-

膜处理技术与混凝沉淀、过滤、活性炭吸附等污水深度处理常规技术相比,具有处理效率高、出水水质稳定、占地面积小、便于自动化操作等优点,因而近年来在污水处理及回用领域得到越来越广泛的应用。而在诸多膜材料中,陶瓷膜以其强度高、耐高温、耐酸碱、易清洗、寿命长等优点成为当前最具发展潜力的新型膜分离材料,基于陶瓷膜应用的膜法废水处理技术亦成为国内外相关研究的热点[1-5]。膜污染是膜法水处理技术共同面临的技术难题,如何在阐明陶瓷膜膜污染机理的基础上,充分发挥陶瓷膜废水处理技术优势,开发陶瓷膜膜污染高效控制技术方法,已成为陶瓷膜废水处理技术理论研究与推广应用领域亟待解决的问题[6]。

国内外学者针对膜污染机理和控制开展了大量研究工作,常见的膜污染控制方法主要有强化预处理、膜材料改性、运行优化控制等[7-14]。其中,运行优化控制是减缓膜污染最为经济有效的手段,一般是通过合理调控初始膜通量、过滤时间、间歇时间、反冲洗时间、反冲洗强度、反冲洗频率等运行参数,实现膜污染过程的有效减缓,延长膜单元稳定运行周期。

为进一步挖掘陶瓷膜废水处理技术潜力,提高陶瓷膜运行稳定性,本研究以驻济某高校中水站二级出水为处理对象,开发陶瓷膜小试反应器,在测定陶瓷膜自身水处理特性的基础上,以初始膜通量、过滤时间、间歇时间、反冲洗时间作为陶瓷膜反应器关键运行控制参数,设计四因素三水平正交实验,优选陶瓷膜处理二级出水工况,考察了最优运行工况下陶瓷膜对二级出水中各污染物去除效能,结合对原水、膜污染层的表征与膜污染阻力分析,揭示了陶瓷膜膜污染机理,进而形成具有针对性的陶瓷膜运行优化控制技术,为陶瓷膜在废水处理及回用领域的进一步推广应用提供参考。

-

1)实验装置。本研究采用的平板陶瓷膜处理市政污水二级出水实验装置如图1所示。进水箱、出水箱和反冲洗水箱均为PVC材质;开启进水离心泵,将原水由进水箱泵入膜池;膜池由有机玻璃制成,有效容积250 L;膜池内平行设置4组陶瓷膜组件,陶瓷膜为购自山东某工业陶瓷研究院的同一批次全新平板陶瓷膜,膜材质为α-Al2O3,膜孔径为0.1 μm,有效过水面积为0.112 8 m2,pH 为2~12,温度上限60 ℃;膜池内设置传感式恒温加热棒2根,控制膜池内水温恒定在25 ℃;膜组件底部设有微孔曝气管,由曝气泵供气,经气体转子流量计控制气量,曝气强度控制在5 L·min−1;膜后采用型号BT300-2J蠕动泵负压抽吸出水,出水蠕动泵转速1~300 r·min−1,采用真空压力表在线监测出水压力;为防止离子吸附造成反冲洗过程膜孔内无机污染,反冲洗采用去离子水,经型号BT300-2J蠕动泵正压泵入陶瓷膜,反冲洗强度控制在1 L·min−1;设置电磁阀和时间继电器构成自动控制装置实现出水泵、反冲洗泵自动启闭。

2)实验用水取自驻济某高校中水站的二级出水。该中水站工艺流程为:曝气调节—水解酸化—缺氧/好氧生物接触氧化—沉淀—过滤—消毒—二级出水。二级出水水质指标为:水温为5~20 ℃、pH=7.8~8.4、浊度3.63~6.82 NTU、色度0.183~0.551度、COD 39~76 mg·L−1、UV254 0.108~0.147 cm−1、氨氮5~16 mg·L−1、TP 3.25~5.08 mg·L−1。

-

1)膜通量测定。采用体积法进行平板陶瓷膜膜通量测定,即由电子秒表计时,由量筒量取5 min内通过一定膜面积(本实验所用平板陶瓷膜面积为0.112 8 m2)的过滤液体积,根据式(1)计算膜通量。

式中:J为膜通量,L·(m2·h)−1;V为一定时间内量取的过滤液体积,L;S为膜面积,m2;t为测量时间,h。

2)陶瓷膜运行优化控制正交实验。膜污染除受膜自身性质、原水水质等因素影响外,主要受温度、初始膜通量、曝气条件、过滤时间、间歇时间、反冲洗周期、反冲洗强度、反冲洗时间等系列运行控制因素的影响[15-24]。本实验所采用的膜材料为同一批次平板陶瓷膜,且原水水质较稳定,故不考虑膜材料差异、原水水质变化等因素对膜污染的影响。本研究将运行控制因素优化作为实现膜污染有效控制的关键技术手段,结合对现有相关文献的汇总分析,遴选出初始膜通量、过滤时间、间歇时间和水力反冲洗时间4个运行参数作为平板陶瓷膜运行优化控制的关键因子,每个关键控制因子均取3个水平,构建四因素三水平正交实验,开展平板陶瓷膜反应器处理市政污水二级出水运行优化控制实验研究。

3)正交实验数据分析。本研究中,以SPSS (statistical package for the social science)软件对运行优化控制正交实验结果进行统计分析。基于各运行控制因素方差分析,得出4个关键控制因素对响应值(平均膜通量)的影响显著性;基于各运行控制因素的单因素统计数据分析,得出各关键运行控制因素的最佳水平,验证运行优化控制正交实验结果。

4)扫描电子显微镜-能谱分析(SEM-EDS)。通过扫描电子显微镜-能谱分析仪(SEM-EDS,QUANTA FEG250,美国FEI公司,美国),分析平板陶瓷膜表面形貌。样品在分析前需进行预处理,采用真空冷冻干燥法去除膜片样品自由水、结合水和毛细水;将膜片样品黏贴在SEM专用单晶硅台上,用IB-5(Giko)型离子溅射镀膜仪于样品上喷金1 min;对膜片样片选取的代表性区域,利用EDS进行膜面污染层元素定性分析,并利用EDS对原水进行元素定性对比分析。

5)傅里叶变换红外光谱分析(FTIR)。通过傅里叶变换红外光谱仪(FTIR, Nicolet IS10,美国赛默飞世尔科技公司,美国)对比分析原水和膜面污染层有机物及部分无机物官能团信息。样品在分析前需进行预处理,原水、膜片污染层样品真空冷冻干燥72 h,去除样品中的自由水、结合水和毛细水;利用研磨好的溴化钾压片,将样品与溴化钾按1∶1 000的比例混合;压片后利用FTIR对样品进行红外谱图测定,FTIR工作条件为:频率4 cm−1,扫描波长4 000~400 cm−1,谱图为32次扫描的平均值。利用Omnic8.0对FTIR产生的数据进行处理和分析。

6)常规指标分析测试。COD、UV254、SS、浊度、色度、氨氮、总磷、pH等常规指标根据水和废水监测分析方法[25]进行测定。

-

陶瓷膜自身良好的水处理特性是保证平板陶瓷膜反应器良好运行的决定因素之一。本研究首先对平板陶瓷膜清水通量、临界通量等自身水处理特性进行了测定。

1)平板陶瓷膜清水通量。以蒸馏水作为膜前原水,测定平板陶瓷膜清水通量。通过调节蠕动泵转速,逐步提高平板陶瓷膜操作压力,操作压力分别控制在2、5、9、13、22 kPa,每个压力梯度持续30 min,以测得的每5 min滤出液体积带入式(1)计算膜通量,把测得的稳定通量作为平板陶瓷膜清水通量。平板陶瓷膜清水通量随膜压变化如图2所示。由图2可以看出,本实验条件下,平板陶瓷膜清水通量基本与膜压成正比,当膜压达到22 kPa时,平板陶瓷膜平均清水通量值可达736.65 L·(m2·h)−1。清水通量大,从一方面说明平板陶瓷膜性能优良,是理想的膜材料。

2)平板陶瓷膜临界通量。本研究采用通量阶梯法测定平板陶瓷膜临界通量。以驻济某高校中水站的二级出水作为膜前原水。调节蠕动泵转速分别为40、50、60、70、80、90、100 r·min−1,稳步提高平板陶瓷膜操作压力,每一转速下维持稳定运行30 min,以测得的每5 min滤出液体积带入式(1)计算平均膜通量。膜通量和膜压随时间的变化如图3所示。由图3可以看出,在运行的前180 min内,即平板陶瓷膜运行通量不超过81 L·(m2·h)−1时,平板陶瓷膜连续30 min内的膜压基本可以稳定在同一个水平上;运行180 min之后,即平板陶瓷膜运行通量高于81 L·(m2·h)−1后,膜压则随运行时间的继续增加而不断上升,且上升速率很快,同时伴有膜通量的下降,说明膜通量高于81 L·(m2·h)−1后,发生了不可恢复膜污染,膜通量达到临界通量。因此,确定本实验条件下平板陶瓷膜处理市政污水二级出水临界通量为81 L·(m2·h)−1,在此临界通量下,平板陶瓷膜至少可以稳定运行30 min。

-

1)平板陶瓷膜运行优化控制正交实验设计。本研究为优化平板陶瓷膜处理市政污水二级出水运行控制条件,设计开展了四因素三水平正交实验,以期筛选得出最佳运行工况。正交实验设计如表1所示。根据表1正交实验设计安排,依次开展九种工况下平板陶瓷膜处理市政污水二级出水运行实验,每一工况下同时运行2片全新陶瓷膜作为平行实验,同时观测两片陶瓷膜的膜通量及跨膜压差随时间的变化情况,以每一工况下2片膜平均膜通量的均值作为对应工况下的平均膜通量。

2)平板陶瓷膜运行优化控制正交实验结果分析。不同运行工况下平板陶瓷膜处理市政污水二级出水平均膜通量实验结果如图4所示。由图4可见,各运行工况下平板陶瓷膜处理市政污水二级出水平均膜通量由大到小顺序为S7> S6> S9> S4> S5> S8> S2> S3> S1;S7运行工况下,即蠕动泵转速200 r·min−1(对应初始膜通量200 L·(m2·h)−1)、过滤时间10 min、水力反冲时间30 s、间歇运行时间2 min,平板陶瓷膜平均产水量最大,为43.08 L·(m2·h)−1;S1运行工况下,平板陶瓷膜平均产水量最小,为18.18 L·(m2·h)−1。直观确定S7运行工况为平板陶瓷膜处理市政污水二级出水最佳运行工况。

随后采用SPSS软件对上述正交实验结果进行处理分析。各运行控制因素方差分析结果如表2所示。df为自由度,Sig为显著性,Sig值越小说明该运行控制因素对平板陶瓷膜平均产水量的影响越显著。由表2各运行控制因素的方差分析数据可以看出,四因素对平板陶瓷膜处理市政污水二级出水平均膜通量影响显著性的顺序依次为蠕动泵转速(即初始膜通量)>间歇时间>过滤时间>水力反冲时间。

采用SPSS软件对各运行控制因素对应的平板陶瓷膜平均膜通量进行了统计分析,结果如表3所示。表中统计得出了每个运行控制因素对应的3个水平下平板陶瓷膜平均膜通量均值、标准误差和置信区间。由表3各运行控制因素下平板陶瓷膜平均膜通量的统计分析可知,各运行控制因素分别为以下水平时平均膜通量统计均值更高,即蠕动泵转速200 r·min−1、过滤时间10 min、水力反冲时间30 s、间歇时间2 min,这与前述四因素三水平正交实验直观得出的最佳运行工况S7一致,统计分析数据进一步验证了正交实验结果。

-

1)产水效能研究。本研究对最佳运行工况下平板陶瓷膜处理市政污水二级出水长期运行的产水效能进行了实验考察。运行工况采用前期正交实验确定的最佳运行工况S7,即蠕动泵转速200 r·min−1、过滤时间10 min、水力反冲时间30 s、间歇时间2 min;其他运行参数为,水温恒定25 ℃,连续曝气,曝气强度5 L·min−1,水力反冲洗强度为1 L·min−1。采用全新平板陶瓷膜作为本实验阶段用膜,正式实验开始前,以蒸馏水作为膜前原水,抽吸2 h对陶瓷膜进行预清洗,并测定其清水通量与前述实验确定的清水通量对比,以确保空白状态下陶瓷膜产水性能稳定性。最佳运行工况下平板陶瓷膜处理市政污水二级出水长期运行膜通量变化情况如图5所示。从图5可以看出,在最佳运行工况下,平板陶瓷膜处理市政污水二级出水,其膜通量在运行初期的100 h衰减较快,由198.81 L·(m2·h)−1下降至67.43 L·(m2·h)−1;运行100 h后膜通量衰减逐渐放缓,在100 ~400 h,膜通量相对稳定,接近平均膜通量43.08 L·(m2·h)−1;运行400 h以内,水力反冲洗对膜通量恢复有较好的效果;运行400 h之后,水力反冲洗对平板陶瓷膜膜通量恢复效果显著下降,说明此阶段已形成了较为密实的滤饼层;运行至730 h,膜通量已衰减至15.42 L·(m2·h)−1,此时平板陶瓷膜产水效能极低,说明膜污染已经非常严重,滤饼层逐渐被压实并形成了泥饼层,水力反冲对膜通量恢复已无效果,必须采取化学清洗等手段使其通量恢复。为保证平板陶瓷膜处理市政污水二级出水时较高的产水率,本研究界定最佳运行工况下平板陶瓷膜稳定运行时间为16 d(384 h),在此运行时间内平板陶瓷膜膜通量可始终保持在平均膜通量43.08 L·(m2·h)−1以上。由上述研究结果可以看出,最佳运行工况下,平板陶瓷膜处理市政污水二级出水可以在保持较高产水率的前提下,稳定运行16 d,说明通过前期正交实验所遴选的最佳运行工况,可有效保证平板陶瓷膜系统产水稳定性;同时由图5的膜通量变化也可以看出,即便是在最佳运行工况下,膜污染依然是不可避免。

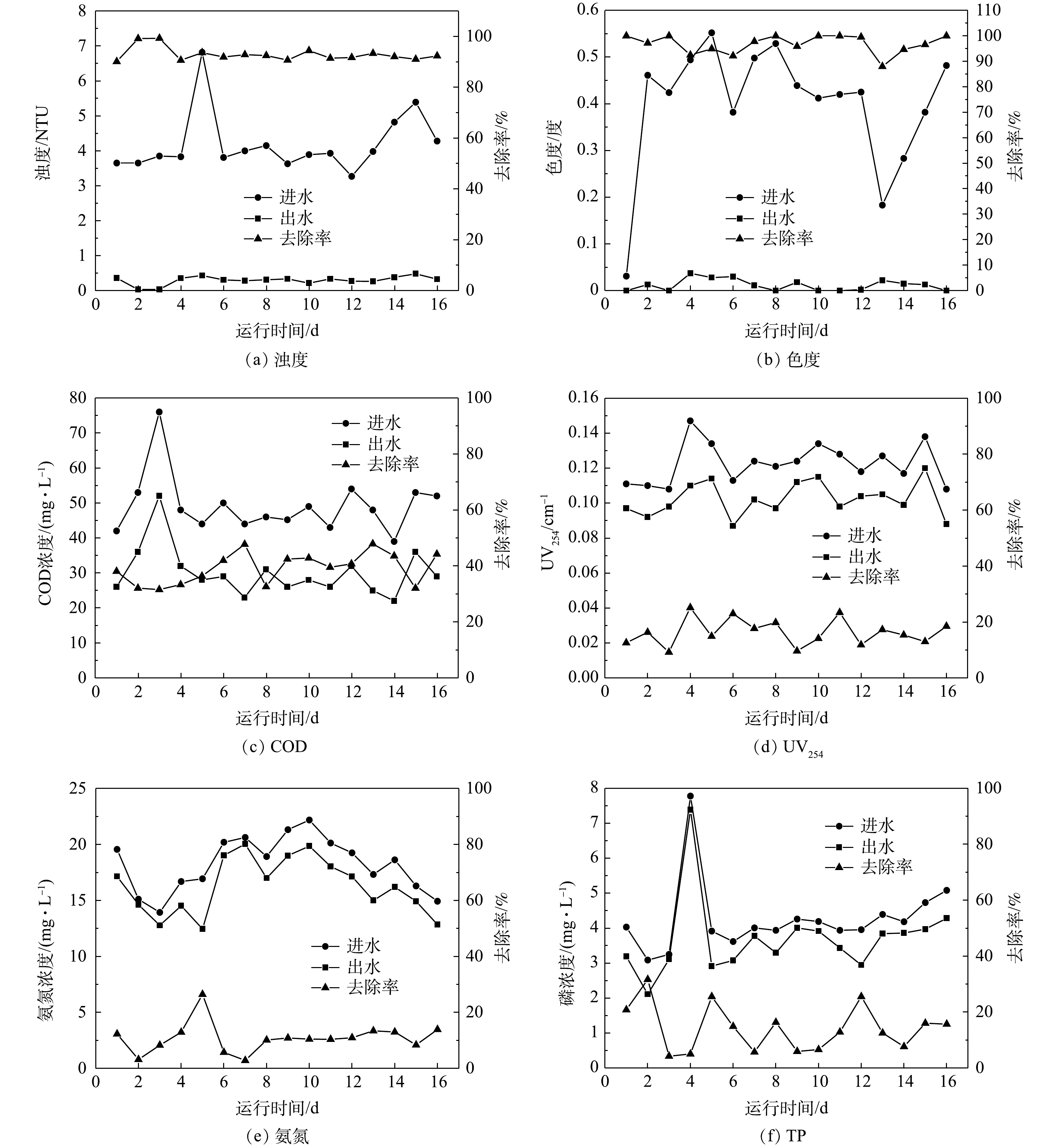

2) 污染物去除效能研究。本研究在考察长期运行条件下平板陶瓷膜系统产水效能的同时,对最佳运行工况下平板陶瓷膜处理市政污水二级出水污染物去除效能也进行了实验考察。平板陶瓷膜系统对浊度、色度、COD、UV254、氨氮、总磷等污染物去除效能如图6所示。

由图6(a)和图6(b)可以看出,市政污水二级出水经平板陶瓷膜过滤后,出水浊度、色度显著降低,出水浊度保持在0.5 NTU以下,平均去除率为93.50%;出水色度保持在0.022 度以下,平均去除率97.62%。由图6(c)可知,平板陶瓷膜对市政污水二级出水COD去除率在30.77%~40.9%,平均值为39.19%,系统COD为22~52 mg·L−1,平均值为28.74 mg·L−1。系统出水的浊度、色度及COD满足《城市污水再生利用 城市杂用水水质》(GB/T 18920-2002)标准要求。

由图6(d)可以看出,平板陶瓷膜对市政污水二级出水中UV254表征的芳香族和腐殖质类有机物去除率为9.25%~25.17%,平均去除率为15.29%,系统出水UV254值在0.088~0.118 cm−1,平均值为0.1 cm−1。本研究中平板陶瓷膜对市政污水二级出水UV254指标去除率较低,主要是因为本研究原水为经生化处理后的市政污水二级出水,原水中UV254所表征的芳香族和腐殖质类有机物含量较低,陶瓷膜对上述物质截留量有限;后期FTIR表征结果亦证明,原水及造成膜污染的有机物主要为含C=O双键的脂肪族类化合物和酰胺类物质,而非UV254所表征的含C=C双键和C=O双键的芳香族类化合物及腐殖酸类物质。

由图6(e)和图6 (f)可以看出,平板陶瓷膜对市政污水二级出水中氨氮平均去除率为12.87%,出水氨氮平均浓度为15.74 mg·L−1,系统出水氨氮指标满足《城市污水再生利用 城市杂用水水质》(GB/T 18920-2002)中城市绿化、建筑施工用水要求;系统总磷平均去除率为16.79%,出水总磷平均质量浓度为3.81 mg·L−1。上述实验结果表明,平板陶瓷膜对市政污水二级出水中氮磷无明显去除能力,这与膜法水处理技术去除污水中氮磷等营养物质效能较低的一般性结论相一致。

-

1)膜污染成分分析。采用EDS对原水和平板陶瓷膜污染层进行了元素组成及含量对比表征(图7)。由图7中原水和平板陶瓷膜污染层的元素对比分析可见,平板陶瓷膜在处理市政污水二级出水后,所形成的污染层发生了明显的C、N、Si元素富集现象。污染层中C元素含量为35.09%,较原水增加了18.37%;N元素含量为17.53%,较原水增加了13.57%;说明造成平板陶瓷膜膜污染的主要污染物是含C、N有机物。此外,污染层中Si元素含量为2.90%,较原水增加了2.53%,污染层中还检测出了原水中未检出的Fe、Al等元素,说明金属离子也是造成平板陶瓷膜污染的重要原因。

实验中还通过FTIR对原水和膜污染层有机物及部分无机物官能团信息进行了对比分析,如图8所示。图8中,3 428 cm−1处NH伸缩振动为脂肪族酰胺基特征峰,1 650 cm−1处C=O拉伸为羰基特征峰,1 260 cm−1处为无机硅化合物特征峰,700~750 cm−1处为CH2特征峰。对比分析原水和污染层红外光谱可以发现,原水特征官能团主要为无机硝酸盐基团、NH基、NH2基、CH2基和C=O基,由此可以看出,原水主要污染物为无机硝酸盐类、脂肪族类和酰胺类;而相比原水,陶瓷膜污染层主要特征官能团中无机硝酸盐基团不再明显,NH基、CH2基变化不大,C=O基和无机硅化物类则更加明显;因而可以判定造成陶瓷膜污染的有机污染物主要以脂肪族类和酰胺类为主,无机污染物则主要以硅化物类为主。FTIR与EDS结果相对应,同时也解释了图6所反映出的平板陶瓷膜对UV254表征的芳香族和腐殖质类有机物去除能力较低的原因。

2) 膜污染阻力分析。本实验根据标准的Darcy定律过滤模型来确定平板陶瓷膜过滤过程中的阻力分布情况[1-2,26-32],由式(2)计算膜总过滤阻力Rt,进而计算阻力分步情况。

式中:Rt为膜总过滤阻力,m−1;ΔP为跨膜压差,Pa;J为膜通量,L·(m2·h)−1;μ为料液黏度,Pa·s;Rm为新膜自身过滤阻力,m−1;Ri为膜孔内污染产生的过滤阻力,m−1;Rc为浓差极化边界层造成的过滤阻力,m−1;Rg为凝胶层造成的过滤阻力,m−1。

通过3次平行实验测定并计算各部分过滤阻力,所得平板陶瓷膜各部分过滤阻力及占总阻力比例如表4所示。由表4可以得出,在本实验条件下,平板陶瓷膜自身过滤阻力Rm,约占总过滤阻力的14%~15%,这部分阻力由平板陶瓷膜材料和膜孔径决定;膜孔内污染产生的过滤阻力Ri,约占总过滤阻力的8%~10%,这部分阻力主要发生在膜滤开始阶段,所占比例小,且随着操作压力的增大变化更不明显;浓差极化边界层造成的过滤阻力Rc,约占总过滤阻力的9%~14%,这部分阻力由浓差极化产生,是可逆的,通常可以通过优化运行控制参数来克服;凝胶层造成的过滤阻力Rg,约占总过滤阻力的63%~68%,这部分过滤阻力是由于污染物颗粒在膜面不断积累浓度达到饱和析出、沉积所产生的,需要通过反冲洗或者化学清洗去除。

通过以上对平板陶瓷膜处理市政污水二级出水过程中各部分过滤阻力的分析可知,凝胶层阻力是影响平板陶瓷膜过滤过程的最主要因素,对平板陶瓷膜膜污染的形成起主导作用。

-

1)平板陶瓷膜处理市政污水二级出水最优运行工况为蠕动泵转速200 r·min−1(对应初始膜通量200 L·(m2·h)−1)、过滤时间10 min、水力反冲时间30 s、间歇运行时间2 min,此时平板陶瓷膜平均产水量最大,为43.08 L·(m2·h)−1;正交实验结果的方差分析得出,四因素对平均膜通量影响显著性依次为蠕动泵转速(即初始膜通量)>间歇时间>过滤时间>水力反冲时间,单因素统计分析得出的最佳水平组合与正交实验得出的最优工况相一致。

2)最佳运行工况下平板陶瓷膜处理市政污水二级出水可保持稳定运行16 d(384 h),在此期间膜通量可始终保持在平均膜通量43.08 L·(m2·h)−1以上,出水浊度、色度分别保持在0.5 NTU、0.022 度以下,出水COD平均值为28.74 mg·L−1,上述3项出水水质指标满足《城市污水再生利用 城市杂用水水质》(GB/T 18920-2002)标准要求;平板陶瓷膜对市政污水二级出水中的UV254、氨氮和总磷的平均去除率均较低,约为15%左右。

3)造成陶瓷膜污染的有机污染物主要以脂肪族类和酰胺类为主,无机污染物则主要以硅化物类为主,无机金属离子也是造成膜污染的重要原因;凝胶层阻力是影响平板陶瓷膜过滤过程的最主要因素,对平板陶瓷膜膜污染的形成起主导作用。

陶瓷膜处理二级出水运行优化控制与膜污染机制分析

Operational optimization control and membrane fouling mechanism analysis of ceramic membrane treating secondary treated effluent

-

摘要: 实现膜污染有效控制是充分发挥陶瓷膜在废水处理及回用领域适用性的关键。为此,构建了平板陶瓷膜反应器,针对性地开展了平板陶瓷膜处理市政污水二级出水运行优化控制与膜污染机制分析研究。结果表明,通过四因素三水平正交实验,得出本实验条件下最佳运行控制工况为:蠕动泵转速200 r·min−1(对应初始膜通量200 L·(m2·h)−1)、过滤时间10 min、水力反冲时间30 s、间歇运行时间2 min;在此运行工况下,平板陶瓷膜可保持平均膜通量43.08 L·(m2·h)−1以上稳定运行16 d(384 h),期间系统出水浊度、色度、COD等水质指标稳定满足《城市污水再生利用 城市杂用水水质》(GB/T 18920-2002)标准要求;原水和膜污染层元素及官能团对比表征结果表明,脂肪族类、酰胺类、无机硅化物类以及无机金属离子是造成膜污染的主要污染物,而凝胶层阻力则对平板陶瓷膜膜污染形成起主导作用。Abstract: Achieving effective control of membrane fouling was the key to giving full play to the applicability of ceramic membrane in the field of wastewater treatment and reuse. In this study, a flat sheet ceramic membrane reactor was constructed, and the operational optimization control and membrane fouling mechanism analysis of flat sheet ceramic membrane treating secondary effluent from municipal sewage treatment plant were carried out. Through a four-factor three-level orthogonal test, the optimal operating control condition of flat sheet ceramic membrane treating secondary effluent was determined as follows: peristaltic pump speed was 200 r·min−1 corresponding to the initial membrane flux of 200 L·(m2·h)−1, filtration time was 10 minutes, hydraulic backwashing time was 30 seconds, and intermittent running time was 2 minutes. Under this optimal operating condition, the flux of flat sheet ceramic membrane could maintain stable running for 16 d (384 h) over the average membrane flux of 43.08 L·(m2·h)−1. During this period, turbidity, chroma, COD and other water quality indicators of the effluent could stably meet the standard requirements of The Reuse of Urban Recycling Water — Water Quality Standard for Urban Miscellaneous Water Consumption (GB/T 18920-2002). The comparative characterization results of elements and functional groups of the raw water and the membrane fouling layer showed that aliphatics, amides, inorganic silicides and inorganic metal ions were the main pollutants that caused membrane fouling. And the resistance of the gel layer played the leading role in the fouling formation of flat sheet ceramic membrane.

-

膜处理技术与混凝沉淀、过滤、活性炭吸附等污水深度处理常规技术相比,具有处理效率高、出水水质稳定、占地面积小、便于自动化操作等优点,因而近年来在污水处理及回用领域得到越来越广泛的应用。而在诸多膜材料中,陶瓷膜以其强度高、耐高温、耐酸碱、易清洗、寿命长等优点成为当前最具发展潜力的新型膜分离材料,基于陶瓷膜应用的膜法废水处理技术亦成为国内外相关研究的热点[1-5]。膜污染是膜法水处理技术共同面临的技术难题,如何在阐明陶瓷膜膜污染机理的基础上,充分发挥陶瓷膜废水处理技术优势,开发陶瓷膜膜污染高效控制技术方法,已成为陶瓷膜废水处理技术理论研究与推广应用领域亟待解决的问题[6]。

国内外学者针对膜污染机理和控制开展了大量研究工作,常见的膜污染控制方法主要有强化预处理、膜材料改性、运行优化控制等[7-14]。其中,运行优化控制是减缓膜污染最为经济有效的手段,一般是通过合理调控初始膜通量、过滤时间、间歇时间、反冲洗时间、反冲洗强度、反冲洗频率等运行参数,实现膜污染过程的有效减缓,延长膜单元稳定运行周期。

为进一步挖掘陶瓷膜废水处理技术潜力,提高陶瓷膜运行稳定性,本研究以驻济某高校中水站二级出水为处理对象,开发陶瓷膜小试反应器,在测定陶瓷膜自身水处理特性的基础上,以初始膜通量、过滤时间、间歇时间、反冲洗时间作为陶瓷膜反应器关键运行控制参数,设计四因素三水平正交实验,优选陶瓷膜处理二级出水工况,考察了最优运行工况下陶瓷膜对二级出水中各污染物去除效能,结合对原水、膜污染层的表征与膜污染阻力分析,揭示了陶瓷膜膜污染机理,进而形成具有针对性的陶瓷膜运行优化控制技术,为陶瓷膜在废水处理及回用领域的进一步推广应用提供参考。

1. 材料与方法

1.1 实验材料

1)实验装置。本研究采用的平板陶瓷膜处理市政污水二级出水实验装置如图1所示。进水箱、出水箱和反冲洗水箱均为PVC材质;开启进水离心泵,将原水由进水箱泵入膜池;膜池由有机玻璃制成,有效容积250 L;膜池内平行设置4组陶瓷膜组件,陶瓷膜为购自山东某工业陶瓷研究院的同一批次全新平板陶瓷膜,膜材质为α-Al2O3,膜孔径为0.1 μm,有效过水面积为0.112 8 m2,pH 为2~12,温度上限60 ℃;膜池内设置传感式恒温加热棒2根,控制膜池内水温恒定在25 ℃;膜组件底部设有微孔曝气管,由曝气泵供气,经气体转子流量计控制气量,曝气强度控制在5 L·min−1;膜后采用型号BT300-2J蠕动泵负压抽吸出水,出水蠕动泵转速1~300 r·min−1,采用真空压力表在线监测出水压力;为防止离子吸附造成反冲洗过程膜孔内无机污染,反冲洗采用去离子水,经型号BT300-2J蠕动泵正压泵入陶瓷膜,反冲洗强度控制在1 L·min−1;设置电磁阀和时间继电器构成自动控制装置实现出水泵、反冲洗泵自动启闭。

2)实验用水取自驻济某高校中水站的二级出水。该中水站工艺流程为:曝气调节—水解酸化—缺氧/好氧生物接触氧化—沉淀—过滤—消毒—二级出水。二级出水水质指标为:水温为5~20 ℃、pH=7.8~8.4、浊度3.63~6.82 NTU、色度0.183~0.551度、COD 39~76 mg·L−1、UV254 0.108~0.147 cm−1、氨氮5~16 mg·L−1、TP 3.25~5.08 mg·L−1。

1.2 实验方法

1)膜通量测定。采用体积法进行平板陶瓷膜膜通量测定,即由电子秒表计时,由量筒量取5 min内通过一定膜面积(本实验所用平板陶瓷膜面积为0.112 8 m2)的过滤液体积,根据式(1)计算膜通量。

stringUtils.convertMath(!{formula.content}) (1) 式中:J为膜通量,L·(m2·h)−1;V为一定时间内量取的过滤液体积,L;S为膜面积,m2;t为测量时间,h。

2)陶瓷膜运行优化控制正交实验。膜污染除受膜自身性质、原水水质等因素影响外,主要受温度、初始膜通量、曝气条件、过滤时间、间歇时间、反冲洗周期、反冲洗强度、反冲洗时间等系列运行控制因素的影响[15-24]。本实验所采用的膜材料为同一批次平板陶瓷膜,且原水水质较稳定,故不考虑膜材料差异、原水水质变化等因素对膜污染的影响。本研究将运行控制因素优化作为实现膜污染有效控制的关键技术手段,结合对现有相关文献的汇总分析,遴选出初始膜通量、过滤时间、间歇时间和水力反冲洗时间4个运行参数作为平板陶瓷膜运行优化控制的关键因子,每个关键控制因子均取3个水平,构建四因素三水平正交实验,开展平板陶瓷膜反应器处理市政污水二级出水运行优化控制实验研究。

3)正交实验数据分析。本研究中,以SPSS (statistical package for the social science)软件对运行优化控制正交实验结果进行统计分析。基于各运行控制因素方差分析,得出4个关键控制因素对响应值(平均膜通量)的影响显著性;基于各运行控制因素的单因素统计数据分析,得出各关键运行控制因素的最佳水平,验证运行优化控制正交实验结果。

4)扫描电子显微镜-能谱分析(SEM-EDS)。通过扫描电子显微镜-能谱分析仪(SEM-EDS,QUANTA FEG250,美国FEI公司,美国),分析平板陶瓷膜表面形貌。样品在分析前需进行预处理,采用真空冷冻干燥法去除膜片样品自由水、结合水和毛细水;将膜片样品黏贴在SEM专用单晶硅台上,用IB-5(Giko)型离子溅射镀膜仪于样品上喷金1 min;对膜片样片选取的代表性区域,利用EDS进行膜面污染层元素定性分析,并利用EDS对原水进行元素定性对比分析。

5)傅里叶变换红外光谱分析(FTIR)。通过傅里叶变换红外光谱仪(FTIR, Nicolet IS10,美国赛默飞世尔科技公司,美国)对比分析原水和膜面污染层有机物及部分无机物官能团信息。样品在分析前需进行预处理,原水、膜片污染层样品真空冷冻干燥72 h,去除样品中的自由水、结合水和毛细水;利用研磨好的溴化钾压片,将样品与溴化钾按1∶1 000的比例混合;压片后利用FTIR对样品进行红外谱图测定,FTIR工作条件为:频率4 cm−1,扫描波长4 000~400 cm−1,谱图为32次扫描的平均值。利用Omnic8.0对FTIR产生的数据进行处理和分析。

6)常规指标分析测试。COD、UV254、SS、浊度、色度、氨氮、总磷、pH等常规指标根据水和废水监测分析方法[25]进行测定。

2. 结果与讨论

2.1 平板陶瓷膜自身水处理特性分析

陶瓷膜自身良好的水处理特性是保证平板陶瓷膜反应器良好运行的决定因素之一。本研究首先对平板陶瓷膜清水通量、临界通量等自身水处理特性进行了测定。

1)平板陶瓷膜清水通量。以蒸馏水作为膜前原水,测定平板陶瓷膜清水通量。通过调节蠕动泵转速,逐步提高平板陶瓷膜操作压力,操作压力分别控制在2、5、9、13、22 kPa,每个压力梯度持续30 min,以测得的每5 min滤出液体积带入式(1)计算膜通量,把测得的稳定通量作为平板陶瓷膜清水通量。平板陶瓷膜清水通量随膜压变化如图2所示。由图2可以看出,本实验条件下,平板陶瓷膜清水通量基本与膜压成正比,当膜压达到22 kPa时,平板陶瓷膜平均清水通量值可达736.65 L·(m2·h)−1。清水通量大,从一方面说明平板陶瓷膜性能优良,是理想的膜材料。

2)平板陶瓷膜临界通量。本研究采用通量阶梯法测定平板陶瓷膜临界通量。以驻济某高校中水站的二级出水作为膜前原水。调节蠕动泵转速分别为40、50、60、70、80、90、100 r·min−1,稳步提高平板陶瓷膜操作压力,每一转速下维持稳定运行30 min,以测得的每5 min滤出液体积带入式(1)计算平均膜通量。膜通量和膜压随时间的变化如图3所示。由图3可以看出,在运行的前180 min内,即平板陶瓷膜运行通量不超过81 L·(m2·h)−1时,平板陶瓷膜连续30 min内的膜压基本可以稳定在同一个水平上;运行180 min之后,即平板陶瓷膜运行通量高于81 L·(m2·h)−1后,膜压则随运行时间的继续增加而不断上升,且上升速率很快,同时伴有膜通量的下降,说明膜通量高于81 L·(m2·h)−1后,发生了不可恢复膜污染,膜通量达到临界通量。因此,确定本实验条件下平板陶瓷膜处理市政污水二级出水临界通量为81 L·(m2·h)−1,在此临界通量下,平板陶瓷膜至少可以稳定运行30 min。

2.2 平板陶瓷膜运行优化控制正交实验结果分析

1)平板陶瓷膜运行优化控制正交实验设计。本研究为优化平板陶瓷膜处理市政污水二级出水运行控制条件,设计开展了四因素三水平正交实验,以期筛选得出最佳运行工况。正交实验设计如表1所示。根据表1正交实验设计安排,依次开展九种工况下平板陶瓷膜处理市政污水二级出水运行实验,每一工况下同时运行2片全新陶瓷膜作为平行实验,同时观测两片陶瓷膜的膜通量及跨膜压差随时间的变化情况,以每一工况下2片膜平均膜通量的均值作为对应工况下的平均膜通量。

表 1 L9(34)正交实验设计Table 1. Orthogonal experiment design of four-factor three-level工况 蠕动泵转速/(r·min−1) 过滤时间/min 水力反冲时间/s 间歇时间/min S1 50 10 20 1 S2 50 20 40 2 S3 50 30 30 4 S4 100 10 40 4 S5 100 20 30 1 S6 100 30 20 2 S7 200 10 30 2 S8 200 20 20 4 S9 200 30 40 1 2)平板陶瓷膜运行优化控制正交实验结果分析。不同运行工况下平板陶瓷膜处理市政污水二级出水平均膜通量实验结果如图4所示。由图4可见,各运行工况下平板陶瓷膜处理市政污水二级出水平均膜通量由大到小顺序为S7> S6> S9> S4> S5> S8> S2> S3> S1;S7运行工况下,即蠕动泵转速200 r·min−1(对应初始膜通量200 L·(m2·h)−1)、过滤时间10 min、水力反冲时间30 s、间歇运行时间2 min,平板陶瓷膜平均产水量最大,为43.08 L·(m2·h)−1;S1运行工况下,平板陶瓷膜平均产水量最小,为18.18 L·(m2·h)−1。直观确定S7运行工况为平板陶瓷膜处理市政污水二级出水最佳运行工况。

随后采用SPSS软件对上述正交实验结果进行处理分析。各运行控制因素方差分析结果如表2所示。df为自由度,Sig为显著性,Sig值越小说明该运行控制因素对平板陶瓷膜平均产水量的影响越显著。由表2各运行控制因素的方差分析数据可以看出,四因素对平板陶瓷膜处理市政污水二级出水平均膜通量影响显著性的顺序依次为蠕动泵转速(即初始膜通量)>间歇时间>过滤时间>水力反冲时间。

表 2 各运行控制因素方差分析Table 2. Variance analysis of operating control factors源 Ⅲ型平方和 df 均方 F Sig 校正模型 1 170.29* 8 146.286 78.423 2.053×10-7 截距 16 759.609 1 16 759.609 8 984.691 8.210×10-15 蠕动泵转速 654.734 2 327.267 175.499 6.176×10−8 过滤时间 184.064 2 92.031 49.337 1.411×10−5 水力反冲时间 79.321 2 39.660 21.262 3.891×10−4 间歇时间 252.172 2 126.086 67.594 3.792×10−6 误差 16.788 9 1.865 总计 17 946.688 18 校正的总计 1 187.079 17 注:R2=0.986(调整R2=0.973);*表示此正交实验中显著水平为0.05。 采用SPSS软件对各运行控制因素对应的平板陶瓷膜平均膜通量进行了统计分析,结果如表3所示。表中统计得出了每个运行控制因素对应的3个水平下平板陶瓷膜平均膜通量均值、标准误差和置信区间。由表3各运行控制因素下平板陶瓷膜平均膜通量的统计分析可知,各运行控制因素分别为以下水平时平均膜通量统计均值更高,即蠕动泵转速200 r·min−1、过滤时间10 min、水力反冲时间30 s、间歇时间2 min,这与前述四因素三水平正交实验直观得出的最佳运行工况S7一致,统计分析数据进一步验证了正交实验结果。

表 3 各运行控制因素对应平均膜通量统计分析Table 3. Statistical analysis of average membrane fluxes corresponding to operating control factors运行控制因素及其水平设定 各因素水平对应的平均膜通量统计值 因素 因素水平 算术平均值/(L·(m2·h)−1) 标准误差 95%置信区间下限 95%置信区间上限 蠕动泵转速 50.00 r·min−1 22.022 0.558 20.761 23.284 100.00 r·min−1 34.064 0.558 32.802 35.325 200.00 r·min−1 35.455 0.558 34.194 36.717 过滤时间 10.00 min 32.276 0.558 31.014 33.537 20.00 min 26.026 0.558 24.764 27.287 30.00 min 31.240 0.558 30.978 32.501 水力反冲时间 20.00 s 27.704 0.558 26.443 28.965 30.00 s 31.089 0.558 29.827 32.350 40.00 s 28.749 0.558 27.487 30.010 间歇时间 1.00 min 27.716 0.558 26.454 28.977 2.00 min 35.804 0.558 34.543 37.065 4.00 min 28.022 0.558 26.760 29.283 2.3 最佳运行工况下平板陶瓷膜处理市政污水二级出水长期运行效能研究

1)产水效能研究。本研究对最佳运行工况下平板陶瓷膜处理市政污水二级出水长期运行的产水效能进行了实验考察。运行工况采用前期正交实验确定的最佳运行工况S7,即蠕动泵转速200 r·min−1、过滤时间10 min、水力反冲时间30 s、间歇时间2 min;其他运行参数为,水温恒定25 ℃,连续曝气,曝气强度5 L·min−1,水力反冲洗强度为1 L·min−1。采用全新平板陶瓷膜作为本实验阶段用膜,正式实验开始前,以蒸馏水作为膜前原水,抽吸2 h对陶瓷膜进行预清洗,并测定其清水通量与前述实验确定的清水通量对比,以确保空白状态下陶瓷膜产水性能稳定性。最佳运行工况下平板陶瓷膜处理市政污水二级出水长期运行膜通量变化情况如图5所示。从图5可以看出,在最佳运行工况下,平板陶瓷膜处理市政污水二级出水,其膜通量在运行初期的100 h衰减较快,由198.81 L·(m2·h)−1下降至67.43 L·(m2·h)−1;运行100 h后膜通量衰减逐渐放缓,在100 ~400 h,膜通量相对稳定,接近平均膜通量43.08 L·(m2·h)−1;运行400 h以内,水力反冲洗对膜通量恢复有较好的效果;运行400 h之后,水力反冲洗对平板陶瓷膜膜通量恢复效果显著下降,说明此阶段已形成了较为密实的滤饼层;运行至730 h,膜通量已衰减至15.42 L·(m2·h)−1,此时平板陶瓷膜产水效能极低,说明膜污染已经非常严重,滤饼层逐渐被压实并形成了泥饼层,水力反冲对膜通量恢复已无效果,必须采取化学清洗等手段使其通量恢复。为保证平板陶瓷膜处理市政污水二级出水时较高的产水率,本研究界定最佳运行工况下平板陶瓷膜稳定运行时间为16 d(384 h),在此运行时间内平板陶瓷膜膜通量可始终保持在平均膜通量43.08 L·(m2·h)−1以上。由上述研究结果可以看出,最佳运行工况下,平板陶瓷膜处理市政污水二级出水可以在保持较高产水率的前提下,稳定运行16 d,说明通过前期正交实验所遴选的最佳运行工况,可有效保证平板陶瓷膜系统产水稳定性;同时由图5的膜通量变化也可以看出,即便是在最佳运行工况下,膜污染依然是不可避免。

2) 污染物去除效能研究。本研究在考察长期运行条件下平板陶瓷膜系统产水效能的同时,对最佳运行工况下平板陶瓷膜处理市政污水二级出水污染物去除效能也进行了实验考察。平板陶瓷膜系统对浊度、色度、COD、UV254、氨氮、总磷等污染物去除效能如图6所示。

由图6(a)和图6(b)可以看出,市政污水二级出水经平板陶瓷膜过滤后,出水浊度、色度显著降低,出水浊度保持在0.5 NTU以下,平均去除率为93.50%;出水色度保持在0.022 度以下,平均去除率97.62%。由图6(c)可知,平板陶瓷膜对市政污水二级出水COD去除率在30.77%~40.9%,平均值为39.19%,系统COD为22~52 mg·L−1,平均值为28.74 mg·L−1。系统出水的浊度、色度及COD满足《城市污水再生利用 城市杂用水水质》(GB/T 18920-2002)标准要求。

由图6(d)可以看出,平板陶瓷膜对市政污水二级出水中UV254表征的芳香族和腐殖质类有机物去除率为9.25%~25.17%,平均去除率为15.29%,系统出水UV254值在0.088~0.118 cm−1,平均值为0.1 cm−1。本研究中平板陶瓷膜对市政污水二级出水UV254指标去除率较低,主要是因为本研究原水为经生化处理后的市政污水二级出水,原水中UV254所表征的芳香族和腐殖质类有机物含量较低,陶瓷膜对上述物质截留量有限;后期FTIR表征结果亦证明,原水及造成膜污染的有机物主要为含C=O双键的脂肪族类化合物和酰胺类物质,而非UV254所表征的含C=C双键和C=O双键的芳香族类化合物及腐殖酸类物质。

由图6(e)和图6 (f)可以看出,平板陶瓷膜对市政污水二级出水中氨氮平均去除率为12.87%,出水氨氮平均浓度为15.74 mg·L−1,系统出水氨氮指标满足《城市污水再生利用 城市杂用水水质》(GB/T 18920-2002)中城市绿化、建筑施工用水要求;系统总磷平均去除率为16.79%,出水总磷平均质量浓度为3.81 mg·L−1。上述实验结果表明,平板陶瓷膜对市政污水二级出水中氮磷无明显去除能力,这与膜法水处理技术去除污水中氮磷等营养物质效能较低的一般性结论相一致。

2.4 平板陶瓷膜处理市政污水二级出水膜污染形成机制分析

1)膜污染成分分析。采用EDS对原水和平板陶瓷膜污染层进行了元素组成及含量对比表征(图7)。由图7中原水和平板陶瓷膜污染层的元素对比分析可见,平板陶瓷膜在处理市政污水二级出水后,所形成的污染层发生了明显的C、N、Si元素富集现象。污染层中C元素含量为35.09%,较原水增加了18.37%;N元素含量为17.53%,较原水增加了13.57%;说明造成平板陶瓷膜膜污染的主要污染物是含C、N有机物。此外,污染层中Si元素含量为2.90%,较原水增加了2.53%,污染层中还检测出了原水中未检出的Fe、Al等元素,说明金属离子也是造成平板陶瓷膜污染的重要原因。

实验中还通过FTIR对原水和膜污染层有机物及部分无机物官能团信息进行了对比分析,如图8所示。图8中,3 428 cm−1处NH伸缩振动为脂肪族酰胺基特征峰,1 650 cm−1处C=O拉伸为羰基特征峰,1 260 cm−1处为无机硅化合物特征峰,700~750 cm−1处为CH2特征峰。对比分析原水和污染层红外光谱可以发现,原水特征官能团主要为无机硝酸盐基团、NH基、NH2基、CH2基和C=O基,由此可以看出,原水主要污染物为无机硝酸盐类、脂肪族类和酰胺类;而相比原水,陶瓷膜污染层主要特征官能团中无机硝酸盐基团不再明显,NH基、CH2基变化不大,C=O基和无机硅化物类则更加明显;因而可以判定造成陶瓷膜污染的有机污染物主要以脂肪族类和酰胺类为主,无机污染物则主要以硅化物类为主。FTIR与EDS结果相对应,同时也解释了图6所反映出的平板陶瓷膜对UV254表征的芳香族和腐殖质类有机物去除能力较低的原因。

2) 膜污染阻力分析。本实验根据标准的Darcy定律过滤模型来确定平板陶瓷膜过滤过程中的阻力分布情况[1-2,26-32],由式(2)计算膜总过滤阻力Rt,进而计算阻力分步情况。

stringUtils.convertMath(!{formula.content}) (2) 式中:Rt为膜总过滤阻力,m−1;ΔP为跨膜压差,Pa;J为膜通量,L·(m2·h)−1;μ为料液黏度,Pa·s;Rm为新膜自身过滤阻力,m−1;Ri为膜孔内污染产生的过滤阻力,m−1;Rc为浓差极化边界层造成的过滤阻力,m−1;Rg为凝胶层造成的过滤阻力,m−1。

通过3次平行实验测定并计算各部分过滤阻力,所得平板陶瓷膜各部分过滤阻力及占总阻力比例如表4所示。由表4可以得出,在本实验条件下,平板陶瓷膜自身过滤阻力Rm,约占总过滤阻力的14%~15%,这部分阻力由平板陶瓷膜材料和膜孔径决定;膜孔内污染产生的过滤阻力Ri,约占总过滤阻力的8%~10%,这部分阻力主要发生在膜滤开始阶段,所占比例小,且随着操作压力的增大变化更不明显;浓差极化边界层造成的过滤阻力Rc,约占总过滤阻力的9%~14%,这部分阻力由浓差极化产生,是可逆的,通常可以通过优化运行控制参数来克服;凝胶层造成的过滤阻力Rg,约占总过滤阻力的63%~68%,这部分过滤阻力是由于污染物颗粒在膜面不断积累浓度达到饱和析出、沉积所产生的,需要通过反冲洗或者化学清洗去除。

表 4 各部分过滤阻力及占总阻力比例Table 4. Each filtration resistance and its proportion to the total resistance实验次数 Rt/(1011m−1) Rt占比/% Rm/(1011m−1) Rm占比/% Ri/(1011m−1) Ri占比/% Rc/(1011m−1) Rc/占比/% Rg/(1011m−1) R g占比/% 1 38.03 100 5.55 14.6 3.28 8.6 3.53 9.3 25.67 67.5 2 39.66 100 5.51 13.9 3.45 8.7 4.44 11.2 26.26 66.2 3 38.83 100 5.51 14.2 3.69 9.5 5.13 13.2 24.50 63.1 均值 38.84 100 5.52 14.2 3.47 8.9 4.37 11.2 25.48 65.6 通过以上对平板陶瓷膜处理市政污水二级出水过程中各部分过滤阻力的分析可知,凝胶层阻力是影响平板陶瓷膜过滤过程的最主要因素,对平板陶瓷膜膜污染的形成起主导作用。

3. 结论

1)平板陶瓷膜处理市政污水二级出水最优运行工况为蠕动泵转速200 r·min−1(对应初始膜通量200 L·(m2·h)−1)、过滤时间10 min、水力反冲时间30 s、间歇运行时间2 min,此时平板陶瓷膜平均产水量最大,为43.08 L·(m2·h)−1;正交实验结果的方差分析得出,四因素对平均膜通量影响显著性依次为蠕动泵转速(即初始膜通量)>间歇时间>过滤时间>水力反冲时间,单因素统计分析得出的最佳水平组合与正交实验得出的最优工况相一致。

2)最佳运行工况下平板陶瓷膜处理市政污水二级出水可保持稳定运行16 d(384 h),在此期间膜通量可始终保持在平均膜通量43.08 L·(m2·h)−1以上,出水浊度、色度分别保持在0.5 NTU、0.022 度以下,出水COD平均值为28.74 mg·L−1,上述3项出水水质指标满足《城市污水再生利用 城市杂用水水质》(GB/T 18920-2002)标准要求;平板陶瓷膜对市政污水二级出水中的UV254、氨氮和总磷的平均去除率均较低,约为15%左右。

3)造成陶瓷膜污染的有机污染物主要以脂肪族类和酰胺类为主,无机污染物则主要以硅化物类为主,无机金属离子也是造成膜污染的重要原因;凝胶层阻力是影响平板陶瓷膜过滤过程的最主要因素,对平板陶瓷膜膜污染的形成起主导作用。

-

表 1 L9(34)正交实验设计

Table 1. Orthogonal experiment design of four-factor three-level

工况 蠕动泵转速/(r·min−1) 过滤时间/min 水力反冲时间/s 间歇时间/min S1 50 10 20 1 S2 50 20 40 2 S3 50 30 30 4 S4 100 10 40 4 S5 100 20 30 1 S6 100 30 20 2 S7 200 10 30 2 S8 200 20 20 4 S9 200 30 40 1 表 2 各运行控制因素方差分析

Table 2. Variance analysis of operating control factors

源 Ⅲ型平方和 df 均方 F Sig 校正模型 1 170.29* 8 146.286 78.423 2.053×10-7 截距 16 759.609 1 16 759.609 8 984.691 8.210×10-15 蠕动泵转速 654.734 2 327.267 175.499 6.176×10−8 过滤时间 184.064 2 92.031 49.337 1.411×10−5 水力反冲时间 79.321 2 39.660 21.262 3.891×10−4 间歇时间 252.172 2 126.086 67.594 3.792×10−6 误差 16.788 9 1.865 总计 17 946.688 18 校正的总计 1 187.079 17 注:R2=0.986(调整R2=0.973);*表示此正交实验中显著水平为0.05。 表 3 各运行控制因素对应平均膜通量统计分析

Table 3. Statistical analysis of average membrane fluxes corresponding to operating control factors

运行控制因素及其水平设定 各因素水平对应的平均膜通量统计值 因素 因素水平 算术平均值/(L·(m2·h)−1) 标准误差 95%置信区间下限 95%置信区间上限 蠕动泵转速 50.00 r·min−1 22.022 0.558 20.761 23.284 100.00 r·min−1 34.064 0.558 32.802 35.325 200.00 r·min−1 35.455 0.558 34.194 36.717 过滤时间 10.00 min 32.276 0.558 31.014 33.537 20.00 min 26.026 0.558 24.764 27.287 30.00 min 31.240 0.558 30.978 32.501 水力反冲时间 20.00 s 27.704 0.558 26.443 28.965 30.00 s 31.089 0.558 29.827 32.350 40.00 s 28.749 0.558 27.487 30.010 间歇时间 1.00 min 27.716 0.558 26.454 28.977 2.00 min 35.804 0.558 34.543 37.065 4.00 min 28.022 0.558 26.760 29.283 表 4 各部分过滤阻力及占总阻力比例

Table 4. Each filtration resistance and its proportion to the total resistance

实验次数 Rt/(1011m−1) Rt占比/% Rm/(1011m−1) Rm占比/% Ri/(1011m−1) Ri占比/% Rc/(1011m−1) Rc/占比/% Rg/(1011m−1) R g占比/% 1 38.03 100 5.55 14.6 3.28 8.6 3.53 9.3 25.67 67.5 2 39.66 100 5.51 13.9 3.45 8.7 4.44 11.2 26.26 66.2 3 38.83 100 5.51 14.2 3.69 9.5 5.13 13.2 24.50 63.1 均值 38.84 100 5.52 14.2 3.47 8.9 4.37 11.2 25.48 65.6 -

[1] ASIF M B, ZHANG Z H. Ceramic membrane technology for water and wastewater treatment: A critical review of performance, full-scale applications, membrane fouling and prospects[J]. Chemical Engineering Journal, 2021, 418: 18. [2] LI C, SUN W J, LU Z D, et al. Ceramic nanocomposite membranes and membrane fouling: A review[J]. Water Research, 2020, 175: 21. [3] SAMAEI S M, GATO-TRINIDAD S, ALTAEE A. The application of pressure-driven ceramic membrane technology for the treatment of industrial wastewaters: A review[J]. Separation and Purification Technology, 2018, 200: 198-220. doi: 10.1016/j.seppur.2018.02.041 [4] 成小翔, 梁恒. 陶瓷膜饮用水处理技术发展与展望[J]. 哈尔滨工业大学学报, 2016, 48(8): 1-10. doi: 10.11918/j.issn.0367-6234.2016.08.001 [5] 万昱堃, 夏圣骥. 陶瓷膜制备及在水处理中的应用[J]. 净水技术, 2016, 35(2): 102-104. doi: 10.3969/j.issn.1009-0177.2016.02.021 [6] 张诗洋, 单历元, 廖松义, 等. 陶瓷膜在废水处理领域中的研究进展[J]. 工业水处理, 2021, 41(4): 31-36. [7] 何林娟, 邹康兵, 盛云鸽, 等. 预处理对东江原水超滤过程中膜污染的控制作用[J]. 中国给水排水, 2021, 37(1): 16-21. [8] HALLE C, HUCK P M, PELDSZUS S, et al. Assessing the performance of biological filtration as pretreatment to low pressure membranes for drinking water[J]. Environmental Science & Technology, 2009, 43(10): 3878-3884. [9] JEGATHEESAN V, SENARATNE N, STEICKE C, et al. Powdered activated carbon for fouling reduction of a membrane in a pilot-scale recirculating aquaculture system[J]. Desalination and Water Treatment, 2009, 5(1/2/3): 1-5. [10] WAN Y, XIE P C, WANG Z P, et al. Application of UV/chlorine pretreatment for controlling ultrafiltration (UF) membrane fouling caused by different natural organic fractions[J]. Chemosphere, 2021, 263: 14. [11] 李宁. 基于原子层沉积的PVDF微滤膜表面亲水改性及膜污染控制机制[D]. 哈尔滨: 哈尔滨工业大学, 2019. [12] 汪婧, 张翔, 黄乐, 等. 曝气冲刷对膜生物反应器膜污染的控制机理研究进展[J]. 环境污染与防治, 2020, 42(5): 619-623. [13] 丁慧, 彭兆洋, 李毅, 等. 无机陶瓷膜处理油田采出水[J]. 环境工程学报, 2013, 7(4): 1399-1404. [14] 陈叶, 宋玉栋, 常福成, 等. 混凝沉淀前处理对丙烯酸丁酯废水陶瓷膜过滤膜污染的影响[J]. 环境工程学报, 2014, 8(7): 2772-2778. [15] ZHANG X M, YUE X P, LIU Z Q, et al. Impacts of sludge retention time on sludge characteristics and membrane fouling in a submerged anaerobic-oxic membrane bioreactor[J]. Applied Microbiology and Biotechnology, 2015, 99(11): 4893-4903. doi: 10.1007/s00253-015-6383-x [16] ASLAM M, LEE P H, KIM J. Analysis of membrane fouling with porous membrane filters by microbial suspensions for autotrophic nitrogen transformations[J]. Separation and Purification Technology, 2015, 146: 284-293. doi: 10.1016/j.seppur.2015.03.042 [17] SHEN L G, LEI Q, CHEN J R, et al. Membrane fouling in a submerged membrane bioreactor: Impacts of floc size[J]. Chemical Engineering Journal, 2015, 269: 328-334. doi: 10.1016/j.cej.2015.02.002 [18] BANI-MELHEM K, AL-QODAH Z, AL-SHANNAG M, et al. On the performance of real grey water treatment using a submerged membrane bioreactor system[J]. Journal of Membrane Science, 2015, 476: 40-49. doi: 10.1016/j.memsci.2014.11.010 [19] 仵海燕, 李开明, 陈中颖, 等. MBR中胞外聚合物对膜污染影响的研究进展[J]. 环境工程, 2012, 30(6): 47-51. [20] KIMURA K, NISHIMURA S I, MIYOSHI R, et al. Application of glyco-blotting for identification of structures of polysaccharides causing membrane fouling in a pilot-scale membrane bioreactor treating municipal wastewater[J]. Bioresource Technology, 2015, 179: 180-186. doi: 10.1016/j.biortech.2014.12.017 [21] 李晨, 张大帅, 张小朋, 等. 间歇时间对超滤膜处理污水膜通量的影响[C]//中国环境科学学会. 2017中国环境科学学会科学与技术年会论文集. 厦门, 2017: 4. [22] 王明明. 弱电场作用下陶瓷膜MBR运行效果及膜污染控制研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. [23] 王旭亮, 李宗雨, 董泽亮, 等. 超滤过程的膜污染和运行条件优化[J]. 工业用水与废水, 2019, 50(1): 1-4. doi: 10.3969/j.issn.1009-2455.2019.01.001 [24] 敖漉, 刘文君, 方振东, 等. 超滤膜污染的主要成因与控制膜污染的预处理技术[J]. 后勤工程学院学报, 2017, 33(4): 41-47. doi: 10.3969/j.issn.1672-7843.2017.04.008 [25] 国家环境保护总局. 水和废水监测分析方法[M]. 4版. 北京: 中国环境科学出版社, 2002. [26] 田岳林, 刘桂中, 袁栋栋, 等. 陶瓷膜污染阻力构成试验及膜污染机理研究[C]//中国环境科学学会. 2012中国环境科学学会学术年会论文集. 南宁, 2012: 7. [27] 张金斌, 曾坚贤, 张学俊, 等. 陶瓷膜处理含镍电镀废水[J]. 环境工程学报, 2016, 10(4): 1699-1705. doi: 10.12030/j.cjee.20160419 [28] LI M, ZHAO Y, ZHOU S, et al. Resistance analysis for ceramic membrane microfiltration of raw soy sauce[J]. Journal of Membrane Science, 2007, 299(1): 122-129. [29] 周振, 姚吉伦, 庞治邦, 等. 电絮凝延缓陶瓷微滤膜污染[J]. 环境工程学报, 2016, 10(5): 2279-2283. doi: 10.12030/j.cjee.201510020 [30] 吕玉正, 方涛, 师杰, 等. 多孔陶瓷膜双向过滤阻力试验分析[J]. 后勤工程学院学报, 2013, 29(1): 34-39. [31] 裴亮. 不同运行条件对超滤膜通量阻力的影响研究[J]. 过滤与分离, 2017, 27(4): 6-9. doi: 10.3969/j.issn.1005-8265.2017.04.002 [32] 田岳林, 袁栋栋, 李汝琪. 陶瓷膜污染过程分析与膜清洗方法优化[J]. 环境工程学报, 2013, 7(1): 253-257. -

下载:

下载: