-

含铜原料在熔炼过程中会释放大量重金属,熔炼原料中所含的锌、铜、铅、锰等重金属在氧化气氛和高温环境中,加上烟气中SO2的作用,容易形成ZnO、CuO、PbO、MnO等氧化物,并以大气为介质迁移到地下水和土壤等,对周边环境造成威胁[1-2]。国务院办公厅印发了《禁止洋垃圾入境推进固体废物进口管理制度改革实施方案》[3],其中包括限制铜精矿、铜锍和废铜的进口,禁止铜冶炼渣、冶炼烟尘、含铜污泥等的进口。为引导进口高品质含铜原料,研究进口含铜原料熔炼过程污染物释放特征变得尤为重要。

目前,国内对于进口含铜原料的处理方式多为在高温还原气氛下火法熔炼。火法熔炼是炼铜最重要的过程,即在1 000~1 250 ℃高温下,使铜原料和熔剂在熔炼炉内进行熔炼,炉料中的铜、硫及未氧化的铁形成硫铁铜共熔体,炉料中的SiO2、Al2O3、CaO、FeO一起形成液态炉渣[4]。其中,温度和熔剂是影响含铜原料熔炼过程重金属释放的2个重要因素[5-6]。温度主要通过改变重金属的饱和蒸汽压力影响其挥发迁移,重金属的蒸汽压随温度的升高而增大,从而提高其挥发效率[7-9]。柴桢[10]提出,废杂铜熔炼过程保持炉内温度在1 250 ℃左右,可在保证铜的回收率的同时提高杂质元素的去除效率。周凯等[11]研究了进口再生铜材冶炼烟气中的重金属,控制冶炼温度在1 200 ℃以下可有效控制烟气中杂质元素的挥发。另外,熔炼等高温状态下的重金属的挥发行为也受气体组分的影响,石英熔剂的添加能与重金属元素形成不同化合价态的硅酸盐等不易挥发物,从而能够在去除含铜原料中杂质的同时降低熔炼烟气中各类重金属的产生[12-13]。熔炼过程中,Fe/SiO2的含量对炉渣性质起决定作用,通过提高炼铜弃渣的SiO2含量和熔炼温度会降低铜氧化物在炉渣中的溶解度[14]。

目前,全面禁止进口废物政策实施后,尚缺乏基于进口含铜原料特性及熔炼工艺等对于熔炼过程重金属释放特征的相关研究。本研究将从不同温度和不同熔剂条件出发,在实验室采用高温管式炉模拟进口铜精矿、铜硫、铜转炉渣和含铜污泥的熔炼过程,比较其熔炼烟气中重金属的释放特性,以探寻进口含铜原料熔炼的最佳温度和熔剂添加比例,以期为我国进口含铜原料熔炼烟气中重金属污染源控制以及海关对于含铜原料的高效监管提供基础数据支撑。

-

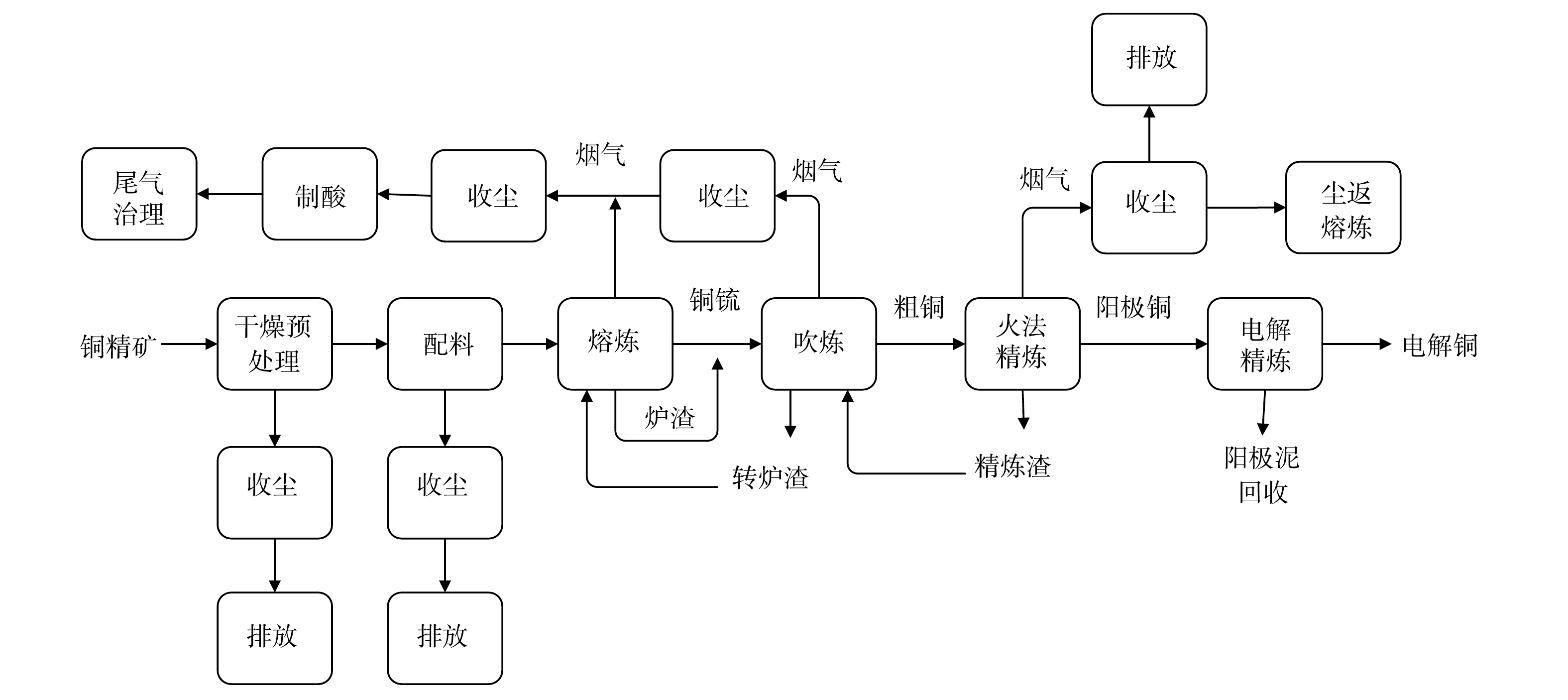

本研究选择进口量大的铜精矿和其中间产物铜锍为主要研究对象,同时比较铜锍吹炼第一阶段形成的铜转炉渣、印刷线路板生产和电镀过程中产生的含铜污泥等不同原料熔炼烟气中重金属产生的差异。通过采集宁波某铜冶炼厂和南宁海关留存的样品,利用五点采样法,每个点采集50 kg,混合后带回实验室。每份样品称取100 g,研磨机研磨至样品通过200目筛网,将样品于105 ℃烘干后移至干燥器中留作实验用。含铜物料冶炼工艺流程如图1所示。利用X射线荧光光谱仪(XRF)分析样品干基的成分,分析结果如表1所示。

-

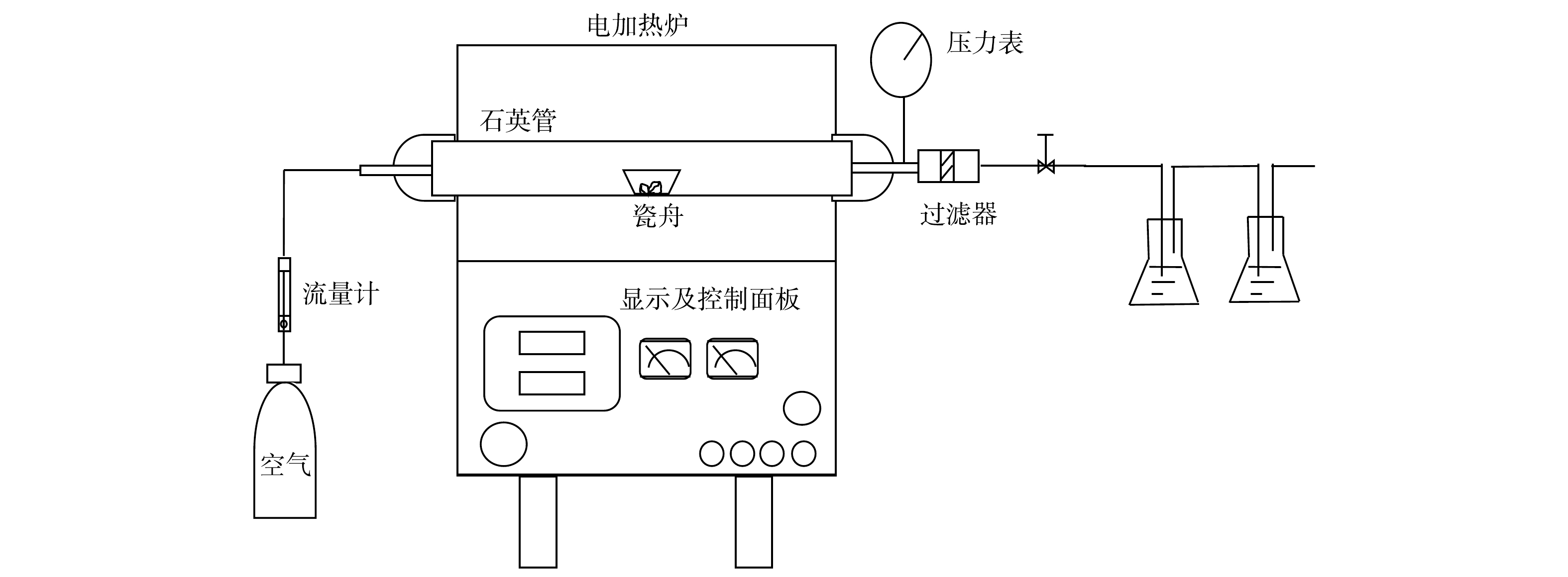

实验室模拟反应装置如图2所示。该装置主要由通气装置(T40 L,气体为21%空气和79%氮气组成的合成空气)、高温管式炉装置(KJ-T1 700,郑州科佳电炉有限公司,最大功率为5 kW,最高调节温度为1 500 ℃,升温速率为10 ℃·min−1,刚玉管内径60 mm,刚玉瓷舟大小为100 mm×40 mm×22 mm)、重金属收集系统(两级洗气瓶串联组成,洗气瓶内装有200 mL的10%的H2O2和5%的浓硝酸混合组成的吸收液)3部分组成,用于模拟进口含铜原料熔炼及烟气收集过程。

-

分别称取50 g供试样品,按比例添加熔剂石英,搅拌均匀后待管式炉升至模拟温度,将瓷舟迅速推入管式炉中部并密封处置,持续通入混合空气反应30 min,模拟过程中产生的烟气通过过滤器后进入重金属收集系统,吸收液定容至500 mL。用ICP-MS检测仪(Agilent Technology Co,1500 A,Ltd,USA)测定熔炼烟气吸收液中Mn、Zn、Cu、As、Pb 5种重金属元素的质量分数,取3次实验的平均值,所有平行双样的分析误差均小于20%,加标回收率为85%~115%,符合《水质 32种元素的测定 电感耦合等离子体发射光谱法》(HJ776-2015)[15]质量控制标准。

-

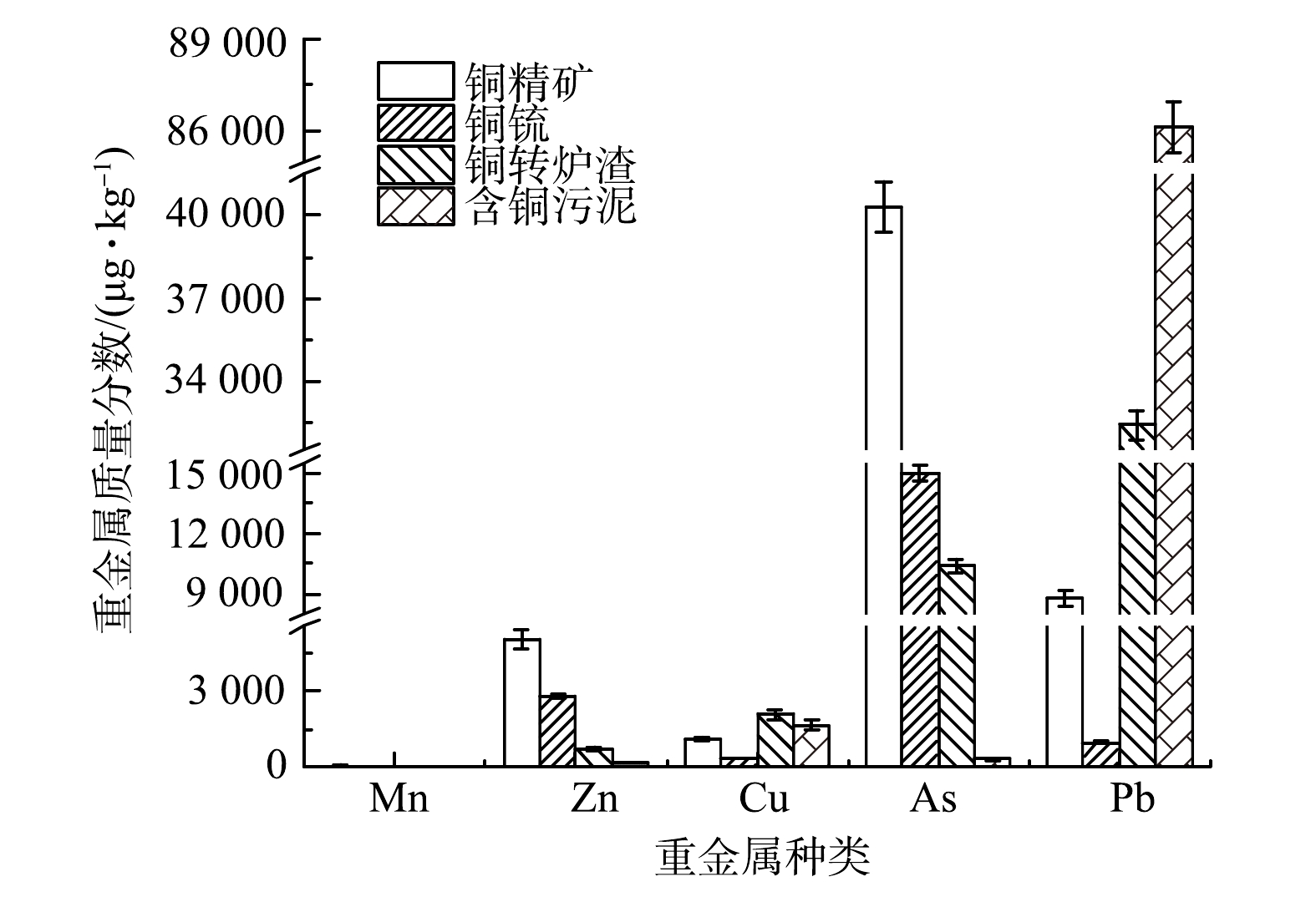

1)不同种类的进口含铜原料熔炼烟气中重金属释放特性。选用铜精矿、铜锍、铜转炉渣及含铜污泥4种含铜原料作为研究对象,控制熔炼温度为1 200 ℃,熔剂石英的添加比例为36%。

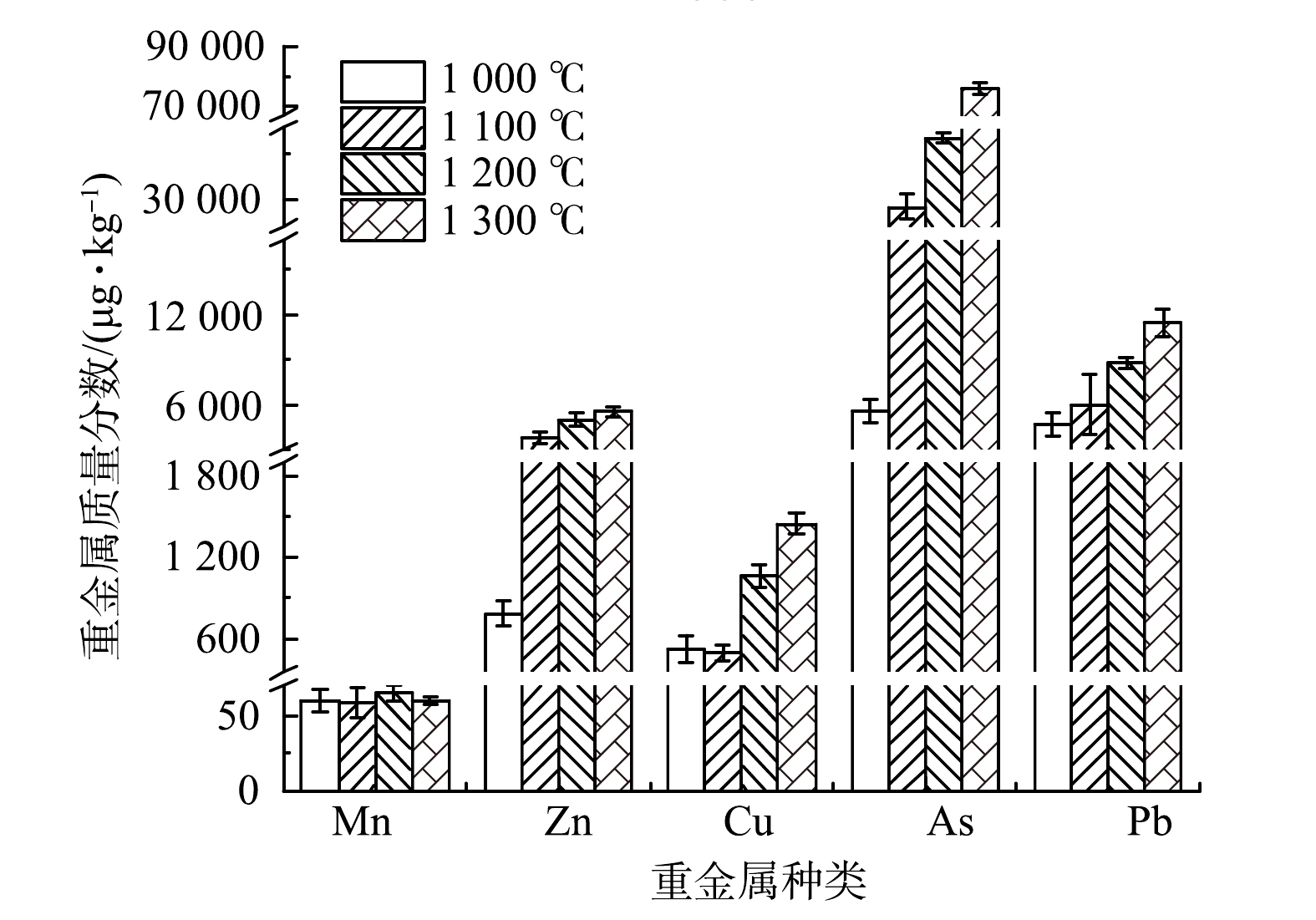

2)温度对进口含铜原料熔炼烟气中重金属释放的影响。选用进口量大的铜锍和铜精矿为研究对象,自变量熔炼温度设置为1 000、1 100、1 200、1 300 ℃,控制熔剂石英的添加比例为36%。

3)熔剂添加比例对进口含铜原料熔炼烟气中重金属释放的影响。选用进口量大的铜锍和铜精矿为研究对象,因为熔剂石英的添加比例主要由硅铁比决定,硅铁比为1.2~1.7 [16],根据样品中Fe元素的质量分数,所以自变量石英的添加比例设置为0、18%、36%。控制熔炼温度为1 200 ℃。

-

进口铜精矿、铜锍、铜转炉渣和含铜污泥原料熔炼烟气中重金属释放特性如图3所示。4种进口含铜原料熔炼烟气中重金属质量分数的分布差异较大,总体上铜精矿和含铜污泥熔炼烟气中的重金属高于铜锍和铜转炉渣。其中,进口铜精矿熔炼烟气中的重金属主要来自于As,其质量分数分别是铜锍、铜转炉渣和含铜污泥的2.70、3.88和131.93倍。这是由于:进口铜精矿多为硫砷铜精矿,Cu、As主要以Cu3AsS4化合物状态存在[17-18],当温度超过700 ℃便会发生完全的脱砷反应(反应机制见式(1)~式(2)),铜精矿熔炼过程Cu富集于铜锍形成Cu2S、FeS组成的共熔体 [19-20],其他大部分元素与加入的熔剂形成炉渣液相,因此,进口铜精矿中的熔炼烟气质量分数高于铜锍和铜转炉渣。进口含铜污泥熔炼烟气中Pb的质量分数最高,分别是进口铜精矿、铜锍和铜转炉渣的9.9、88.3和2.66倍。这是因为:印刷线路板的刻蚀液以及电镀产生的废液中含有大量的导电能力强的Pb元素,部分废液被滞留在含铜污泥中,而Pb的活性较强,在高温和氧化气氛条件下大量挥发,导致其熔炼烟气中Pb的质量分数升高。综上所述,4种进口含铜原料熔炼烟气中重金属As、Pb质量分数高于其他重金属,在对进口铜精矿和含铜污泥回收利用时,应分别着重考虑熔炼烟气中As、Pb的处理。

-

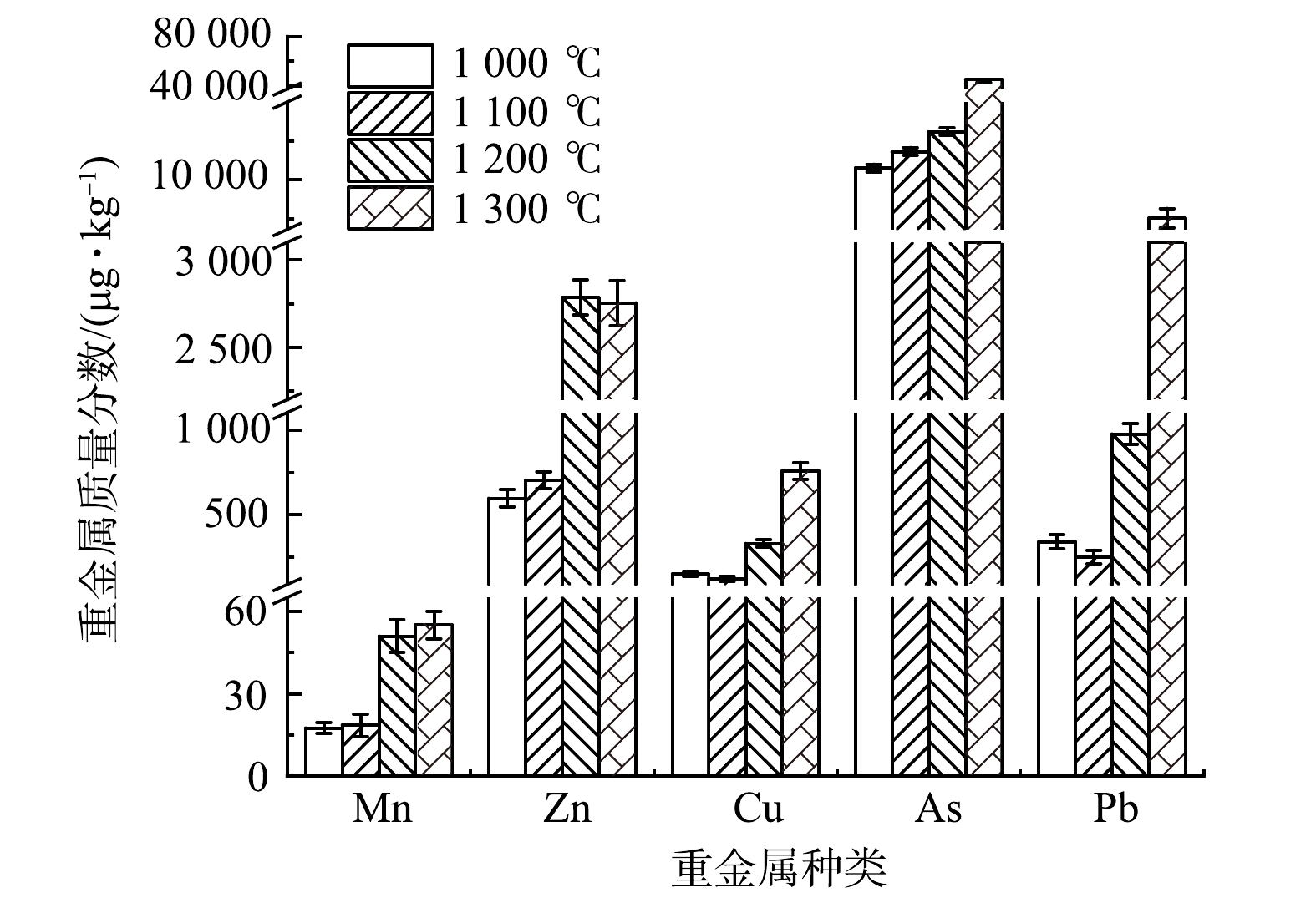

温度对进口铜精矿熔炼烟气中重金属释放质量分数的影响如图4所示。当熔炼温度从1 000 ℃升至1 300 ℃时,Zn、Cu、As和Pb重金属质量分数随着温度增加而增加,Mn质量分数变化不大,且整体呈现出As>Pb>Zn>Cu>Mn的规律。当温度为1 000 ~1 100 ℃时,Zn、As的质量分数分别增加了482%、518%,Pb的质量分数增加则相对缓慢。铜精矿中伴随着氯元素的存在,氯在高温下容易和重金属反应生成氯化物,Zn、As和Pb的氯化物蒸发压力高于其氧化物,因此更容易挥发[9, 21-22]。这与谭鹏夫等[23]研究铜炉渣的研究结果相似。Cu属于较难挥发的重金属,当温度超过1 200 ℃时,Cu挥发率有所增加,但总体增幅不大。这说明温度对Cu挥发率的影响小于对Zn、As、Pb挥发的影响。这与胡济民[24]发现飞灰焚烧温度对Cu挥发的影响小于Pb的结果相似。随着熔炼温度增加,熔炼烟气中Mn质量分数变化不大,变化幅度为60.0 ~65.0 μg·kg−1,Mn在铜精矿中整体占有比例较小,整体的挥发比例亦不大。综上所述,铜精矿熔炼温度控制在1 100 ℃以下时,可有效减少进口铜精矿熔炼烟气中重金属的释放。

温度对进口铜锍熔炼烟气中重金属释放影响质量分数的影响如图5所示。当温度从1 000 ℃升至1 300 ℃时,Zn、Cu、As和Pb重金属质量分数随着温度增加而增加,Mn浓度变化不大,且整体呈现出As>Pb>Zn>Cu>Mn的规律。这与铜精矿熔炼烟气中重金属释放的规律类似。当温度从1 100 ℃升至1 200 ℃时,Zn、As和Pb的质量分数分别增加了3.65、0.14和1.85倍。进口铜锍在运输过程会沾染各种杂质包括Cl元素,少量的Cl和Zn、As等便会结合生成易挥发的ZnCl2、AsCl3,从而促进Zn和As等元素的挥发[25]。这与柴桢[10]报道的研究结果不一致,该研究中,随着温度从1 100 ℃升至1 200 ℃,废杂铜熔炼烟气中Pb挥发率变化不明显。这可能与反应过程熔剂剂的添加比例不同有关,熔剂越多,则有更多的Pb氧化物参与造渣反应而进入炉渣。当温度在1 200 ℃以下时,熔炼烟气中Pb质量分数较低。这是因为:铜锍中的Pb主要以硫化物形式存在,温度低于1 200 ℃时PbS多与Cu2S、FeS形成低熔共晶体进入渣相,继续升温则PbS被氧化为PbO,最终导致烟气中Pb的质量分数迅速增加[26]。随着熔炼温度增加,熔炼烟气中Mn质量分数较小且增加相对缓慢,低于55.0 μg·kg−1,挥发比例较小。综上所述,控制进口铜锍冶炼温度在1 200 ℃以下,可有效减少烟气中各类重金属的释放。

-

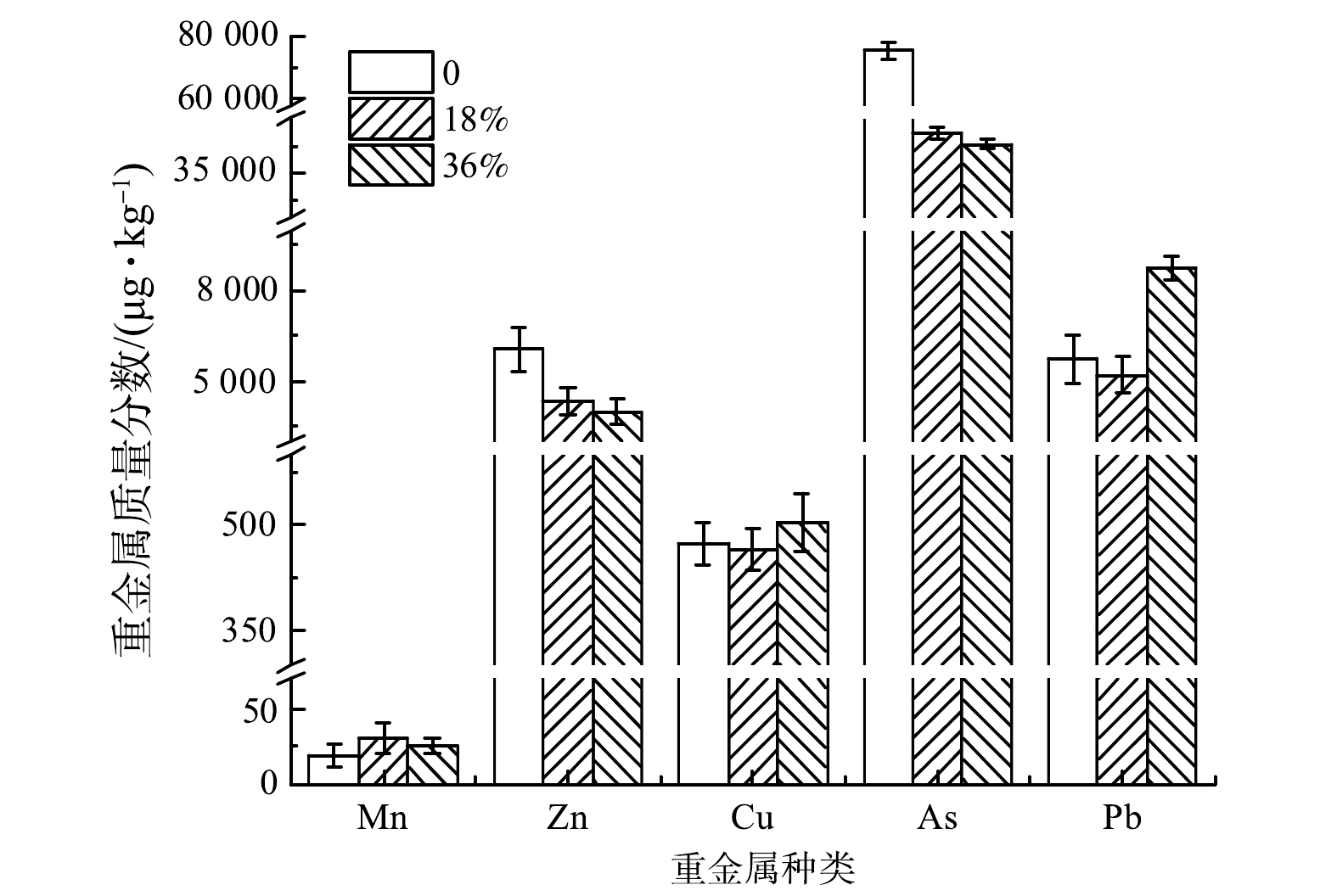

控制熔炼温度为1 200 ℃,不同的熔剂添加比例对进口铜精矿熔炼烟气中重金属释放的影响如图6所示。石英对铜精矿熔炼烟气中各类重金属挥发的抑制效果有所差别。铜精矿熔炼烟气中Zn和As的质量分数随熔剂添加比例的增加而降低,随着熔剂比例由0增至18%,Zn、As的质量分数分别降低了28%和44%,这说明添加较少的熔剂时已经在很大程度上降低了Zn、As金属元素的产生。这是因为,加入石英的与铜精矿在高温熔融下产生了造渣反应,Zn、As等元素被固溶在SiO2网状结构中,从而形成不易挥发的硅酸盐物质[27]。随熔剂比例的增加,熔炼烟气中Cu、Pb和Mn的质量分数变化不大。Cu难以与SiO2反应,故随着熔剂的增加,熔炼烟气中Cu质量分数变化不大。降低重金属的最大挥发效果与体系中两类反应机制有关:一类是重金属与Cl元素结合生成的易挥发机制;一类是重金属与硅铝反应形成的难挥发机制[12,14]。PbCl2能促进Pb的挥发,而PbSiO3则抑制铅的挥发,随熔剂添加比例的增加,熔炼烟气Pb的挥发质量分数变化不大,这说明该反应体系中氯化物的促进挥发机制和SiO2的抑制挥发机制相均衡。综上所述,控制进口铜精矿熔炼过程熔剂的添加比例在18%左右,可有效减少烟气中重金属的释放。

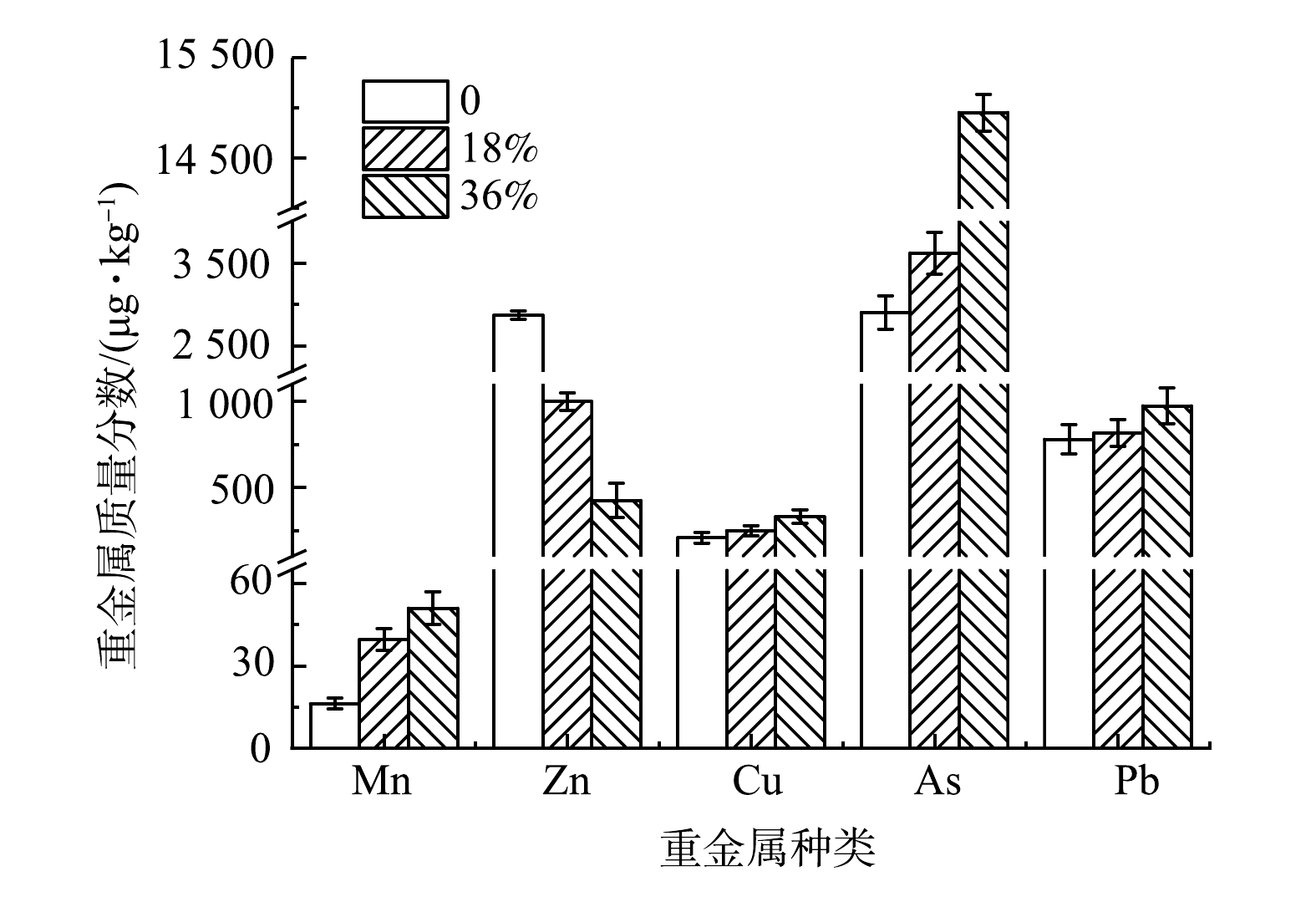

控制熔炼温度为1 200 ℃,不同熔剂添加比例对进口铜锍熔炼烟气中重金属释放的影响如图7所示。随着熔剂添加比例的增加,进口铜锍熔炼烟气中重金属变化规律不一致。铜锍熔炼烟气中Mn质量分数变化不大,其质量分数均不超过50 μg·kg−1,而Zn的质量分数呈下降趋势。熔剂由0增至18%时,Zn质量分数降幅达85.2%,其原因与铜精矿熔炼烟气中Zn质量分数降低的原因一致。熔剂由18%增至36%时,As质量分数增加了3.13 倍,这说明熔剂的大量添加不仅没有抑制铜锍中As的挥发,反而促进了烟气中As质量分数增加。这可能是由于熔炼温度为1 200 ℃,该温度接近于铜锍的软化温度,铜锍和熔剂SiO2在一起则会发生烧结现象,影响砷气化物的逸出,进而影响脱砷率[28]。与铜精矿类似,铜锍熔炼烟气中Cu的挥发效果受熔剂添加比例的影响不大。另外,随熔剂比例的增加,铜锍熔炼烟气中Pb的质量分数变化不大,这与铜精矿熔炼烟气中Pb挥发规律类似。可见,SiO2网状结构对Pb的包括作用不明显。这与JAKOB等[29]报道的研究结果类似:在Al2O3-CaO-SiO2体系中,Pb的挥发率达98%~100%。以上研究表明,虽然铜锍冶炼过程中添加熔剂对烟气中Cu、As、Pb等重金属没有明显的抑制作用,但考虑到熔剂添加对Zn、As挥发的抑制作用以及铜锍中的FeO与加入的熔剂反应造渣有利于降低炉渣中的铜质量分数,所以铜锍冶炼过程中熔剂添加比例在18%左右为宜。

-

1)进口铜精矿和含铜污泥熔炼烟气重金属质量分数高于进口铜锍和铜转炉渣。其中,进口铜精矿熔炼烟气中As的质量分数最高,进口含铜污泥熔炼烟气中Pb的质量分数最高。

2)随着温度增加,进口铜精矿和进口铜锍熔炼烟气中重金属的释放规律类似,即Zn、Cu、As和Pb的质量分数随温度增加而增加,而Mn的质量分数变化不大。分别控制进口铜精矿、进口铜锍的熔炼温度在1 100、1 200 ℃以下,可有效减少熔炼烟气中重金属的释放。

3)随着熔剂添加比例的增加,进口铜精矿熔炼烟气中Zn、As的质量分数有所下降,Mn、Cu和Pb质量分数变化不大;进口铜锍熔炼烟气中As的质量分数随熔剂添加比例的增加而增加,而Zn的质量分数逐渐减少。控制进口铜精矿、进口铜锍熔剂添加比例在18%左右可有效减少熔炼烟气中重金属的释放。

典型进口含铜原料熔炼烟气中重金属的释放特性

Release characteristics of heavy metals in smelting flue gas of typical imported copper-bearing raw materials

-

摘要: 为了解我国进口含铜原料熔炼烟气中重金属的释放特性,以近年进口申报的铜精矿、铜锍、铜转炉渣和含铜污泥4种典型含铜原料为研究对象,通过高温管式炉模拟研究不同含铜物料、熔炼温度、熔剂添加比例等条件下,熔炼烟气中重金属的释放特性。结果表明,4种进口含铜原料熔炼烟气中As、Pb质量分数较高,进口铜精矿和含铜污泥熔炼烟气重金属质量分数高于进口铜锍和铜转炉渣;熔炼温度从1 000 ℃升至1 300 ℃时,铜精矿和铜锍熔炼烟气中Zn、Cu、As、Pb等重金属的质量分数随着温度的升高而增加,Mn的质量分数随温度升高变化不大;熔剂添加比例由0增至18%时,铜精矿熔炼烟气中Zn、As的质量分数分别降低了28%、44%,Mn、Cu和Pb质量分数变化不大,进口铜锍熔炼烟气中Zn质量分数减少了85.2%,As的质量分数则随熔剂添加比例的增加而增加。本研究结果可为进口含铜原料熔炼烟气中重金属减排提供参考。Abstract: To understand the release characteristics of heavy metals in the melting flue gas of imported copper-bearing raw materials in China, four typical copper-containing materials, namely copper concentrate, copper matte, copper converter slag, and copper-bearing sludge, were imported in recent years as research objects, and the distribution characteristics of heavy metals in the melting flue gas was studied by high-temperature tube furnace simulation under the conditions of different copper-containing materials, melting temperatures and melt addition ratios. The results showed that the four imported copper-bearing raw materials contain high As and Pb mass fractions in smelting flue gas, imported copper concentrate and copper-containing sludge smelting flue gas has a higher concentration of heavy metals than imported copper matte and copper converter slag; the mass fractions of Zn, Cu, As and Pb in the melting flue gas of copper concentrate and copper matte increased with the increase of temperature when the melting temperature increased from 1 000 ℃ to 1 300 ℃, and the mass fractions of Mn did not change significantly with the increase of temperature; when the flux addition ratio is increased from 0 to 18%, the mass fractions of Zn and As in copper concentrate and copper matte smelting flue gas decreased by 28% and 44% respectively, while the mass fractions of Mn, Cu and Pb does not change much, the mass fractions of Zn in the flue gas of imported copper matte smelting decreased by 85.2%, while the mass fractions of As increased with the increase of flux addition ratio. This study can provide a reference for the reduction of heavy metals in the smelting flue gas of imported copper-bearing raw materials.

-

随着城镇污水厂氮、磷排放标准日趋严格,对于低碳氮比的城镇污水,脱氮工艺中碳源不足[1]成为其深度脱氮的瓶颈,而通过厌氧氨氧化自养脱氮则无需碳源[2]。单级自养脱氮工艺(single-stage nitrogen removal using anammox and partial nitritation, SNAP)集短程硝化与厌氧氨氧化过程于一体,工艺流程短、占地面积小、投资成本低,应用前景良好。目前,SNAP工艺主要用于处理污泥消化液和老龄化垃圾渗滤液[3]等低碳氮比的高氨氮废水[4],而对于如城镇污水(

NH+4 低氨氮废水SNAP系统的构建,通常通过接种厌氧氨氧化特种污泥来实现[6-7]。HENDRICKX等[8]通过在UASB反应器中接种厌氧氨氧化颗粒污泥,在进水

NH+4 NH+4 NH+4 一方面,进水中有机碳源对厌氧氨氧菌有抑制作用;另一方面,由于SNAP工艺TN去除率存在上限(硝氮残留11%)[12],故在进水中适当引入碳源,对副产物硝氮进行反硝化脱氮或短程反硝化[13],可提高系统的脱氮效能。WANG等[14]采用SNAP系统处理垃圾渗滤液(

NH+4 NH+4 本研究针对低氨氮废水(模拟城镇污水)SNAP系统构建难度大、接种厌氧氨氧化污泥成本高、工程应用复杂以及进水中有机碳源对系统脱氮效能有影响等问题,利用天然椰丝纤维比表面积大、多孔、容积密度小、能为微生物提供更多的附着繁殖空间[17]、生物相容性好、对底物传质性能及耐久性能良好等优点,将天然椰丝纤维作为SNAP系统的填料,开展低氨氮废水SNAP系统自然挂膜构建研究。在进水氨氮质量浓度递减(由(100±3) mg·L−1降至(50±2) mg·L−1)的条件下,重点探究了采用自然挂膜构建SNAP系统的方法;在成功构建SNAP系统的基础上,考察了进水COD/TN对低氨氮废水SNAP系统脱氮效能及脱氮路径的影响。此外,利用16SrRNA高通量测序技术,探究了各系统中的功能菌属及微生物作用机制,以期为低氨氮废水单级自养脱氮的工程应用提供参考。

1. 实验材料与方法

1.1 实验装置

如图1所示,实验装置采用好氧序批式生物膜反应器,反应器高40 cm,内径20 cm,有效容积为10 L,内设天然椰丝纤维作为填料,体积填充率为50%。采用曝气机通过砂头充氧,供气量由气体流量计计量;采用恒温箱控制反应器温度。

1.2 实验水质

用于实验的模拟废水采用NH4HCO3、KH2PO4、CaCl2、Fe2(SO4)3、MgSO4配制而成。模拟废水水质如下:实验阶段Ⅰ不加碳源,

NH+4 NH+4 NH+4 1.3 实验方法

1)基于自然挂膜的低氨氮废水SNAP系统构建。在水温为(30±1) ℃的条件下,进水NH4-N质量浓度采用由高至低的方式运行。实验第Ⅰ阶段:氮负荷为0.1 kg·(m3·d)−1,进水

NH+4 NH+4 2) COD/TN对系统脱氮效能的影响。第Ⅲ阶段,采用平行实验,考察COD/TN对低氨氮废水SNAP系统效能及微生物种群的影响。在水温为(30±1) ℃、氮负荷为0.1 kg·(m3·d)−1、DO质量浓度为0.5~2.3 mg·L−1的条件下,控制进水COD/TN分别为0、0.2、0.5、1、2。

实验期间在各反应器周期运行结束时采集水样,测试

NH+4 NO−2 NO−3 NH+4 2. 结果与讨论

2.1 系统构建及微生物种群

1)系统构建。基于自然挂膜的低氨氮废水SNAP系统构建过程中氮质量浓度逐日变化曲线如图2所示。在实验第Ⅰ阶段,在进水NH4-N质量浓度为100 mg·L−1时,反应器运行了80 d。反应器运行第1~7天,为了富集微生物,DO控制在3.51~5.17 mg·L−1,系统出水

NH+4 反应器运行至第8~13天时,为了抑制硝化菌,强化亚硝化菌富集,DO控制在0.75~1.20 mg·L−1。系统硝化作用减弱,出水

NO−3 NO−2 NH+4 NO−2 NH+4 NO−2 反应器运行至第14~36天时,系统DO控制为1.38~1.62 mg·L−1,使得系统出水亚氮/氨氮值在1.3左右,为厌氧氨氧化菌的富集提供有利条件;运行至第36天时,出水

NH+4 NO−2 反应器运行至第37~70天时,该阶段反应器DO控制在1.03~1.32 mg·L−1,期间出水

NH+4 NH+4 NO−2 NO−3 反应器运行至第71~80天时,该阶段系统DO控制为1.23~1.46 mg·L−1,系统出水

NH+4 NH+4 反应器运行至第81~84天时,系统DO控制为1.42~1.57 mg·L−1,由于实验时DO偏高导致系统出现

NO−3 NH+4 NH+4 采用自然挂膜成功构建低氨氮废水SNAP系统,采用天然椰丝纤维作为填料是重要原因。经BET测试,该填料孔隙率为6.007%,孔隙面积为514.5 m2·g−1,中孔直径为54.212 9 nm,堆积密度为0.802 9 g−1,较人工组合填料生物亲和性好(本研究同时还设置了一组以组合填料为对照组进行比对)。如表1所示:一方面,天然椰丝纤维自然富集了更多的微生物菌群,有利于微生物增殖,且天然椰丝纤维较组合填料对功能菌群富集能力更强;另一方面,进水氨氮质量浓度采用由高至低的梯度运行方式,在较高氨氮质量浓度条件下,强化了SNAP系统中功能菌群的优势富集。在本研究中,同时设置了进水

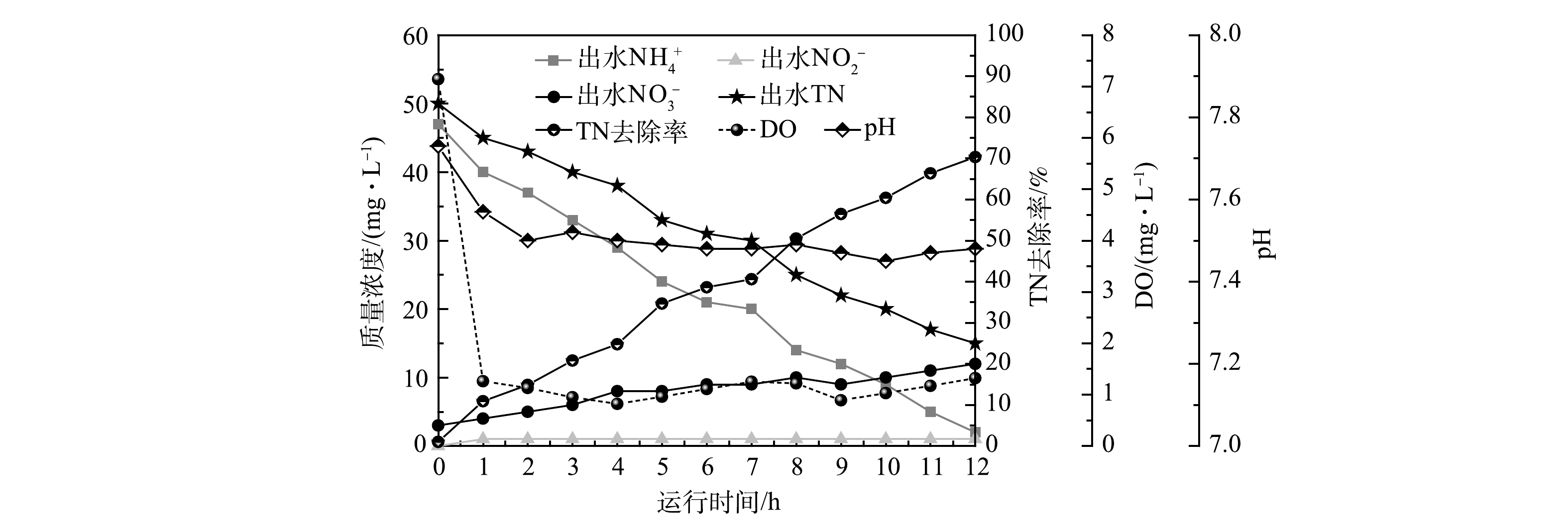

NH+4 NH+4 NO−3 表 1 填料微生物多样性对比Table 1. Comparison microbial diversity in filler填料种类 多样性指数 均匀度指数 丰富度指数 组合填料 2.972 0.948 23 天然椰丝纤维填料 3.048 0.947 25 在低氨氮废水SNAP系统稳定运行后,监测了系统运行第110个周期内氮素、DO、pH的变化规律,结果如图3所示。系统周期运行过程中,

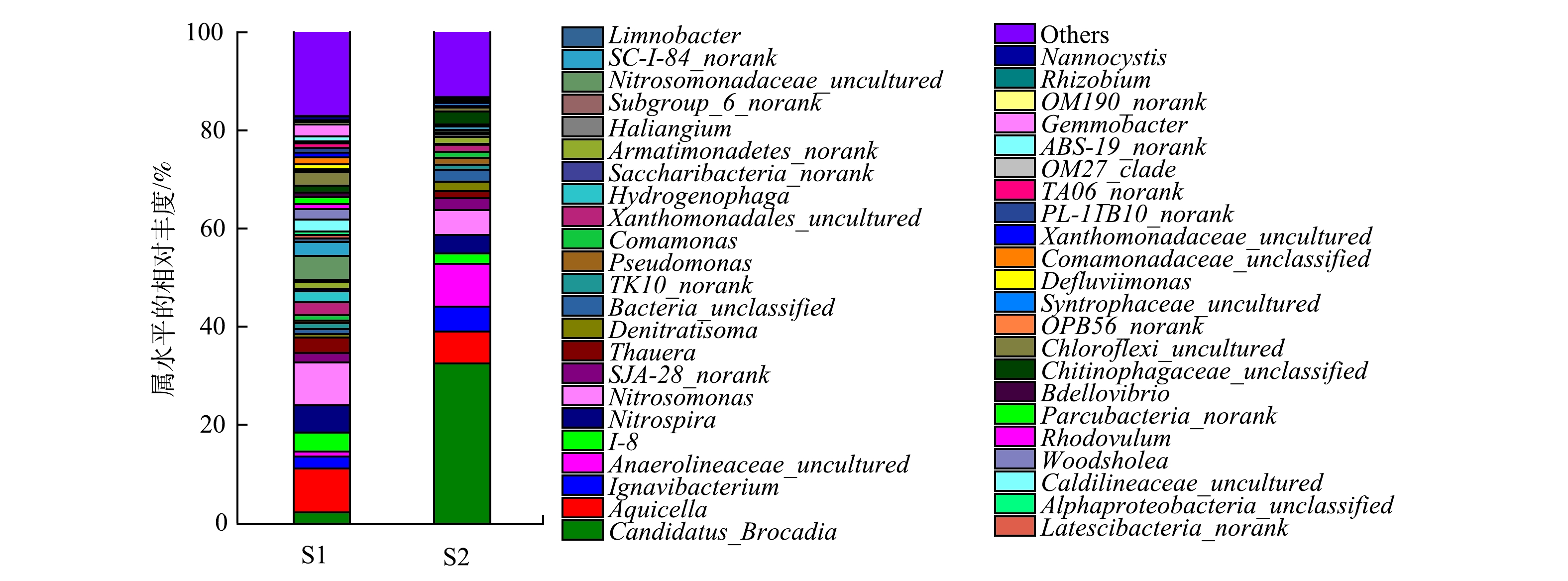

NH+4 NO−2 NO−3 NH+4 2)构建系统的微生物种群。为探究构建过程系统生物种群的演替规律,分别取反应器构建过程中第30天(S1)和第140天(S2)的生物膜样品,进行了微生物种群结构分析。S1、S2样品测序覆盖率、OUT、多样性指数等结果见表2和图4。如表2所示,S1和S2的测试覆盖率分别为0.998 493、0.997 345。这说明测序结果能反映样本的真实情况。S1和S2的OTU值分别为425和428,数目差异很小,表明微生物菌群结构无明显变化。SI和S2的Ace指数、Chao指数逐渐增大,说明系统在第30~140天物种丰富度增加。Shannon和Simpson 指数降低,表明系统在第30~140天样本的生物多样性有所增加。

表 2 样品多样性指数Table 2. Alpha-diversity of the sample样品 OTU Ace Chao Shannon Simpson S1 425 449 449 4.72 0.018 6 S2 428 497 507 3.61 0.106 6 S1、S2在门、属水平上微生物种群结构及相对丰度如图4和图5所示。系统构建过程中S1、S2系统中优势菌门类主要有Proteobacteria (47.8%、24.3%)、Planctomycetes (5.7%、36.5%)、Chlorobi (7.0%、8.7%)、Chloroflexi (1.9%、12.4%)、Nitrospirae (1.9%、3.8%)。有研究表明:系统脱氮功能菌亚硝化菌属于Proteobacteria门;厌氧氨氧化菌属于Planctomycetes门,随着运行时间的增加成为优势菌门;亚硝酸盐氧化菌属于Nitrospirae门。在本研究中,同时还设置了一组以组合填料为对照组的SNAP系统构建的平行实验,与天然椰丝纤维填料构建的生物系统进行对比。结果表明:组合填料中优势菌门类主要有Proteobacteria (34.9%)、Planctomycetes (23.7%)、Chlorobi (16%)、Chloroflexi (7.1%)、Nitrospirae (4.3%);Proteobacteria、Planctomycetes菌门丰度低于椰丝纤维填料系统中的相对丰度较高,表明天然椰丝纤维填料富集功能菌能力更强。

由图5可知,在属水平上,S1、S2系统中脱氮优势功能菌属主要有Candidatu sBrocadia (2.1%、32.4%)、Nitrosomonas (8.8%、5.1%)、Nitrospira (5.6%、3.8%)。其中,Candidatus Brocadia为厌氧氨氧化菌[19],反应器运行至第30天时出现厌氧氨氧化菌,运行至第140天时相对丰度显著增加,成为优势菌属;Nitrosomonas为亚硝化单胞菌属[20],相对丰度由第30天的降为第140天时的5.1%;Nitrospira为硝化菌属,第140天时相对丰度降至3.8%,表明系统中硝化菌被抑制。此外,采用组合填料的对照组中,优势功能菌属主要有Candidatus Brocadia (18.2%)、Nitrosomonas (3.3%)、Nitrospira (2.9%),其相对丰度均低于椰丝纤维填料系统。上述实验结果表明,低氨氮废水SNAP系统构建过程中,系统的主要脱氮功能菌为亚硝化菌Nitrosomonas和厌氧氨氧化菌Candidatus Brocadia,通过天然椰丝纤维填料自然挂膜可以强化功能菌群的富集,构建出SNAP系统。

2.2 COD/TN对系统脱氮效能及微生物种群的影响

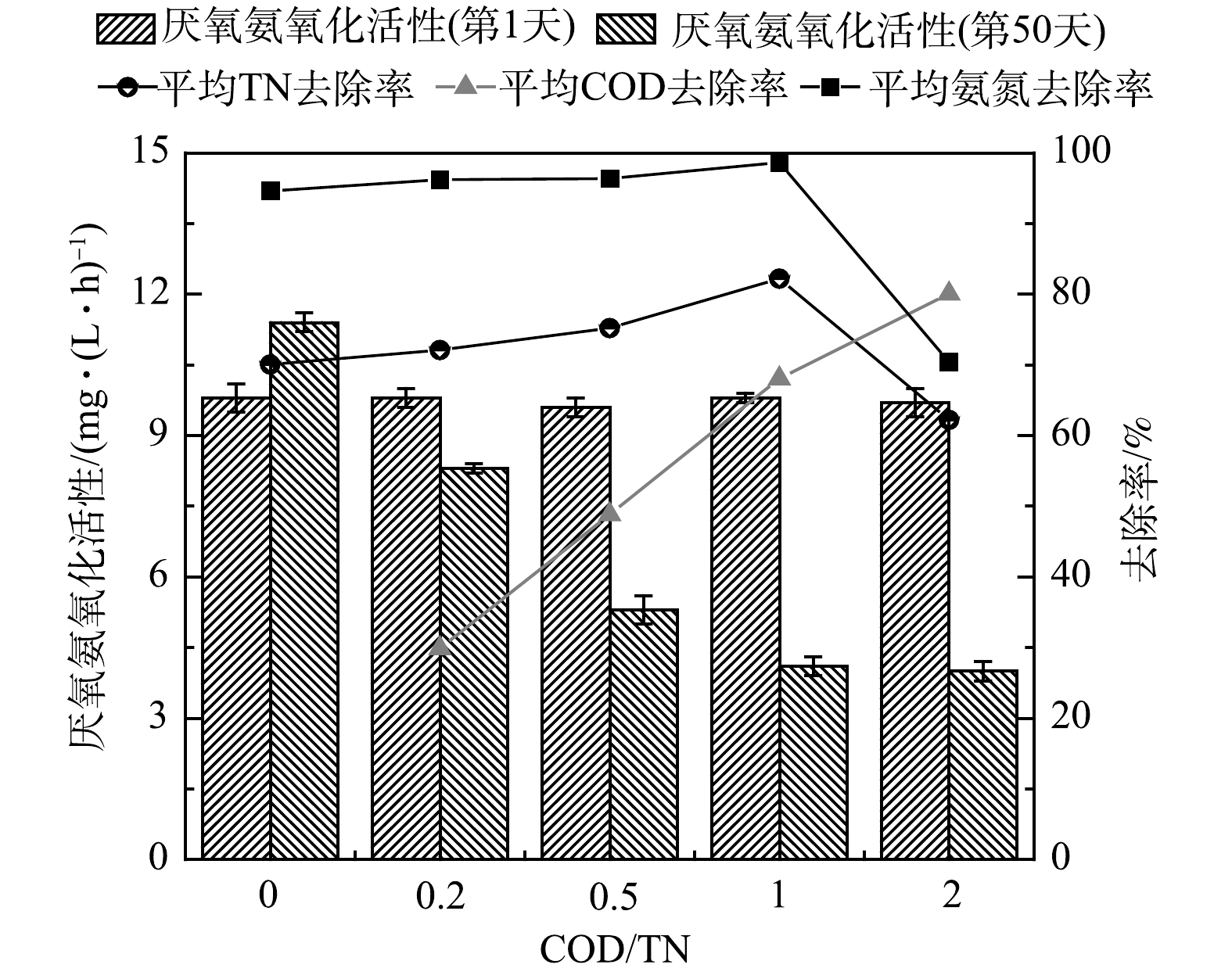

1)COD/TN对系统脱氮效能的影响。由图6可看出,随着进水C/N增加,系统中厌氧氨氧化菌活性逐渐下降,TN去除率先增加后降低。当COD/TN为0、0.2、0.5、1、2时,系统

NH+4 NH+4 当COD/TN≤0.2时,系统以厌氧氨氧化自养脱氮路径为主,异养反硝化菌脱氮为辅;当COD/TN为0.5~1.5时,厌氧氨氧化菌属丰度和活性逐渐下降,反硝化菌属相对丰度增加,此时,系统脱氮路径以短程硝化反硝化为主,以厌氧氨氧化自养脱氮为辅。当COD/TN>2 时,系统中亚硝化菌、厌氧氨氧化功能菌群丰度进一步降低,系统通过短程硝化反硝化、厌氧氨氧化路径的脱氮能力进一步降低。上述结果表明,为了保证低质量浓度氨氮废水SNAP系统稳定高效运行,需要在SNAP系统前需要设置废水有机物去除工艺单元。

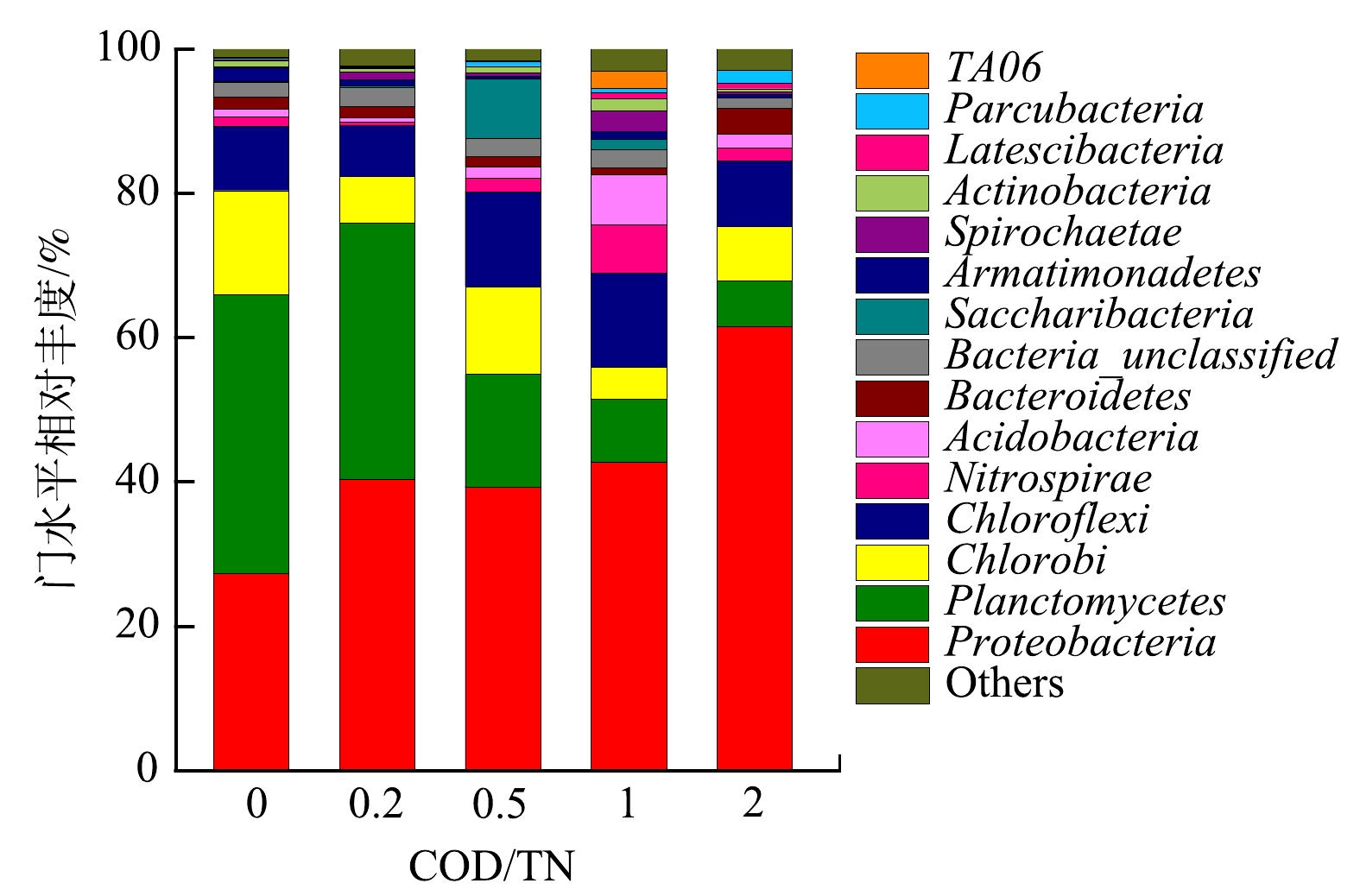

2) COD/TN对系统微生物种群的影响。分别取COD/TN为0、0.2、0.5、1、2时反应器运行稳定后的生物膜样品,进行16S rRNA高通量测序,门、属水平上微生物种群结构及相对丰度如图7和图8所示。当COD/TN为0、0.2、0.5、1、2时,系统优势功能菌门类主要有Proteobacteria (27.3%、40.3%、39.2%、42.7%、61.5%)、Planctomycetes (38.6%、35.6%、15.7%、8.7%、6.3%)、Nitrospirae (1.3%、0.5%、1.8%、6.7%、1.8%)。其中,厌氧氨氧化菌属于Planctomycetes门,随着COD/TN增加,该菌门丰度显著降低;大部分异养反硝化菌属于Proteobacteria菌门,随着COD/TN增加,Proteobacteria门相对丰度增加。

在COD/TN为0、0.2、0.5、1、2的系统中,优势脱氮功能菌属主要有亚硝化菌Nitrosomonas (3.4%、3.7%、5.3%、8.7%、1.3%); 厌氧氨氧化菌Candidatus Brocadia (37.6%、32.2%、8.4%、3.7%、1.0%);在COD/TN为0.2、0.5、1、2的系统中,异养反硝化菌属主要有Thauera (1.8%、3.0%、9.8%、3.4%)、Denitratisoma (0.5%、1.0%、2.2%、9.4%)、Pseudomonas (0.4%、0.8%、2.5%、9.0%),Bdellovibrio (0.2%、0.5%、0.5%、1.1%),反硝化菌属总丰度分别为2.9%、5.3%、15.0%、22.9%。当COD/TN为0.2、0.5、1时,系统内亚硝化菌属相对丰度增加,进水中COD消耗部分溶解氧,使反应器中DO维持在较低水平,因而有利于亚硝化菌富集;但当COD/TN为2时,由于有机物质量浓度增加导致溶解氧质量浓度降低,对亚硝化菌属形成抑制,系统脱氮效能显著降低;随着COD/TN增加,厌氧氨氧化菌属的相对丰度显著下降。上述结果表明:对于低氨氮废水,当COD/TN≤0.2时,系统主要脱氮路径为厌氧氨氧化;当COD/TN为0.5~1.5时,系统脱氮路径以短程硝化反硝化为主,厌氧氨氧化为辅;当COD/TN≥2 时,系统中亚硝化菌、厌氧氨氧化功能菌群丰度进一步降低,系统通过短程硝化反硝化、厌氧氨氧化路径脱氮能力进一步降低。

3. 结论

1)在温度为(30±1) ℃、氮负荷为0.1 kg·(m3·d)−1、进水NH4+-N质量浓度梯度降低的条件下,以天然椰丝纤维为填料的低氨氮废水SNAP系统采用自然挂膜方式,反应器运行85 d时系统初步构建成功,并稳定运行至第140天,NH4+-N、TN去除率分别为94.58%、70.07%;所构建的SNAP系统中,脱氮功能菌属主要有Nitrosomonas(5.1%)、Candidatus Brocadia(32.4%)。

2)进水COD/TN对低氨氮废水SNAP系统的脱氮效能影响显著。当COD/TN为0、0.2、0.5、1、2时,TN平均去除率分别为70.07%、72.09%、75.18%、82.19%、62.19%。随着进水COD/TN增加,厌氧氨氧化活性逐渐下降。

3)进水COD/TN对低氨氮废水SNAP系统脱氮路径影响显著。当COD/TN≤0.2时,系统以厌氧氨氧化自养脱氮路径为主;当COD/TN为0.5~1.5时,系统脱氮路径以短程硝化反硝化为主,厌氧氨氧化自养脱氮为辅;当COD/TN≥2 时,系统通过短程硝化反硝化、厌氧氨氧化路径脱氮能力进一步降低。系统中优势脱氮功能菌属主要有Nitrosomonas、Candidatus Brocadia、Thauera、Denitratisoma 、Pseudomonas、Bdellovibrio。

-

表 1 进口含铜样品的元素组成

Table 1. Elemental analysis of imported copper samples

%(质量分数) 供试样品 Cu Fe S Si As Zn Pb Ca Al Mn 其他 铜精矿 30.10 23.49 14.84 2.56 1.33 1.08 1.15 0.81 0.68 0.09 23.94 铜锍 33.38 15.15 12.46 8.37 4.79 1.59 0.61 0.31 0.41 0.13 22.90 铜转炉渣 16.70 39.39 5.21 4.72 - 1.87 0.47 - 0.64 0.05 30.95 含铜污泥 29.71 21.48 1.81 1.48 - 1.03 0.25 4.97 2.55 - 36.72 -

[1] BOHDAN K, ADELA S, VOJTECH E, et al. Variability of the copper isotopic composition in soil and grass affected by mining and smelting in Tsumeb, Namibia[J]. Chemical Geology, 2018, 493: 121-135. doi: 10.1016/j.chemgeo.2018.05.035 [2] 陶美娟, 周静, 梁家妮, 等. 大型铜冶炼厂周边农田区大气重金属沉降特征研究[J]. 农业环境科学学报, 2014, 33(7): 1328-1334. doi: 10.11654/jaes.2014.07.011 [3] 中华人民共和国国务院办公厅. 禁止洋垃圾入境推进固体废物进口管理制度改革实施方案[EB/OL].[2017-07-27]. http://www.gov.cn/zhengce/content/2017-07/27/content_5213738.htm. [4] 于海波. 铜火法吹炼、精炼脱杂工艺技术研究与应用[D]. 云南: 昆明理工大学, 2020. [5] ERDENEBOLD U, CHOI H M, WANG J P. Recovery of pig iron from copper smelting slag by reduction smelting[J]. Archives of Metallurgy and Materials, 2018, 63(4): 1793-1798. [6] LI L, HU J H, WANG H. Smelting oxidation desulfurization of copper slags[J]. Journal of Iron & Steel Research, 2012, 19(12): 14-20. [7] MAO C, CUI Z, ZHAO B. Slag chemistry of bottom blown copper smelting furnace at Dongying Fangyuan[M]. Springer International Publishing, 2015. [8] 付中华, 张延玲, 王玉刚, 等. 熔融条件下飞灰中Zn与Pb的挥发行为及其影响因素[J]. 过程工程学报, 2009, 9(S1): 473-481. [9] ZHOU C C, LIU G J, XU Z Y, et al. Effect of ash composition on the partitioning of arsenic during fluidized bed combustion[J]. Fuel, 2017, 204: 91-97. doi: 10.1016/j.fuel.2017.05.048 [10] 柴祯. 废杂铜冶炼过程中污染物迁移转化规律研究[D]. 北京: 中国矿业大学, 2014. [11] 周凯, 高红, 岳波, 等. 典型进口废铜废铝初级加工原料模拟熔炼烟气中重金属产生特性研究[J]. 环境科学研究, 2021, 34(6): 1482-1488. [12] JIAO F C, ZHANG L, SONG W J, et al. Effect of inorganic particulates on the condensation behavior of lead and zinc vapors upon flue gas cooling[J]. Proceedings of the Combustion Institute, 2013, 34(2): 2821-2829. doi: 10.1016/j.proci.2012.07.062 [13] PARK K, HYUN J, MAKEN S, et al. Vitrification of municipal solid waste incinerator fly ash using Brown's gas[J]. Energy & Fuels, 2005, 19(1): 258-262. [14] 边瑞民, 王智, 魏传兵, 等. 降低炼铜弃渣含铜技术的应用研究[J]. 有色金属(冶炼部分), 2018(4): 10-14. [15] 中华人民共和国环境保护部. 水质32种元素的测定 电感耦合等离子体发射光谱法: GB HJ 776-2015[S]. 北京: 中国环境科学出版社, 2016. [16] 李良斌, 代红坤, 李强, 等. 旋浮熔炼+旋浮吹炼与富氧侧吹熔炼+多枪顶吹连续吹炼工艺比较[J]. 有色金属(冶炼部分), 2021(2): 51-59. [17] 谭春梅. 处理高砷铜精矿的火法冶金处理技术[J]. 中国有色冶金, 2016, 45(4): 1-6. doi: 10.3969/j.issn.1672-6103.2016.04.001 [18] CAMUS F, DILLES J H. A special issue devoted to porphyry copper deposits of northern chile[J]. Economic Geology, 2001, 96(2): 233-237. doi: 10.2113/gsecongeo.96.2.233 [19] 李科, 罗永春, 徐祥, 等. 顶吹熔炼过程冰铜品位控制实践[J]. 有色金属(冶炼部分), 2016(11): 8-11. [20] SARRAFI A, RAHMATI B, HASSANI H R, et al. Recovery of copper from reverberatory furnace slag by flotation[J]. Minerals Engineering, 2004, 17(3): 457-459. doi: 10.1016/j.mineng.2003.10.018 [21] ABANADES S, FLAMANT G, GAUTHIER D. Kinetics of heavy metal vaporization from model wastes in a fluidized bed[J]. Environmental Science & Technology, 2002, 36(17): 3879-3884. [22] 宋闯. 垃圾焚烧飞灰中重金属高温挥发影响因素分析[J]. 环境保护与循环经济, 2015, 35(5): 40-42. doi: 10.3969/j.issn.1674-1021.2015.05.011 [23] 谭鹏夫, 张传福. 铜熔炼中熔炼温度对伴生元素分配行为的影响[J]. 有色金属, 1998, 50(2): 59-63. [24] 胡济民. 垃圾焚烧过程中重金属铅和铜迁移分布特性的研究[D]. 上海: 华东理工大学, 2018. [25] WANG K S, CHIANG K Y, LIN S M, et al. Effects of chlorides on emissions of toxic compounds in waste incineration: Study on partitioning characteristics of heavy metal[J]. Chemosphere, 1999, 38(8): 1833-1849. doi: 10.1016/S0045-6535(98)00398-1 [26] 周叶刚, 李江涛, 李汝云, 等. 铜火法冶炼过程中杂质元素的分布规律及对回收率的影响机理探究[J]. 中国有色冶金, 2019, 48(4): 9-16. doi: 10.3969/j.issn.1672-6103.2019.04.004 [27] STUCKI S, JAKOB A. Thermal treatment of incinerator fly ash: Factors influencing the evaporation of ZnCl2[J]. Waste Management, 1998, 17(4): 231-236. doi: 10.1016/S0956-053X(97)10020-4 [28] 万新宇, 齐渊洪, 高建军, 等. 含砷铜渣高温焙烧过程中砷的挥发行为[J]. 有色金属工程, 2017, 7(4): 40-45. doi: 10.3969/j.issn.2095-1744.2017.04.009 [29] JAKOB A, STUCKI S, KUHN P. Evaporation of heavy metals during the heat treatment of municipal solid waste incinerator fly ash[J]. Environmental Science & Technology, 1995, 29(9): 2429-2436. -

下载:

下载: