-

医疗废物高温蒸汽处理工艺是典型的非焚烧技术,在国内外得到了广泛应用[1-5]。灭菌效果是其首要指示指标。影响灭菌效果的关键因素是在一定灭菌温度下的灭菌时间[6]。灭菌时间包括微生物的热死亡时间和水蒸汽热量的热穿透时间。热死亡时间是生物指示剂嗜热型脂肪杆菌芽孢在湿热灭菌状态下的死亡时间[7];而热穿透时间是指灭菌室内的热量进入医疗废物内部,使各点都达到相同灭菌温度所需要的热传递时间。在某一灭菌温度下的热死亡时间是确定的,而且其数值相对很短(如132 ℃时,热死亡时间为0.5 min)[8]。因此,决定灭菌时间的重要因素之一是该灭菌温度下的热穿透时间。

医疗废物高温蒸汽处理是一个复杂的热质传递过程。由于其所处理的物料具有成分复杂、状态不固定的特点,因此,难以用传统的热质传递理论对其进行数学模拟。有技术人员研究了影响热穿透时间的相关因素[9-10],但未能定量描述热穿透时间与其影响因素之间的关系。也有研究者[11]利用多孔物料的传递理论建立了该过程的热质传递模型,并以B-D试纸为实验用品对其进行了验证。鉴于废纸只是医疗废物的成分之一,该模型也不完全适用于实际医疗废物热穿透时间的理论计算。

灭菌温度和灭菌时间是医疗废物处理标准中必须明确的工艺参数。由于热穿透时间难以用理论计算来确定,因此,不同标准中灭菌时间差别很大。世界卫生组织推荐,灭菌温度120 ℃时灭菌时间为30 min[12];我国的标准中规定的灭菌温度是134 ℃,灭菌时间45 min[13]。

本研究以实际医疗废物为样品,对热穿透时间进行实验,实验中综合考虑了试样装填密度、试样体积、灭菌温度及灭菌室真空情况等工艺条件对高温蒸汽处理工艺热穿透时间的影响。研究中使用的实验装置为脉动真空型医疗废物高温蒸汽灭菌器,该技术类型的灭菌器在医疗废物处理工程中普遍使用。本实验结果可为医疗废物高温蒸汽处理工艺工程实践提供有益的数据参考。

全文HTML

-

经初步消毒后的医疗废物。其各成分的体积组成如下:纱布、废纸类物料占40%;塑料、橡胶类物品(输液管,塑料注射器,瓶盖等)占30%;玻璃类物品(小药瓶等)占20%;其他类物品(各类包装盒、食品垃圾等)占10%。

-

研究中采用灭菌室容积为6 m3的脉动真空型灭菌器(GTMS-Ⅱ-6型,天津格林泰科环保科技有限公司,见图1)。该装置主要由灭菌室、真空泵、过滤器、温度与压力传感器、工艺管路和控制系统组成,可以根据实验要求改变工艺参数。根据本实验的实验要求,对GTMS -Ⅱ灭菌器进行了工艺改造,增加了测温热电阻和温度显示仪,用于测量和显示实验样品内部的温度变化。实验装置示意图见图2。试样的承装容器为实际工程中采用的灭菌车,容积分别为1 m3和0.5 m3。分侧面开孔(孔径φ10 mm)和不开孔2种,见图3。

-

实验按照不同的灭菌温度(120 ℃和134 ℃)、不同的灭菌条件(不抽真空和脉动真空)和不同类型的承装容器(侧面开孔和不开孔)3类情况分别进行,共有8种组合(见表1)。在每组实验中,同时测量并记录4个承装容器(容积分别是1 m3和0.5 m3,装填状态分别压实和松散)内试样中心的温度变化。

实验中脉动真空工艺中的真空度设定值为75 kPa,共抽真空3次。通过喷入蒸汽破坏真空,喷入蒸汽2次,每次蒸汽喷入后达到的压力为50 kPa。松散装填时的样品密度为170 kg·m−3,压实装填时的密度为340 kg·m−3。

实验时,先通过夹套加热将灭菌室温度升到90 ℃。推进承装试样的灭菌车,关闭密封门后进行脉动真空操作(或不抽真空操作)。之后,向灭菌室喷入蒸汽迅速升温,当灭菌室内达到设定的灭菌温度时,开始记录各试样中部测温点处的温度及时间,继续维持灭菌室处于恒定的灭菌温度,直到试样测温点处达到设定的灭菌温度。

1.1. 实验材料

1.2. 实验装置

1.3. 实验方法

-

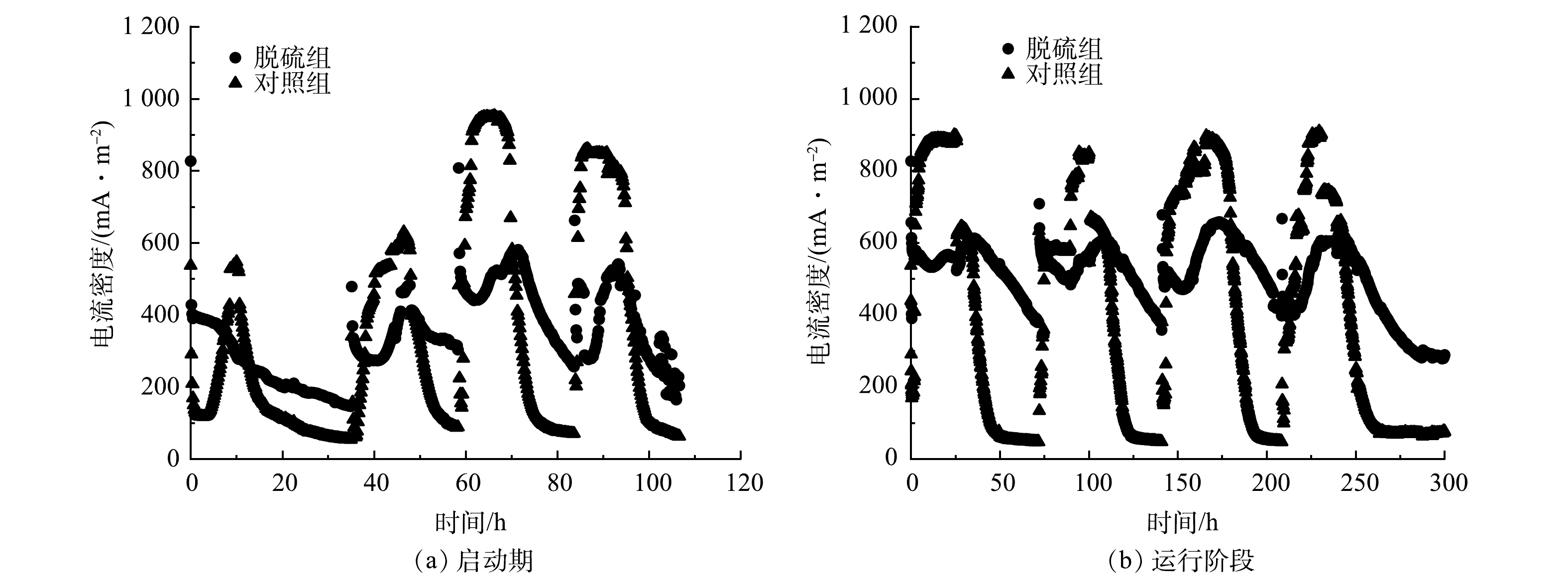

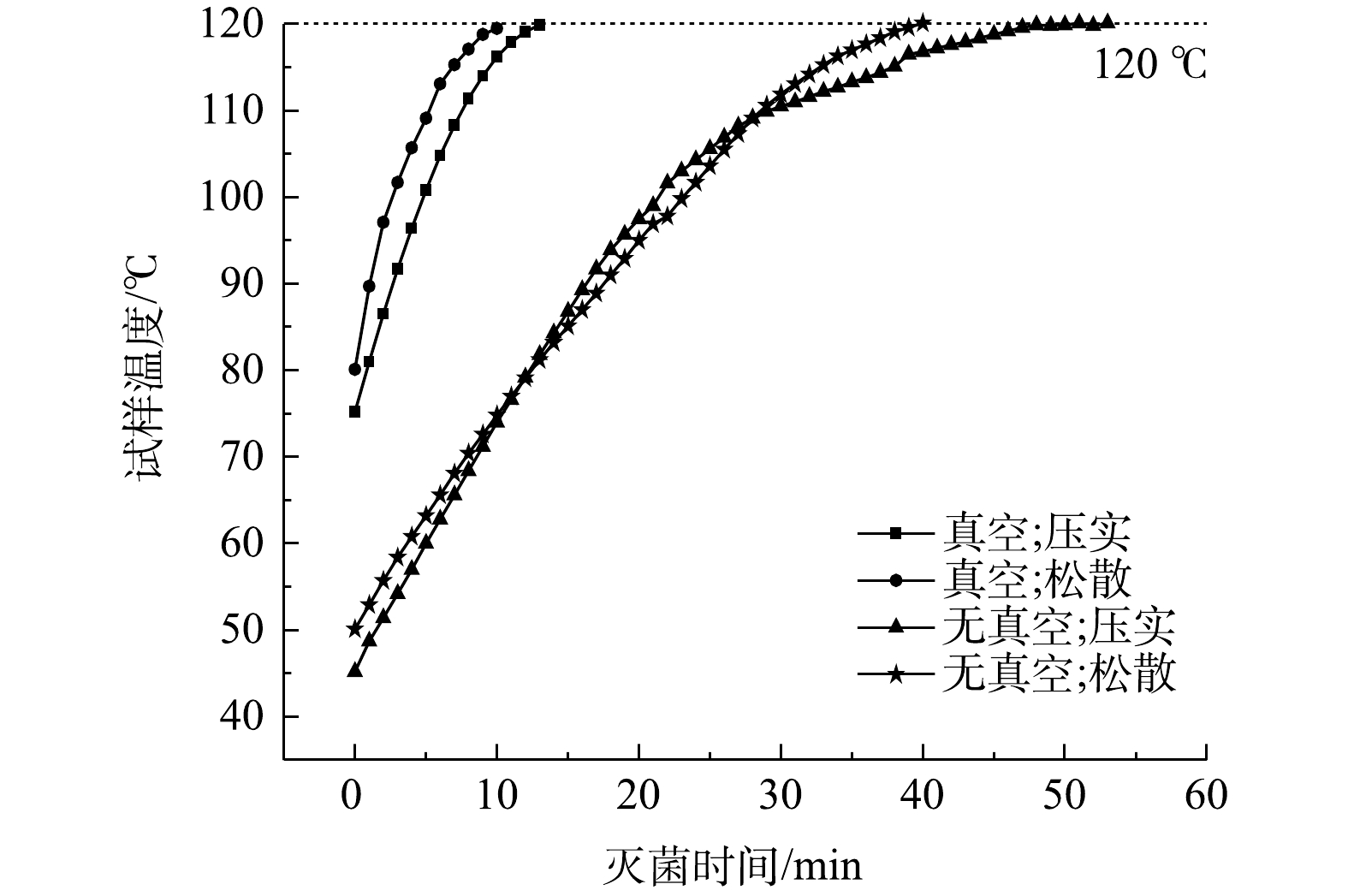

图4和图5分别是医疗废物置于1 m3和0.5 m3灭菌车,在相同灭菌温度下试样中心的温度变化情况。可以发现,脉动真空操作可以明显地缩短热穿透时间,该结果与相关研究中的结论一致[14]。灭菌器内原有空气的存在对热量传递的影响可能有2个方面:一是减弱了空气“冷岛”效应;二是减少了灭菌室内不凝气的量,使灭菌室内的气体更接近饱和水蒸气状态,当蒸汽冷凝后,形成局部负压[6],促进了水蒸气分子向医疗废物孔隙的扩散。

灭菌器内原有的空气会改变灭菌器内混合气体的组成比例,也相应改变了灭菌室内压力和温度的关系。唐欣昀等[15]利用Antoine方程描述了在不同空气残留量下灭菌室内压力和温度的关系。依据其计算方法,在灭菌温度为120 ℃时,当第一次抽真空达到25 kPa(绝压)时,蒸汽通入后对应的压力为223.88 kPa(绝压),蒸汽喷入前后的压差为208.89 kPa;如果不抽真空,直接向灭菌室喷入蒸汽,灭菌室内的压力为324.97 kPa(绝压),与初始状态的压力差为223.64 kPa。结果表明,真空操作反而降低压差,理论上不利于水蒸汽向医疗废物空隙扩散。然而,本实验及部分研究[6-12]均得到了排除空气有利于热量传递的结论,这说明压差的消极影响可能小于前述2方面的积极影响,因此,抽真空操作仍然有利于热穿透。

由图4和图5还可以发现,与松散状态相比,压实状态明显需要更长的热穿透时间。OLIVIA等[9]利用纸尿裤模拟医疗废物进行灭菌效果实验,亦发现将纸尿裤绑紧时生物指示剂难以杀灭。其可能的原因是,物料在压实状态造成的高密度增加了单位体积下加热医疗废物所需的热量,并且致密物料较小的孔隙阻碍了水蒸气分子的扩散,因此,物料压实延长了热穿透时间。

-

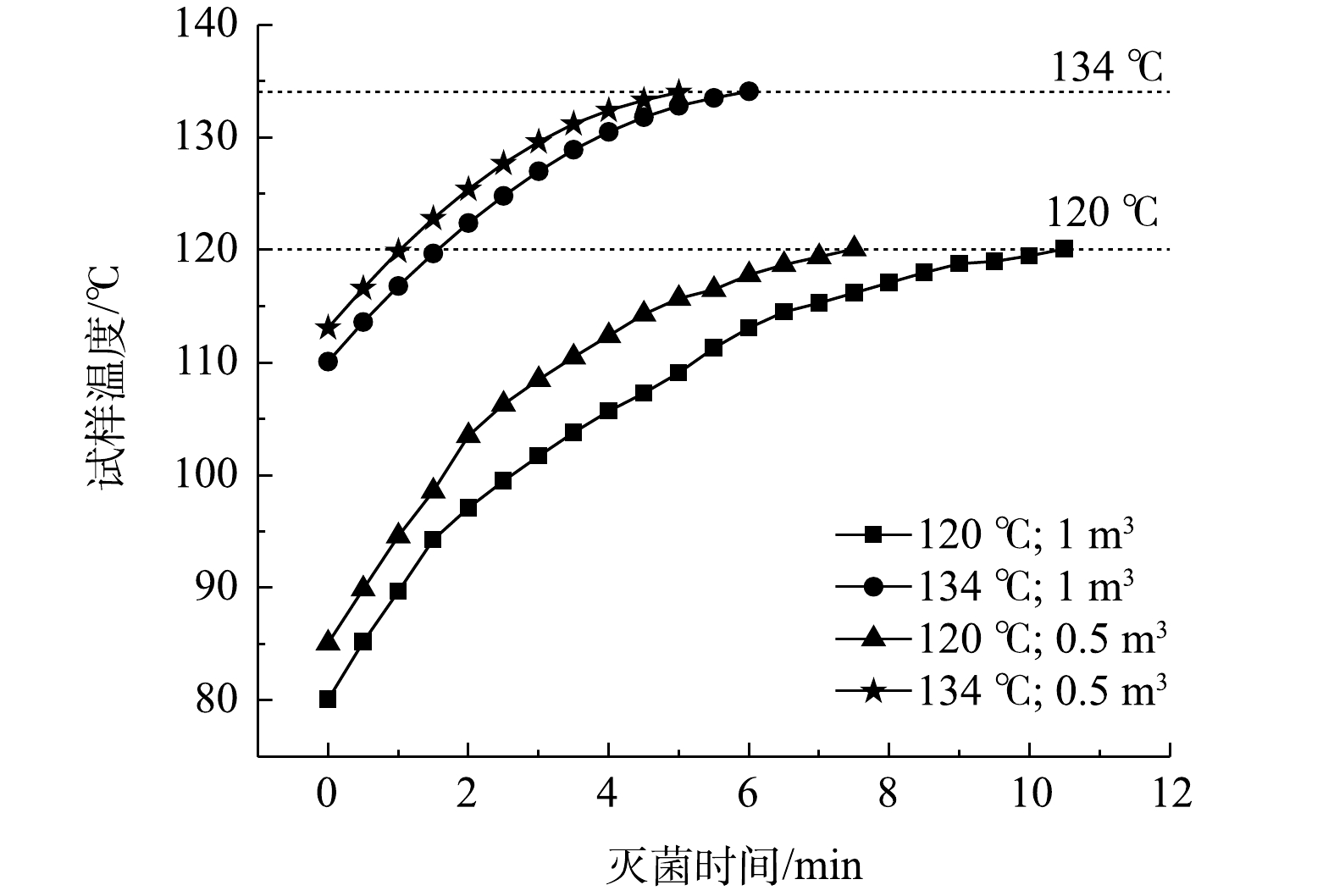

图6和图7分别为压实物料和松散物料在不同温度和体积下的热穿透时间变化情况。结果表明,灭菌温度越高,所需的热穿透时间就越短。在较高的灭菌温度下,温度梯度较大且有利于热量的传导。另外,温度高时灭菌室的压力也高,加快了水蒸气向医疗废物孔隙中的转移。

灭菌车容积的大小对热穿透时间也有一定的影响[16]。对比不同的实验数据发现,车容积的影响趋势基本一致:灭菌车容积越大,热穿透时间越长。这是因为,灭菌车容积越大,填装的物料越多,需要的热量也越多;同时,体积越大,热量需要传递的路径就越长。

-

在实际灭菌工程中,采用的灭菌车有开孔和不开孔2种。图8和图9对比的是灭菌车开孔与否对热穿透时间的影响。可以发现,小车侧壁开孔对热穿透有一定的促进作用,该结果与相关文献报道结果[16]一致。这是因为,相比于不开孔小车,水蒸气除了可以从开孔小车上口进入灭菌车之外,还同时从小车的侧壁开孔处向医疗废物中进行扩散。同时,本研究中还发现,小车侧壁开孔的影响程度亦受其他工艺条件的影响。在松散装填、真空操作、灭菌温度134 ℃时,1 m3不开孔小车相比于1 m3开孔小车的热穿透时间只增加了1 min。相比之下,压实状态、不抽真空、灭菌温度120 ℃时,1 m3不开孔小车的热穿透时间达到64 min,比1 m3开孔小车延长了11 min。值得注意的是,该条件下的不开孔小车的灭菌时间超过了标准规定的灭菌时间。

脉动真空操作可以极大地弥补小车不开孔的不足。这是因为,在3次真空后,水蒸气可以通过小车上口进入灭菌车,并在负压的作用下,迅速地扩散到松散的医疗废物内部,从而极大地降低了开孔与否的影响。在压实和未抽真空时,水蒸气只能靠扩散及不断冷凝的作用,慢慢地向医疗废物中渗透。因此,在无真空的情况下,开孔与否对热传递时间有着更为明显的影响。

通过实验还发现,将松散的医疗废物体积压缩至50%时,已达到人工压实的极限。国内实际工程中配置的灭菌车的一般小于1 m3(多为0.8~0.9 m3),而且采用松散装填方式。从保证医疗废物安全处理的角度出发,针对脉动真空类型设备,建议以1 m3无孔小车、压实状态下的实验数据为参考来确定灭菌时间。此时,在灭菌温度为134 ℃、空气排除率不低于83%的灭菌条件下,热穿透时间为12 min,而该温度下的热死亡时间为0.5 min,因此,灭菌时间设定为13 min为宜。

2.1. 真空与否和装填状态对热穿透时间的影响

2.2. 灭菌温度与试样体积对热穿透时间的影响

2.3. 灭菌车侧壁开孔与否对热穿透时间的影响

-

1)在实际灭菌工程中,为了确保灭菌效果,最佳处理条件是真空操作和松散填装。

2)最难实现热穿透的情况是采用不开孔灭菌车、无真空操作及压实状态,在实际操作中应该避免这种情况出现。

3)对于脉动真空型灭菌器,在灭菌温度为134 ℃,空气排除率不低于83%的灭菌条件下,灭菌时间最低为13 min,可作为该类型设备灭菌时间的参考。

下载:

下载:

百度学术

百度学术