-

煤炭、建材、水泥、电力等行业可排放大量的粉尘颗粒物,对人们的健康与生活环境造成巨大风险,因此,粉尘颗粒物的收集具有重要的现实意义[1]。滤筒除尘器以其除尘效率高、过滤面积大、阻力小、价格低、占地面积小等优点而被广泛运用于除尘领域[2]。除尘器的技术关键在于滤筒清灰,清灰的好坏直接影响着除尘器的长期稳定运行[3-4]。目前,应用最广泛的清灰技术是脉冲喷吹[5]。但是,传统的脉冲喷吹容易造成滤筒上部压力小而清灰失效,及底部压力过大而滤料破损[6-7]。

国内外学者针对脉冲喷吹压力、喷吹时间、喷吹高度和喷吹管直径等众多因素对滤筒脉冲清灰进行了研究[8-13]。在滤筒结构优化方面,LI等[14]在滤筒内部安装圆锥体,通过实验证明了其有利于增加滤筒侧壁压力且清灰均匀性得到改善。杨燕霞等[2]通过对金锥滤筒(滤筒内设置锥形过滤面)脉冲清灰性能的研究,揭示了金锥对脉冲清灰性能的影响机制。张亚蕊等[15]通过对内置锥形体滤筒的数值模拟,将普通滤筒和内置锥形体滤筒的速度云图、压力云图进行对比,得出了内置锥形滤筒的清灰效果会有明显改善的结论。QIU等[16]通过建立褶式金锥滤筒的数值模型,探究了内锥高度对脉喷性能的影响,结果表明,随着内锥高度的增加,滤筒脉喷的均匀性得到改善。

在脉冲喷嘴改进方面,胡峰源等[17]利用数值模拟方法对比了传统喷嘴和拉瓦尔型喷嘴的清灰性能,结果表明,拉瓦尔型喷嘴的平均侧壁压力峰值增大了53.2%。胥海伦等[18]利用数值模拟对比了不同开口形式的散射器的流场分布,结果表明,随着散射器开口增大,气流诱导量也会随之增大(开口散射器上部直径为30 mm时,诱导气流量是无散射器的8.5倍)。刘东等[19]利用实验对比了不同锥度上部开口散射器的清灰性能,结果表明,在一定范围内,锥度的增大能有效增大滤筒清灰强度。虽然单独对滤筒或喷嘴结构的研究都已完善,但对喷嘴和滤筒共同优化的研究鲜有报道。

本研究将普通喷嘴、文丘里喷嘴分别与普通滤筒、金锥滤筒组合,通过数值模拟,研究了4种条件下喷吹压力的时空分布,分析了滤筒内壁测点压力的变化规律,考察了喷吹高度对清灰性能的影响,以期对滤筒除尘器的优化设计提供参考。

-

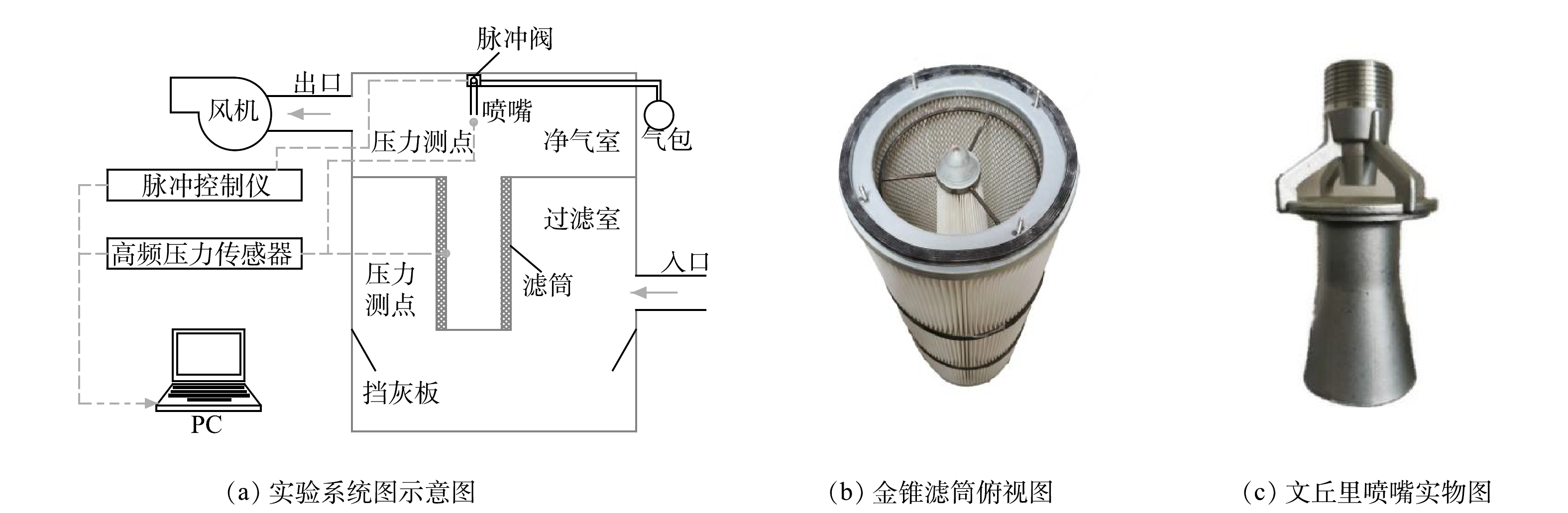

模拟时,参照了图1(a)所示的脉冲喷吹除尘系统,其中除尘器箱体的长、宽、高分别为 1 225、750、1 550 mm,滤筒(无纺布长绒棉涤纶材质)竖直安装在除尘器内部,喷嘴位于滤筒的正上方。金锥滤筒如图1(b)所示,是在普通滤筒(外形长度660 mm,直径240 mm,滤料厚度0.6 mm)的内部增加锥形过滤面,其直径为200 mm,顶部设有金属锥体,锥体高度为40 mm、底部直径为65 mm。文丘里喷嘴如图1(c)所示,是在普通喷嘴(直径25 mm)的基础上增加了诱导口,诱导口顶部距离普通喷嘴7 mm,上部为带有12 mm边沿的中空圆台,其顶部直径、底部直径、高度分别为51、35、10 mm,下部同样为中空圆台,其顶部直径、底部直径、高度分别为35、52、60 mm,中间由35 mm高的中空圆柱体连接。脉冲喷吹使用20 L的气包,初始压力为0.5 MPa,喷吹时长为0.15 s。压力测点布设在滤筒内壁中部,所用传感器为压电陶瓷高频动态压力传感器MYD-1530A(

ϕ7mm×17mm )。 -

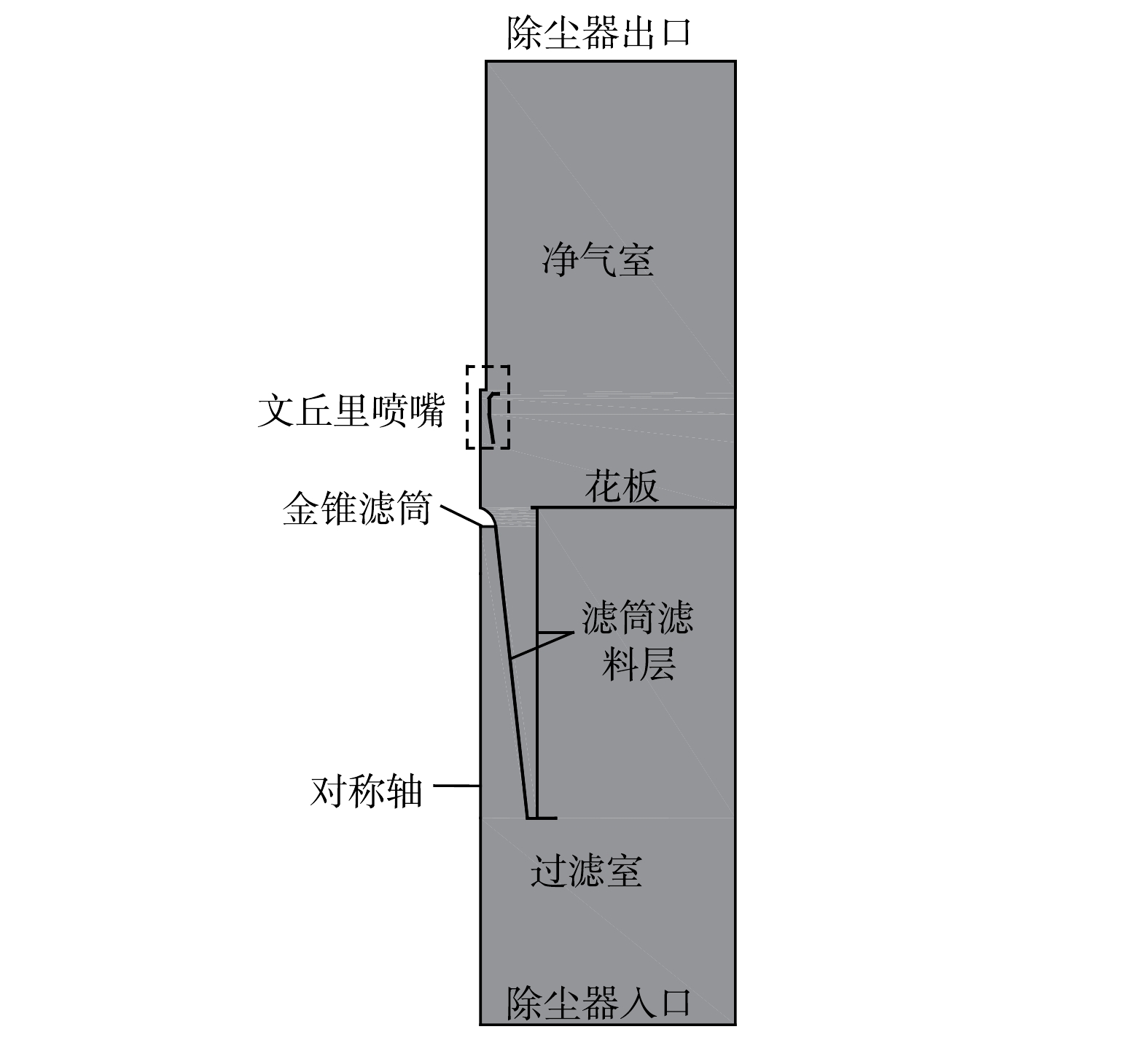

为节省计算量,将中心轴对称结构的滤筒简化为二维,同时,将矩形截面的箱体简化为圆柱形箱体,并保持各部位截面积不变。通过计算可知,简化的圆柱形箱体的截面半径为541 mm。为满足对喷吹高度的研究,将模型中箱体的高度增加到2 050 mm。简化后的二维模型如图2所示。

-

模拟边界条件如下:将除尘器的顶面和底面设置为压力出口,壁面设置成标准无滑移边界,喷嘴设置为压力入口,滤筒的滤料层设置为多孔介质区。模拟涉及的流体看作为可压缩、非稳态、等温的湍流,选用Realizable k-ε湍流模型和压力-速度耦合算法。喷吹过程中未考虑粉尘的存在和滤筒的形变。

入口压力通过实验获取,实验时,在喷嘴出口下方10 mm处设置高频压力传感器(测试后移走),传感器可测得喷嘴处喷出气流的压力值,随后可将其与时间的变化曲线进行分段拟合,并得到喷嘴出口压力随时间变化的曲线。按照上述方法,通过更换喷嘴,可分别测试得到普通喷嘴和文丘里喷嘴的出口压力随时间的变化曲线,分别为式(1)和式(2)。

式中:pc为普通喷嘴的出口压力,kPa;pd为文丘里喷嘴的出口压力,kPa;t为时间,s。

将式(1)和式(2)以UDF的形式分别导入普通喷嘴和文丘里喷嘴的模拟中,时间步长设置为0.000 5 s。

由脉冲袋式除尘器手册[1]可知,喷吹气量与过滤面积成正比。由于普通滤筒和金锥滤筒的过滤面积存在差异,故2种条件下的喷嘴出口压力也应该存在系数差,计算过程如下。

通过式(3)和脉冲喷吹前后气包内的绝对压力,可计算得到喷吹实际耗气量[20]。

式中: Qp 为在脉冲时间 t 内喷吹气量,m3·次−1;p0、p1为喷吹前后气包内的绝对压力,MPa;pa为当地的标准大气压力,取 0.099 91 MPa;V 为气包容积,20×10−3 m3;k为绝热指数,空气取k=1.4。

由实验测试结果可知,普通喷嘴条件下,初始气包压力为0.50 MPa,喷吹剩余压力为0.32 MPa,喷嘴出口最大压力为95.31 kPa。而金锥滤筒的过滤面积为普通滤筒的1.62倍,可求得金锥滤筒的初始气包压力应为0.72 MPa,对应的喷嘴出口压力峰值为171.21 kPa,即金锥滤筒对应的喷嘴出口压力应为同等条件下普通滤筒的1.80倍。

过滤材料区域(多孔介质层)的计算通过在标准流体方程上附加动力源

Δp 来实现,该动力源由黏性损失项和惯性损失项组成,计算方法见式(4)。式中:

Δp 为压力;μ 为层流黏度;α 为渗透率;C2为压强跃升系数;v为法向加速度;Δh 为介质厚度;ρ 为空气密度。另外,根据已有研究[21],可用达西公式表示有限厚度的多孔介质的黏性损失项,而对于多孔介质内部速度较低的流动,其惯性损失项可忽略。经实验测试与计算,所用滤料的厚度为0.6 mm,在过滤风速为0.5 m·min−1时压降为17.9 Pa,故其黏性损失系数

1/α 为2.0×1011 m−2。 -

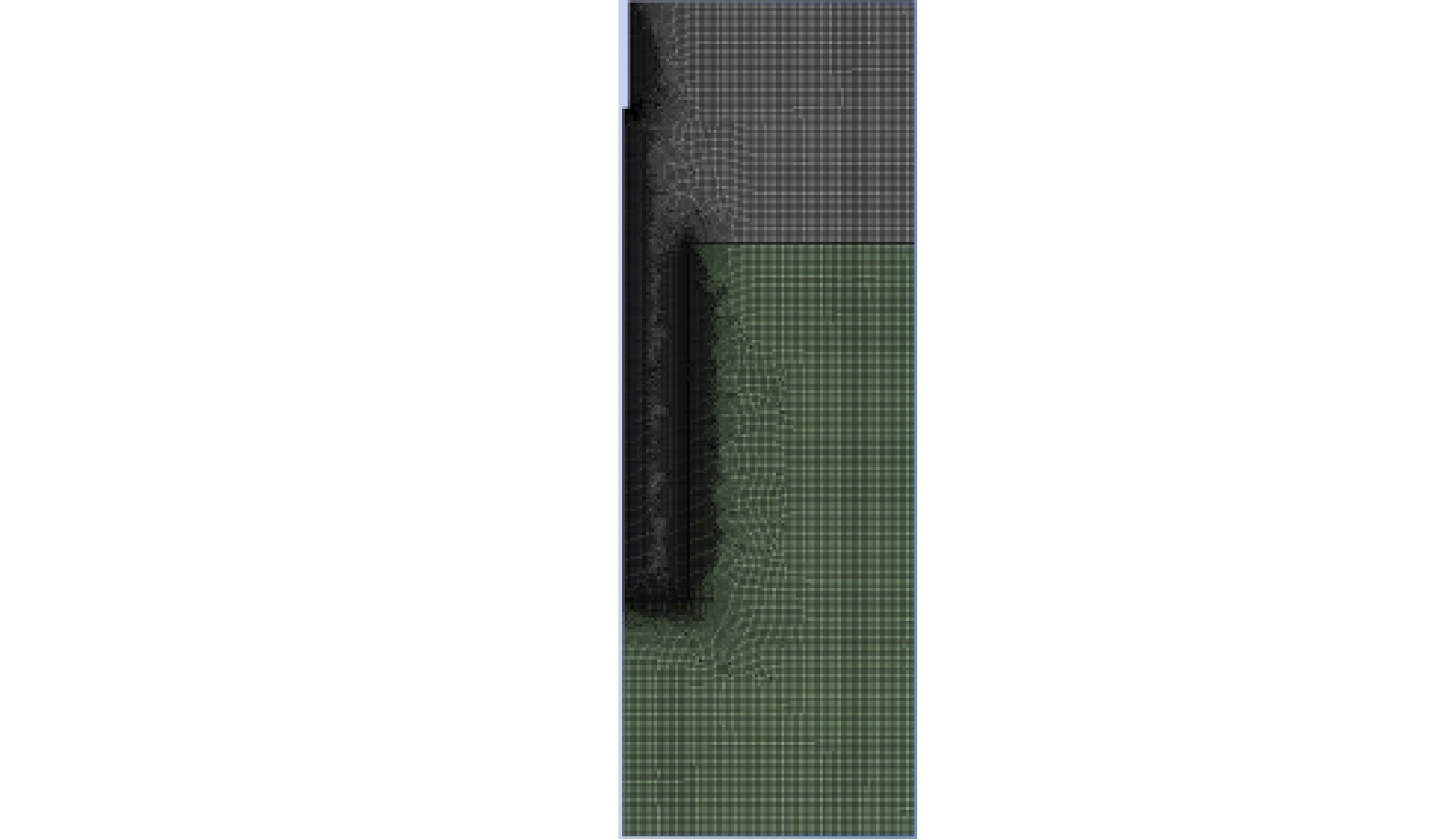

网格划分采用结构化网格,划分后网格节点总数为24.14×103 个、元素23.74×103 个,划分结果如图3所示。为了验证网格的独立性,对网格进行了加密处理,加密后的网格节点总数为33.34×103 个、元素32.84×103 个。

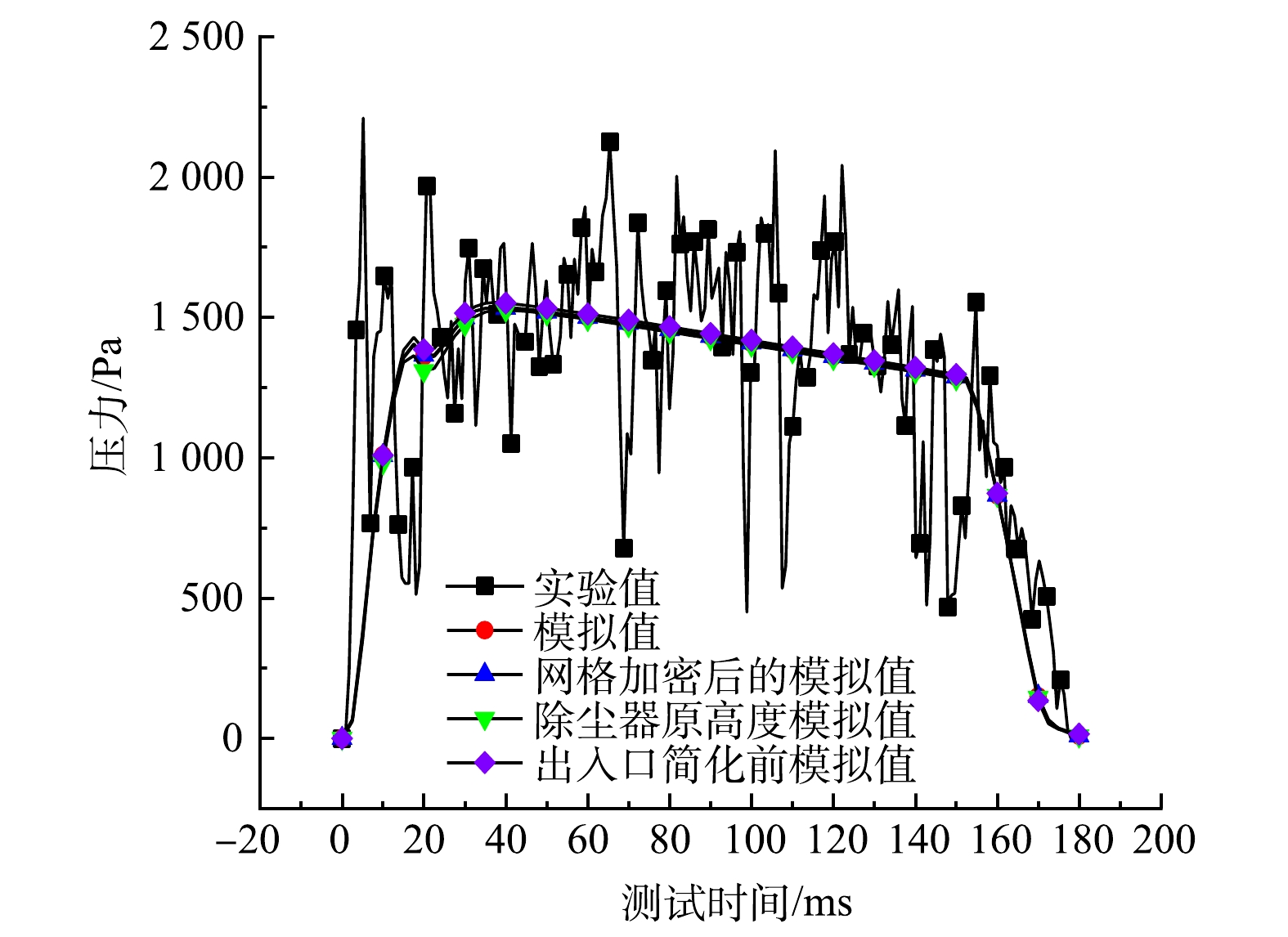

在气包初始压力为0.5 MPa、脉冲宽度为0.15 s、喷吹高度为250 mm、普通喷嘴和普通滤筒组合的条件下,滤筒内壁中间测点压力的模拟结果如图4所示。对比网格加密前后滤筒内壁中间测点压力值的变化情况,发现网格加密前后压力的模拟值基本吻合。由此可知,加密前的网格已经符合网格独立性的要求,因此,本研究采用加密前的结构化网格。

为进一步研究喷吹高度的影响,对除尘器的净化室进行了加高,并将除尘器的实际出入口简化为箱体顶面和底面。模拟结果表明,增加净化室高度前后以及出入口简化前后的模拟结果基本一致,可认为增加的净化室高度以及除尘器出入口的简化对所关注的滤筒内部气流的影响可以忽略。

由图4中模拟值与实验值的对比结果可知,二者的变化趋势整体吻合,压力均值基本相同,主要的不同是模拟的数值波动弱于实验值。这可能是模拟过程中并未考虑滤筒侧壁区域的流固耦合,而实际脉冲喷吹过程中筒壁会在脉冲喷吹的冲击波作用下发生振动,并由此引起传感器运动,导致测试数据的波动。

-

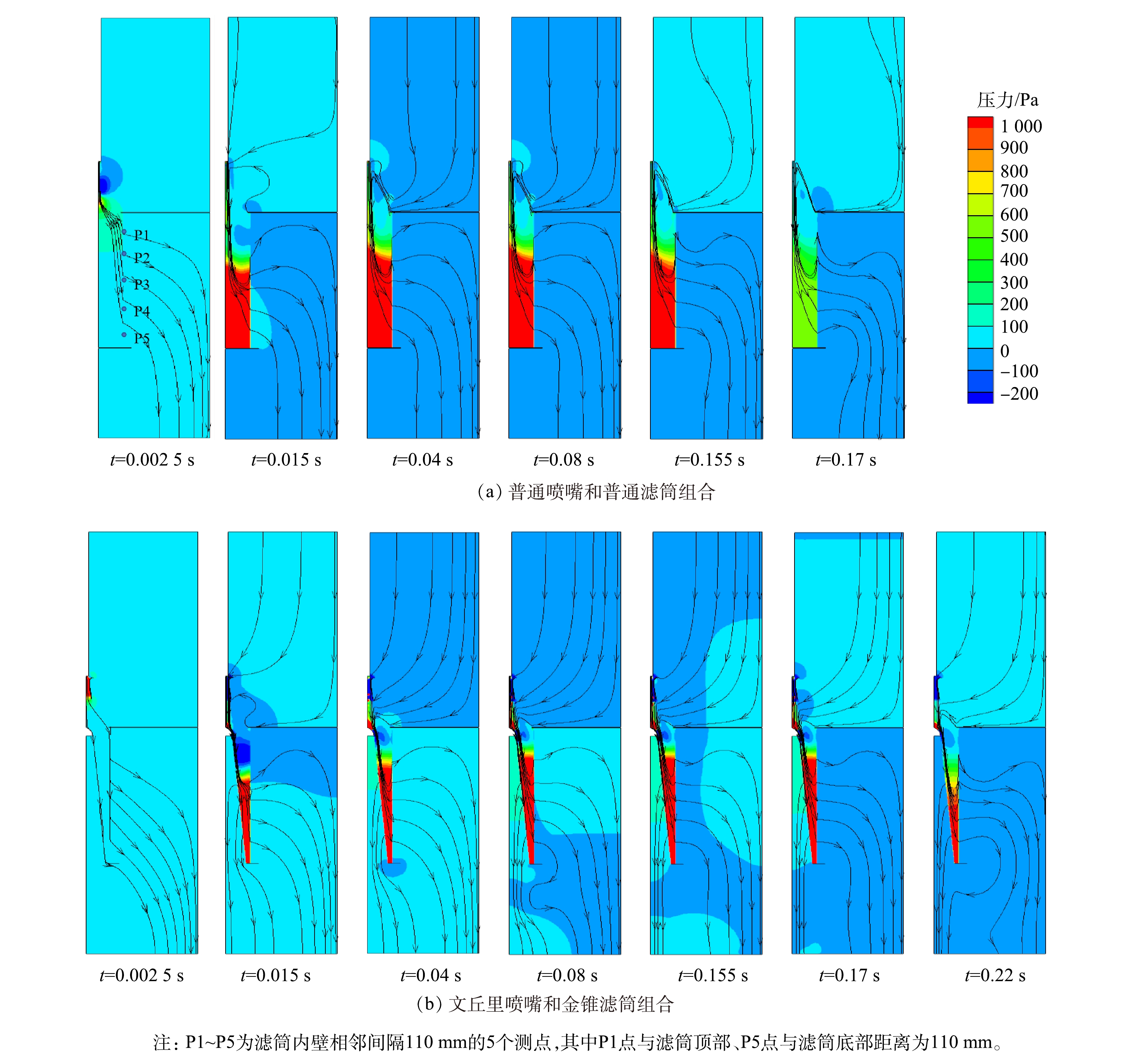

图5为模拟得到的喷吹高度为250 mm时,滤筒在脉冲喷吹过程中的静压力变化及流场流线变化。

在普通喷嘴和普通滤筒的组合(图5(a))的情况下,气流从喷嘴处喷出,产生卷吸作用,诱导周围气流进入滤筒。随后,高速的气流撞击到普通滤筒的底部,静压从底部开始往上蓄积,使得滤筒底部静压较大而顶部较小。在约0.04 s时,滤筒内压力达到最大并维持一段时间;在0.155 s之后,滤筒内部压力逐渐下降。滤筒顶部常常喷吹压力过小,甚至出现负压,造成清灰不足。

与普通喷嘴和普通滤筒的组合情况相比,文丘里喷嘴和金锥滤筒组合条件下(图5(b)),虽然滤筒内压力蓄积的过程基本相同,但滤筒内蓄积的压力更大,上部清灰不足的区域更小,且滤筒内压力在约0.08 s时达到稳定,约0.170 s时开始降低。

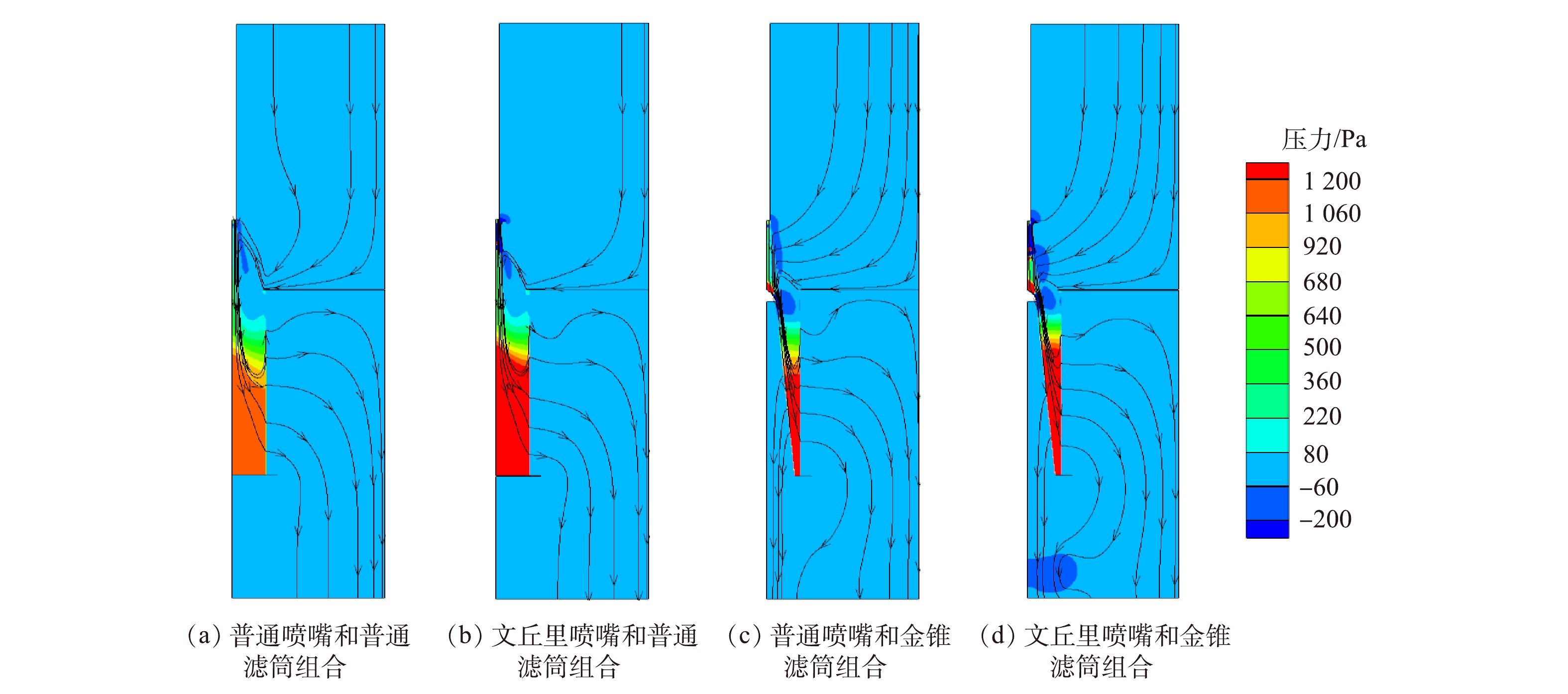

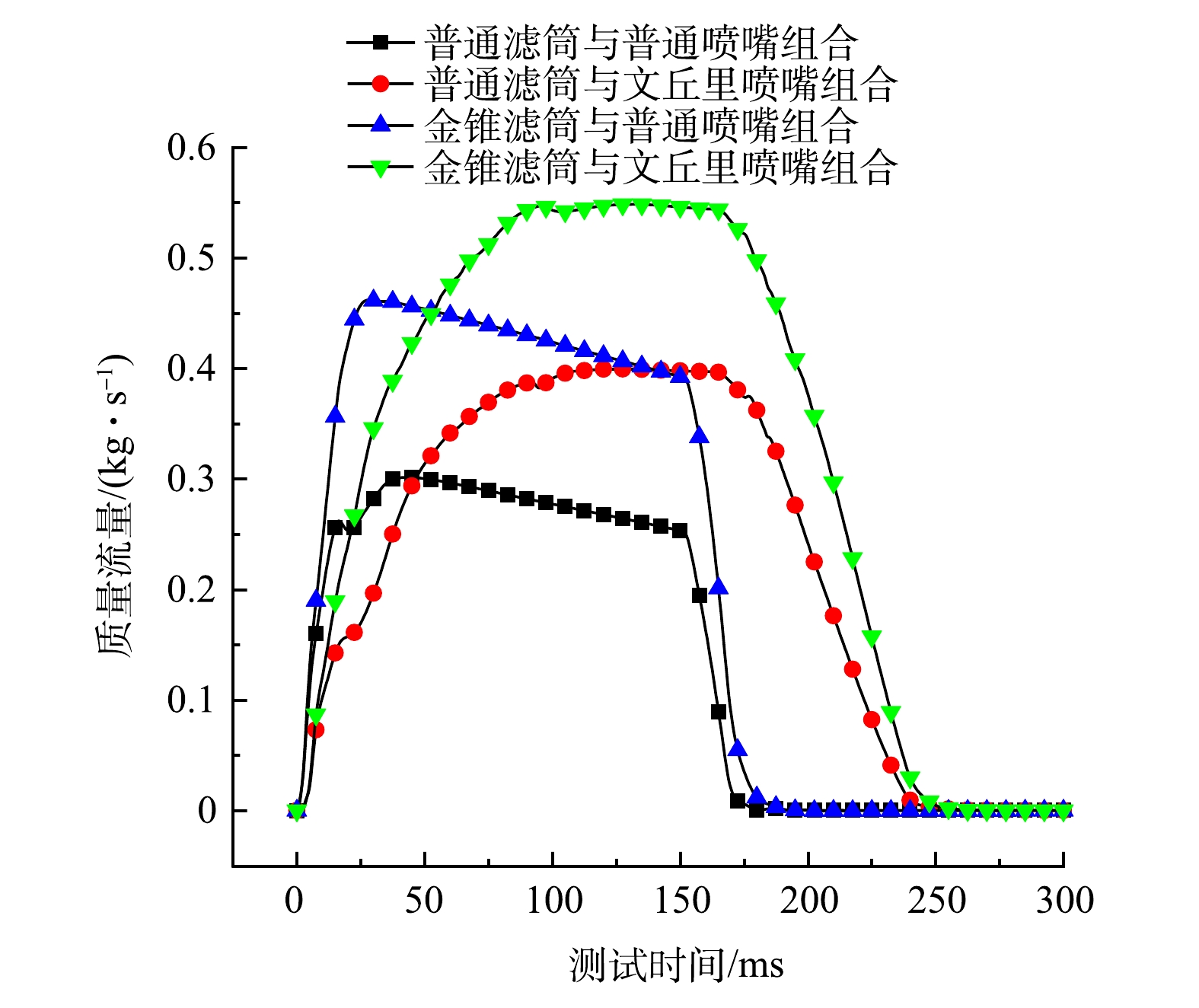

本研究进一步对比了4种组合(普通喷嘴和普通滤筒、文丘里喷嘴和普通滤筒、普通喷嘴和金锥滤筒、文丘里喷嘴和金锥滤筒)达到稳定状态时,除尘器内的静压力云图和流线图(图6)。图7为在初始条件下,4种组合对应的滤筒内部的质量流量随时间变化的曲线。

由脉冲喷吹过程中普通滤筒和金锥滤筒内压力和流线变化(图6(a)和(c)或图6(b)和(d))的对比结果可知,金锥滤筒内喷吹压力的蓄积效果更好,清灰不足的区域更小。造成这种现象的主要原因:与普通滤筒相比,金锥滤筒的过滤面积更大而内部空间更小,因而单位滤筒空间进入的喷吹气流更多,产生的气流压能更强。

由普通喷嘴和文丘里喷嘴的压力云图和流线图(图6(a)和(b)或图6(c)和(d))的对比结果可知,无论是在普通滤筒还是在金锥滤筒的条件下,文丘里喷嘴产生的喷吹压力都要强于普通喷嘴。由对应滤筒内部的质量流量变化(图7)可知,文丘里喷嘴通过诱导口诱导周围二次气流,可增加滤筒内部的喷吹气量。此外,文丘里喷嘴的缩扩结构能够加速喷吹气流,并且能够阻碍从喷嘴处喷出的气流的扩散作用,减少动能的耗散。在普通滤筒条件下,扩散后的气流在喷嘴下方收缩并产生局部漩涡,因而消耗较多气流能量;而在金锥滤筒条件下,由于金锥的导流作用,扩散后的喷吹气流能直接进入滤筒内部而存在较少的局部漩涡,气流阻力相对更小。

-

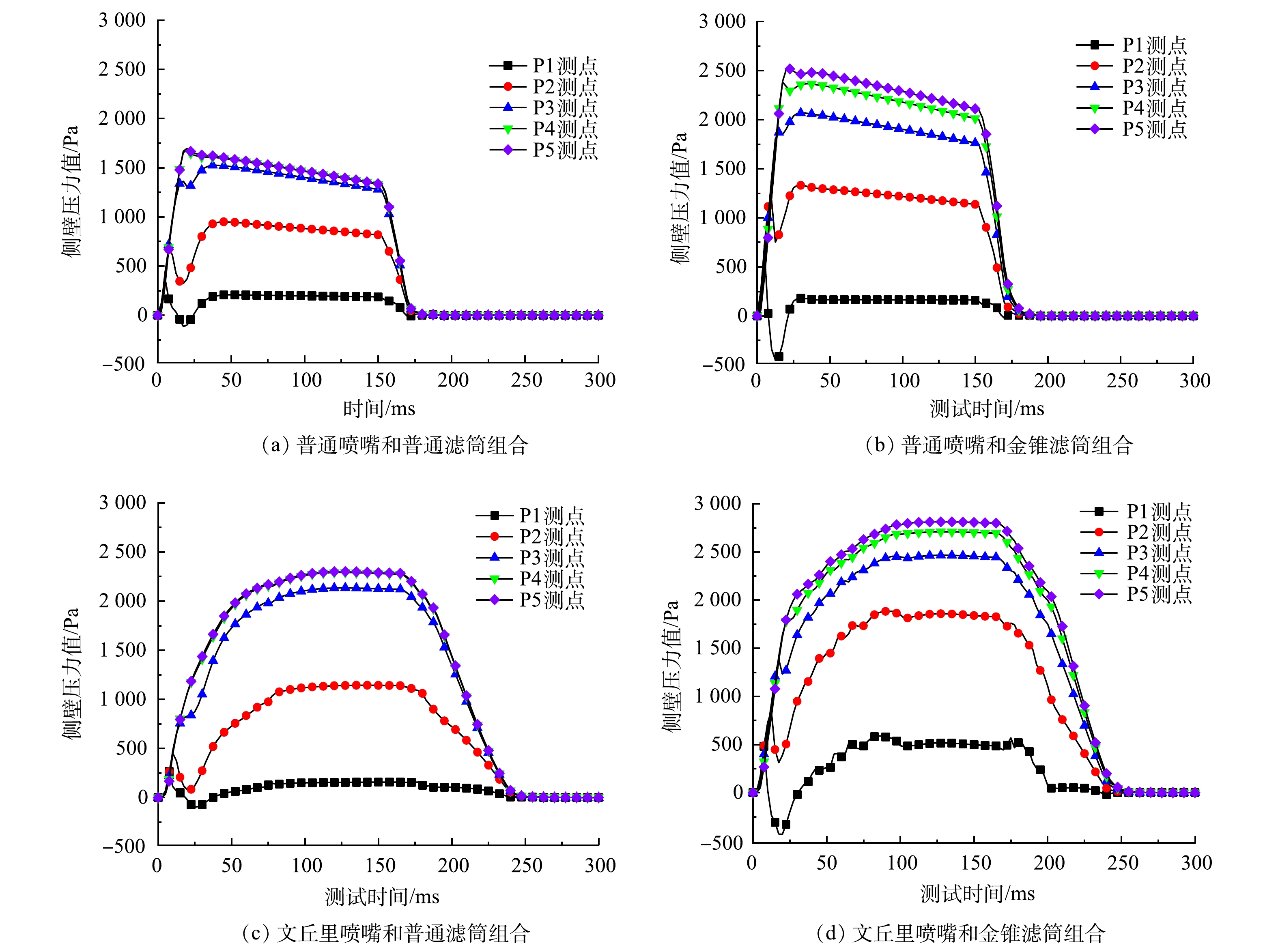

为进一步比较4种情况下滤筒内的压力分布,分别选取滤筒内部距离滤筒上沿110、220、330、440和550 mm的5个点(图5),并绘制各测点的侧壁压力随时间的变化图(图8)。

在普通喷嘴条件下(图8(a)和图8(b)),滤筒内的压力分布均在约0.040 s时达到峰值,且持续一段时间后,在约0.155 s时开始降低;而在文丘里喷嘴条件下(图8(c)和图8(d)),滤筒内的压力分布到0.080 s才能达到最大值,并持续到0.170 s时开始减弱,这种压力随时间的变化趋势与第2.2节所述的一致。

4种组合均为P3~P5测点压力相近且最大,P2测点次之,P1测点压力最小。在普通喷嘴和普通滤筒组合条件下,P3~P5测点压力峰值为1 525~1 695 Pa,P2为949 Pa,P1为381 Pa;文丘里喷嘴和金锥滤筒组合时,P3~P5测点压力为2 465~2 812 Pa,P2为1 882 Pa,P1为588 Pa。由普通滤筒条件下各测点的压力分布可知,使用文丘里喷嘴时,滤筒内中下部的压力峰值显著上升,而上部压力峰值不及普通喷嘴。

由普通喷嘴条件下各测点的压力分布可知,金锥滤筒对所有测点的压力峰值均具有加强作用。在文丘里喷嘴与金锥滤筒组合及普通喷嘴与普通滤筒组合条件下,由各测点的压力分布可知,文丘里喷嘴与金锥滤筒组合条件下,各测点的压力峰值均会得到明显提升,其中P2点的提升尤为显著,提升了1.98倍。

综上可知,文丘里喷嘴可以加强滤筒内中、下部的压力,并且在与金锥滤筒的组合条件下,也能提高上部的喷吹压力,即文丘里喷嘴和金锥滤筒能够协同优化脉冲喷吹的性能。

-

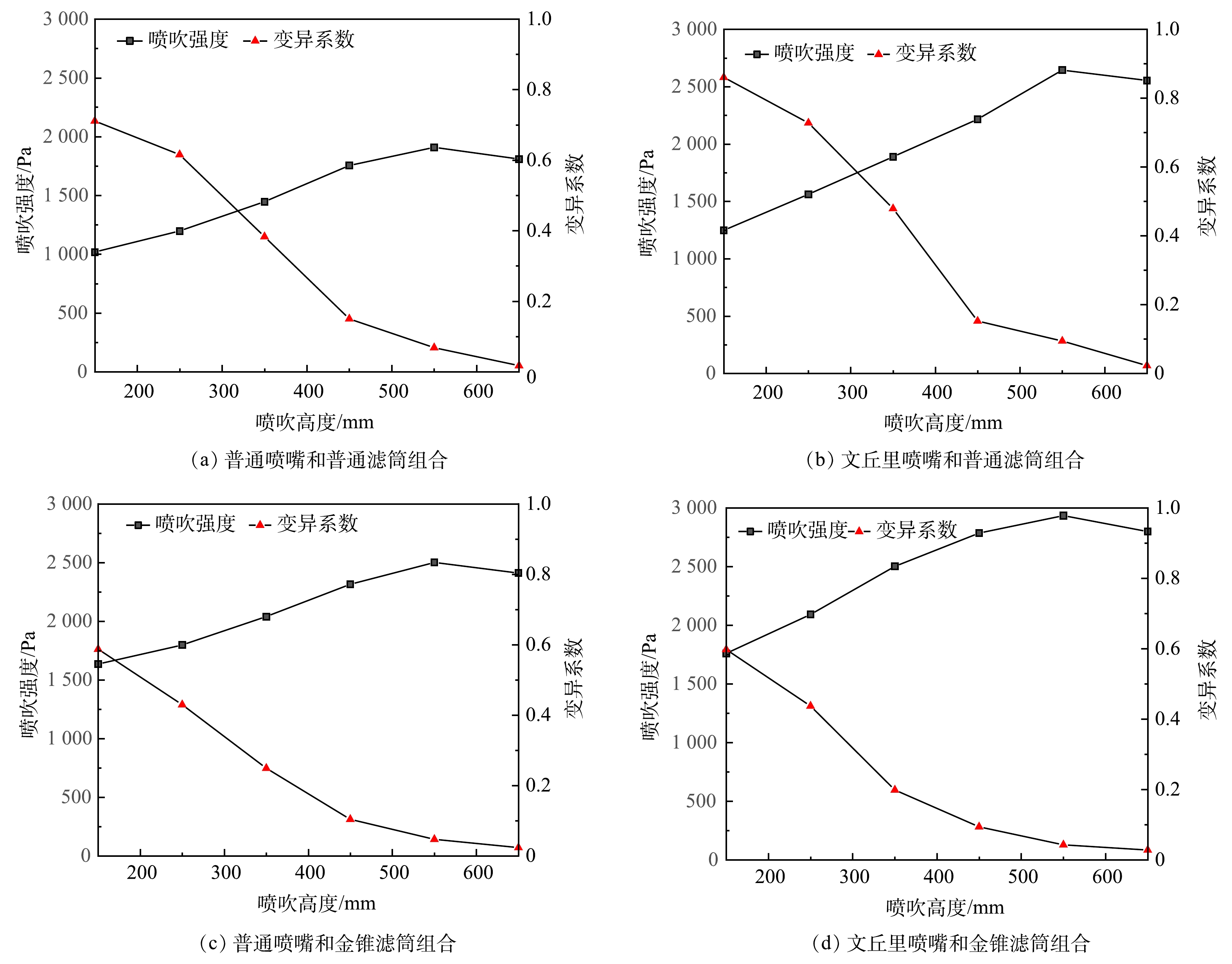

为进一步研究文丘里喷嘴和金锥滤筒的协同作用,分析了喷吹性能随喷吹高度的变化(图9)。

喷吹性能常用喷吹强度和变异系数来描述。喷吹强度是指滤筒内各测点正压力峰值的平均值,其值与喷吹强度成正比;变异系数是描述滤筒内压力分布的均匀性指标,用标准差和平均值的比值来表示,变异系数越小,滤筒内压力分布的均匀性越好[22-23]。

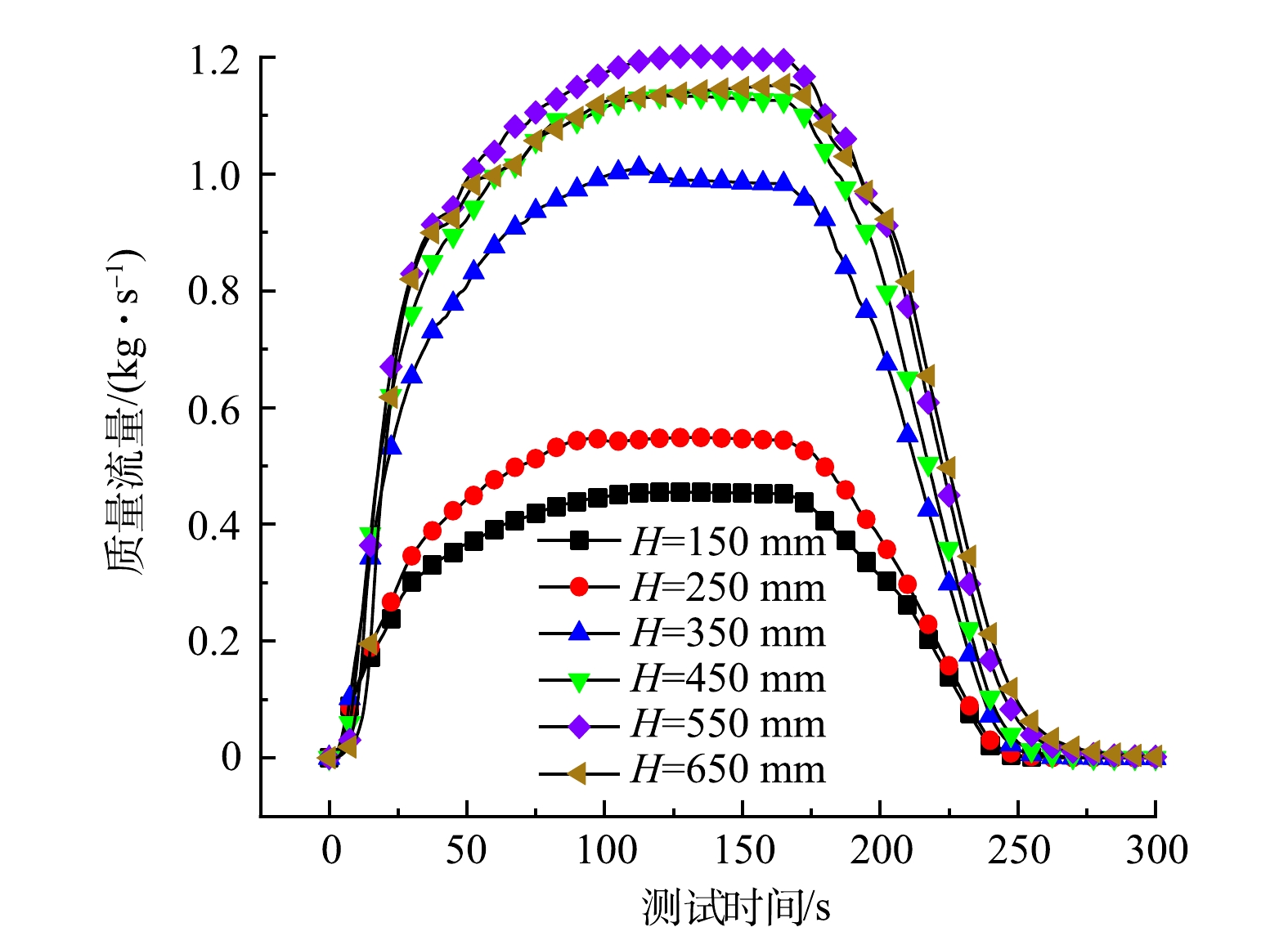

由图9可知,4种组合均表现为,喷吹强度随喷吹高度的增大先增大后减小,并在喷吹高度为550 mm时达到最大值。由文丘里喷嘴和金锥滤筒组合条件下各高度的质量流量(图10)可知,这主要是由不同高度下喷嘴诱导气流流量发生变化所导致的。从文丘里喷嘴喷出的气流会在压差的作用下诱导周围空气,高度的改变造成周围流量的变化,进而改变了滤筒内气流的质量流量;并且,脉冲气流的诱导作用存在最大值,在高度超过550 mm时,周围气流并不能被全部诱导,因此造成质量流量的下降。

随着喷吹高度的增大,变异系数逐渐变小,即滤筒内压力分布的均匀性越来越好。这主要是由于,喷吹过程中,从喷嘴喷出的气流会以一定的角度扩散,使得喷吹气流的横截面不断变大。喷吹高度的增加,使到达滤筒顶部的气流的截面积变大,增强了上部清灰效果,从而造成了均匀性的改善。

由普通喷嘴和文丘里喷嘴(图9(a)和(b)或图9(c)和(d))条件下喷吹性能的对比结果可知,在普通滤筒和金锥滤筒条件下,文丘里喷嘴的喷吹强度的平均值是普通喷嘴的1.32和1.17倍,文丘里喷嘴的变异系数的平均值是普通喷嘴的1.20和0.97倍。虽然文丘里喷嘴的喷吹强度要优于普通喷嘴,但变异系数(尤其是喷吹高度较小时)要大于普通喷嘴,即滤筒内的压力分布不如普通喷嘴均匀。

由普通滤筒和金锥滤筒(图9(a)和(c)或图9(b)和(d))条件下喷吹性能的对比结果可知,在普通喷嘴和文丘里喷嘴条件下,金锥滤筒的喷吹强度是普通滤筒的1.39和1.23倍,金锥滤筒的变异系数是普通滤筒的0.74和0.60倍。金锥滤筒条件下不仅喷吹强度得到提升,相较于普通滤筒,金锥滤筒的变异系数也要更小。这说明,金锥滤筒对进入滤筒的气流具有导流作用,可以使其更加均匀,这与第2.3节中的论述一致。

将文丘里喷嘴和金锥滤筒组合(图9(d))条件下的喷吹性能分别与文丘里喷嘴和普通滤筒(图9(b))以及普通喷嘴和金锥滤筒(图9(c))相对比,可以发现,在喷吹强度上,文丘里喷嘴和金锥滤筒组合分别是文丘里喷嘴和普通滤筒以及普通喷嘴和金锥滤筒的1.23和1.17倍,变异系数分别是0.60和0.97倍。文丘里喷嘴和金锥滤筒的组合无论是在喷吹强度,还是在压力分布的均匀性上,都是最好的。这说明,两者的组合具有协同作用,可以优化脉冲喷吹性能。

综合分析可知,文丘里喷嘴主要有利于提升喷吹强度,金锥滤筒主要改善喷吹气流的均匀性,文丘里喷嘴和金锥滤筒的组合则同时提高喷吹强度和喷吹均匀性。并且,在所研究的喷吹高度范围内,相比于同高度的普通喷嘴和普通滤筒组合,文丘里喷嘴和金锥滤筒组合在喷吹高度为150~350 mm时喷吹强度提升最显著,在350~550 mm时喷吹均匀性改善效果最好。为此,建议在文丘里喷嘴和金锥滤筒组合条件下采用喷吹高度350 mm以获得最佳喷吹性能,此时其喷吹强度为2 501.27 Pa,变异系数为0.19,分别是普通喷嘴和普通滤筒组合时的1.73倍和0.51倍。

-

1)在普通喷嘴与普通滤筒、文丘里喷嘴与普通滤筒、普通喷嘴与金锥滤筒及文丘里喷嘴与金锥滤筒4种组合中,脉冲喷吹气流均为自底部向上蓄积,滤筒内侧壁压力分布均表现为底部压力大而上部压力小的趋势。

2)与普通喷嘴相比,文丘里喷嘴主要通过增强气流的卷吸作用、加大进入滤筒内的喷吹气量,进而提高喷吹强度;与普通滤筒相比,金锥滤筒内的金锥主要通过对喷吹气流进行导流、改善滤筒内流场分布,进而提高喷吹均匀性;文丘里喷嘴和金锥滤筒可实现组合式优化喷吹性能。

3)文丘里喷嘴和金锥滤筒组合条件下,在喷吹高度为150~350 mm时喷吹强度最佳,而喷吹均匀性在喷吹高度为350~550 mm时最好。因此,建议文丘里喷嘴和金锥滤筒组合时采用喷吹高度350 mm以实现最佳喷吹性能。

文丘里喷嘴改进金锥滤筒脉喷清灰性能的数值模拟

Numerical simulation of the performance of pulse jet dust cleaning of venturi nozzle improved golden cone filter

-

摘要: 针对除尘滤筒脉冲反吹清灰均匀性差、强度不足的缺点,构建了脉冲喷吹滤筒除尘器CFD数值模型,考察了文丘里喷嘴和金锥滤筒组合条件下的清灰性能。结果表明,无论是文丘里喷嘴还是金锥滤筒的使用或二者组合使用,滤筒内喷吹压力均为底部大而上部小;文丘里喷嘴和金锥滤筒可单独或组合式优化喷吹性能;在喷吹高度为150~550 mm时,喷吹强度和均匀性整体上随喷吹高度的增大而逐渐增强,当喷吹高度为350 mm时,文丘里喷嘴和金锥滤筒组合使用的优化效果最佳,喷吹强度和均匀性分别提高了1.72和1.96倍。本研究结果可为脉喷清灰滤筒除尘器的优化提供参考。Abstract: The pulse injection of the traditional dust collector has the disadvantages of poor uniformity and insufficient strength. In this study, a CFD model of the pulse-jet filter cartridge was constructed. The dust removal performance under the combined conditions of venturi nozzle and golden cone filter cartridge was investigated. The result showed that, for venturi nozzle, golden cone filter cartridge or their combination, the pressure in the filter cartridge was large at the bottom and small at the top. Venturi nozzle, golden cone filter could or their combination could optimize the injection performance. When the blowing distance was 150~550 mm, both the pulse-jet intensity and uniformity totally increased with the blowing distance. When the blowing distance was 350 mm, the best pulse-jet performance occurred with the combination of venturi nozzle and golden cone filter cartridge, the pulse-jet intensity and uniformity increased by 1.72 and 1.96 times, respectively. The research can provide a reference for the optimization of the pulse-jet dust collector.

-

Key words:

- dust collector /

- pulse-jet /

- dust removal performance /

- venturi nozzle /

- gold cone filter /

- numerical simulation

-

化学氧化修复是有机污染场地常见的修复技术之一[1],其修复机理主要是通过强氧化剂与有机污染物发生氧化还原反应,使得污染物转化为稳定、低毒或无毒性物质[2]。常见的化学氧化剂有活化过硫酸盐、Fenton、类Fenton、高锰酸钾、臭氧等,其中活化过硫酸盐以其易活化、适应性广、效果好等优点而成为研究热点[3-4]。化学氧化能快速而高效地去除土壤中的各类有机污染物,具有修复效率高、修复速率快、普适性强等优点[5]。然而,加入大量化学氧化剂往往会导致土壤理化性质改变、微生物生态系统破坏、带来二次污染等隐患[6]。

微生物修复技术通过微生物的生长代谢作用,将有机污染物转化成简单无机物,从而达到去除环境中有机污染物的目的[7],包括生物刺激(添加营养物质)、生物强化(添加高效降解菌或生物催化剂(基因和酶))和曝气系统(曝气增氧)等[8]。与化学氧化等其他技术相比,微生物修复技术能够有效避免二次污染问题,其成本更低,更易于维护,但也存在修复时间长、对环境要求比较严格等缺点[9],故在实际污染场地的应用中,仍具有一定的局限性。

为了解决单项修复技术的局限性,实现更高的有机污染物去除率的目标,可以使用多种方法联合修复[10]。近年来的研究表明,化学氧化和微生物联合修复是一种可行的联合修复方法,具有广泛的应用前景[11-12]。然而,在此前化学氧化-微生物联用技术的研究中,微生物降解主要依赖土著微生物,重点关注的是化学氧化剂对土壤微生物生态系统的影响,关于化学预氧化联合微生物强化或微生物刺激技术(即预氧化后强化微生物降解作用)的研究较少[13-14]。

菲作为土壤中常见的多环芳烃污染物之一,对人类健康具有严重威胁[15]。针对菲污染土壤修复的研究主要集中于化学氧化、微生物降解等单一方法[16],本研究将化学氧化和微生物修复技术相结合,旨在探究化学预氧化后强化微生物降解对土壤中菲的降解效应,重点关注低浓度过硫酸盐预氧化耦合生物强化和生物刺激技术对菲降解的促进效应,以及修复期间土壤各项理化性质的变化情况,为化学氧化-微生物联用修复技术的应用提供参考。

1. 材料与方法

1.1 供试土壤

实验采用人工模拟的污染土壤,其制备方法如下:在5 kg洁净土壤中加入50 mL 10 g·L−1菲的丙酮溶液,充分混匀后,老化1个月。土壤各项理化指标:菲浓度(98.70±3.23) mg·kg−1,pH 7.42±0.06,有机质含量(34.79±0.89) g·kg−1,总磷含量(0.617±0.02) g·kg−1,总氮含量(0.732±0.02) g·kg−1,微生物数量(5.73±0.70)×107 CFU·g−1。土壤机械组成:(2.71±0.02)%黏粒,(36.28±1.21)%粉粒,(61.01±2.11)%砂粒。

1.2 实验材料

1)化学试剂。PHE(纯度>98%)购自Sigma-Aldrich(中国上海);色谱纯试剂:丙酮,正己烷,二氯甲烷;分析纯试剂:Na2S2O8,KH2PO4,NaNO3等。这些试剂均购自国药集团化学试剂有限公司(中国北京)。

2)菌剂。使用实验室筛选、保存的高效菲降解菌Acidovorax sp.JG5制备菌剂,该菌在1 d内对浓度100 mg·L−1菲的降解率为90%以上。菌剂制备方法如下:从斜管培养基中挑取1环Acidovorax sp.JG5菌株,接种至富集培养基中,在30 ℃、180 r·min−1条件下,恒温振荡培养至对数生长期,于4 ℃、8 000g下,离心分离10 min,收集菌体,用无菌生理盐水洗涤2次后重悬,并调节OD600值为0.3。

1.3 实验处理

实验共设10个处理组(如表1所示),每个处理组设3个重复。取菲污染土壤150 g于250 mL锥形瓶内,根据表1中设定的浓度,加入过硫酸钠和适量去离子水,调节水土比为3∶5。搅拌均匀后,盖上无菌透气膜,放置于50 ℃水浴锅中,反应72 h后取出,转移至30 ℃恒温培养箱中静置。在化学氧化降解期间,每隔24 h取样测定体系中过硫酸盐浓度;第1、3、5、7 天分别取样测定土壤pH、微生物数量;化学氧化前后,测定土壤中菲浓度。化学预氧化后,通过添加不同药剂,将化学预氧化后的实验组分为表1所示的9组实验组。其中:C-CK实验组加入抑菌剂NaN3,以抑制后续微生物活性,作为单独化学氧化对照组;仅加入等量去离子水的实验组命名为CK组,作为化学氧化-土著微生物降解对照组;B-CK组仍然仅添加等量去离子水,以作为单独微生物降解对照组。所有实验组均根据表1中设定的浓度,加入菌剂、各类营养物质或去离子水。放置于30 ℃、80%湿度恒温培养箱中,静置培养,每隔7 d取样测定土壤pH、微生物数量和菲浓度。

表 1 实验处理组Table 1. Experimental treatment groups实验处理组 处理组简称 添加药剂 单独微生物降解对照 B-CK 化学氧化阶段:不进行化学氧化,仅加入等量去离子水 微生物降解阶段:等量去离子水 单独化学氧化对照 C-CK 化学氧化阶段:0.1 mmol·g−1 Na2S2O8 微生物降解阶段:0.1 mL·g−1 0.2 mol·L−1 NaN3 化学氧化-土著微生物降解对照 CK 化学氧化阶段:0.1 mmol·g−1 Na2S2O8 微生物降解阶段:等量去离子水 化学氧化+营养物质N刺激 C+N 化学氧化阶段:0.1 mmol·g−1 Na2S2O8 微生物降解阶段:0.187 mol·g−1 NaNO3 化学氧化+营养物质P刺激 C+P 化学氧化阶段:0.1 mmol·g−1 Na2S2O8 微生物降解阶段:0.018 7 mol·g−1 KH2PO4 化学氧化+营养物质NP刺激 C+NP 化学氧化阶段:0.1 mmol·g−1 Na2S2O8 微生物降解阶段:0.187 mol·g−1 NaNO3;0.018 7 mol·g−1 KH2PO4 化学氧化+生物强化 CBA 化学氧化阶段:0.1 mmol·g−1 Na2S2O8 微生物降解阶段:0.1 mL·g−1 菌液 化学氧化+生物强化+营养物质N刺激 CBA+N 化学氧化阶段:0.1 mmol·g−1 Na2S2O8 微生物降解阶段:0.1 mL·g−1 菌液;0.187 mol·g−1 NaNO3 化学氧化+生物强化+营养物质P刺激 CBA+P 化学氧化阶段:0.1 mmol·g−1 Na2S2O8 微生物降解阶段:0.1 mL·g−1 菌液;0.018 7 mol·g−1 KH2PO4 化学氧化+生物强化+营养物质NP刺激 CBA+NP 化学氧化阶段:0.1 mmol·g−1 Na2S2O8 微生物降解阶段:0.1 mL·g−1 菌液;0.187 mol·g−1 NaNO3;0.018 7 mol·g−1 KH2PO4 1.4 分析方法

使用紫外分光光度法[17]测定体系中过硫酸盐浓度。使用pH计(PB-10,Sartorius)测定体系中pH。微生物计数(土壤中活细菌数)的测定参考标准ISO 6222(1999)。按照赵丹等[18]的研究方法,使用气相色谱-质谱联用仪(Agilent 7890A-5975C)测定土壤中菲浓度。

1.5 数据分析

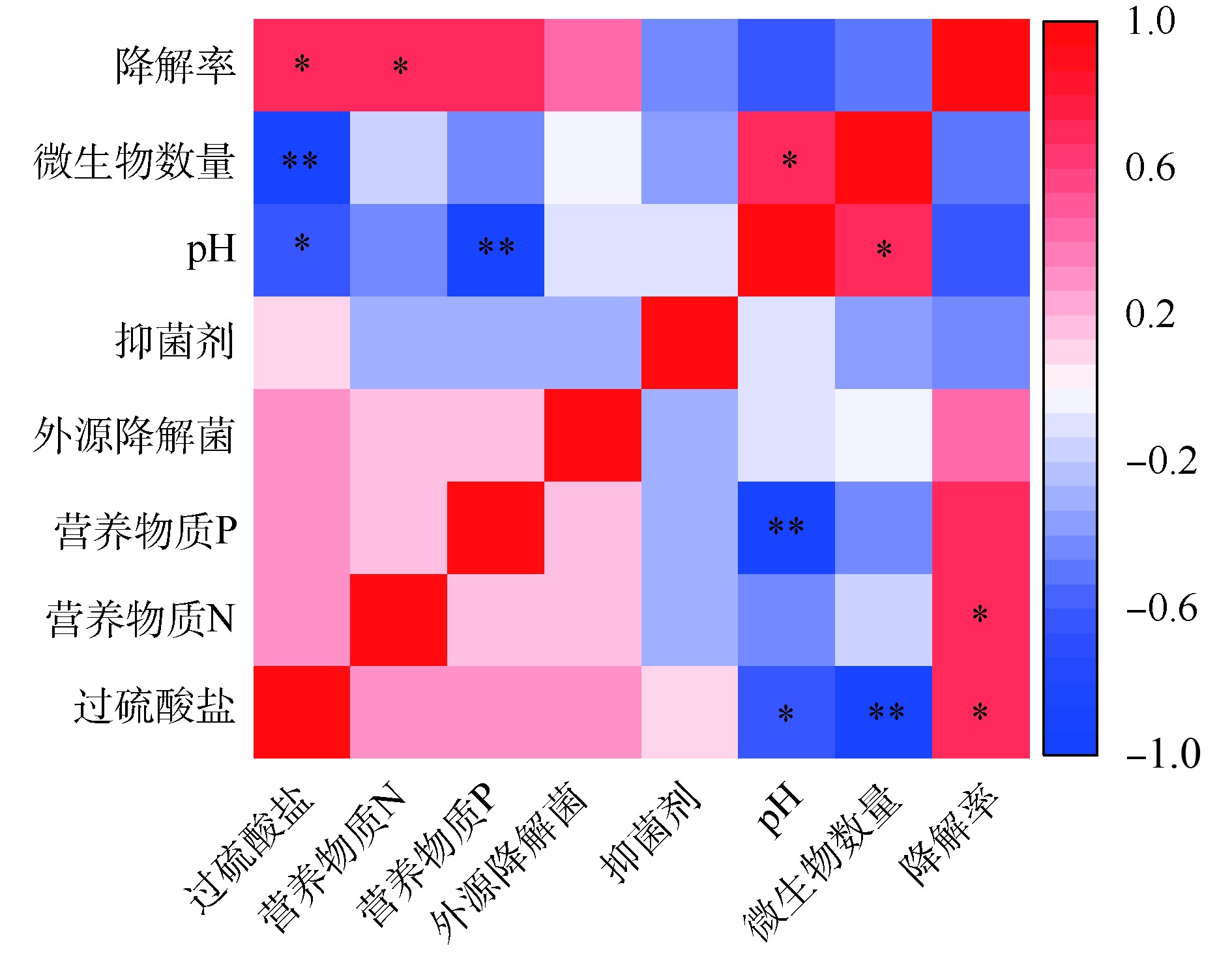

使用Origin 2016软件(OriginLab Corporation,USA)制作图表,SPSS软件和R语言包进行相关性分析和显著性分析,并绘制heatmap图。

2. 结果与讨论

2.1 化学预氧化阶段土壤中过硫酸盐浓度变化及菲的降解率

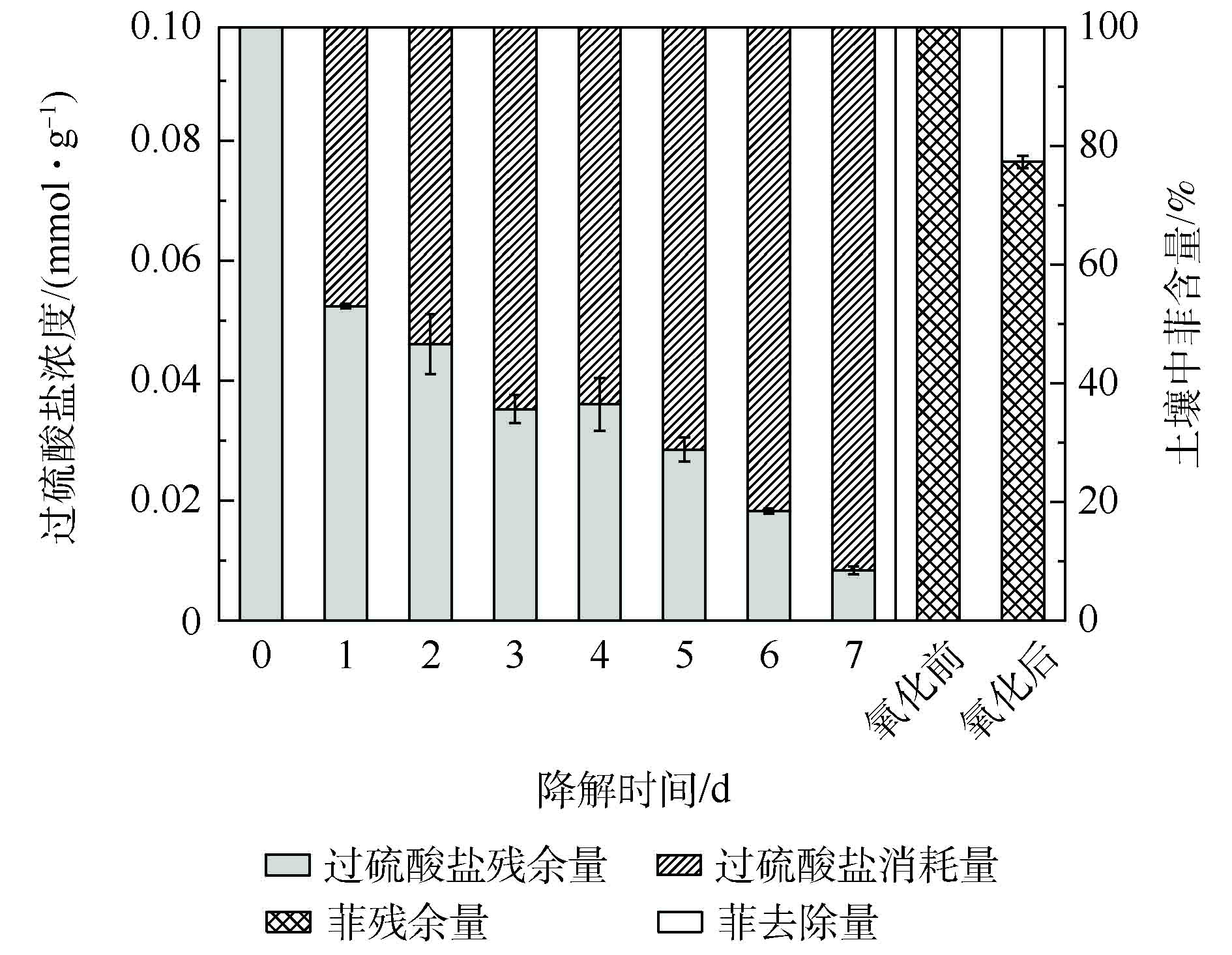

使用热活化过硫酸盐对菲污染土壤进行预氧化,土壤中过硫酸盐浓度随时间的变化情况及化学氧化前后土壤菲降解率如图1所示。加入氧化剂过硫酸钠反应1 d后,土壤中过硫酸盐浓度由0.1 mmol·g−1下降至0.052 mmol·g−1,降幅达近50%。随后的几天内,过硫酸盐持续消耗,到第7天,土壤中过硫酸盐基本消耗完毕。化学预氧化阶段到此结束,土壤菲的降解率达22.7%。随后加入降解菌剂或营养物质,开始进行菲的微生物降解。

2.2 预氧化后强化微生物降解对土壤菲降解的影响

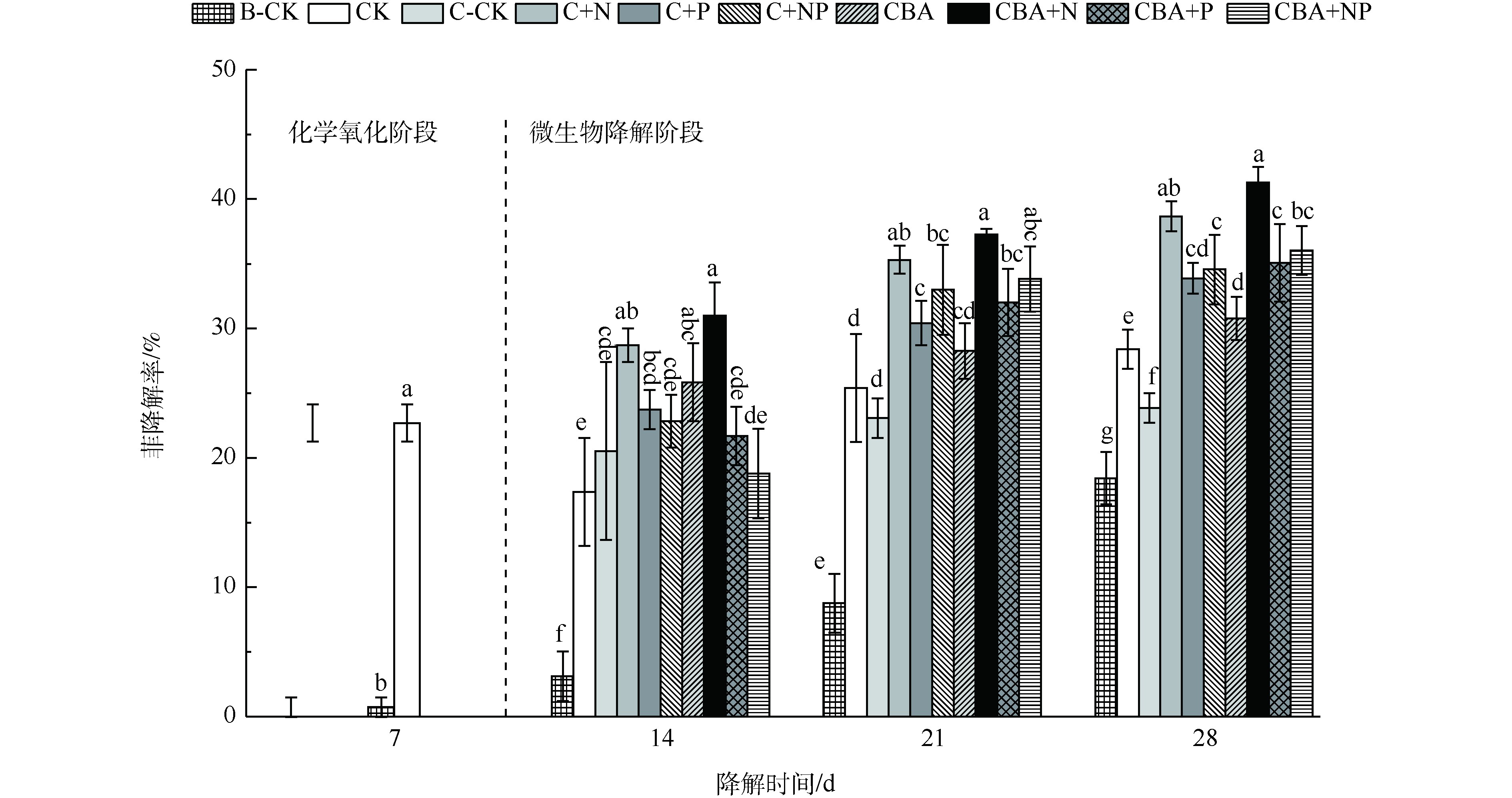

化学预氧化后强化微生物降解对土壤中菲的降解率如图2所示。前7 d内(化学氧化阶段),单独土著微生物降解对照组(B-CK)仅去除了0.73%的菲,而活化过硫酸钠降解了22.7%的菲(对照组CK)。化学预氧化后,进一步培养B-CK、C-CK和CK等3组对照组,到第28天,B-CK最终降解率为18.43%,加入了抑菌剂NaN3的单独化学氧化对照组C-CK最终降解率为23.85%,而进行了化学预氧化-土著微生物降解的对照组CK的最终降解率为28.39%,分别较C-CK和B-CK提高4.54%和9.96%。上述结果表明,化学预氧化较单独微生物降解更能快速降解土壤中的菲,且化学预氧化后,残余的土壤微生物仍能对土壤中的菲进一步降解,进而取得更高的菲降解率,这为化学预氧化后强化微生物降解土壤中菲的研究提供了理论基础。

为进一步提高化学预氧化后土壤中多环芳烃菲的微生物降解率,通过生物强化(添加外源降解菌)和生物刺激(添加营养物质)2种手段,强化预氧化后土壤中微生物对菲的降解,结果如图2(微生物降解阶段)所示。可以看出:化学预氧化后,同时添加营养物质N和高效降解菌的实验组CBA+N,对土壤中菲的降解率最高,达41.29%;其次为添加营养物质N的实验组C+N(38.65%)。营养物质N和高效降解菌的加入,有效促进了土壤中菲的微生物降解,各实验组较对照组C-CK的降解率提高13%~17.44%,较未经生物强化的对照组CK提高8.46%~12.9%。

相比于营养物质N,添加营养物质P及NP复合营养液,对土壤中菲的微生物降解的促进有一定的迟滞性,营养物质添加1周后,菲的降解率增幅最高,仅为1.02%。自第2周起,才表现出明显的降解,最终实验组C+P、C+NP、CBA+P和CBA+NP中降解率分别达到33.86%、34.54%、35.06%和36.03%,较对照组C-CK提高10.01%~12.18%,较未经生物强化的对照组CK提高5.47%~7.64%。菲的降解结果表明,化学预氧化后耦合生物强化和生物刺激技术能够有效强化污染土壤中菲的降解。

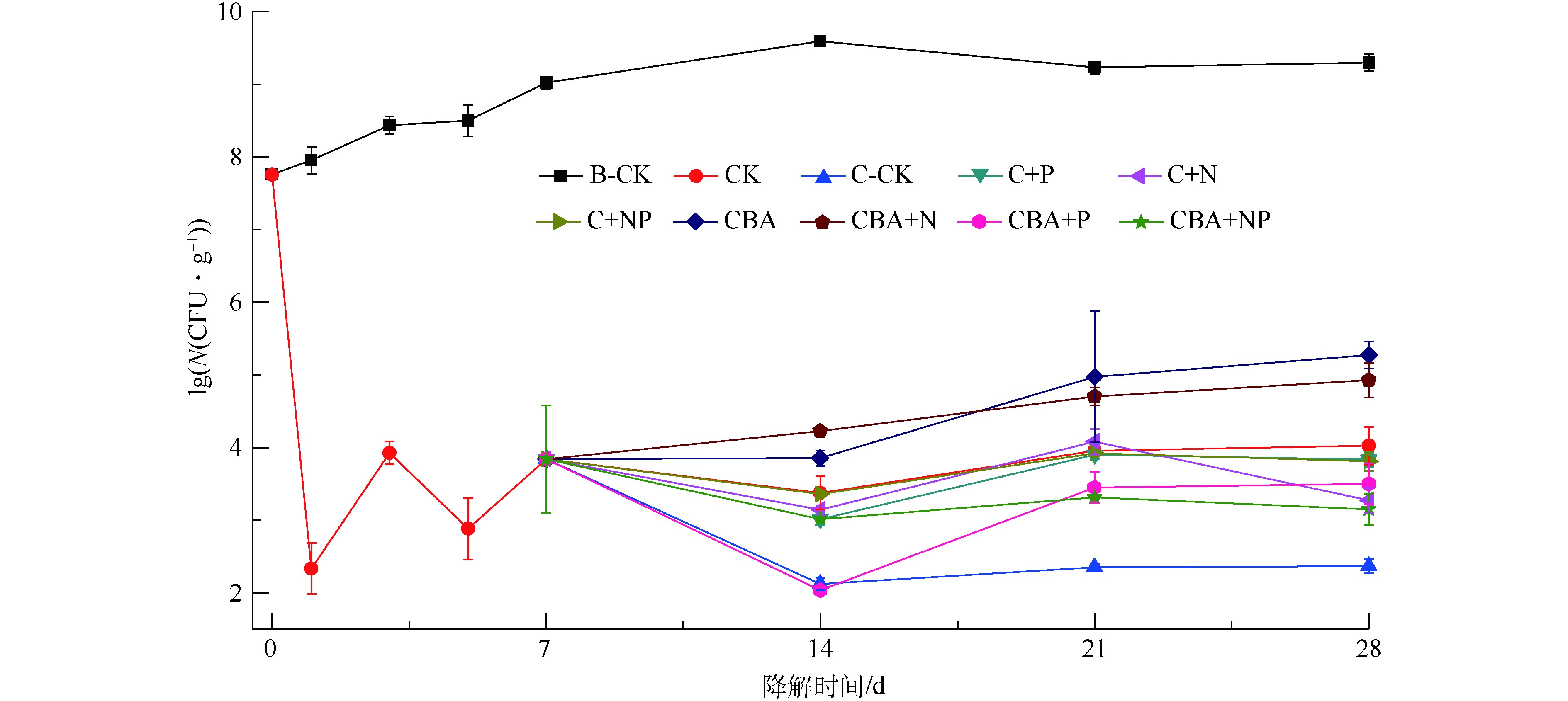

2.3 降解期间土壤微生物数量变化规律

如图3所示,化学预氧化会导致土壤中微生物数量急剧下降,但随着营养物质和高效降解菌的加入及培养时间的延长,微生物数量逐渐恢复。化学预氧化后同时加入菌剂和N盐,对微生物生长促进作用最强,P盐的加入对微生物生长的影响为先抑制后促进。在化学预氧化处理的实验组中,过硫酸钠的加入导致土壤中微生物数量急剧下降,从7.76lgN(N表示微生物菌落数,单位为CFU·g−1,下同)下降至2.33lgN。培养7 d后,微生物数量缓慢恢复至3.84lgN。营养物质P(实验组C+P、C+NP、CBA+P和CBA+NP)的加入,在短期内(第7~14天),抑制了土壤微生物数量的增长,各处理中微生物数量下降了3~63 CFU·g−1;而在后续培养中(第14~28天),微生物数量迅速增长。添加营养物质N及外源降解菌(实验组C+N、CBA、CBA+N),可有效促进土壤中微生物数量的增长。在第14~28天,除添加抑菌剂NaN3的对照组C-CK外,所有化学氧化-微生物联用实验组中土壤微生物数量均逐渐回升,增长率达4.10%~71.74%。这是生态系统稳定性的体现[19],也是化学氧化-微生物联用修复技术得以实现的基础。

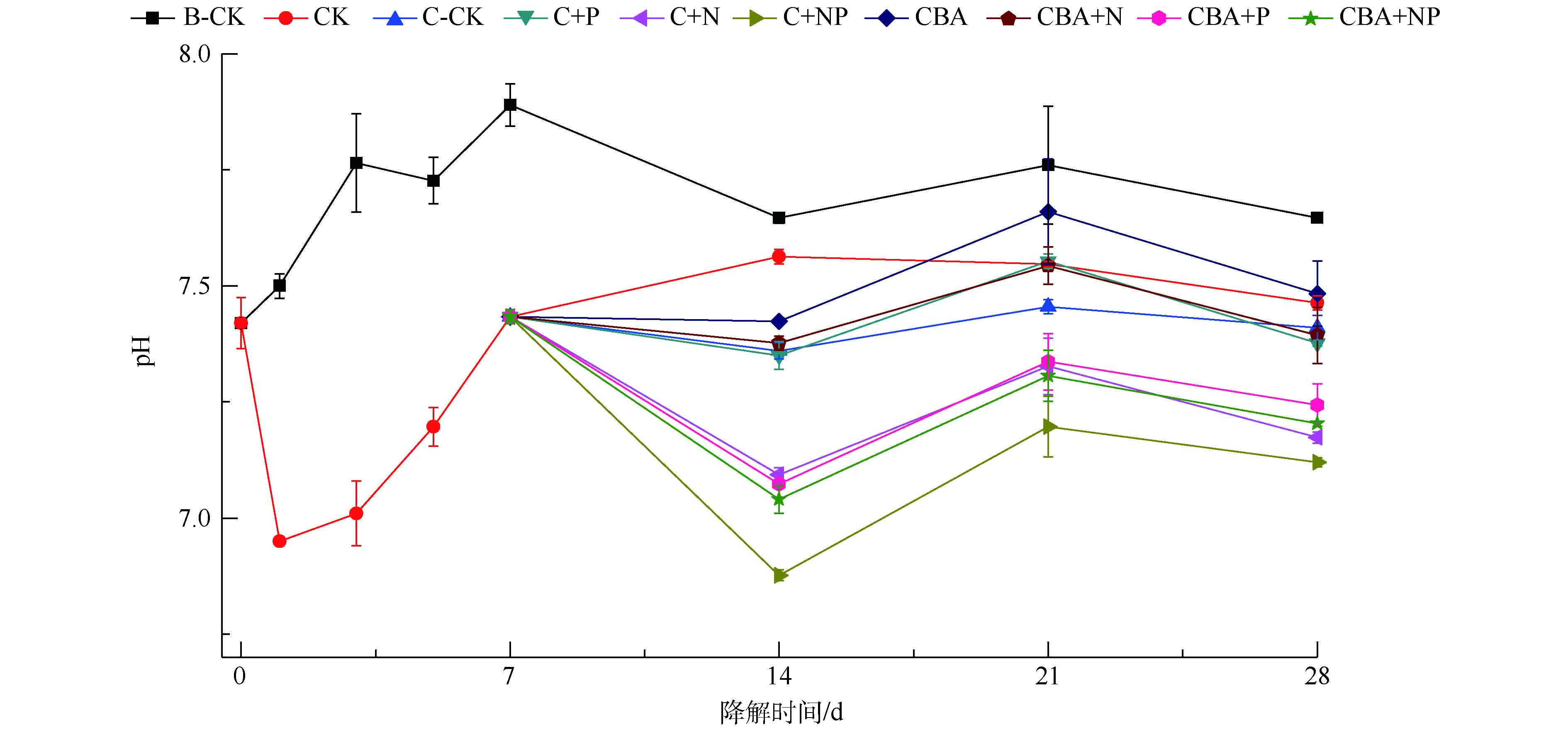

2.4 降解期间土壤pH变化规律

在化学预氧化作用下,强化微生物降解土壤中多环芳烃菲期间,土壤pH的变化情况见图4。化学氧化-微生物联用修复实验组中pH变化规律为先下降,后上升,最后维持稳定。在单独微生物降解对照组B-CK中,土壤pH从7.42上升至7.89,最后相对稳定地维持在7.70左右。这可能是土壤中土著微生物生长代谢期间,产生了某种碱性中间产物而导致的。过硫酸盐和P盐会导致土壤pH急剧下降,加入菌剂和N盐对pH影响较小。在化学预氧化实验组中,过硫酸盐的加入使得土壤pH由7.42迅速下降至6.95,随着过硫酸盐的消耗,pH逐渐恢复至氧化前水平。加入营养物质或菌剂,短期内会不同程度抑制土壤pH的持续升高。添加营养物质N和菌剂,对土壤pH抑制的程度较小,土壤pH仅轻微降低0.01~0.08,最终维持在7.37~7.48。而在添加了营养物质P的实验组C+P、C+NP、CBA+P和CBA+NP中,土壤pH下降幅度较大,分别下降了0.34、0.55、0.36和0.39。随着培养时间的增加,各实验组pH均逐渐回升,最终维持在7.12~7.24。

2.5 降解体系内各因素间相关性分析

使用Pearson相关系数、T检验,对氧化剂、营养物质、菌剂和抑菌剂与土壤pH、微生物数量和菲降解率间的相关性进行分析,结果如图5所示。土壤中菲的降解率与过硫酸盐、营养物质和菌剂添加呈正相关,与抑菌剂、土壤pH呈负相关,其中过硫酸盐和营养物质N 2个因素与菲的降解率之间均具有显著的正相关性(P<0.05)。这也进一步证实了化学氧化结合生物强化和生物刺激,对土壤中菲的降解的促进作用。土壤pH与营养物质P呈显著负相关(r=−0.869,P<0.01),与过硫酸盐浓度呈显著负相关(r=−0.642,0.01<P<0.05)。微生物数量与过硫酸盐呈显著负相关(r=−0.898,P<0.01),与土壤pH呈显著正相关(r=0.724,0.01<P<0.05)。这说明过硫酸盐的加入对土壤pH和微生物数量具有严重负面影响。

2.6 讨论

氧化剂的加入会导致土壤pH和微生物数量急剧下降,但随着培养时间的增加,二者逐渐回升。土壤pH的下降可能是由于加入到污染土壤中的过硫酸钠活化分解,产生·

SO2−4 自由基的同时生成了大量

SO2−4 和H+,使得土壤pH下降[20]。微生物数量的下降,一方面可能是由于pH骤然降低,土壤微生物难以适应,进而大量死亡。OGAWA等[21]指出,过高或过低的pH均会抑制土壤中微生物的生长。这也解释了在微生物降解阶段,加入酸式盐KH2PO4作为P源后,土壤微生物数量随着pH的降低而再一次下降的原因。另一方面,过硫酸盐分解产生的强氧化性自由基·

SO2−4 也可能是导致土壤微生物数量迅速减少的原因之一。有研究表明,强氧化性的自由基及各种活性物质能够渗透进入细菌的细胞膜(壁),并破坏细胞内的成分,导致细胞死亡[22-23]。·

SO2−4 可能会攻击细菌的细胞膜(壁),使得细胞膜(壁)破裂,导致细菌大量死亡。然而,化学氧化剂虽然在短期内会对微生物造成较大影响,但最终会随着时间的增加而逐渐恢复[19]。这使得化学氧化-微生物联用修复有机污染土壤成为可能。

化学预氧化后添加营养物质和高效降解菌能够有效强化微生物对菲的降解,进而提高化学氧化-微生物联合修复对土壤中有机污染物的去除率。有研究表明,生物添加和生物刺激能够有效促进微生物对土壤中有机污染物的降解[24]。本实验使用热活化过硫酸钠进行化学预氧化后,添加外源高效降解菌和不同类型的营养物质,强化土壤微生物对残余多环芳烃的降解。各个处理最终降解率依次为CBA+N>C+N>CBA+NP>CBA+P>C+NP>C+P>CBA>CK>C-CK>B-CK。同时加入高效降解菌和营养物质N,能达到最优的降解效果。这与前人的研究结果稍有不同。ROY等[25]研究了加入降解菌和营养物质对土壤微生物降解总石油烃的促进作用,结果表明,同时加入降解菌和N、P 2种营养物质,对微生物的降解促进作用最强,其次为同时加入降解菌和营养物质N。造成这一差异的原因:一方面可能是在不同土壤中,微生物对不同类型营养物质的敏感性不同;另一方面则可能是由于作为P源添加的营养液为KH2PO4。KH2PO4属于酸式盐,导致降解体系中pH降低(如图3所示),在反应初期抑制了微生物活性,从而影响了微生物的降解效果。总的来说,在化学预氧化后,对土壤进行生物强化和生物刺激,可有效强化土壤微生物对残余有机污染物的降解,提高联用修复技术对有机污染物的修复效率。

将化学氧化与微生物修复技术相结合,对实际污染土壤的修复而言更具有参考价值。有研究表明,高浓度的过硫酸盐、高锰酸钾、Fenton等化学氧化剂对土壤微生物活性和理化性质均会带来不同程度的负面影响[26]。在使用化学氧化法修复各类有机污染土壤时,为保证修复效率,往往依赖于高浓度高剂量化学氧化剂的添加,这会带来严重的二次污染问题[27]。而微生物修复技术则存在修复时间长、难以修复高浓度污染场地等缺点,使其在实际污染场地修复的应用上仍存在较大的局限性[28]。本实验采用低浓度过硫酸盐对菲污染土壤进行预氧化,在降低了污染物浓度的同时有效减少了对土壤的二次污染,降低了土壤毒性;随后辅以生物强化和生物刺激2种典型的微生物修复技术对土壤中的菲进一步降解,最终获得了较高的降解率。这从绿色和可持续发展角度为有机污染土壤修复技术提供了新思路。

3. 结论

1)化学预氧化后耦合生物强化和生物刺激等手段能够有效强化微生物对土壤中菲的降解,是一种可行的化学氧化-微生物联合修复技术。活化过硫酸盐预氧化后,同时加入营养物质N和高效降解菌,对土壤中菲降解的促进作用最强;营养物质P(KH2PO4)的加入对菲降解的促进作用存在滞后现象;仅添加高效降解菌,对土壤中菲降解的促进作用最差。

2)氧化剂过硫酸钠和营养物质P(KH2PO4)的加入,在短期内会导致土壤pH和微生物数量急剧下降。随着培养时间的延长,pH和微生物数量会逐渐恢复。

3)土壤中菲的降解率与过硫酸盐和营养物质N的添加呈显著正相关。微生物数量与过硫酸盐的添加呈负相关,与土壤pH呈正相关。土壤pH受过硫酸盐和营养物质P的负面影响较大。

-

-

[1] 张殿印, 王纯. 脉冲袋式除尘器手册[J]. 北京:化学工业出版社, 2011: 2-3. [2] 杨燕霞, 张明星, 秦文茜, 等. 脉冲喷吹内置锥形滤筒的清灰性能[J]. 中国粉体技术, 2019, 25(1): 76-80. [3] ROTHWELL E. Design and operating characteristics of reverse-jet assemblies for pulse-jet dust collectors[J]. Filtration & Separation, 1988, 25(4): 257-262. [4] LI Q Q, ZHANG M X, QIAN Y L, et al. The relationship between peak pressure and residual dust of a pulse-jet cartridge filter[J]. Powder Technology, 2015, 283: 302-307. doi: 10.1016/j.powtec.2015.05.038 [5] 胥海伦, 李岚溪, 沈玉妹, 等. 上部开孔锥形散射器对滤筒脉冲清灰效果的影响[J]. 环境工程学报, 2017, 11(10): 5549-5553. doi: 10.12030/j.cjee.201612095 [6] 张一帜, 陈海焱, 覃金珠. 滤筒除尘器及应用现状[J]. 能源与环境, 2009(5): 47-52. doi: 10.3969/j.issn.1672-9064.2009.05.021 [7] 杨军瑞, 胥海伦, 陈海焱. 脉冲喷吹滤筒除尘器在低尘环境中应用的可行性分析[J]. 能源环境保护, 2010, 24(2): 6-9. doi: 10.3969/j.issn.1006-8759.2010.02.002 [8] 瞿晓燕, 沈恒根. 袋式除尘器清灰气源设计与脉冲阀性能探讨[J]. 环境工程, 2008, 26(2): 23-26. [9] TSAI C J, LU H C. Numerical and experimental study of cleaning process in pulse-jet fabric filtration systems[J]. Journal of Aerosol Science, 1996, 30(11): 3243-3249. [10] 林莉君, 陈海焱, 周喜, 等. 脉冲喷吹滤筒除尘器清灰性能的实验研究[J]. 暖通空调, 2009, 39(4): 148-151. doi: 10.3969/j.issn.1002-8501.2009.04.036 [11] 蒋存刚, 李纪锦, 李勇, 等. 影响脉冲袋式除尘器清灰效果的因素探讨[J]. 橡胶工业, 2007, 54(1): 49-51. doi: 10.3969/j.issn.1000-890X.2007.01.011 [12] 姜洋, 谭志洪, 刘丽冰, 等. 响应面法优化袋式除尘器脉冲清灰性能[J]. 环境工程学报, 2014, 8(7): 2969-2974. [13] 杨迪, 陈海焱, 李怀玉. 喷吹压力和脉冲宽度对脉冲喷吹滤筒除尘器清灰效果的影响[J]. 安全与环境学报, 2008, 8(5): 73-76. doi: 10.3969/j.issn.1009-6094.2008.05.020 [14] LI J L, LI S H, ZHOU F B. Effect of cone installation in a pleated filter cartridge during pulse-jet cleaning[J]. Powder Technology, 2015, 284: 245-252. doi: 10.1016/j.powtec.2015.06.071 [15] 张亚蕊, 韩云龙, 钱付平, 等. 新型滤筒除尘器性能的数值模拟[J]. 过程工程学报, 2016, 16(1): 48-54. doi: 10.12034/j.issn.1009-606X.215314 [16] QIU J, WU D S, CHEN D R, et al. Reverse pulsed-flow cleaning of pleated filter cartridges having an inner pleated filter cone[J]. Process Safety and Environmental Protection, 2021, 146: 481-489. doi: 10.1016/j.psep.2020.11.025 [17] 胡峰源, 谭志洪, 熊桂龙, 等. 用于袋式除尘器的拉瓦尔型喷嘴脉冲清灰性能分析[J]. 环境工程, 2019, 37(6): 117-122. [18] 胥海伦, 周苗苗, 张情, 等. 开口散射器对滤筒除尘脉冲清灰效果的影响[J]. 环境工程学报, 2017, 11(8): 4647-4652. doi: 10.12030/j.cjee.201611187 [19] 刘东, 余洪浪, 王令, 等. 上部开口散射器提高脉冲喷吹清灰性能实验[J]. 环境工程, 2019, 37(8): 138-142. [20] 周奇杰, 陈海焱, 张明星, 等. 脉冲阀喷吹量对滤筒除尘器清灰性能的影响[J]. 暖通空调, 2011, 41(6): 100-105. doi: 10.3969/j.issn.1002-8501.2011.06.025 [21] LI J L, WANG P, WU D S, et al. Numerical study of opposing pulsed-jet cleaning for pleated filter cartridges[J]. Separation and Purification Technology, 2020, 234: 116086. doi: 10.1016/j.seppur.2019.116086 [22] 颜翠平, 张明星, 吕娟, 等. 脉冲喷吹大风量滤筒除尘器的清灰变化过程研究[J]. 环境工程学报, 2016, 10(2): 829-834. doi: 10.12030/j.cjee.20160250 [23] WU Q, LI J, WU D, et al. Effects of overall length and od on opposing pulse-jet cleaning for pleated filter cartridges[J]. Aerosol and Air Quality Research, 2020, 20: 432-443. -

DownLoad:

DownLoad: