-

水力压裂技术是一项油气田增产的重要技术手段[1]。在水力压裂过程中,会产生大量压裂返排液,这些返排液中含有高浓度的有机物、盐类物质、悬浮物、重金属及天然存在的放射性物质等污染物[2],若处理不当直接外排,将会对周围土壤、地表水系[3]、大气环境[4]等造成严重污染。

有机物是压裂返排液的主要污染物,目前大多数研究采用物理化学法去除返排液中的有机物,如混凝沉淀法[5]、Fenton氧化法[6]及臭氧催化氧化法[7]等。虽然物理化学法对返排液中有机物有较好的去除效果,但处理成本较高;另外,反应的副产物如芬顿铁泥等可能会给环境带来二次污染。与物理化学方法相比,生物处理法不仅可以有效去除压裂返排液中有机污染物,同时还具有显著的经济优势[8-9],因此,生物法对压裂返排液的处理效果受到了许多学者的关注。

目前,去除压裂返排液中有机物的生物处理技术主要包括活性污泥法、好氧颗粒污泥法、生物膜法等。由于压裂返排液中含有高浓度有机污染物且水质复杂多变,因此,通常采用组合工艺对返排液进行处理。YANG等[10]采用絮凝-Fenton氧化-SBR组合工艺处理油田压裂返排液,COD去除率达到97.1%;王海蒙[11]采用Fenton氧化-混凝沉降-水解酸化-SBBR-活性炭吸附的组合工艺处理压裂返排液,COD去除率达到99%以上。然而,有研究发现单一生物法对返排液同样具有较好的处理效果。陈翱翔等[9]采用好氧颗粒污泥处理压裂返排液,其COD去除率为74%~81%;KEKACS等[12]采用好氧生物法处理返排液,其COD去除率可达到90%以上。可以看出,目前压裂返排液的生物处理以好氧生物处理法为主。虽然好氧生物处理法可实现对压裂返排液的高效处理,但好氧生物法能耗大、处理成本高。而与好氧工艺相比,厌氧生物处理技术具有回收能源、运行成本低等优势[13],已经成为高浓度有机废水处理的主流工艺。有研究[14-15]表明,厌氧工艺可以有效去除油田采出水中的难降解有机化合物,而有关压裂返排液厌氧生物处理的研究尚未见报道。

本研究采用厌氧颗粒污泥处理压裂返排液,研究了压裂返排液的厌氧生物降解特性,同时监测了甲烷的产量,以评估能源回收潜力;此外,对厌氧处理前后的废水样品进行了表征,以评价有机物组分和分子质量分布的变化,以期为压裂返排液厌氧处理技术的工程应用提供参考。

-

实验所用胍胶、有机硼交联剂、破胶剂等均为油田在用商品,配液用水为实验室自来水。首先配制0.4%胍胶溶液,根据需求向胍胶溶液中加入一定量的破胶剂(过硫酸铵),搅拌均匀,得到压裂液基液;按照一定交联比向基液中加入有机硼交联剂并搅拌均匀,即可得到可挑挂的压裂返排液冻胶。将压裂返排液冻胶在80 ℃下破胶1 h,得到模拟压裂返排液。模拟压裂返排液呈灰黄色,COD为(8 425±120) mg∙L−1,TOC为(3 752±75) mg∙L−1,TDS为(6 720±150) mg∙L−1,pH=9.4±0.5,电导率为(13.2±0.4) mS∙cm−1。

-

实验所用的接种污泥取自某造纸厂的厌氧反应器,污泥质量浓度为(52 400±290) mg∙L−1,pH为7.2,采用产甲烷潜力分析仪(洛克泰克,RTK-BMP-I)进行序批式实验。

1)研究初始浓度对压裂返排液厌氧处理的影响。设置4个厌氧反应器,分别编号为A、B、C、D,向反应器中加入150 mL的厌氧颗粒污泥和150 mL不同浓度的模拟压裂返排液,各反应器中COD分别为917.5、2 012.2、3 632.3和4 380.7 mg∙L−1,将pH调节至7.0±0.1, 并通氮气5 min以达到厌氧环境。实验期间,反应器中的温度和搅拌强度分别控制在35 ℃和80 r·min−1,使用氢氧化钠溶液吸收反应器中产生的CO2,并每天记录甲烷产量。甲烷累计产量基本平稳时则认为反应结束,取样测定各个反应器中耗氧有机物的质量浓度(以COD计),考察其初始浓度对压裂返排液厌氧处理的影响。

2)研究压裂返排液的厌氧生物降解特性。向反应器里接种240 mL厌氧污泥和60 mL模拟压裂返排液作为实验组,向另一组反应器中接种240 mL厌氧污泥和60 mL自来水作为对照组,以消除颗粒污泥自身厌氧消化对产气量的影响。实验条件及操作同上步研究。所有实验均设置3组重复,定期取样用于COD、TOC、分子质量和官能团等指标的测定。

-

取污水处理厂好氧池末端泥水混合液2 L于烧杯中,静置沉淀,弃去上清液,加入纯水,反复淘洗3次。分别取500 mL淘洗后的活性污泥和经厌氧处理后的压裂返排液于烧杯中(污泥质量浓度约为3 800 mg∙L−1),曝气使溶解氧质量浓度在2 mg∙L−1以上,定时取样测定COD值。

-

COD采用哈希DRB 200COD快速消解仪和DR3900分光光度计进行测定;TOC采用总有机碳测定仪(德国Elementar公司,vario TOC)测定;废水有机物成分利用紫外可见分光光度计(岛津,UV2600A)和荧光光谱仪(英国爱丁堡,爱丁堡FS5)进行分析;利用凝胶色谱分析仪(Waters 公司,Waters 2695 GPC)测定废水中的分子质量分布。有机物官能团的变化采用真空傅里叶红外光谱仪(德国布鲁克公司,Vertex70)进行鉴定。取样品10 mL,在−80 ℃下冷冻干燥48 h,将干燥后的样品与溴化钾充分混合研磨,制成压片,然后进行红外光谱分析。扫描范围为4 000~400 cm−1。

-

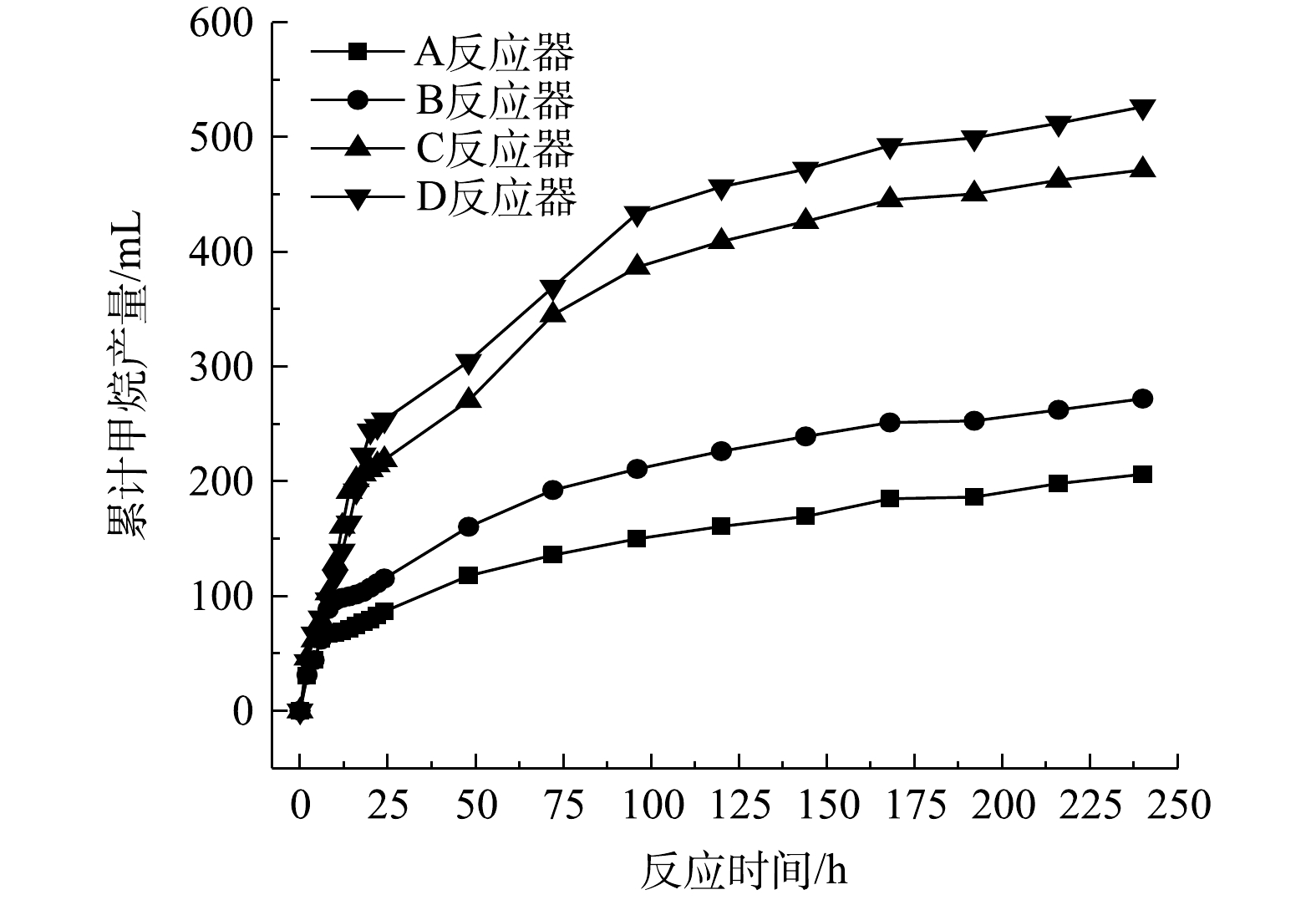

通过控制压裂返排液添加量,分析压裂返排液厌氧处理过程中有机物初始浓度对厌氧消化性能的影响,结果如表1所示。当反应结束时,A、B、C、D反应器中COD去除率分别为80.2%、84.0%、86.4%及85.4%。可以看出,不同初始浓度下的COD去除率相差不大,说明初始浓度对压裂返排液有机物的厌氧生物降解没有显著影响。此外,由图1可以看出,不同耗氧有机物(以COD计)初始浓度下的厌氧处理过程中累计甲烷产量呈现相似的变化趋势,均表现为在实验初始阶段甲烷产量迅速升高,随后增长速度变缓直至趋于平稳,说明耗氧有机物(以COD计)初始浓度并不影响压裂返排液厌氧生物降解过程。以上结果表明,耗氧有机物初始浓度的变化不会影响压裂返排液厌氧生物降解,只会影响反应时间,因此,在后续的实验中将采用较低的初始耗氧有机物浓度以加快实验进度。

-

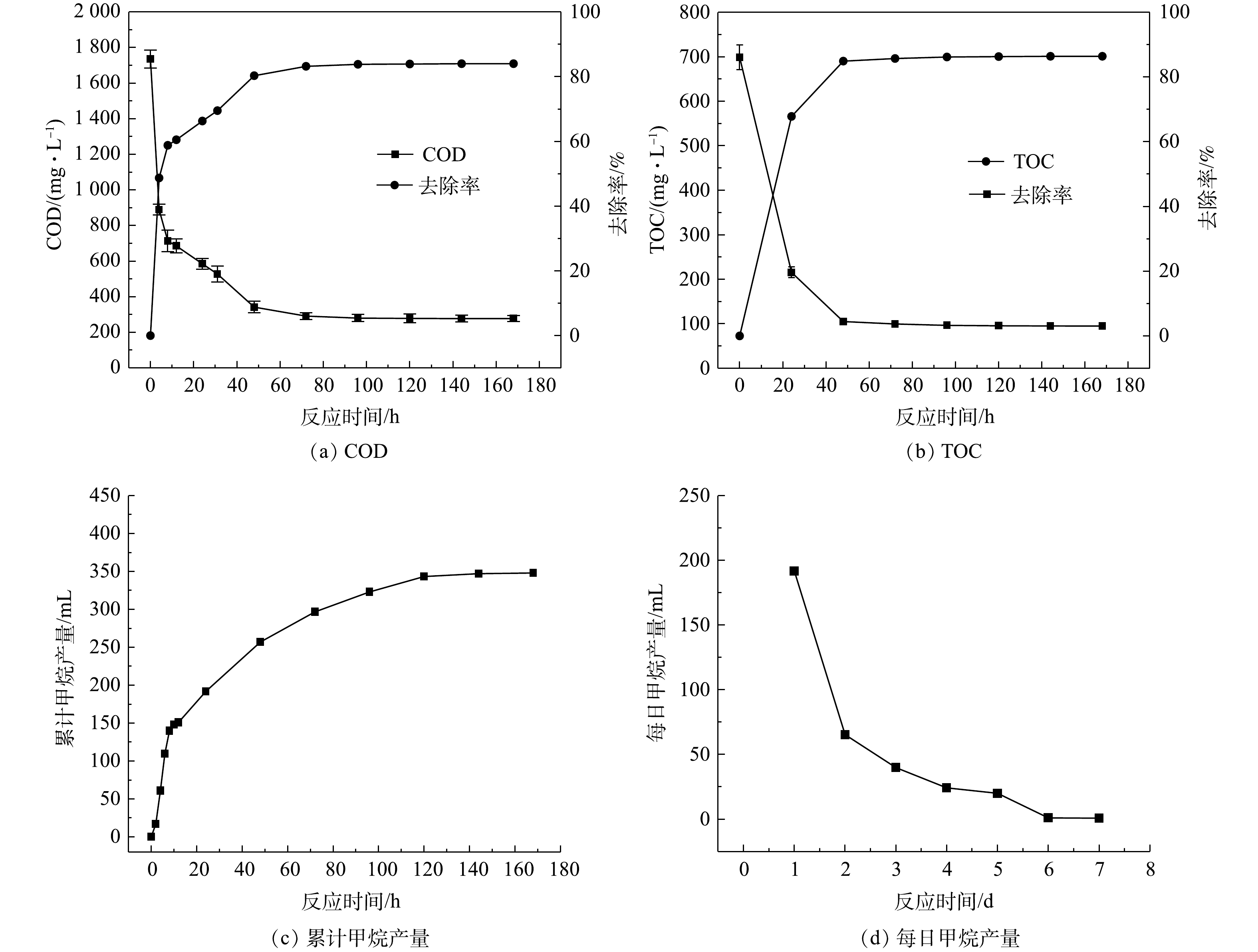

1)COD、TOC去除及甲烷产量。图2反映了压裂返排液厌氧消化过程中COD、TOC及甲烷产量的变化情况。由图2(a)可知,前12 h,COD值迅速降低,由1 735.2 mg∙L−1降低至685.2 mg∙L−1,COD去除率达到60.5%;在反应12~48 h,COD值缓慢下降,由685.2 mg∙L−1降低至341.7 mg∙L−1;经过48 h的厌氧消化,COD基本趋于稳定,最终COD值为277.2 mg∙L−1,COD去除率为84.0%。

TOC的变化如图2(b)所示。在前24 h,TOC值迅速下降,由698.5 mg∙L−1降至215.5 mg∙L−1,TOC去除率为67.8%;经过48 h的厌氧消化,TOC降低至105.2 mg∙L−1并几乎趋于稳定,最终TOC为94.9 mg∙L−1,TOC去除率为86.4%,与COD的去除效果基本相当。在生物法处理压裂返排液的研究[8]中发现,曝气生物滤池可去除压裂返排液中99%以上的有机成分;ZHANG等[16]利用好氧颗粒污泥处理页岩气返排液,TOC去除率为(79±1)%;钟显等[17]通过曝气塘处理压裂返排液,COD去除率可达到91.1%。在本研究中,压裂返排液经过厌氧处理,COD和TOC去除率分别可达到84.0%和86.4%,表明压裂返排液可以进行厌氧生物处理,并且具有较好的厌氧降解特性。

产气量是评价废水厌氧处理性能的重要指标。反应过程中累计甲烷产量变化如图2(c)所示。在前12 h,甲烷产量迅速升高,累计甲烷产量达到151.9 mL,这与有机物在此阶段发生快速降解现象相吻合;之后随着有机物降解速度减慢,每日甲烷产量逐渐降低,使得累计甲烷产量增加缓慢且最终趋于稳定,反应结束时累计甲烷产量为347.9 mL,每克耗氧有机物(以COD计)能产生688.2 mL的甲烷。

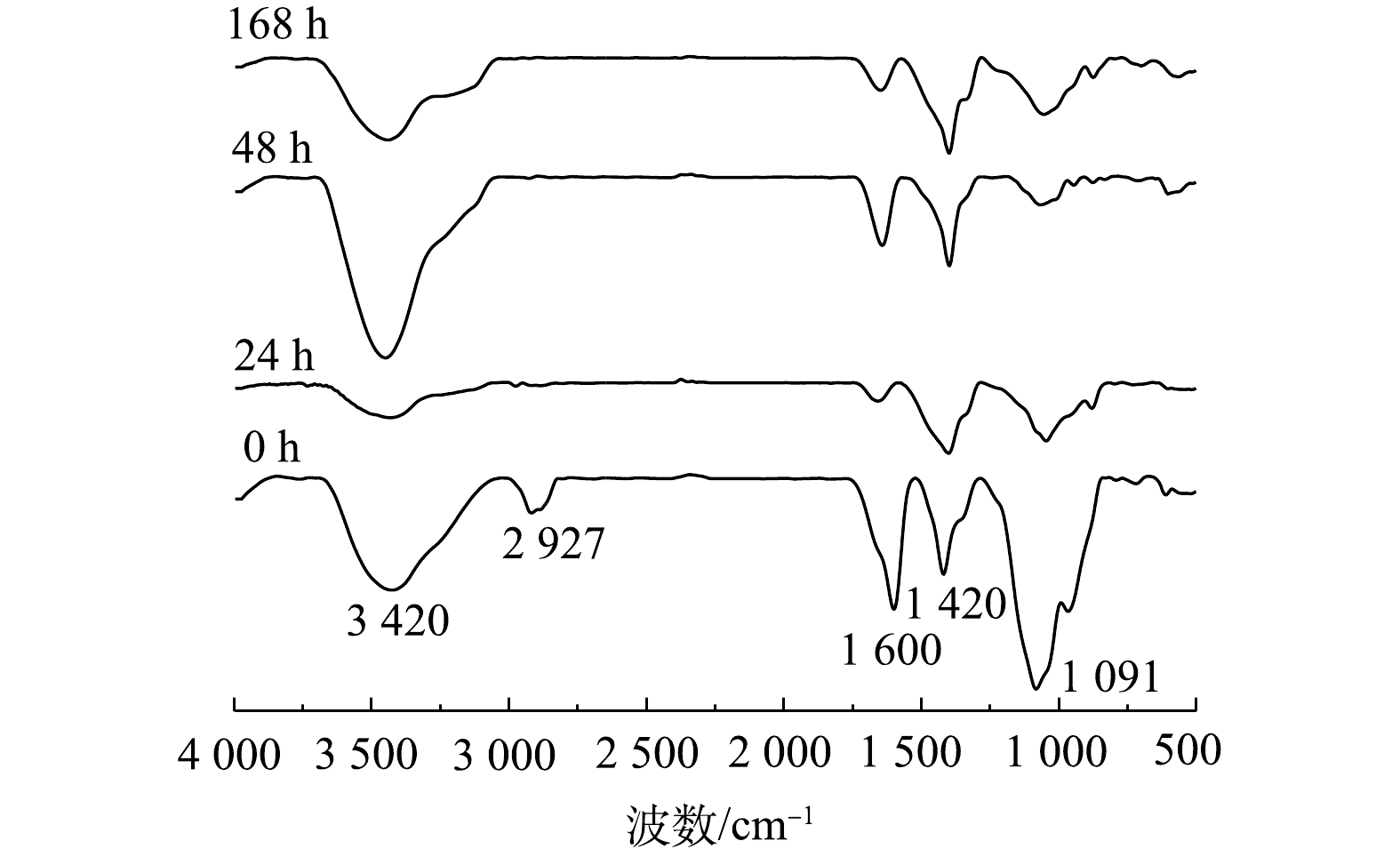

2)红外光谱分析。通过红外光谱分析可以识别水样中有机化合物的特征官能团和特定分子结构[18]。图3为压裂返排液厌氧生物处理过程中的红外光谱分析结果。由图3可知,压裂返排液处理前的特征吸收峰有3 420、2 927、1 600、1 420、1 091、964 cm−1。600~900 cm−1为指纹图谱区,此处吸收峰表明废水中含有不饱和键[19-20]。樊月[21]对压裂返排液进行红外光谱分析,得到了类似的特征吸收峰。3 350~3 500 cm−1处的吸收峰是O—H键的伸缩振动,说明废水中含有大量糖类有机物[22];胍胶是一种由半乳糖和甘露糖组合而成的多聚糖,说明压裂返排液中有机物的主要有机成分为糖类物质,这与FERRER等[23]、LESTER等[24]的研究结果一致。2 900~3 000 cm−1处为C—H键伸缩振动吸收峰,表明未处理返排液中含有饱和烷烃类物质。1 580~1 620 cm−1处为与羧酸C=O键共轭的芳香族C=C双键伸缩振动,表明返排液中含有芳香烃类有机化合物。1 390~1 420 cm−1处为羧酸类O—H的弯曲振动[18],此处存在吸收峰可能是由于返排液中胍胶被氧化断键生成大量含有羧基的物质所致。950~1 125 cm−1处的吸收峰是多糖类化合物C—O键的伸缩振动[25]。由此可见,未处理的压裂返排液中含有大量残留的胍胶以及含有不饱和双键类、芳香类等有机污染物。

压裂返排液经过24 h厌氧处理后,位于3 420、2 927、1 091 cm−1处的吸收峰强度急剧降低,返排液中有机物得到有效降解,这与COD在此阶段快速降低的情况一致。1 600 cm−1处吸收峰发生偏移至1 640 cm−1,经分析,该峰为单核芳烃的C=C的伸缩振动峰[25]。这表明压裂返排液经厌氧微生物作用,将有机物芳环结构逐渐分解为单个的芳香环。而随着生物反应的进行,1 420 cm−1处吸收峰转移至1 398 cm−1,1 300~1 400 cm−1为脂肪族化合物C—H的伸缩振动,这表明压裂返排液中的羧酸类污染物可能逐渐降解为脂肪族类化合物。

当处理48 h时,1 091 cm−1处峰强度进一步减少,说明胍胶被氧化降解;而3 420 cm−1处的吸收峰增大,表明胍胶分子经厌氧微生物氧化降解后产生了其它含有O—H基团的物质。另外1 640 cm−1处峰增大,推测1 635~1 645 cm−1处的吸收峰可能是羧酸根中C=O的伸缩振动峰,也可能是水的O—H的面内振动峰[26],此处峰增大可能是由于胍胶被氧化断键生成大量羧基,这与郭广军等[26]和韩洪晶等[27]在研究胍胶降解过程中得到的结论类似。随着反应进行至168 h时,各个峰强度均有所降低,说明压裂返排液中有机物得到进一步降解。红外光谱分析结果表明,压裂返排液中有机物在厌氧条件下可以得到有效的降解。

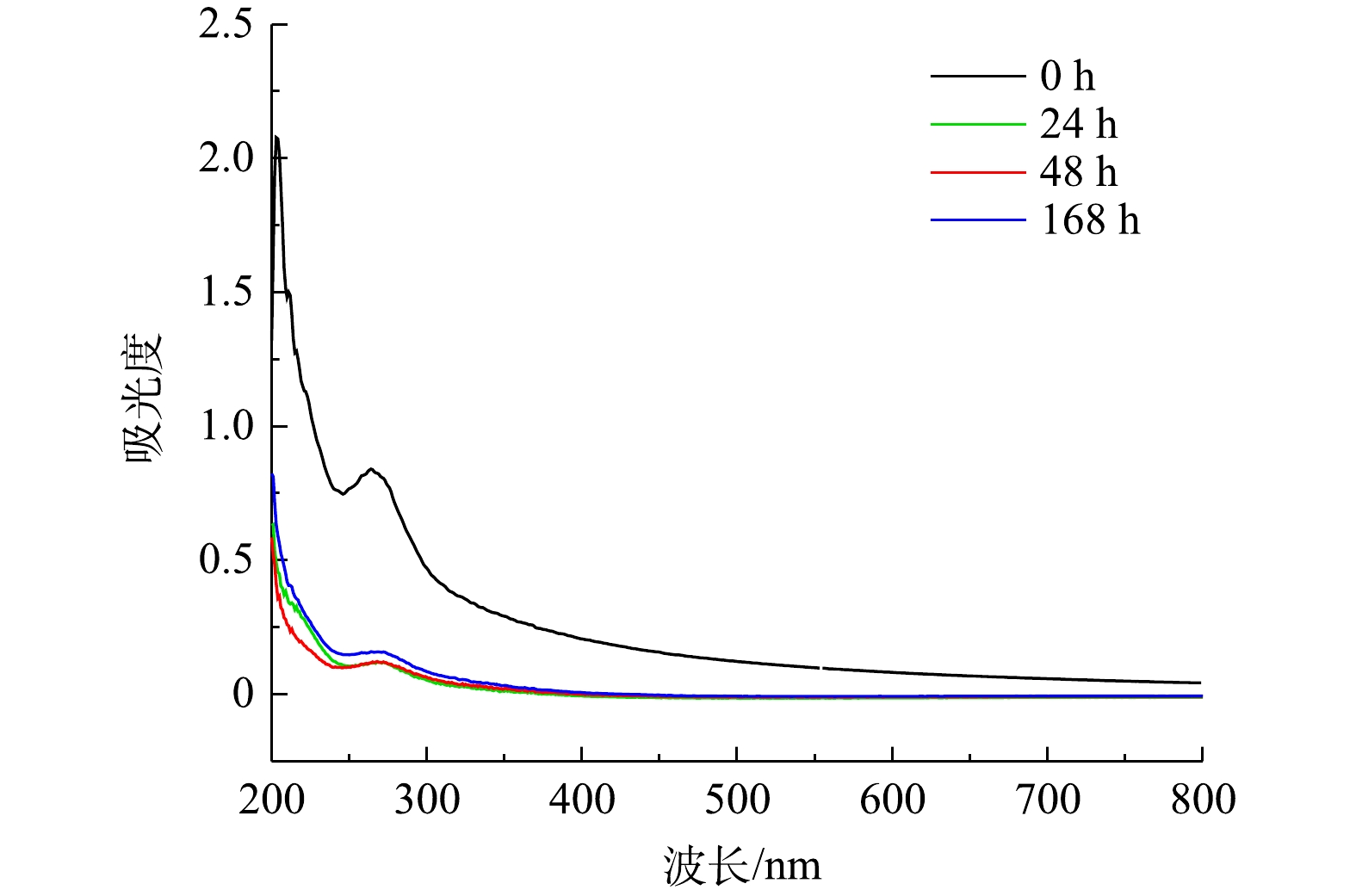

3)紫外可见光谱分析。图4反映了压裂返排液厌氧处理过程中UV-Vis 的变化情况。由图4可知,未处理的压裂返排液在紫外光波长范围内出现了芳香族化合物的特征吸收峰,在200~210 nm处出现显著的由苯环结构环状共轭系统π→π*跃迁产生的E带吸收;在230~280 nm出现了明显的B带吸收[28]。FU[29]对压裂返排液进行紫外光谱分析,也发现了类似的特征吸收峰。UV254是评价水中有机物的重要指标[30]。有研究[31]表明,UV254能够反映包括芳香族化合物在内的具有不饱和双键结构的物质,UV254值越高代表溶液中的不饱和物质越多。SUVA254代表水样中芳香成分和总溶解性有机质之间的比率,计算方法为吸光度强度除以溶解性有机质含量,其值越高表示测定水样中的水生腐殖物质含量越多[32]。

由表2可以看出,压裂返排液厌氧处理过程中,在反应24 h时,B带、E带特征吸收峰的吸光度值急剧降低,并且UV254、SUVA254均降低,说明废水中芳香族化合物可能被降解,苯环结构可能被破坏,这与红外光谱分析结果一致,也与COD在此阶段快速降低的情况相吻合。在反应48 h时,B带特征吸收峰有所减弱,UV254降低、SUVA254升高,这是因为厌氧微生物将压裂返排液中易生物降解的多糖等非芳香类物质大量去除,而芳香族物质去除较少,其结果导致SUVA254升高[33]。在李达[34]、单莉莉[25]的研究中也出现类似现象。在168 h时,B带特征吸收峰略微增大,SUVA254升高,这是微生物代谢过程中产生的溶解性代谢副产物导致的[35]。YAN等[32]在研究生物处理淀粉废水时也得到了类似结论。

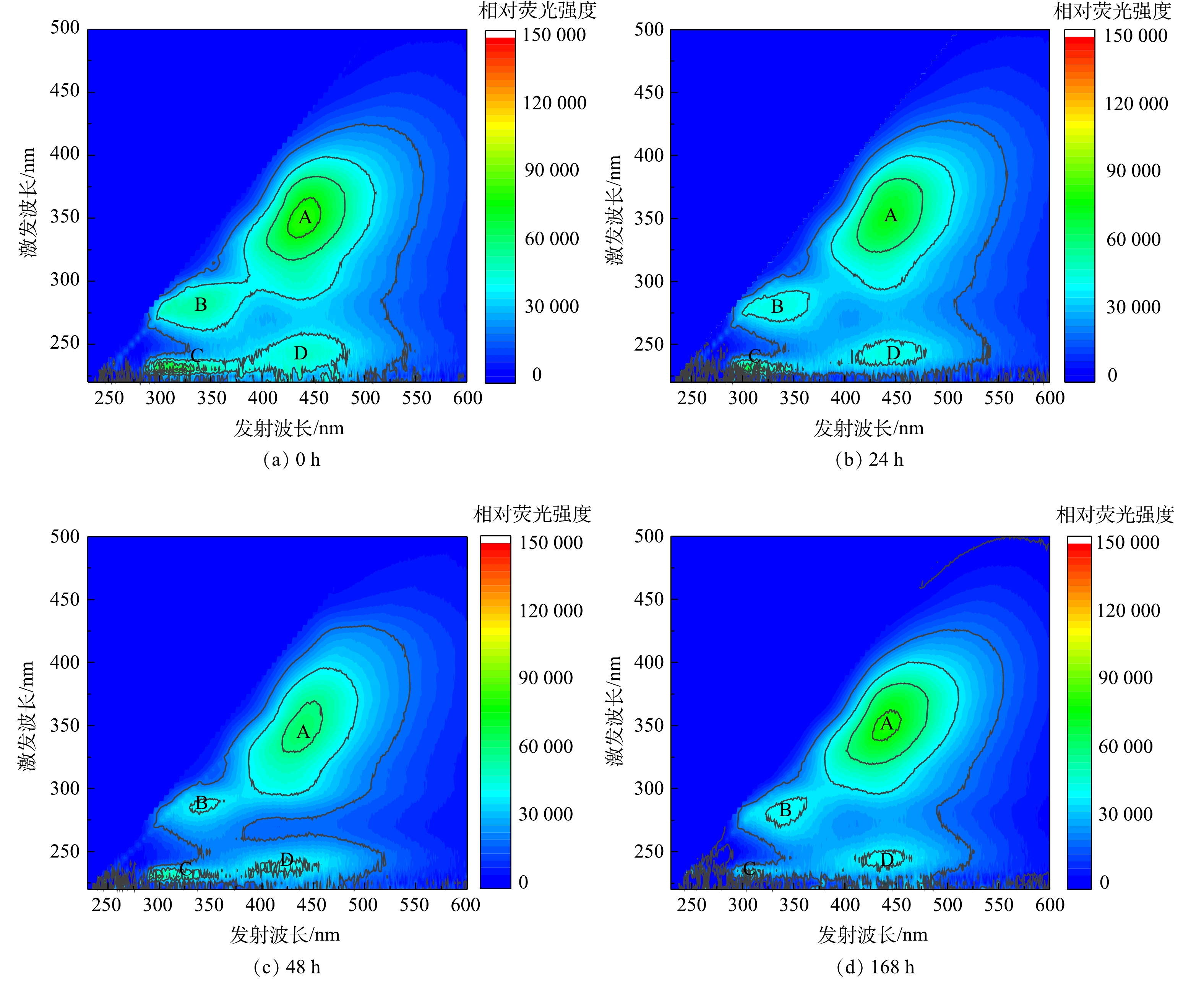

4)三维荧光光谱分析。三维荧光光谱可以提供大量关于溶解性有机物演化的信息[19]。压裂返排液在处理各时段的三维荧光光谱如图5所示。根据CHEN等[36]的研究结果,图5中可以辨别出以下主要荧光峰:峰A(Ex 250~400 nm,Em 380~500 nm)为类腐殖酸物质;峰B(Ex 250~400 nm,Em 280~380 nm)为可溶性微生物代谢产物;峰C(Ex<250 nm,Em<380 nm)为芳香族蛋白质类物质及峰D(Ex 220~250 nm,Em 380~450 nm)为富里酸类物质。由图5可以看出,在厌氧处理前24 h中,由于有机物在厌氧微生物的作用下发生快速降解,压裂返排液中出现的荧光峰强度明显降低,压裂返排液中荧光物质得到有效去除;随着生物反应的进行,各个峰的荧光强度进一步降低。当处理时间为168 h时,芳香族蛋白质类物质的荧光峰几乎完全消失,说明厌氧处理对压裂返排液中蛋白类物质有较好的处理效果。这与张一欣等[37]的研究结果一致。而此时可溶性微生物代谢产物、类腐殖酸物质及富里酸类物质荧光峰强度均有所升高,这是由于微生物在降解废水中有机物的同时产生了腐殖酸等物质[38],这与紫外光谱分析结果一致。另外,经过微生物的酶促作用,易生物降解的蛋白类物质也会转化为腐殖质等物质[39]。李达[34]、YAN等[32]的研究中也发现,随着反应的进行,腐殖酸类物质相应增多。

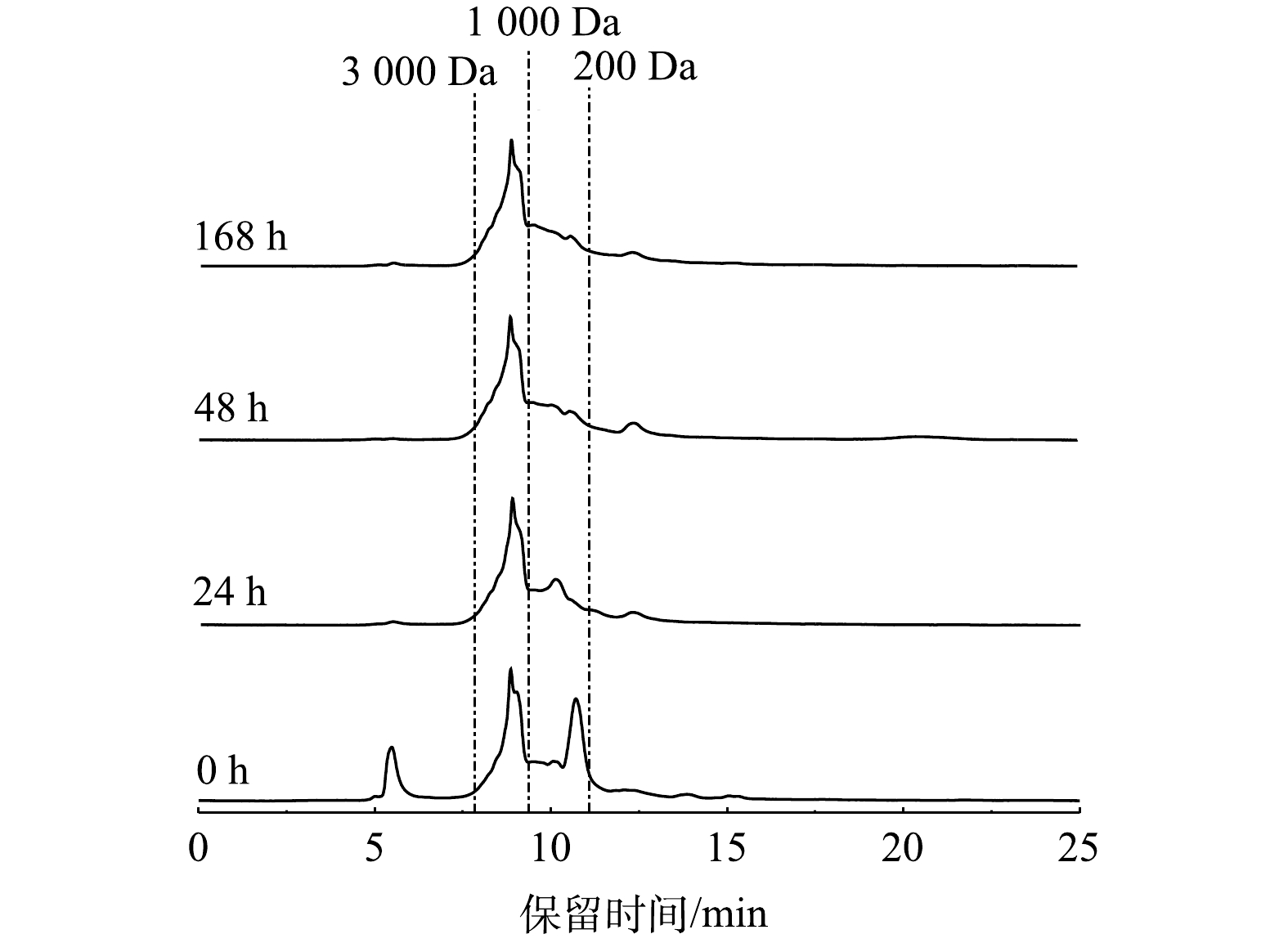

5)分子质量分析。图6为压裂返排液厌氧处理过程中溶解性有机质的凝胶渗透色谱图。据报道,停留时间越短的有机物具有越高的表观分子质量[40]。由图6可以看出,压裂返排液处理前在保留时间为5.4、8.8、10.07、10.7、12.2、13.8及15.1 min有明显的吸收峰,其中在5.4、8.8及10.7 min处的峰面积较大,表明原水中有机物分子质量主要分布在在3 000 Da以上、1 000~3 000 Da以及200~1 000 Da。金鹏康等[41]对压裂返排液中有机物分子质量进行分析,也得到了类似的分布。随着生物反应进行,当处理时间为24 h时,仅在5.4、8.8、10.07和12.2 min有明显吸收峰,13.8 min和15.1 min处的吸收峰消失,说明分子质量小于200 Da的有机物被降解,这可能是由于小分子质量有机物容易被生物降解,被微生物优先利用,转化为甲烷,因此,此时甲烷的产气量也快速升高,COD含量快速下降,这与图2中的结果吻合。此时5.4 min处吸收峰面积明显减少,这是由于水解酸化细菌将分子质量在3 000 Da以上的大分子有机物降解转化为小分子物质。当处理时间为48 h时,保留时间为5.4、8.8和10.07 min的峰面积减少,而保留时间为12.2 min的峰面积增加。这说明在厌氧微生物的作用下,压裂返排液中的大分子物质被进一步分解为小分子物质。当处理时间为168 h时,在保留时间为5.4 min和8.8 min处的峰面积略有增加,分子质量在3 000 Da以上和1 000~3 000 Da的有机物增多。这是因为微生物代谢过程中产生了大分子的腐殖酸类物质[25]。YAN等[32]在研究生物处理淀粉废水时也发现了随着反应进行分子质量有增加的现象。此结果与三维荧光、紫外光谱研究结果相一致。

-

表3反映了好氧工艺降解压裂返排液厌氧出水过程中COD的变化情况。结果表明,经24 h好氧处理后,COD由处理前的170.5 mg∙L−1降低至132.6 mg∙L−1,去除率仅为22.2%。通过对压裂返排液厌氧出水的三维荧光光谱(图5)分析可知,压裂返排液经过厌氧处理后简单的芳香族蛋白质等易生物降解物质的荧光峰基本上消失。然而,由于类腐殖酸物质自身的难降解性以及微生物自身的新陈代谢作用,导致厌氧出水中类腐殖酸物质仍然占有较高的比例。类腐殖酸的大量存在可能是限制好氧工艺处理压裂返排液厌氧出水的主要因素,因此,需要采用高级氧化等方法对其进行深度处理。

-

1)压裂返排液具有良好的厌氧生物降解特性。经过168 h厌氧处理,COD和TOC由处理前的1 735.2 mg∙L−1和698.5 mg∙L−1分别降低至277.2 mg∙L−1和94.9 mg∙L−1,对应的去除率分别为84.0%和86.4%,每克耗氧有机物(以COD计)能产生688.2 mL的甲烷。

2)厌氧生物处理可以显著去除压裂返排液中残余的胍胶、芳香族化合物和类腐殖酸等有机物,从而实现对有机物的高效去除。

3)压裂返排液中有机物分子质量主要分布在3 000 Da以上、1 000~3 000 Da以及200~1 000 Da,厌氧处理将分子质量小于200 Da的有机物优先去除,同时将大分子有机物分解为小分子物质,从而进一步被微生物降解再得以去除。

油田压裂返排液的厌氧处理特性

Anaerobic treatment characteristics of oilfield fracturing flowback fluid

-

摘要: 油田压裂返排液中含有高浓度有机物、盐类物质和悬浮物等污染物,如不妥善处置直接外排会对环境产生严重危害。以配制的胍胶压裂返排液为研究对象,采用厌氧颗粒污泥对其进行处理,以COD、TOC去除率及甲烷产量为考察指标,研究了压裂返排液的厌氧生物降解特性。结果表明,压裂返排液经168 h厌氧处理后,COD和TOC由处理前的1 735.2 mg∙L−1和698.5 mg∙L−1 降低至277.2 mg∙L−1和94.9 mg∙L−1,去除率分别为84.0%和86.4%,每克COD能产生688.2 mL的甲烷。采用红外光谱、紫外可见光谱以及三维荧光光谱对压裂返排液厌氧处理过程中有机物的组分及光谱特性进行了分析,发现厌氧生物处理可显著去除压裂返排液中芳香族化合物和类腐殖酸等物质。凝胶渗透色谱分析结果表明,压裂返排液中分子质量小于200 Da的有机物在厌氧处理过程中被优先去除。此外,将厌氧工艺出水进行好氧生物处理,COD去除率仅为22.2%,说明厌氧处理后的压裂返排液可生物降解性较差,需要采用高级氧化等方法进行深度处理。Abstract: Oilfield fracturing flowback fluid contains pollutants such as high concentrations of organic matter, salinity, and suspended solids. If oilfield fracturing flowback fluid is not disposed properly, direct discharge would cause severe harm to the environment. In this study, anaerobic granular sludge was employed to treat the prepared guar gum fracturing flowback fluid, and its anaerobic biodegradation characteristics was explored with COD and TOC removal rates and methane production as the indicators. The results demonstrated that after 168 h treatment, COD and TOC decreased from 1 735.2 mg∙L−1 and 698.5 mg∙L−1 before anaerobic treatment to 277.2 mg∙L−1 and 94.9 mg∙L−1 after anaerobic treatment with the corresponding removal rates of 84.0% and 86.4%, respectively. Meanwhile, the evolution of dissolved organic matter (DOM) in oilfield fracturing flowback fluid during the anaerobic biological treatment was investigated. The DOM was sampled at different treatment stages and characterized through Fourier transform infrared (FTIR) spectroscopy, fluorescence excitation-emission matrix (EEM), and UV-Vis. The results revealed that organic pollutants such as aromatic compounds and humic substances could be significantly removed by anaerobic biological treatment. Gel permeation chromatography (GPC) indicated that the organic matter with molecular weight (MW) less than 0.2 kDa was first removed during the anaerobic treatment. In addition, aerobic biological treatment was used to treat the effluent from anaerobic treatment unit and the COD removal efficiency was only 22.2%, indicating that the fracturing flowback after anaerobic treatment had low biodegradability and the advanced oxidation method would be needed for deep treatment.

-

表 1 不同初始浓度下厌氧处理压裂返排液过程中COD的变化

Table 1. COD changes during anaerobic treatment of fracturing wastewater at different initial concentrations

反应器编号 COD/(mg∙L−1) COD去除率/% 反应前 反应后 A 917.5 181.5 80.2 B 2 012.2 321.1 84.0 C 3 632.3 492.3 86.4 D 4 380.7 638.7 85.4 表 2 压裂返排液厌氧处理过程中UV254及SUVA254的变化

Table 2. Changes of UV254 and SUVA254 during anaerobic treatment of fracturing flowback fluid

反应时间/h UV254 SUVA254 0 0.78 0.11 24 0.11 0.05 48 0.10 0.10 168 0.15 0.16 表 3 好氧降解压裂返排液厌氧出水过程中COD的变化情况

Table 3. COD changes during aerobic treatment of the effluent after anaerobic treatment

反应时间/h COD/(mg∙L−1) COD去除率/% 0 170.5 — 4 158.7 6.9 8 146.1 14.3 12 138.3 18.8 24 132.6 22.2 -

[1] ZHANG Z. Combined treatment of hydroxypropyl guar gum in oilfield fracturing wastewater by coagulation and the UV/H2O2/ferrioxalate complexes process[J]. Water Science and Technology, 2018, 77(3): 565-575. doi: 10.2166/wst.2017.552 [2] ESTRADA J M, BHAMIDIMARRI R. A review of the issues and treatment options for wastewater from shale gas extraction by hydraulic fracturing[J]. Fuel, 2016, 182(15): 292-303. [3] 李乐楠. 油田压裂返排液处理技术研究综述[J]. 石化技术, 2018, 25(1): 193. [4] 黄靓, 李慧强, 杨平, 等. 页岩气压裂返排液的组成及处理技术[J]. 环境科学与技术, 2016, 39(S2): 172-177. [5] 王志强, 王新艳, 郝华伟. 混凝预处理油田压裂返排液试验研究[J]. 广东化工, 2014, 41(8): 47-49. doi: 10.3969/j.issn.1007-1865.2014.08.024 [6] 高玺莹, 王宝辉, 彭宏飞, 等. 标准Fenton试剂处理压裂余液的实验研究[J]. 水资源与水工程学报, 2010, 21(2): 139-141. [7] 冀忠伦, 周立辉, 赵敏, 等. 臭氧催化氧化处理压裂废液的实验研究[J]. 环境工程, 2011, 29(S1): 117-119. [8] RILEY S M, OLIVEIRA J, REGNERY J, et al. Hybrid membrane bio-systems for sustainable treatment of oil and gas produced water and fracturing flowback water[J]. Separation and Purification Technology, 2016, 171: 297-311. doi: 10.1016/j.seppur.2016.07.008 [9] 陈翱翔. 好氧颗粒污泥SBR处理页岩气开采水力压裂返排废水的研究[D]. 重庆: 重庆大学, 2017. [10] YANG J, LIANG H, LIU Y H, et al. Treatment of oilfield fracturing wastewater by a sequential combination of flocculation, Fenton oxidation and SBR process[J]. Environmental Technology, 2014, 35(21/22/23/24): 2878. [11] 王海蒙. 预处理+生物法处理压裂废水的实验研究[D]. 西安: 西安建筑科技大学, 2013. [12] KEKACS D, DROLLETTE B D, BROOKER M, et al. Aerobic biodegradation of organic compounds in hydraulic fracturing fluids[J]. Biodegradation, 2015, 26(4): 271-287. doi: 10.1007/s10532-015-9733-6 [13] RITTMANN B E, MCCARTY P L. Environmental Biotechnology: Principles and Applications[M]. McGraw-Hill Education, 2001. [14] SU D, CONG L, WANG J, et al. Treatment of oil-field produced water by combined process of anaerobic baffled reactor (ABR)-biological aerated filter (BAF): A pilot study[J]. International Journal of Environment and Pollution, 2009, 38(1/2): 69-80. doi: 10.1504/IJEP.2009.026644 [15] LI G, GUO S, LI F. Treatment of oilfield produced water by anaerobic process coupled with micro-electrolysis[J]. Journal of Environmental Sciences, 2010, 22(12): 1875-1882. doi: 10.1016/S1001-0742(09)60333-8 [16] ZHANG X, CHEN A, ZHANG D, et al. The treatment of flowback water in a sequencing batch reactor with aerobic granular sludge: Performance and microbial community structure[J]. Chemosphere, 2018, 211: 1065-1072. doi: 10.1016/j.chemosphere.2018.08.022 [17] 钟显, 赵立志, 杨旭, 等. 生化处理压裂返排液的试验研究[J]. 石油与天然气化工, 2006(1): 70-72. doi: 10.3969/j.issn.1007-3426.2006.01.022 [18] PENG S, HE X, PAN H. Spectroscopic study on transformations of dissolved organic matter in coal-to-liquids wastewater under integrated chemical oxidation and biological treatment process[J]. Journal of Environmental Sciences, 2018, 70: 206-216. doi: 10.1016/j.jes.2018.04.006 [19] WANG K, LI W, GONG X, et al. Spectral study of dissolved organic matter in biosolid during the composting process using inorganic bulking agent: UV-vis, GPC, FTIR and EEM[J]. International Biodeterioration & Biodegradation, 2013, 85: 617-623. [20] 孙秀玥, 唐珠, 杨新萍. 活性污泥胞外多聚物提取方法的比较[J]. 环境科学, 2018, 39(7): 3306-3313. [21] 樊月. 油田压裂废水的微波/化学氧化联合处理方法研究[D]. 西安: 西安石油大学, 2016. [22] 周圆, 李怀波, 郑凯凯, 等. 新型组合工艺处理印染废水中试效能及微生物菌群分析[J]. 环境工程学报, 2020, 14(11): 126-137. [23] FERRER I, THURMAN E M. Chemical constituents and analytical approaches for hydraulic fracturing waters[J]. Trends in Environmental Analytical Chemistry, 2015, 5: 18-25. doi: 10.1016/j.teac.2015.01.003 [24] LESTER Y, YACOB T, MORRISSEY I, et al. Can we treat hydraulic fracturing flowback with a conventional biological process? The case of Guar Gum[J]. Environmental Science & Technology Letters, 2013, 1(1): 133-136. [25] 单莉莉. CSTR-EGSB-SBR与电化学氧化联合处理纤维素乙醇废水的效能与机制[D]. 哈尔滨: 哈尔滨工业大学, 2017. [26] 郭广军, 周利英, 何建平, 等. 瓜尔胶及其衍生物的过硫酸铵氧化降解研究[J]. 化学研究与应用, 2010, 22(12): 1546-1550. doi: 10.3969/j.issn.1004-1656.2010.12.013 [27] 韩洪晶, 杨元林, 王宝辉. 绿色氧化剂K2FeO4对瓜尔胶的降解实验研究[J]. 硅酸盐通报, 2018, 37(6): 2057-2061. [28] 李才华, 姜枫, 邹秋爽, 等. 臭氧-过硫酸盐工艺深度处理垃圾焚烧渗沥液[J]. 环境工程学报, 2017, 11(4): 2233-2240. doi: 10.12030/j.cjee.201602003 [29] FU H. Treatment of oilfield fracturing wastewater[J]. Petroleum Science and Technology, 2017, 35(17): 1743-1749. doi: 10.1080/10916466.2017.1363777 [30] WANG Y, WU X, YI J, et al. Pretreatment of printing and dyeing wastewater by Fe/C micro-electrolysis combined with H2O2 process[J]. Water Science and Technology, 2018, 2017(3): 707-717. doi: 10.2166/wst.2018.244 [31] 刘璐. 典型煤化工废水中特征污染物的迁移转化及废水毒性削减研究[D]. 北京: 中国科学院大学, 2017. [32] YAN H, NIAN Y, ZHOU Y, et al. A detailed dissolved organic matter characterization of starch processing wastewater treated by a sedimentation and biological hybrid system[J]. Microchemical Journal, 2017, 130: 295-300. doi: 10.1016/j.microc.2016.10.001 [33] WESTERHOFF P, PINNEY M. Dissolved organic carbon transformations during laboratory-scale groundwater recharge using lagoon-treated wastewater[J]. Waste Management, 2000, 20(1): 75-83. doi: 10.1016/S0956-053X(99)00277-9 [34] 李达. 水解酸化-UASB工艺处理煤制气废水的研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. [35] 卜琳. 垃圾渗滤液溶解性有机物在生化-物化处理中的降解规律[D]. 哈尔滨: 哈尔滨工业大学, 2011. [36] CHEN W, WESTERHOFF P, LEENHEER J A, et al. Fluorescence excitation-emission matrix regional integration to quantify spectra for dissolved organic matter[J]. Environmental Science & Technology, 2003, 37(24): 5701-5710. [37] 张一欣, 崔欣欣, 刘淑琴, 等. 三维电极耦合臭氧技术处理油田压裂返排液[J]. 中国环境科学, 2020, 40(5): 417-422. [38] 李志华, 余科, 唐姚辉, 等. 污水厂活性污泥荧光物质的温度敏感性[J]. 环境工程学报, 2017, 11(6): 3399-3404. doi: 10.12030/j.cjee.201603128 [39] 周明罗, 陈海焱, 谌书, 等. 移动床生物膜技术处理校园污水过程中DOM的光谱特征[J]. 光谱学与光谱分析, 2019, 39(7): 2160-2165. [40] LI W, XU Z, WU Q, et al. Characterization of fluorescent-dissolved organic matter and identification of specific fluorophores in textile effluents[J]. Environmental Science and Pollution Research, 2015, 22(6): 4183-4189. doi: 10.1007/s11356-014-3201-4 [41] 金鹏康, 贺栋, 刘岚, 等. 压裂废水粘度对二氧化锰臭氧催化氧化处理特性的影响[J]. 环境工程学报, 2013, 7(10): 3719-3724. -

下载:

下载: