-

含油污泥是石油化工行业在生产、集输等过程产生的一种固体废弃物。其成分复杂,含有大量残留石油类物质、苯系、酚类、蒽、芘等有毒物质,除此之外还含有Cu、Cr、Pb等重金属[1]。含油污泥因具有毒性和易燃性而被列入《国家危险废物名录(2021)》HW08条目中[2]。我国石化行业每年产生的含油污泥约为300×104 t[3]。含油污泥如未经有效处理而任意堆放不仅会侵占土壤、污染水系和大气,还会对人群健康造成严重威胁。然而,含油污泥中含有的石油烃(PHCs)具有很高的回收价值。面对我国环保标准日益严格及能源消耗量增加的现实,如何实现含油污泥的资源化和无害化是当今亟待解决的问题。目前,含油污泥常用的处理技术有焚烧法[4]、化学热洗法[5]、微波法[6-7]、溶剂萃取法[8]等。这些技术共同的弊端是,含油污泥中的PHCs回收不充分,而且会造成二次污染。然而,热解法能充分回收油泥中烃类物质,以实现热解过程中有害成分的“零排放”[9-10]。含油污泥的热解是在高温、缺氧的条件下,利用含油污泥中的有机物的热不稳定性而引起有机物的热分解的过程,最后得到含油污泥热解的三相产物,分别为气体、液体和固体,也被称为干化热解技术[11]。

热解终温是影响热解产物特性的重要因素,许多研究者已对该问题进行了研究。刘颖等[12]发现,有机质发生热解反应的主要温度为350~500 ℃和575~625 ℃;温度越高,热解残渣率和热解残渣含油率越低,热解产气率越高。VIDONISH等[13]发现,在150 ℃时,轻质烃发生分解反应;而在400~500 ℃时,重质油开始发生裂解,热解气态产物主要是CO2、烃类、H2O和CO。GONG等[14]发现,当温度达到200~580 ℃时,油泥热解产生大量挥发性物质及轻质油,当热解温度于580~800 ℃时,有机残渣的分解及某些重金属盐在高温下发生了复杂的化学反应。

然而,在含油污泥热解研究中,对热解终温影响油泥三相产物的分析和产物析出规律的研究不够深入。为此,本实验通过研究不同热解终温下热解油、热解气和热解残渣的特性,为资源化利用含油污泥提供参考。

全文HTML

-

供试污泥取自上海市某炼油厂罐底含油污泥。图1为含油污泥实拍图。油泥外观呈黑褐色且较为粘稠。含油污泥中含水率为14.4%、含油率为27.2%、含固率为53.8%。实验前,对含油污泥进行了理化特性分析,结果如表1所示。油泥中挥发分含量为42.7%、油泥中C元素含量最高为54.9%,C/H比为5.9,热值为16.9 MJ·kg−1。

-

含油污泥热解装置如图2所示。管式炉左端连接氮气瓶,右端冷水槽里连接收集瓶以收集热解油,最后通过干燥器后连接采气袋以收集热解气体。

油泥热解实验。取均匀混合干燥后的油泥样品置于反应器中,实验过程中以氮气为载气,进入管式炉的氧气源由空气提供,其体积分数通过气体流量计控制,进入管式炉总流量控制在100 mL·min−1;以升温速率10 ℃·min−1加热至设定工况温度(400~800 ℃)并恒温30 min。实验完成后,热解残渣冷却后称重密封保存备用;热解的液相组分用二氯甲烷收集,放入通风橱中自然挥发至呈膏状无流动,称重后低温保存;热解气体由载气吹出过二氯甲烷和干燥器后用集气袋收集。

-

采用共沸蒸馏法[15]测定油泥含水率、含油率和含固率;采用GB/T 212-2008[16]分析油泥的水分、灰分和挥发分;采用德国Vario EL III有机元素分析仪测定油泥元素;采用5E-AC/PL自动量热仪测定油泥热值;采用SY/T 5119-2016[17]分析热解油组分;采用 GC2010-plus气相色谱仪分析热解气组分;采用Zeiss Ultra 55扫描电镜观察热解残渣表面结构。

-

1)热解产物产率计算。热解残渣气产率(S)、热解油气产率(L)、热解气产率(G)的计算公式如式(1)~式(3)所示。

式中:O0为干燥油泥质量,g;S0为热解残渣质量,g;L0为热解油质量,g。

2)热解油回收率计算。热解油回收率(ξ)作为衡量热解效率的重要指标,热解油回收率越高,说明油泥热解程度越高,计算公式如式(4)所示。

式中:O0为原干燥油泥重量,g;S0为油泥热解残渣重量,g;α0为油泥灰分重量,g。

3)热解气组分产量计算。含油污泥热解气组分主要研究H2、CH4、CO和CO2。H2、CH4和CO2都可以用气相色谱进行分析得出,CO利用差减法得出。气体产量(Yi)计算公式如式(5)所示。

式中:V为收集的气体总体积,L;ɳi为组分气体的绝对百分比,%;ρi为组分气体密度,H2、CH4、CO和CO2密度分别为0.089、0.717、1.25和1.98 kg·m−3。

1.1. 实验原料

1.2. 实验装置

1.3. 实验方法

1.4. 分析方法

-

在热解过程中,为使含油污泥中矿物油能最大程度地析出,实验前需要确定油泥热解的最佳条件。升温速率是油泥热解过程中的一个重要参数;同时,有研究[18]表明,在载气中通入微量氧气会提高热解反应效率。因此,本实验以油回收率作为衡量热解效率指标,确定热解过程中需要的最佳升温速率和载气中氧气体积分数。

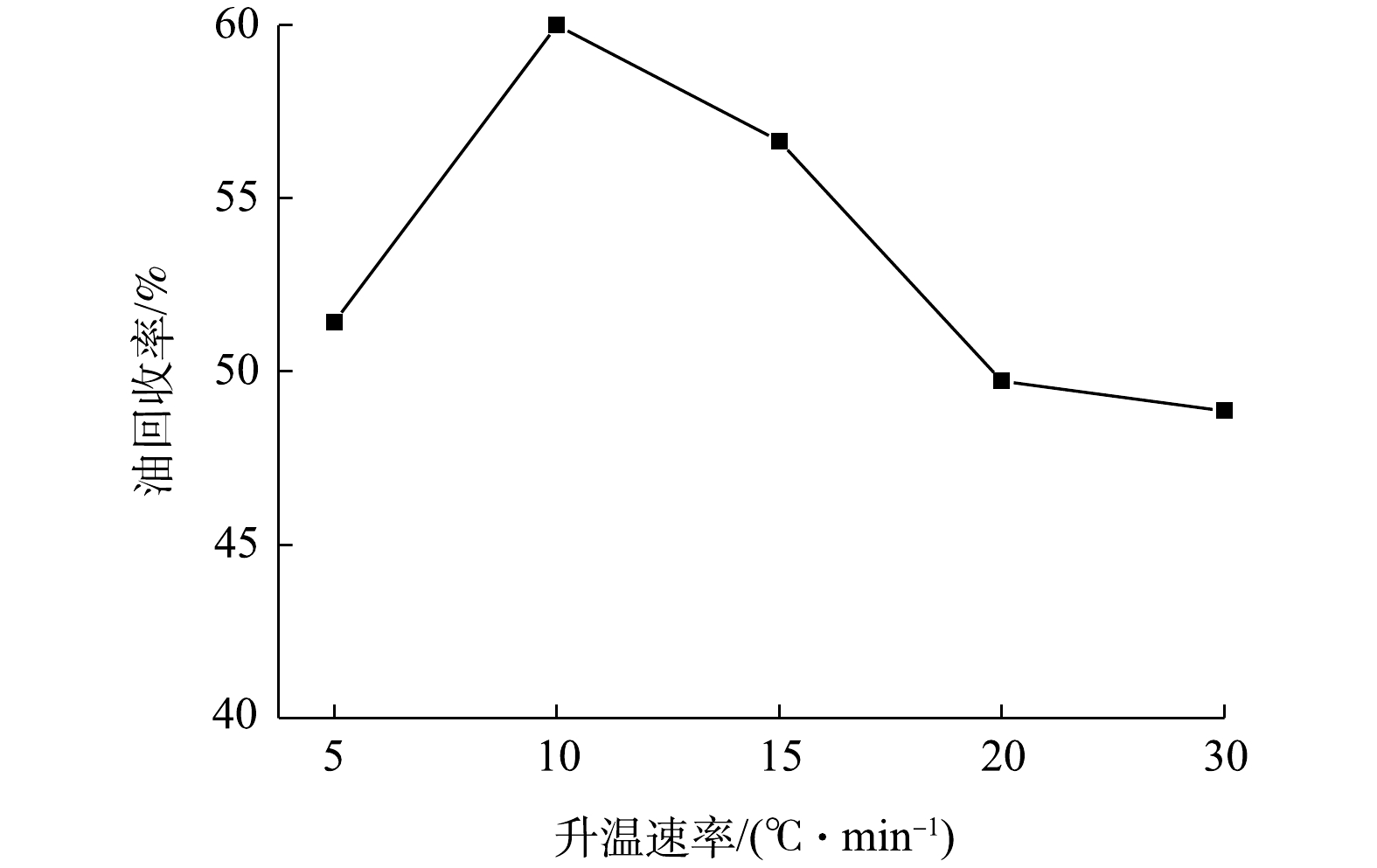

1)升温速率对油回收率的影响。图3反映了不同升温速率下,热解油泥的油回收率变化趋势。从图中可以看出,随着升温速率的加快,含油污泥的油回收率呈现先快速增大后快速减小并趋于稳定的趋势;在升温速率为10 ℃·min−1的条件下,油泥的油回收率最大达到60%。这是因为,当升温速率较低时,相当于油泥在较低的温度下进行热解,污泥中轻组分挥发和重组分热解的速度均较慢,热解时间延长导致了油泥的碳化反应加强,从而降低了油的析出[19];随着升温速率的提高,实验中油泥蒸发加剧,出现沸腾现象,沸腾的泡沫会携带部分含油污泥,残留在管式炉上部而难以反应,最终影响了油回收率。综合来看,最佳升温速率为10 ℃·min−1。

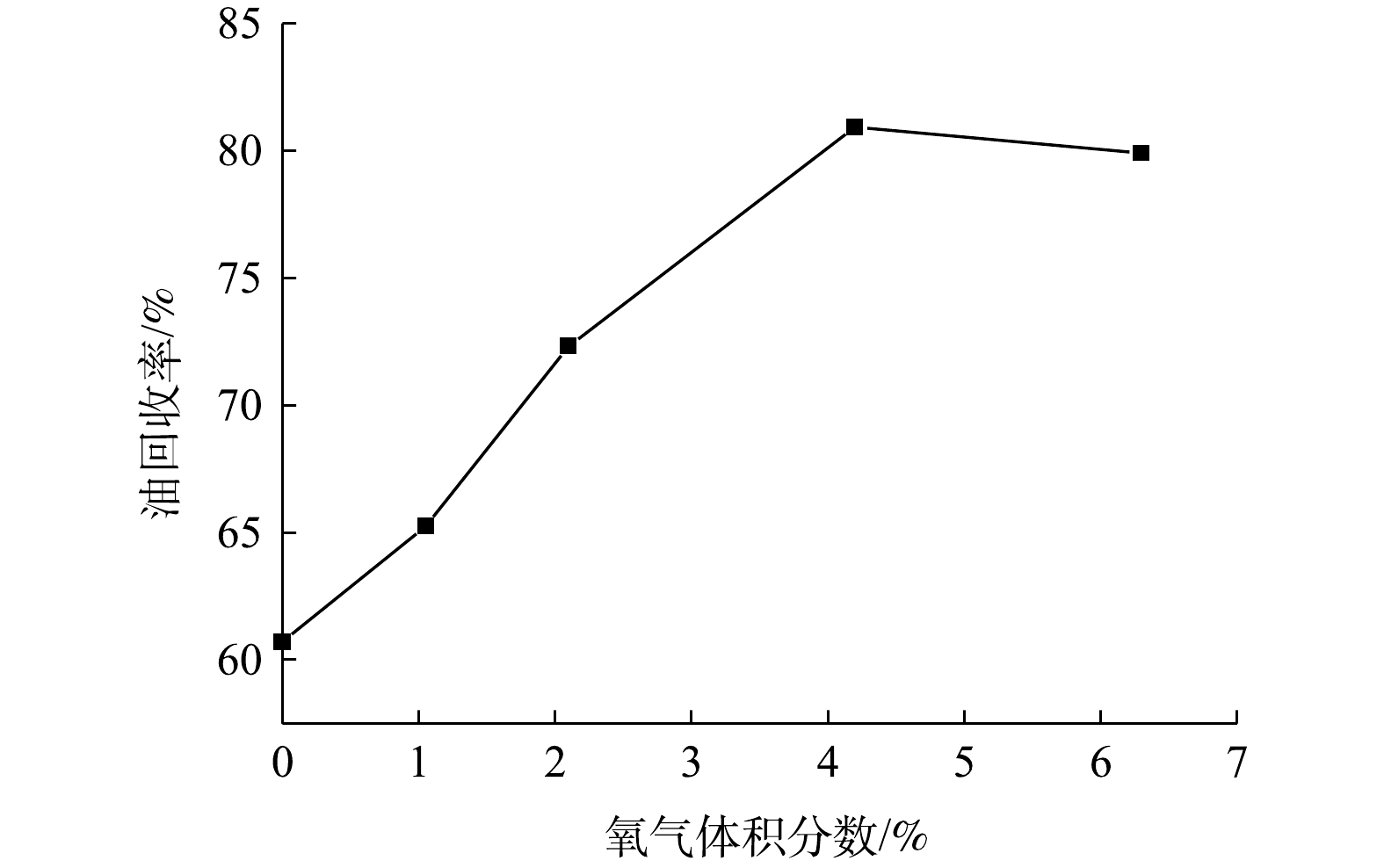

2)氧气体积分数对油回收率的影响。通过改变氧气体积分数分别为0、1.05%、2.1%、4.2%、6.3%,考察低氧气浓度对含油污泥油回收率的影响,结果如图4所示。由图可知,随着氧气体积分数的增加,热解油泥的油回收率明显提高。这说明,低体积分数的氧气参与油泥热解能促进油泥中挥发分的脱除。这是因为,加入低体积分数的氧气可以使含油污泥空隙变大,加快了传质传热效率从而使油泥内部热解更加彻底[20]。氧气体积分数从0增加到4.2%时,油泥油回收率显著提高,从50.71%提高到最大值为70.93%。这是因为,含油污泥在管式炉中热解时,表面油泥首先接触氧气,会消耗部分有机物使油泥表面形成孔隙,提高了热解反应的传质传热效率;继续增加氧气体积分数,油回收率降低,氧气体积分数为6.3%时挥发分转化率为68.9%。这可能是因为,氧气体积分数过大会使油泥表面有机物消耗过多,孔隙坍塌,阻碍油泥内部的继续反应,导致油泥挥发分转化率降低。综上所述,选择最佳氧气体积分数为4.2%。

-

1)热解终温对含油污泥三相产率影响。热解条件确定为升温速率为10 ℃·min−1、载气流量为100 mL·min−1、氧气体积分数为4.2%、热解时间为30 min。控制热解终温分别为400、500、600、700、800 ℃,考察热解终温对油泥热解三相产物特性影响。

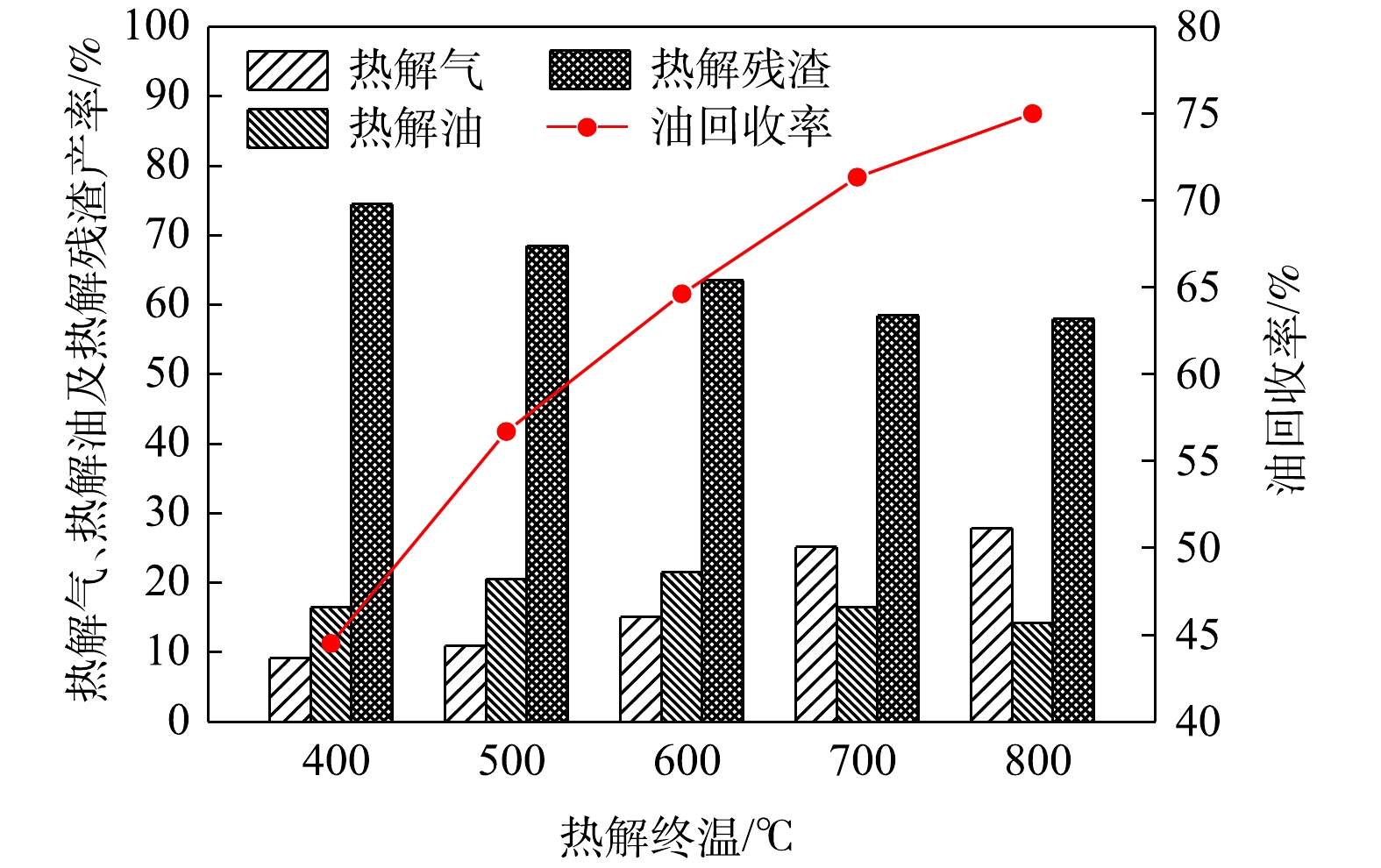

不同热解终温下,油泥三相产物产率及油回收率的变化趋势如图5所示。可以发现,热解终温对油泥热解三相产物分布影响较大,热解终温从400 ℃增加到800 ℃,含油污泥热解残渣量由74.45%降至57.98%;与此同时,油泥的油回收率由44.51%提高至75%。这是因为,提高温度可促进含油污泥中的石油烃类发生挥发、裂解、缩合反应,生成热解油和热解气,最终提高了油回收率。从产物热解油的产率变化可以看出,热解终温对热解油产率有较大影响,其产率呈现先增大后减小的趋势,并在600 ℃达到最高产率为21.46%。热解油在400~600 ℃产率增加,这是因为,提高温度使油泥里较难裂解的重油成分开始转化为轻质油组分析出;而在600~800 ℃时,产率降低则是因为温度进一步升高,使污泥热解产生的热解油组分发生了裂解和缩聚,转化成氢气和甲烷等小分子量气体[21],导致了热解油产率的降低。由图5可以发现,提高热解终温会促进热解气的生成,气体产率由400 ℃时的9.12%增加到800 ℃时的27.87%。这是因为,油泥中轻质组分在高温下会裂解为气体提高产气效率;除此之外,提高油泥热解终温会使热解油组分裂解为H2、CH4等不凝气体,2者的共同作用提高了热解气产率。

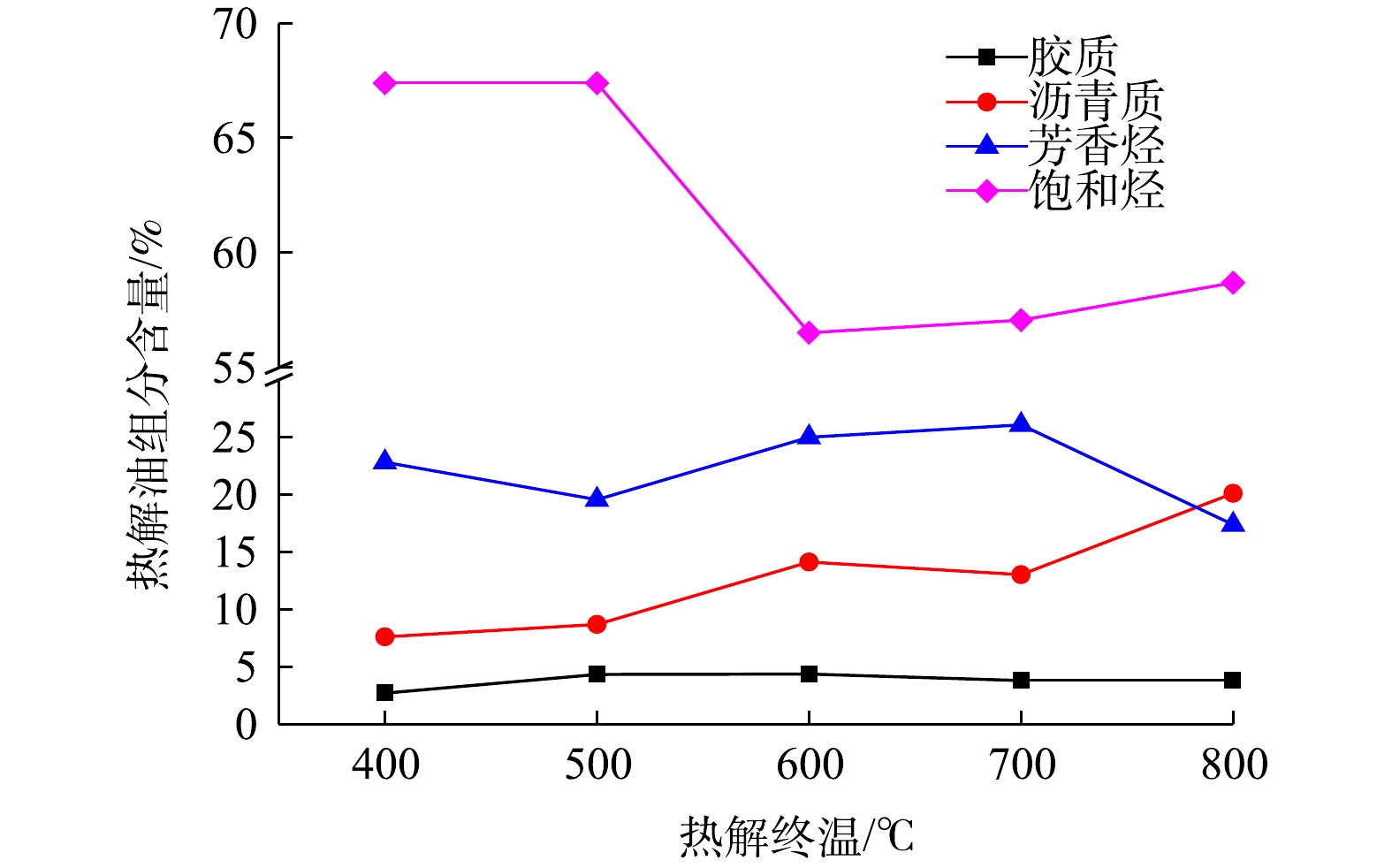

2)热解终温对热解油组分分布影响。含油污泥中石油烃类有机物会裂解为低分子的热解油,分离后得到饱和烃、芳香烃、胶质和沥青质4种组分,图6为不同热解终温下热解油组分的含量。由图6可知,不同热解终温下热解油组分中主要是饱和烃和芳香烃,分别占50%和20%左右,胶质和沥青质含量几乎不受热解终温的影响且含量处于较低水平;由于饱和烃和芳香烃在油泥中含量高且相对分子质量低,所以容易以热解油的形式析出,这也表明热解油的品质较高,有很高的回收利用价值。由图可以发现,饱和烃含量在400和500 ℃时最高为67.39%,在600 ℃时含量明显降低。这是因为,提高热解终温使饱和烃脱氢和聚合反应转化为芳烃和多芳烃,进一步通过重整和芳构化形成重分子热解油[22],使饱和烃含量降低。从图6可以发现,在不同热解终温下芳香烃含量比较稳定维持在20%左右。与此同时,胶质含量从7.61%增加到20.11%,其含量在800 ℃时有明显提升,而芳香烃含量在800 ℃时下降了8.7%,由此可以推测,在此温度下芳香烃有机物缩聚为分子量更大的胶质。综上所述,热解油的品质比较高且提高热解终温没有降低热解油的品质。又因为在600 ℃时,热解油产率最大,热解油组分中饱和烃和芳香烃含量占81.56%。因此,若以回收热解油为目的,选择热解终温为600 ℃较好。

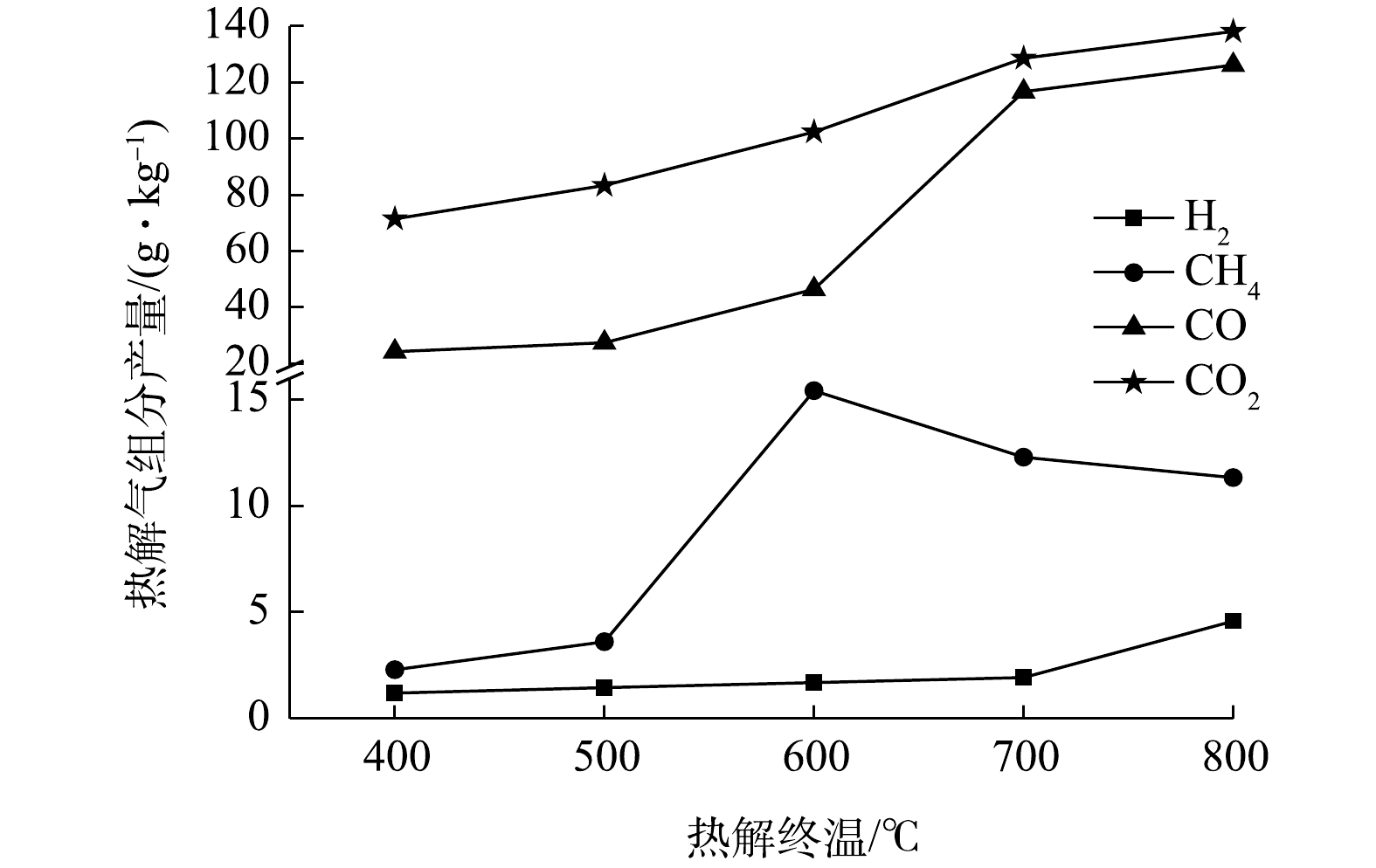

3)热解终温对热解气组分分布影响。图7为不同热解终温下热解气组分产量。可以发现,热解气中主要成分是CO2和CO,且随着温度升高,CO2和CO产量增幅很大,而CH4和H2产量受温度的影响较小。CO2产量从400 ℃时的71.43 g·kg−1增加到800 ℃时的138.10 g·kg−1,较400 ℃时产量提高了1.93倍。这是因为,在高温阶段(600~800 ℃),含油污泥中碳酸盐开始分解为CO2[23],导致在高温下CO2的产率迅速上升。热解终温对CO产量有较强影响,在400 ℃时,CO产量为20.24 g·kg−1,而在800 ℃时产量达到了126.19 g·kg−1,较400 ℃时产量增加了6.23倍;热解终温为700 ℃时。CO产量显著增加。这可能是因为,为在700 ℃时,大分子有机物的裂解缩合及水煤气还原反应产生了大量的CO;此外,低体积分数的氧气会和油泥中有机碳反应生成CO。由图7可知,随着热解终温的不断升高,H2产量趋于稳定,而CH4产量则呈现出先明显增加后缓慢降低的趋势,并在600 ℃时达到最大产量为15.4 g·kg−1;温度从500 ℃增加600 ℃时,CH4产量显著增加。这是因为,在高温下大量油类物质和有机物从含油污泥中析出,重质组分烷烃发生了二次裂解,并有部分长链有机物受热裂解为不凝小分子形成热解气,其中包括H2和 CH4;600 ℃后,CH4 产量出现了小幅下降,因为CH4在高温下会发生如式(6)~式(7)的反应,从而导致CH4产量降低。

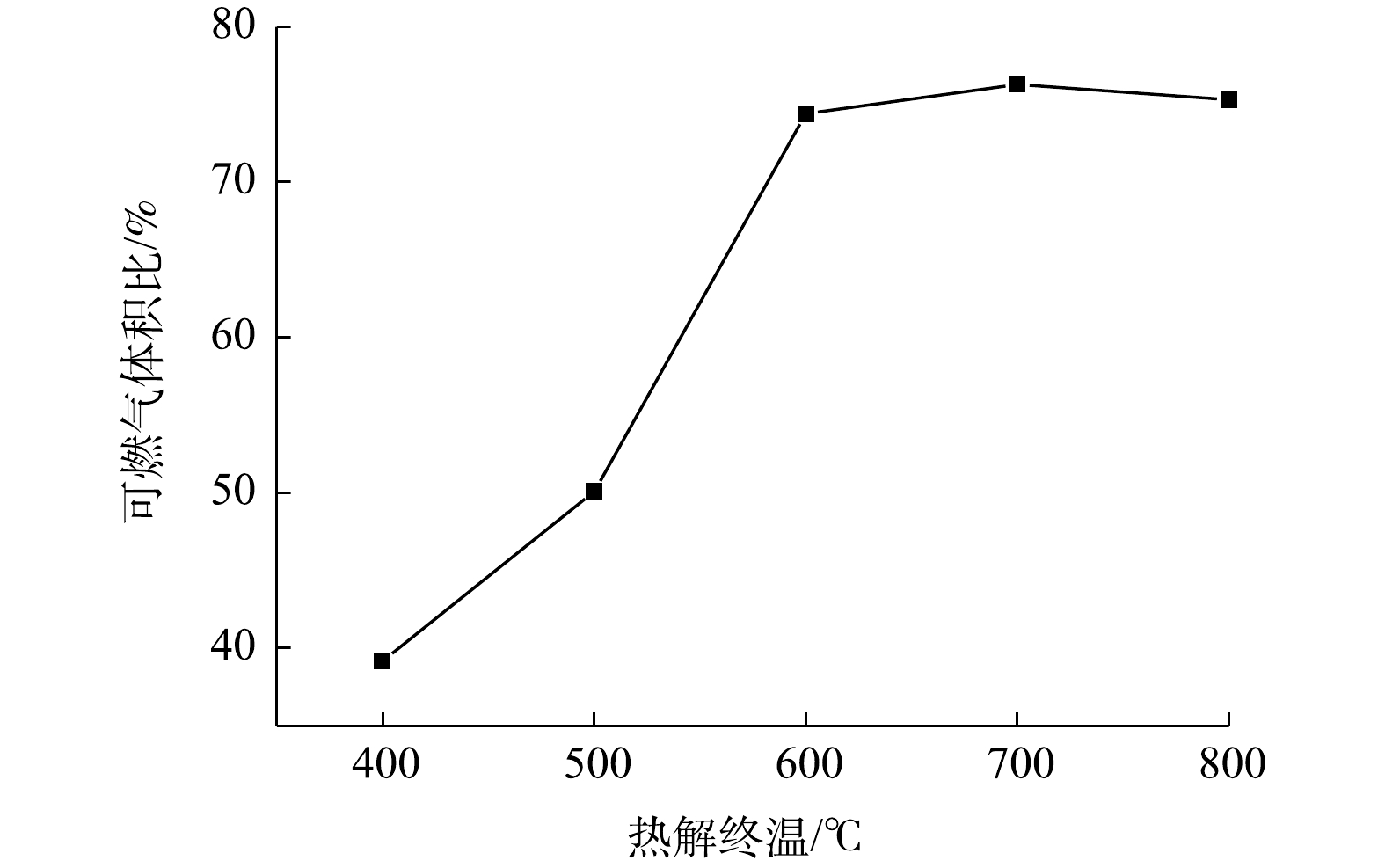

热解气中CO、CH4和H2为可燃气体,为了研究可燃气的能源利用率,现分析热解气中可燃气体的比例。图8为不同热解终温下可燃气比例。可以发现,可燃气比例在400 ℃时为39.2%,增加热解温度后可燃气比例显著提高,在600 ℃时为74.4%;继续提高热解终温可燃气比例保持相对稳定。当热解温度为400 ℃时,油泥热解气以CO2为主,油泥中石油烃类物质的裂解度较低;继续提高热解终温可促进大分子有机物的裂解和缩聚反应,从而导致CO等可燃气含量增加。因此,从回收热解气的角度分析,虽然在600~800 ℃时可燃气比例都较高,但升高热解温度会增加能耗,所以,热解终温选择600 ℃最佳。

4)热解终温对热解残渣性质影响。热解残渣呈黑色块状,有明显孔隙,粘度下降。对热解残渣进行组分分析和热值测定,并考察不同热解终温下热解残渣对碘离子的吸附性能,结果如表2所示。可以看出,热解温度在400~800 ℃范围内,挥发分含量由39.1%降至16.5%,同时残渣热值由12.8 MJ·kg−1降至7.6 MJ·kg−1。这说明,温度越高,热解残渣含油率越低,其相应的热值也越小。在400~600 ℃范围内,挥发分含量下降趋势不明显,进一步提高热解终温则挥发分含量有明显下降趋势。这是因为,提高热解终温加强了重质油的热裂化,提高了油泥中矿物油的回收率。

热解残渣热值较低,不宜做燃料直接使用,但可考虑利用热解残渣制备吸附剂,以实现油泥的资源化利用。因此,本实验研究了热解残渣对碘离子的吸附性能。由表2可知,热解终温对热解残渣的吸附性能影响较大,在400~700 ℃范围内,碘离子吸附量由2 170 mg·g−1急剧升高至2 720 mg·g−1,而后在800 ℃又骤降至1780 mg·g−1。这是因为,在温度较低时,热解油泥主要进行水分和挥发分挥发,碳化不完全,表面孔隙性能较差;热解温度过高时,碳元素挥发,热解完成后留下的是吸附性能差的灰分构成的表面,导致表面孔隙吸附性能下降。800 ℃时的碘离子吸附量比400 ℃时更低。这可能是因为,温度过高出现烧结现象,导致比表面积减小,使吸附量下降。由于在600~700 ℃时,残渣吸附量相差很小,从节约能源角度考虑,选择最佳热解终温为600 ℃。

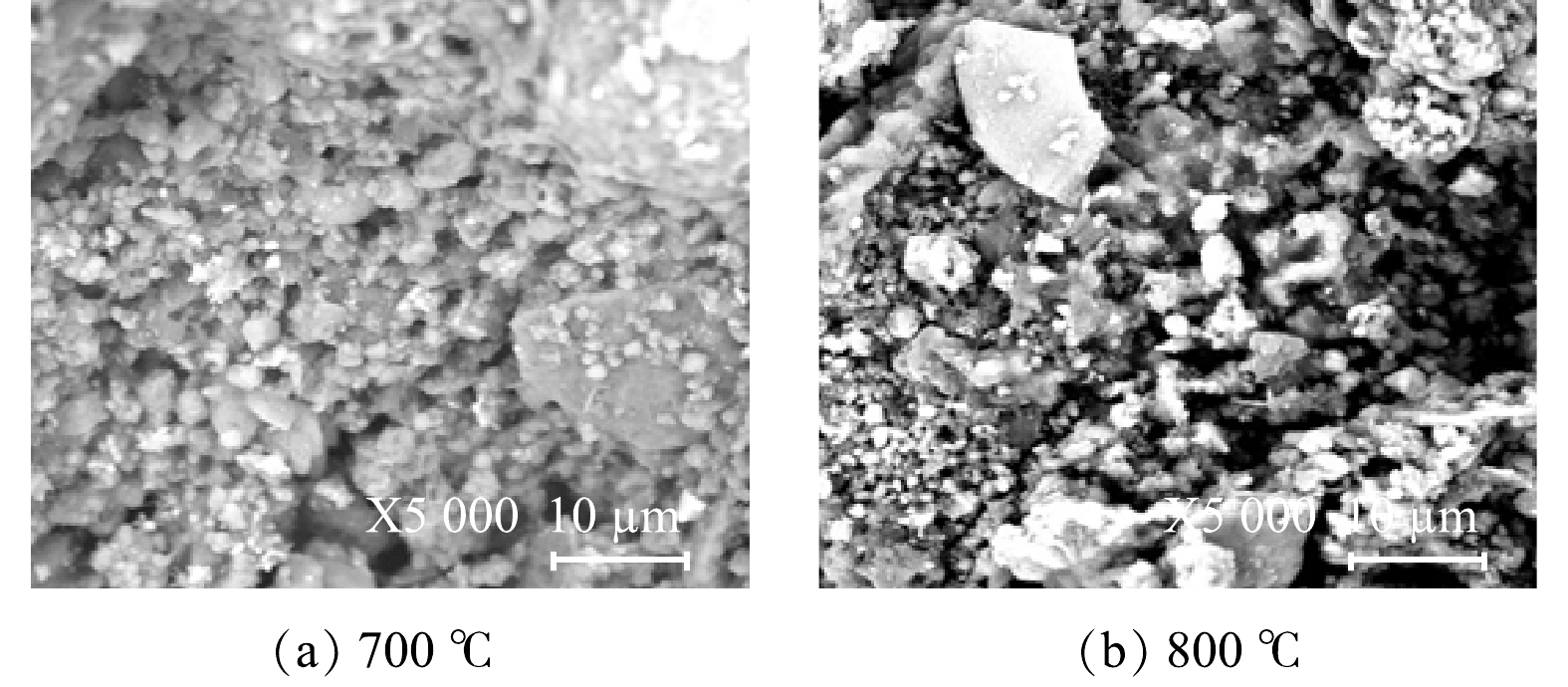

为了能更直观的观察热解残渣的结构变化,采用扫描电镜在5 000倍下观察700 ℃和800 ℃时热解残渣结构,如图9所示。可以观察到,在700 ℃时,热解残渣表面没有结焦现象,无明显微孔结构;同样看到热解残渣表面有大小不一的颗粒凸起。而在800 ℃时,颗粒消失,出现较大的块状结构,发生了塌陷和烧结现象,这会使残渣比表面积大大减少从而降低吸附性能,同时也验证了在800 ℃时残渣对碘离子吸附量下降的结果。这是因为,热解温度增加,含油污泥中的有机碳组分析出,无机物含量增加,使油泥残渣多孔结构破坏,进而导致对碘离子吸附能力下降。

2.1. 含油污泥热解条件的确定

2.2. 热解终温对热解产物特性影响

-

1)油泥热解最佳条件是:升温速率为10 ℃·min−1,载气中氧气体积分数为4.2%。热解终温对油泥三相产物分布有较强影响,增加热解终温可体高油泥中油回收率,在800 ℃时有最大产气率为27.87%,在600 ℃时有最大产油率为21.46%。

2)油泥最佳热解终温为600 ℃,此时热解油的品质较好,热解气中可燃气比例较高,可最大程度实现资源回收。

3)提高热解终温可降低热解残渣的含油量且表现出对碘离子良好的吸附性能,可考虑制备吸附剂。

DownLoad:

DownLoad: