度上升。在本研究中,T1处理组在堆肥结束时总氮浓度最高。这是由于添加的菌剂中有芽孢杆菌。根据PARK等[28]的报道,芽孢杆菌是一种具有固氮功能的微生物,将其加入堆肥中可以帮助减少氮素损失以提高肥效。

2) TOC变化。3个堆体的总有机碳变化如图4(b)所示,其规律和VS曲线相似(图3(b)),均呈现出逐渐降低的趋势。在微生物的作用下,堆体内的含碳有机物参与细菌和真菌代谢被转化为CO2,造成堆体总碳含量减少[8]。从图4(b)中可以看出,TOC的快速下降阶段发生在堆肥初期和中期。这是因为,此时微生物相对活性较高,其对C的利用速率也较快。相较于T2和CK,接种菌剂的T1能更大程度地降解TOC,这可能与菌剂中存在酵母菌和放线菌有关。酵母菌由于其微生物特性和孢子样的细胞结构可以耐高温和对抗低水分环境条件[29]。因此,在堆肥后期,在含水率较低情况下(图2(a)),酵母菌可以分泌水解酶降解木质纤维素。而且,放线菌具有分解纤维素的能力,根据MA等[14]的报道,纤维素的降解主要发生在堆肥中后期。所以,T1在堆肥后期TOC依旧能够保持一定程度的消耗可能与酵母菌和放线菌有关。

-

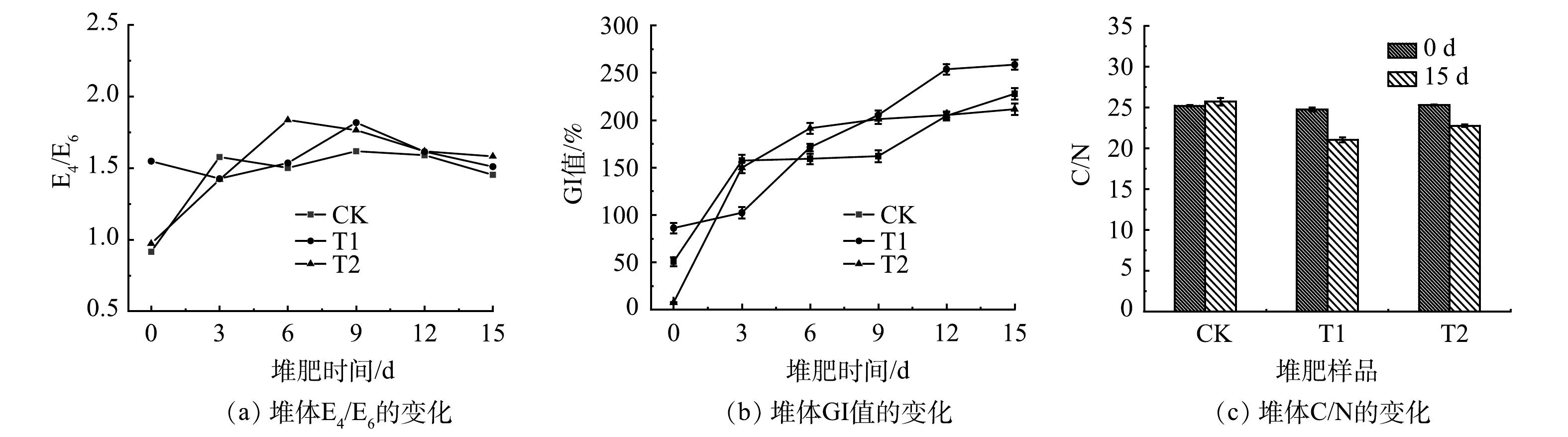

1)腐殖酸光学特性(E4/E6)。有机物的腐殖化程度是衡量堆肥产品质量的农艺标准之一[11]。图5(a)为3个堆体的E4/E6变化曲线,它们大致的规律是均为先升高后降低。T2和CK组从高温期到反应结束,E4/E6值始终高于初始值。这表明大分子的腐殖酸不断分解,堆肥产品的腐殖化程度降低[11]。而添加微生物菌剂的T1中E4/E6在反应结束时有了轻微降低。这表明液相中腐殖酸相对分子质量在增加;该现象可能是外源微生物对餐厨垃圾和污泥中的有机物降解起到促进作用,提高了体系的腐殖化进程[30]。综合来看,向餐厨垃圾和污泥联合堆肥中投加微生物菌剂利于腐殖质的形成,而添加腐熟堆肥相较于对照组则没有明显作用。

2)种子发芽指数(GI)。种子发芽指数是判断堆肥腐熟程度的重要指标,它的大小能反映堆肥产品腐熟程度和植物毒性[20]。由图5(b)可看出,3个堆体的GI值都呈现出逐渐增加的趋势。反应结束时,3个堆体的GI值分别达到了258.54%、211.57%和227.89%。这表明堆肥产品无植物毒性[26]。T1的GI值比CK组高出30.65%。这可能是微生物的加入促进了堆体腐殖化;该现象表明微生物菌剂的投加能够促进堆体腐熟,而腐熟堆肥的添加并不能明显提高GI值,这与MA等[14]的研究结果一致。GI值逐渐升高的原因是:随着堆肥进行,堆体内具有抑制植物生长作用的有机酸和多酚等物质被转化降解,浸提液的植物毒性逐渐被削弱。

3)碳氮比(C/N)。C和N是2种对微生物生长十分重要的营养元素,C可以作为细菌等的能源物质,N是细胞结构的重要组成部分,C/N失衡会导致有机质生物降解性大大降低[8]。C/N可以作为评估堆肥腐熟度的重要指标,一般堆肥结束时,C/N在16~20之间可认为完全腐熟[26]。图5(c)所示为堆肥初始和第15 d的C/N值。相比之下,分别添加微生物菌剂和腐熟堆肥的T1和T2处理组C/N均出现了下降,且T1的下降比例多于T2,为15%;而无任何添加的CK组显示为略微升高,反应结束时比初始值高出1.98%。在堆肥过程中,微生物利用有机物中的C和N进行代谢活动,菌剂和腐熟堆肥的添加加快了微生物对C元素的消耗,从而导致C/N的下降。

-

1)餐厨垃圾和污泥联合好氧堆肥过程中,接种微生物菌剂可以提高堆肥温度,使堆体峰值温度上升到56.8 ℃,并延长高温期(>50 ℃)至5 d左右;添加菌剂后加快了堆体含水率和VS的降低速率,在堆肥结束时水分降幅达到18.31%,VS含量减少了5.95%。这表明微生物菌剂的添加有助于提高堆肥过程中微生物活性,从而促进堆肥减量化和无害化进程。

2)接种微生物菌剂和腐熟堆肥均有利于提高堆肥肥效,但添加菌剂的效果更好。接种菌剂的T1处理组在堆肥结束时TN比例增加了10.70%,总有机碳的比例降低了2.88%;添加腐熟堆肥的T2处理组TN增加了6.20%,总有机碳的降幅为2.14%;未做处理的CK组TN浓度出现了下降,总有机碳的变化也很小。这说明在实际堆肥中可以适当添加菌剂或腐熟堆肥以提高肥效。

3)在促进堆肥腐熟方面,接种微生物菌剂有着更加明显的作用。添加菌剂的处理组E4/E6在堆肥结束时出现了下降,有利于提高堆肥腐殖化。经过15 d的快速堆肥,T1处理组的GI值相较CK组提高了30.65%,为258.54%,C/N减少了15%。这表明在联合堆肥中接种微生物菌剂可以提高腐熟效果。

微生物菌剂强化餐厨垃圾和污泥联合堆肥

Co-composting of food waste and sludge enhanced by microbial agents

-

摘要: 为探究微生物菌剂对餐厨垃圾和污泥联合好氧堆肥的影响,以餐厨垃圾和污泥(湿重1∶1)混合原料为堆肥底物,添加底物总湿重30%的废木屑作为膨胀剂,向底物中分别加入微生物菌剂和腐熟堆肥为处理组,并以不添加外源物作为对照,通过测定堆肥过程中的理化性质、腐熟效果和营养元素的变化,考察菌剂和腐熟堆肥对联合堆肥的促进作用。结果表明,微生物菌剂和腐熟堆肥的添加均能提高联合堆肥的肥效和腐熟效果,但菌剂的作用更佳。在微生物菌剂的作用下,堆体温度快速升高,并且可将高温期延长到5 d;经15 d快速堆肥,体系内含水率下降了18.31%,挥发性固体减少量达5.95%;添加菌剂的处理组在堆肥结束时的种子发芽指数最高,为258.54%,总氮浓度升高了10.70%,碳氮比减少了15%,这说明微生物菌剂有助于提高堆肥腐熟和肥效。微生物菌剂对餐厨垃圾与污泥联合好氧堆肥的减量和腐殖化有着更好的促进作用。本研究结果可为餐厨垃圾和污泥堆肥资源化处理提供参考。Abstract: The effects of inoculating microbial agents were investigated during aerobic co-composting of food waste and sludge. The mixed raw materials of food waste and sludge (wet weight 1:1) were used as the composting substrates, in which the waste sawdust with 30% of the total wet weight of the substrates was added as the conditioning agents. Microbial agents and mature compost were inoculated into the substrates as the treatment groups, and without exogenous substances inoculation was defined as CK. By measuring the changes of physical and chemical properties, maturity effects and nutrient elements in the process of composting, the promoting functions were examined in terms of microbial agents and mature compost on co-composting. The results demonstrated that both of the microbial agents and mature compost could promote the fertilizer efficiency and maturity of co-composting, but by contrast, microbial agents could bring about better results. The temperature of the pile with microbial agents increased rapidly, as well as the high temperature period was extended to 5 days. The water content of the system decreased by 18.31%, and volatile solid had a 5.95% decline. At the end of composting, the treatment group inoculated with microbial agents showed the highest germination index, which reached 258.54%. Under the function of microbial agents, the pile’s total nitrogen concentration increased by 10.70%, and its carbon nitrogen ratio showed a 15% decrease, indicating that microbial agents were conducive to improve compost maturity and fertilizer efficiency. In conclusion, microbial agents exerted a better influence on food waste and sludge aerobic co-composting, which would provide some references for the resourceful treatment of food and sludge.

-

Key words:

- microbial agents /

- food waste /

- sludge /

- composting /

- resource utilization

-

餐厨垃圾和污泥是两种常见的有机固体废物。其中,餐厨垃圾在城市生活垃圾中的占比高达20%~45%[1],污泥年产量已经突破6×107 t (80%含水率)[2],如此巨大数量的有机固废给环境治理带来了严峻挑战。餐厨垃圾和污泥都有着含水率高、有机质丰富和易腐败发臭等特点。此外,两者均含有有害物质,如病原菌和寄生虫卵等[3-4],若不加以处理可能会危害人群健康。目前,我国处理餐厨垃圾和污泥的方法有卫生填埋、焚烧和堆肥等[5]。其中,卫生填埋需要占用大量土地并可能产生渗滤液和温室气体[6];焚烧受制于餐厨垃圾和污泥的高含水率和低热值,而且还可能产生二恶英等废气。相比之下,好氧堆肥有着操作简单、设备投资少、工艺成熟等优点,在实现有机固废“减量化、无害化和资源化”方面得到了广泛应用。

好氧堆肥的原理是利用微生物的代谢活动快速分解底物中的有机成分,在底物减量的同时产热,致使堆体迅速升温杀死其中的寄生虫和病原菌,最终形成有机肥并用于调理土壤[7-9]。单独将餐厨垃圾进行堆肥得到的腐殖质因缺乏P和K等植物营养元素,导致肥效不佳;而污泥中含有丰富的P和K等元素[6],且污泥中还存在多种分解有机物的细菌和真菌。因此,用餐厨垃圾和污泥联合堆肥,不仅能够提高堆肥效率,还可以得到更有价值的腐熟产品,故有利于这两种固体废物的资源化利用。MA等[10]将餐厨垃圾和污泥以不同比例混合进行联合生物处理,证明了餐厨垃圾和污泥协同作用下有着更好的处理效果。ZHANG等[11]研究了不同比例下,餐厨垃圾和污泥联合堆肥情况,结果表明,1∶1湿重配比下得到的腐殖质肥效较单独污泥堆肥更佳。

微生物在好氧堆肥中起着重要作用,其功能是分解有机物。但是,在自然堆肥过程中存在的微生物生长周期长,难以在短时间内实现快速堆肥;而人工筛选的微生物菌剂或腐熟堆肥因具有特定的细菌或真菌,能够有针对性地分解堆体内的有机成分,最终达到提高效率、增强肥效的目的。周营等[5]向餐厨垃圾堆肥中投加复配微生物菌剂,降低了氮素损失;JURADO等[12]发现,接种菌剂后堆体内难分解的半纤维素、纤维素和木质素的降解率分别提高了28%、21%和25%。腐熟堆肥是餐厨垃圾、污泥或粪便等的堆肥腐熟产品,具有多孔结构、含水率低等特点,并且富含微生物,将其添加至堆体中也能对堆肥起到促进作用。马强等[13]发现,在生活垃圾好氧发酵时投加腐熟污泥堆肥能够有效减少氮素损失;YANG等[6]采取覆盖和混合两种方式将腐熟堆肥加入到餐厨垃圾堆肥中,结果表明,混合添加的腐熟堆肥在减少温室气体排放和提高肥效方面有着更显著的作用。由此可见,微生物菌剂和腐熟堆肥的添加能够对好氧堆肥起到很好的促进作用。

目前,大多数研究集中在向单一堆肥组分中添加微生物菌剂或腐熟堆肥,如单独餐厨垃圾堆肥[6]、单独污泥堆肥[14]、单独猪粪堆肥[15]等,向餐厨垃圾和污泥联合好氧堆肥中投加外源菌剂或腐熟堆肥的报道较少,且其理化性质的变化尚不清楚。因此,本实验选用微生物菌剂和腐熟堆肥作为添加剂,以不添加任何外源物作为对照,并以废木屑作为膨胀剂调节C/N、含水率及孔隙率,通过测定相关理化指标和营养元素的变化,并结合腐熟指标,探究这两种添加剂对餐厨垃圾和污泥联合堆肥的影响,以期为联合堆肥研究提供参考。

1. 材料与方法

1.1 实验原料与装置

堆肥所用餐厨垃圾收集于北京市某高校食堂,人工去除骨头等杂物后经清水冲洗掉油和盐,再用粉碎机将其粉碎至糊状。脱水污泥取自北京市某污水处理厂。废木屑收集于北京市某家具城,其粒径为1~2 cm。微生物菌剂购买于山东某生物公司,主要菌种为放线菌、芽孢杆菌、酵母菌和乳酸菌等。其中,放线菌和酵母菌是嗜热菌,能够分解复杂有机物,芽孢杆菌和乳酸菌对堆肥过程中氮素转化有重要影响[16-17]。腐熟堆肥为餐厨垃圾堆肥实验所得的腐熟产物。

实验装置为圆柱桶型,有效容积为5 L,反应器周围用20 mm厚的保温材料减少热量散失,中间有搅拌桨用于搅匀物料,底部设置曝气装置进行通风供氧,采用间歇曝气方式,每12 h通风1次,通风速率为0.4 L·min−1。

1.2 实验设计

本实验以餐厨垃圾和污泥湿重1∶1混合作为联合堆肥底物,以分别添加底物总重15%(湿重)的微生物菌剂和腐熟堆肥为处理组1 (T 1)和处理组2 (T 2),没有任何外源剂投加的为对照组(CK)。3个反应堆体均加入底物总重30%(湿重)的废木屑,将原料调节到合适的含水率和C/N,各堆体的原始理化性质如表1所示。堆肥时间设计为15 d,从实验开始每隔3 d进行1次翻堆,翻堆后分别从各堆体的上、中、下位置多点取相同量的样品,混合均匀后取适量样品将其制备成浸提液用于理化指标的测定。浸提液的制备方法为新鲜样品与去离子水按1∶10配比后在26 ℃恒温震荡器中震荡2 h,随后以3 000 r∙min−1速率离心10 min,过0.45 μm的滤膜后取上清液进行理化指标的测定。

表 1 原料的主要性质Table 1. Primary properties of the raw substrates实验组 材料 含水率% pH TN/% TOC/% VS/% C/N CK 餐厨垃圾+污泥 66.07±0.57 6.20 1.95±0.01 49.12±0.13 84.69±0.13 25.23±0.08 T1 餐厨垃圾+污泥+菌剂 66.59±0.23 6.73 1.96±0.01 48.53±0.13 83.67±0.13 24.77 ±0.24 T2 餐厨垃圾+污泥+腐熟堆肥 66.25±0.04 6.13 1.92±0.01 48.57±0.06 83.74±0.13 25.31±0.08 1.3 测定项目和方法

温度采用插入式感应测温仪每24 h测量1次;pH采用pH计测定浸提液确定;含水率采用重量法测定;氧化还原电位(Oxidation Reduction Potential,ORP)采用氧化还原电极头测定;电导率(Electrical Conductivity,EC)采用CT−20 型便携电导率仪测定;挥发性固体含量(Volatile Solids,VS)采用灼烧法确定。

总有机碳(Total Organic Carbon,TOC)采用《土壤检测标准》(NY/T 1121.6—2006)[18]提供的方法测定;总氮(Total Nitrogen,TN)采用元素分析仪测定;C/N为总有机碳量/总氮量。

腐殖酸光学特性E4/E6(即浸提液在465 nm和665 nm波长处的UV−Vis吸光度比值)的值采用HACH DR600型紫外可见光分光光度计测定;种子发芽指数(Germination Index,GI)的测定参考文献[19],计算方法见式(1)。

相对发芽指数(%)=处理中平均发芽率×处理中平均根长空白中平均发芽率×空白中平均根长×100 (1) 2. 结果与讨论

2.1 联合堆肥中温度的变化

温度是好氧堆肥的重要参数之一,其变化可以反映出堆体内微生物的代谢活动强弱和堆肥效率[20]。好氧堆肥通常经历3个温度变化阶段:升温期→高温期→降温期。图1所示为本实验3个堆体的温度变化曲线。T1、T2和CK都经历了先快速升温到达最高值后逐渐下降到接近室温的稳定水平。3个堆体的温度分别在第5 d、第4 d和第5 d达到最高值41.8、56.8和49.9 ℃。T1处理的峰值温度和升温速率明显高于T2和CK组,且高温期(>50 ℃)持续了5 d,满足堆肥安全卫生标准[21]。微生物利用堆体内丰富的有机物进行代谢和繁殖,并产生了大量的热,致使堆肥温度在前期迅速升高,之后随着易降解有机质的消耗,堆体温度随之逐渐下降。相比之下,虽然添加微生物菌剂和腐熟堆肥均能提高堆肥温度,但是在延长高温期持续时间方面菌剂效果更好。T1处理组添加的微生物菌剂中含有放线菌,这是一种典型的嗜热细菌[17],能够在高温条件下生长并降解复杂有机物。这可能是T1能够长期保持高温状态的原因。

2.2 联合堆肥理化指标变化

1)含水率、pH和电导率。含水率是保证堆肥正常进行的重要条件,含水率过高或过低都会影响微生物的代谢活动[8]。因此,在本研究中,初始含水率都被调到65%左右以保证堆肥正常进行。如图2(a)所示,随着堆肥进行,3个堆体含水率都呈现出下降的趋势,堆肥结束时,T1、T2和CK的含水率分别为56.15%、54.40%和62.56%。在堆肥初期,适宜的含水率和大量易降解有机质利于微生物快速代谢和增殖,促进体系内温度快速升高(图1)。其中,水分一部分用于微生物生长,一部分被蒸发,两者共同作用导致含水率的下降[22]。在堆肥至第9 d后,3个堆体的温度没有出现太大的变化(图1),而含水率持续下降。由此可推测堆肥后期水分蒸发是含水率降低的主要原因。从含水率变化来看,投加菌剂可以更好地提高微生物活性,微生物分解有机物产生热量造成了更多的水分蒸发损失。这一点和温度的变化是一致的(图1)。

pH是堆肥过程中一个重要参数,其变化能够影响到微生物的活性,适当控制pH可以促进堆肥有机物的降解[8,23]。图2(b)为3个不同处理堆体的pH变化曲线,总体呈现出逐渐增加的趋势。到堆肥结束时,T1、T2和CK组的pH分别稳定在8.83、8.57和8.87。这与之前的相关研究结果一致[24]。在堆肥前期,所有堆体的pH均出现了下降,并在第24 h时达到最低值。这可能是堆肥前期易降解的有机质被微生物利用时产生了部分有机酸[25]。随着堆肥的进行,pH都逐渐增加并最终稳定在弱碱性范围内。究其原因,一方面是温度升高导致有机酸挥发,另一方面是在微生物作用下有机氮发生矿化生成了氨氮,两者共同作用下造成了pH的变化[6]。综合3个处理来看,添加微生物菌剂的T1有着最剧烈的pH变化,T2和CK组的pH变化没有太大的差异。这说明腐熟堆肥的添加对pH的影响效果不如微生物菌剂。

电导率(EC)可以反映出堆肥产品的含盐量,高含盐量会抑制植物生长[26]。3个堆体EC的变化如图2(c)所示,T1和CK组的变化均为先升高后降低,T2则一直呈现轻微的上升趋势。反应结束时,3个堆体EC值分别为0.86、0.80和0.69 mS·cm−1,均有了一定程度的增加。一般认为,只要电导率的阈值不超过4 mS·cm−1就不会对植物生长产生毒性[11],故本实验最终堆肥产品均符合安全堆肥的标准。在T1堆肥前期,由于易降解有机物的矿化作用生成了铵盐和磷酸盐,再加之堆体体积的减少,堆体电导率增加[8];随着小分子有机成分的消耗,电导率逐渐下降。这一点和SONG等[21]的研究结果一致。此外,根据MA等[14]的研究结果,添加腐熟堆肥能够增加降温期脲酶的含量,有利于尿素转化为铵盐,导致T2处理组EC值不断上升。总体来看,添加微生物菌剂的T1处理组有着最剧烈的EC变化。这说明菌剂的加入有利于联合堆肥过程中有机物矿化生成盐类物质。

2)氧化还原电位、挥发性固体含量。堆体内氧化还原电位(ORP)的变化可以反映出微生物活性及其对养分的利用情况。由图3(a)可知,3个处理的ORP均呈现出前期升高再逐渐降低,后趋于稳定的趋势。在堆肥最初的24 h里,3个堆体的ORP都达到了最大值,分别为130.8、127.6和124.7 mV。此时,微生物以氧气作为电子受体,利用有机物进行代谢的速率达到最大。随着反应的进行,堆体内的氧气逐渐被消耗,体系内的ORP逐渐降为负值,到反应结束时,3个堆体的ORP分别为−100.8、−85.5和−103.1 mV。整体来看,添加微生物菌剂的T1处理明显低于另外2组。这可能是菌剂中微生物在分解有机物时快速消耗体系内的氧气,而添加腐熟堆肥的T2处理效果不明显,这表明菌剂的加入利于提高微生物活性及其对养分的利用。值得一提的是,从图2(b)和3(a)对比来看,pH和ORP似乎有着相反的变化趋势,即pH越高,所对应的氧化还原电位越低。这和KHALIL等[27]的研究结果一致,而且他们认为,ORP可以作为监测堆肥腐熟的指标。

挥发性固体(VS)的变化如图3(b)所示,3个堆体均呈现出下降趋势。在堆肥结束时,3个堆体的VS都降到最低,分别为78.69%、80.04%和82.79%,分别下跌了5.95%、4.43%和2.24%。以上实验结果表明,T1的VS减少量最多。这可以归因于微生物菌剂的加入增强了细菌和真菌的代谢活动,有机物被快速降解利用。相比于T1和T2处理组,没有任何接种的CK组VS减少量最低。其可能的原因是:CK组缺乏必要的微生物,很难更彻底地分解挥发性有机物。有报道[17]称,放线菌能够在高温条件下生存,其具有降解纤维素和木质素的功能。添加微生物菌剂的T1处理温度高且高温期持续时间长(图1),放线菌分解纤维素和木质素导致T1处理的VS含量减少最多。此外,腐熟堆肥的添加也能促进纤维素和木质素的降解。这是因为,腐熟堆肥中可能存在放线菌,但相较于人工筛选含有放线菌的菌剂,T2的放线菌需要一段时间繁殖才能发挥作用,故T2的VS降解效果不如T1。

2.3 堆肥过程中营养元素的变化

1)总氮(TN)变化。氮(N)是对植物生长起重要作用的元素之一,能够反映出堆肥产品的肥效。3个堆体的TN变化情况如图4(a)所示,T1和T2呈现出先降低后升高的规律,CK组则一直降低。堆肥初期,微生物活性大,堆体快速升温导致氨气挥发。高温能抑制硝化细菌将铵态氮转化为硝态氮的反应,反硝化细菌消耗硝态氮生成氮气加速了氮的损失[13]。随着微生物活动变弱,堆体温度逐渐降低,氮素损失速率低于堆体体积减少速率,造成TN浓度上升。在本研究中,T1处理组在堆肥结束时总氮浓度最高。这是由于添加的菌剂中有芽孢杆菌。根据PARK等[28]的报道,芽孢杆菌是一种具有固氮功能的微生物,将其加入堆肥中可以帮助减少氮素损失以提高肥效。

2) TOC变化。3个堆体的总有机碳变化如图4(b)所示,其规律和VS曲线相似(图3(b)),均呈现出逐渐降低的趋势。在微生物的作用下,堆体内的含碳有机物参与细菌和真菌代谢被转化为CO2,造成堆体总碳含量减少[8]。从图4(b)中可以看出,TOC的快速下降阶段发生在堆肥初期和中期。这是因为,此时微生物相对活性较高,其对C的利用速率也较快。相较于T2和CK,接种菌剂的T1能更大程度地降解TOC,这可能与菌剂中存在酵母菌和放线菌有关。酵母菌由于其微生物特性和孢子样的细胞结构可以耐高温和对抗低水分环境条件[29]。因此,在堆肥后期,在含水率较低情况下(图2(a)),酵母菌可以分泌水解酶降解木质纤维素。而且,放线菌具有分解纤维素的能力,根据MA等[14]的报道,纤维素的降解主要发生在堆肥中后期。所以,T1在堆肥后期TOC依旧能够保持一定程度的消耗可能与酵母菌和放线菌有关。

2.4 好氧堆肥效果分析及评价

1)腐殖酸光学特性(E4/E6)。有机物的腐殖化程度是衡量堆肥产品质量的农艺标准之一[11]。图5(a)为3个堆体的E4/E6变化曲线,它们大致的规律是均为先升高后降低。T2和CK组从高温期到反应结束,E4/E6值始终高于初始值。这表明大分子的腐殖酸不断分解,堆肥产品的腐殖化程度降低[11]。而添加微生物菌剂的T1中E4/E6在反应结束时有了轻微降低。这表明液相中腐殖酸相对分子质量在增加;该现象可能是外源微生物对餐厨垃圾和污泥中的有机物降解起到促进作用,提高了体系的腐殖化进程[30]。综合来看,向餐厨垃圾和污泥联合堆肥中投加微生物菌剂利于腐殖质的形成,而添加腐熟堆肥相较于对照组则没有明显作用。

2)种子发芽指数(GI)。种子发芽指数是判断堆肥腐熟程度的重要指标,它的大小能反映堆肥产品腐熟程度和植物毒性[20]。由图5(b)可看出,3个堆体的GI值都呈现出逐渐增加的趋势。反应结束时,3个堆体的GI值分别达到了258.54%、211.57%和227.89%。这表明堆肥产品无植物毒性[26]。T1的GI值比CK组高出30.65%。这可能是微生物的加入促进了堆体腐殖化;该现象表明微生物菌剂的投加能够促进堆体腐熟,而腐熟堆肥的添加并不能明显提高GI值,这与MA等[14]的研究结果一致。GI值逐渐升高的原因是:随着堆肥进行,堆体内具有抑制植物生长作用的有机酸和多酚等物质被转化降解,浸提液的植物毒性逐渐被削弱。

3)碳氮比(C/N)。C和N是2种对微生物生长十分重要的营养元素,C可以作为细菌等的能源物质,N是细胞结构的重要组成部分,C/N失衡会导致有机质生物降解性大大降低[8]。C/N可以作为评估堆肥腐熟度的重要指标,一般堆肥结束时,C/N在16~20之间可认为完全腐熟[26]。图5(c)所示为堆肥初始和第15 d的C/N值。相比之下,分别添加微生物菌剂和腐熟堆肥的T1和T2处理组C/N均出现了下降,且T1的下降比例多于T2,为15%;而无任何添加的CK组显示为略微升高,反应结束时比初始值高出1.98%。在堆肥过程中,微生物利用有机物中的C和N进行代谢活动,菌剂和腐熟堆肥的添加加快了微生物对C元素的消耗,从而导致C/N的下降。

3. 结论

1)餐厨垃圾和污泥联合好氧堆肥过程中,接种微生物菌剂可以提高堆肥温度,使堆体峰值温度上升到56.8 ℃,并延长高温期(>50 ℃)至5 d左右;添加菌剂后加快了堆体含水率和VS的降低速率,在堆肥结束时水分降幅达到18.31%,VS含量减少了5.95%。这表明微生物菌剂的添加有助于提高堆肥过程中微生物活性,从而促进堆肥减量化和无害化进程。

2)接种微生物菌剂和腐熟堆肥均有利于提高堆肥肥效,但添加菌剂的效果更好。接种菌剂的T1处理组在堆肥结束时TN比例增加了10.70%,总有机碳的比例降低了2.88%;添加腐熟堆肥的T2处理组TN增加了6.20%,总有机碳的降幅为2.14%;未做处理的CK组TN浓度出现了下降,总有机碳的变化也很小。这说明在实际堆肥中可以适当添加菌剂或腐熟堆肥以提高肥效。

3)在促进堆肥腐熟方面,接种微生物菌剂有着更加明显的作用。添加菌剂的处理组E4/E6在堆肥结束时出现了下降,有利于提高堆肥腐殖化。经过15 d的快速堆肥,T1处理组的GI值相较CK组提高了30.65%,为258.54%,C/N减少了15%。这表明在联合堆肥中接种微生物菌剂可以提高腐熟效果。

-

表 1 原料的主要性质

Table 1. Primary properties of the raw substrates

实验组 材料 含水率% pH TN/% TOC/% VS/% C/N CK 餐厨垃圾+污泥 66.07±0.57 6.20 1.95±0.01 49.12±0.13 84.69±0.13 25.23±0.08 T1 餐厨垃圾+污泥+菌剂 66.59±0.23 6.73 1.96±0.01 48.53±0.13 83.67±0.13 24.77 ±0.24 T2 餐厨垃圾+污泥+腐熟堆肥 66.25±0.04 6.13 1.92±0.01 48.57±0.06 83.74±0.13 25.31±0.08 -

[1] AWASTHI M K, WONG J W C, KUMAR S, et al. Biodegradation of food waste using microbial cultures producing thermostable α-amylase and cellulase under different pH and temperature[J]. Bioresource Technology, 2018, 248: 160-170. doi: 10.1016/j.biortech.2017.06.160 [2] DONG Y T, SHAN Y W, GE D D, et al. A sodium dichloroisocyanurate-based conditioning process for the improvement of sludge dewaterability and mechanism studies[J]. Journal of Environmental Management, 2021, 284: 112020. doi: 10.1016/j.jenvman.2021.112020 [3] TING C M, SELVAM A, WONG J W C. Reducing nitrogen loss and salinity during 'struvite' food waste composting by zeolite amendment[J]. Bioresource Technology, 2016, 200: 838-844. doi: 10.1016/j.biortech.2015.10.093 [4] WANG Q D, XU Q Y, DU Z L, et al. Mechanistic insights into the effects of biopolymer conversion on macroscopic physical properties of waste activated sludge during hydrothermal treatment: Importance of the Maillard reaction[J]. Science of the Total Environment, 2021, 769: 144798. doi: 10.1016/j.scitotenv.2020.144798 [5] 周营, 朱能武, 刘博文, 等. 微生物菌剂复配及强化厨余垃圾好氧堆肥效果分析[J]. 环境工程学报, 2018, 12(1): 294-303. doi: 10.12030/j.cjee.201703044 [6] YANG F, LI Y, HAN Y, et al. Performance of mature compost to control gaseous emissions in kitchen waste composting[J]. Science of the Total Environment, 2019, 657: 262-269. doi: 10.1016/j.scitotenv.2018.12.030 [7] LIN L, XU F, GE X, et al. Improving the sustainability of organic waste management practices in the food-energy-water nexus: A comparative review of anaerobic digestion and composting[J]. Renewable and Sustainable Energy Reviews, 2018, 89: 151-167. doi: 10.1016/j.rser.2018.03.025 [8] CHUKWUDI O O, VICTOR C I, VJOYCE N O, et al. Composting technology in waste stabilization: On the methods, challenges and future prospects[J]. Journal of Environmental Management, 2017, 190: 140-157. [9] CHEN Z, LI Y Z, PENG Y Y, et al. Effects of antibiotics on hydrolase activity and structure of microbial community during aerobic co-composting of food waste with sewage sludge[J]. Bioresource Technology, 2021, 321: 124506. doi: 10.1016/j.biortech.2020.124506 [10] MA J, ZHANG L, LI A. Energy-efficient co-biodrying of dewatered sludge and food waste: Synergistic enhancement and variables investigation[J]. Waste Management, 2016, 56: 411-422. doi: 10.1016/j.wasman.2016.06.007 [11] ZHANG D F, LUO W H, LI Y, et al. Performance of co-composting sewage sludge and organic fraction of municipal solid waste at different proportions[J]. Bioresource Technology, 2018, 250: 853-859. doi: 10.1016/j.biortech.2017.08.136 [12] JURADO M M, SUÁREZ-ESTRELLA F, LÓPEZ M J, et al. Enhanced turnover of organic matter fractions by microbial stimulation during lignocellulosic waste composting[J]. Bioresource Technology, 2015, 186: 15-24. doi: 10.1016/j.biortech.2015.03.059 [13] 马强, 孙英杰, 王华伟, 等. 添加腐熟污泥对生活垃圾堆肥氮素转化与损失的影响[J]. 环境工程学报, 2017, 11(7): 4325-4330. doi: 10.12030/j.cjee.201605188 [14] MA C, HU B, WEI M B, et al. Influence of matured compost inoculation on sewage sludge composting: Enzyme activity, bacterial and fungal community succession[J]. Bioresource Technology, 2019, 294: 122165. doi: 10.1016/j.biortech.2019.122165 [15] LI C N, LI H, YAO T, et al. Effects of microbial inoculation on enzyme activity, available nitrogen content, and bacterial succession during pig manure composting[J]. Bioresource Technology, 2020, 306: 123167. doi: 10.1016/j.biortech.2020.123167 [16] 王旭杰, 张文明, 常馨怡, 等 堆肥添加剂降低碳氮损失的微生物学机制研究[J]. 环境科学学报, 2021, 41(10): 4116-4127. [17] ÓSCAR J S, DIEGO A O, SANDRA M. Compost supplementation with nutrients and microorganisms in composting process[J]. Waste Management, 2017, 69: 136-153. doi: 10.1016/j.wasman.2017.08.012 [18] 中华人民共和国农业农村部. 土壤检测标准: NY/T 1121.6—2006[S]. 北京: 中国农业出版社, 2006. [19] 李昌宁, 苏明, 姚拓, 等. 微生物菌剂对猪粪堆肥过程中堆肥理化性质和优势细菌群落的影响[J]. 植物营养与肥料学报, 2020, 26(9): 1600-1611. doi: 10.11674/zwyf.20051 [20] ZHOU J M. The effect of different C/N ratios on the composting of pig manure and edible fungus residue with rice bran[J]. Compost Science & Utilization, 2017, 25(2): 120-129. [21] SONG C H, ZHANG Y L, XIA X F, et al. Effect of inoculation with a microbial consortium that degrades organic acids on the composting efficiency of food waste[J]. Microbial Biotechnology, 2018, 11(6): 1124-1136. doi: 10.1111/1751-7915.13294 [22] YU Z, TANG J, LIAO H, et al. The distinctive microbial community improves composting efficiency in a full-scale hyperthermophilic composting plant[J]. Bioresource Technology, 2018, 265: 146-154. doi: 10.1016/j.biortech.2018.06.011 [23] CHEN P C, CHIU M C, MA H W. Measuring the reduction limit of repeated recycling–a case study of the paper flow system[J]. Journal of Cleaner Production, 2016, 132: 98-107. doi: 10.1016/j.jclepro.2015.04.023 [24] CHANG R X, LI Y M, CHEN Q, et al. Comparing the effects of three in situ methods on nitrogen loss control, temperature dynamics and maturity during composting of agricultural wastes with a stage of temperatures over 70 ℃[J]. Journal of Environmental Management, 2019, 230: 119-127. [25] VALERIIA S, GALYNA K, OLGA S, et al. Study of the Conditions for Accelerating the Composting Process when Adding Microbial Communities[J]. Journal of Ecological Engineering, 2021, 22(3): 11-17. doi: 10.12911/22998993/132603 [26] 李赟, 袁京, 李国学, 等. 辅料添加对厨余垃圾快速堆肥腐熟度和臭气排放的影响[J]. 中国环境科学, 2017, 37(3): 1031-1039. [27] KHALIL A, DOMEIZEL M, PRUDENT P. Monitoring of green waste composting process based on redox potential[J]. Bioresource Technology, 2008, 99(14): 6037-6045. doi: 10.1016/j.biortech.2007.11.043 [28] PARK G, NAM J, KIM J, et al. Structure and Mechanism of Surfactin Peptide from Bacillus velezensis Antagonistic to Fungi Plant Pathogens[J]. Bulletin of the Korean Chemical Society, 2019, 40(7): 704-709. doi: 10.1002/bkcs.11757 [29] GU W J, LU Y S, TAN Z Y, et al. Fungi diversity from different depths and times in chicken manure waste static aerobic composting[J]. Bioresource Technology, 2017, 239: 447-453. doi: 10.1016/j.biortech.2017.04.047 [30] YUAN J, CHADWICK D, ZHANG D, et al. Effects of aeration rate on maturity and gaseous emissions during sewage sludge composting[J]. Waste Management, 2016, 56: 403-410. doi: 10.1016/j.wasman.2016.07.017 -

DownLoad:

DownLoad: