-

由于旋风除尘器对细微颗粒的去除率较低[1],不能满足燃煤工业锅炉烟尘排放达标的要求,很多学者研究了旋风-布袋复合除尘器的性能。SON等[2]设计了一种旋风-布袋复合除尘器,现场实验表明布袋积尘量小,压降降低近30%;赵新义等[3]设计了旋风-布袋复合除尘器,并将其投入生产,除尘器运行良好,去除率可达标。针对更加高效的除尘需求(如排放浓度<5 mg·m−3),须进一步研究其除尘性能,优化其设计。通过实验研究复合除尘器的优化须制作实验装置,耗费时间;而计算流体力学(CFD)模拟可以降低时间和投资成本,并且可以比实验更详细地了解除尘器内部的流动,近几年得到了广泛应用。刘海等[4]使用可实现的k-ε模型模拟了SCX型脱硫除尘器内部的气固两相流场;廉继尧等[5]设计了一种旋风-布袋复合除尘器,模拟其内部流场,发现滤袋内外两侧压差较大,粒径在5 μm以下的颗粒去除率可高达99%;张文青等[6]模拟了开口挡板和底部导流板对旋风-布袋复合除尘器流场的影响,结果表明,挡板的长度对气流分布的影响很大,导流板能够提高气流分布的均匀性。

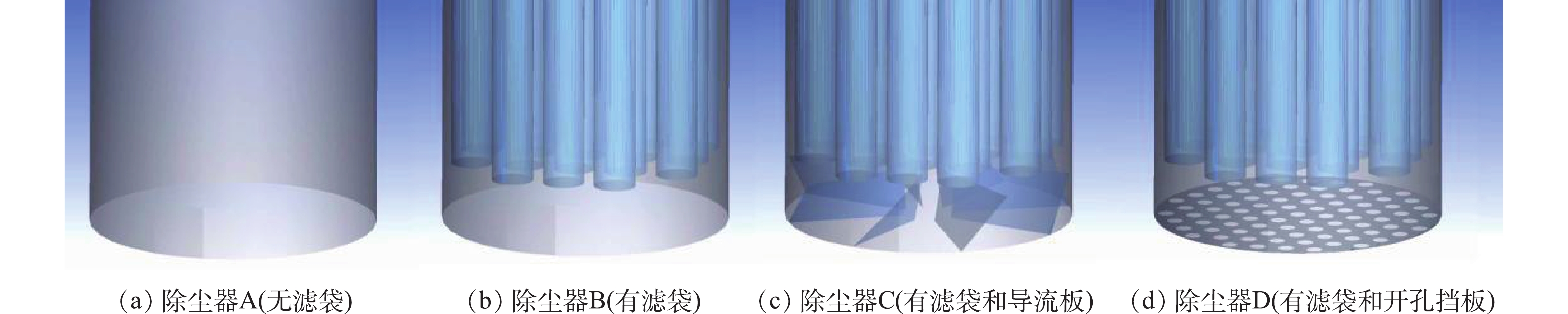

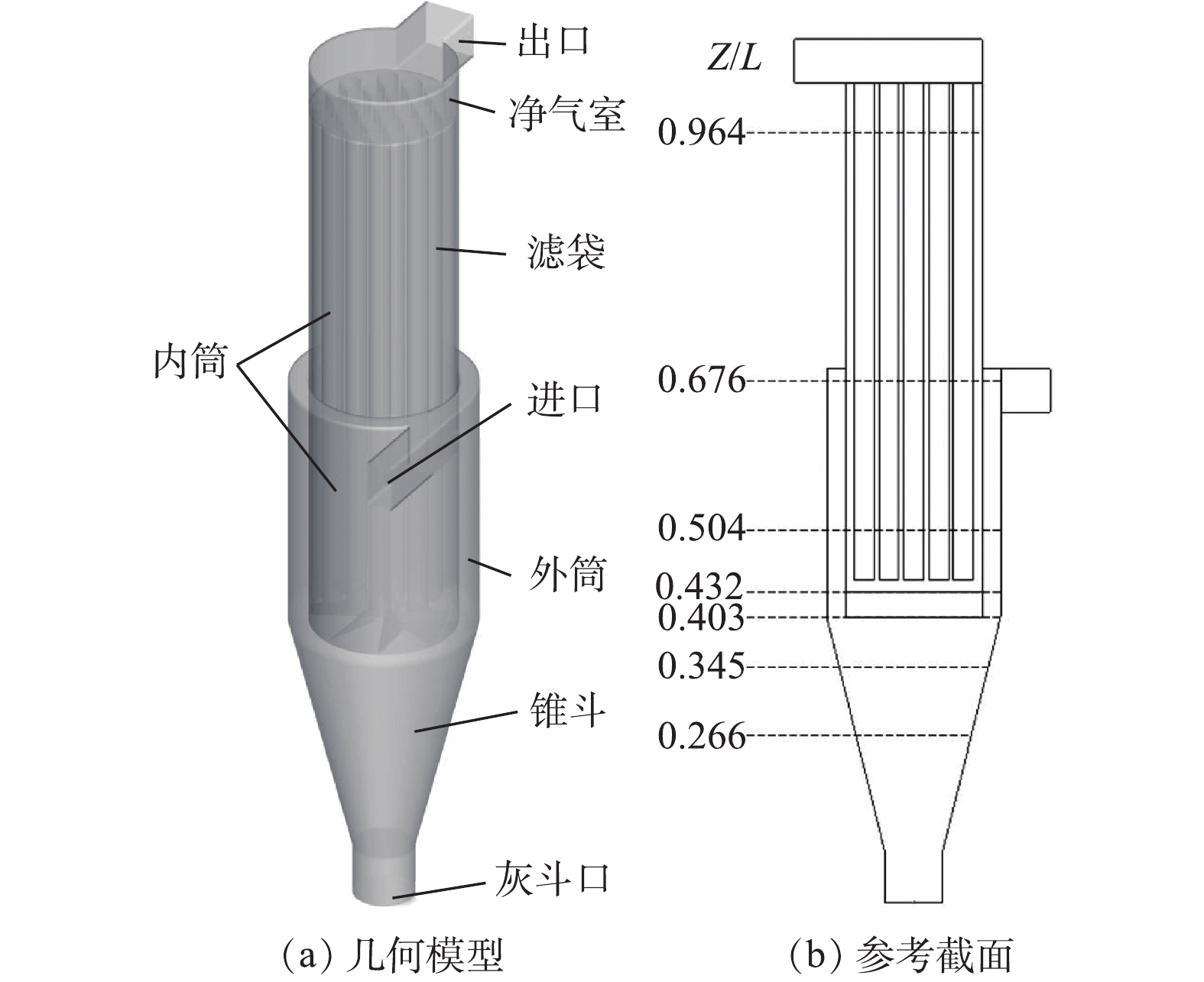

参考旋风除尘器和已有研究[2-6]中对复合除尘器的设计,本研究设计了一种在旋风除尘器的内筒设置滤袋的新型复合除尘器,通过CFD方法,模拟了无滤袋结构的旋风除尘器(A)以及滤袋前无导流板(B)、有导流板(C)或开孔挡板(D)的旋风-布袋复合除尘器的内部流场,考察了不同入口风速和粉尘浓度下除尘器A和C的压降和除尘效率,为复合除尘器的结构优化提供参考。

全文HTML

-

使用ANSYS进行简化建模,4种除尘器仅在内筒结构上有所不同。图1(a)为除尘器C的几何模型,图1(b)为参考截面位置(供模拟分析用)。图2为除尘器A、B、C、D内筒的局部图。除尘器C的导流板共8片,为均匀分布的曲面,每片叶片相隔45°,长度为450 mm,垂直高度为200 mm,每片叶片的上端和下端的夹角为20°。除尘器D挡板的孔径为60 mm,孔距为110 mm,孔间距为50 mm,开孔率为30.05%。除尘器总高为6 950 mm,外筒直径为1 400 mm,内筒直径为1 100 mm,外筒高为2 000 mm,锥斗高为1 900 mm,净气室高为350 mm,滤袋规格为φ160 mm×4 000 mm,共21个滤袋。使用ICEM进行网格划分,除尘器C生成的结构化网格总数约2.4×106个。

-

利用FLUENT 18.0模拟除尘器内部流场,假设气体为常温常压下不可压缩流体[7],质量和动量的守恒方程如式(1)和式(2)所示。

式中:ρ为气体密度,kg·m−3;t为时间,s;υ为气体速度,m·s−1;p为雷诺平均压力,Pa;τ和F分别为应力张量和外力,N;g为重力加速度,m·s−2。

复合除尘器外部为强旋流,而内部滤袋区域气流的流速慢,可假设为层流。鉴于可实现的k-ε模型对于较强旋流、剪切流、边界层流动以及带有分离的流动有很好的表现[8],采用可实现的k-ε模型对除尘器进行模拟,方程见式(3)~式(6)。

式中:k为湍动能,J;ε为湍流耗散率;υi为时均速度,m·s−1;μ和μt分别为流体黏度和湍动黏度,kg·(m·s)−1;Gk为k引起的产生项;E为时均应变率,s−1;σk=1.0;σε=1.2;C1=0.43;C2=1.9。

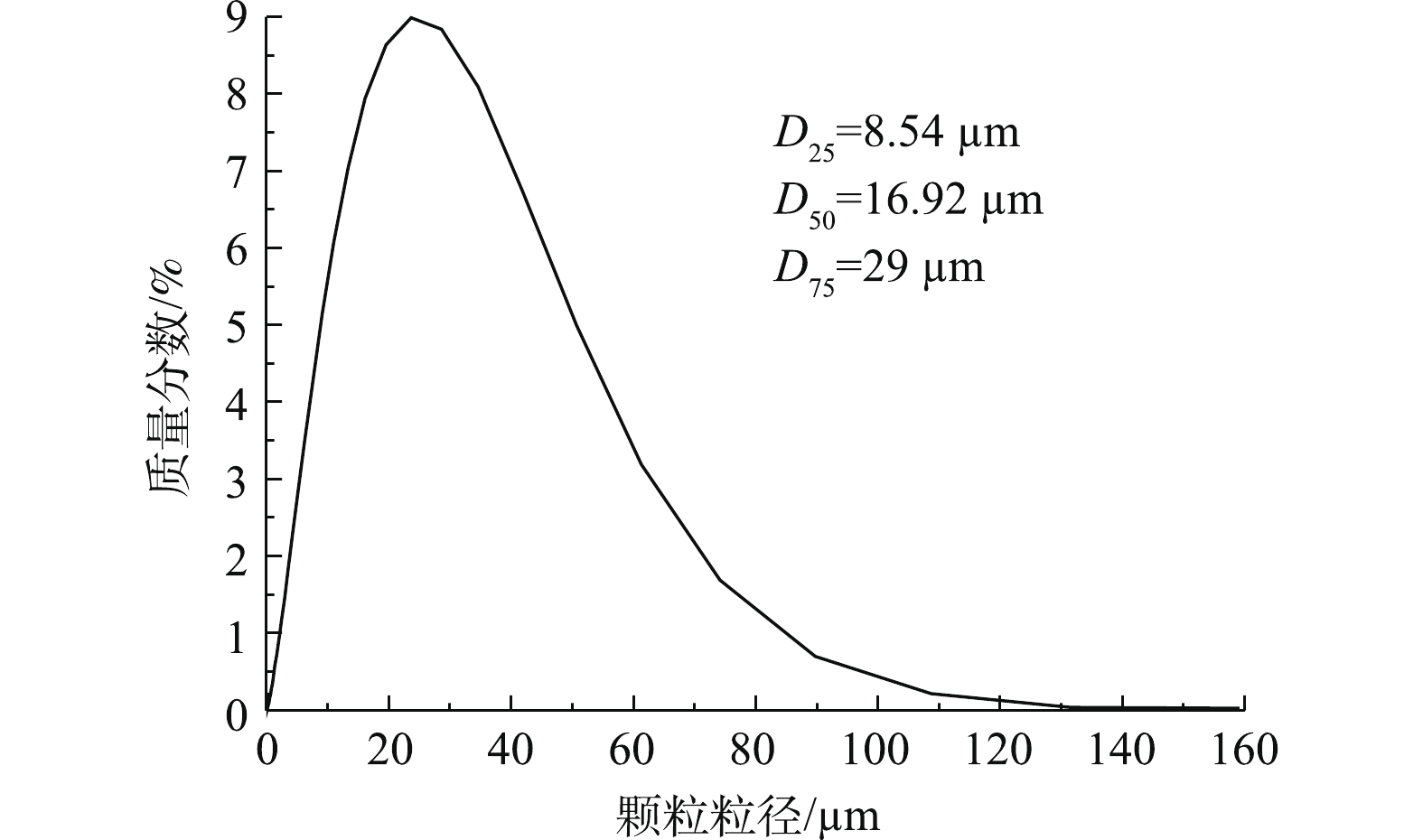

模拟采用某环保公司提供的现场粉尘样,不同粒径的质量分数如图3所示。低浓度颗粒(<10%)对流场的影响和颗粒之间的相互作用可忽略不计[9]。使用离散相模型和随机轨道模型模拟颗粒的运动,并根据粉尘的粒径分布和分级效率得出总除尘效率,方程见式(7)~式(9)。

式中:FD为单位质量颗粒曳力,N;CD为曳力系数;Re为相对雷诺数;υP为颗粒速度,m·s−1;ρp为颗粒密度,kg·m−3;di为颗粒粒径,m;η为总除尘效率;ηi为分级效率;g(di)为质量分数关于粒径的函数。

气流入口边界条件为速度入口;气流出口边界条件为出风口,气流出口处的DPM边界条件为逃逸;滤袋边界条件为多孔跳跃[10],假定渗透率为3×10−12 m2,介质厚度为2 mm,压力跃阶系数C2为0,滤袋的DPM边界条件为捕集;灰斗口边界条件为壁面;灰斗口的DPM边界条件为捕集。压力速度耦合格式为SIMPLE,压力离散格式为PRESTO,动量离散格式、湍动能和湍流耗散率格式均为二阶离散格式。

-

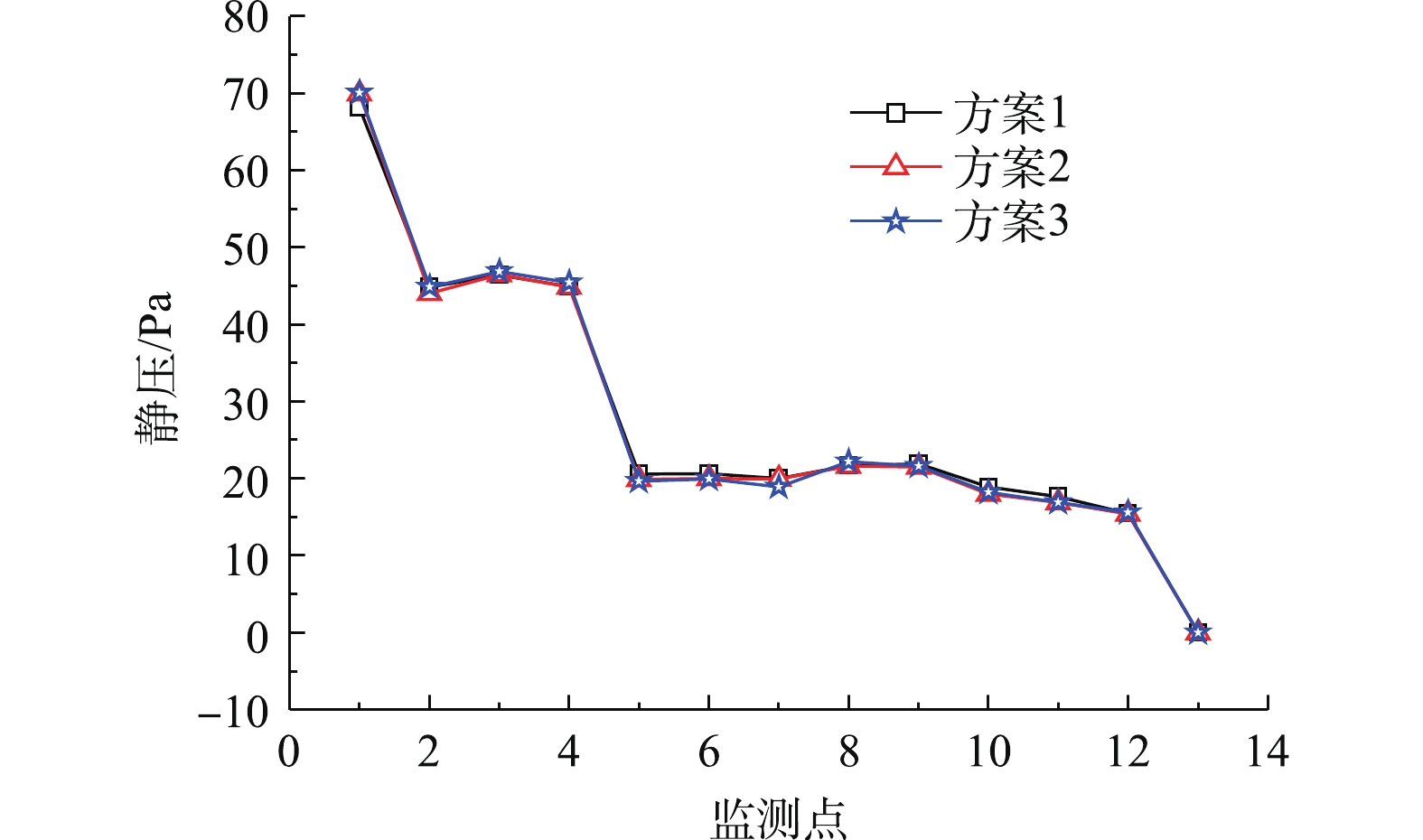

对除尘器A进行网格划分,均为六面体结构网格,方案1中的网格总数为602 855个,方案2中的网格总数为553 968个,方案3中的网格总数为451 767个。沿气流运动方向,由模型入口到出口共选取13个监测点,且记录对应的静压变化,3种方案对应的监测结果如图4所示。2种网格划分方案的计算结果非常接近,误差在5%以内。

1.1. 模型建立与网格划分

1.2. 计算模型和边界条件

1.3. 网格独立性验证

-

实验模拟了入口风速为8~16 m·s−1时各除尘器内的流场,对应的过滤风速为0.8~1.6 m·min−1,处理风量为2 016~4 032 m3·h−1。通过分析比较,本研究以入口风速为8 m·s−1为例,进行流场分析。

-

图5为除尘器A、B、C、D内部气流的流线图。较大的内筒直径导致4种除尘器均存在较为强烈的短路流,由于小颗粒的运动主要受气流影响[1],因此,除尘器A中的小颗粒容易随着短路流和旋返的气流逃逸[11],而在除尘器B、C、D中,通过这种途径进入内筒的小颗粒被滤袋捕集。气流在内筒中的流动表现明显不同:除尘器A内筒的气流为旋流;除尘器B的气流进入内筒后,继续在外圈旋转,至滤袋区直线上升;除尘器C的导流板内气流的速度方向发生明显改变,旋流向中间扩散后,直线上升,部分气流会在旋转绕过导流板后,流向锥斗,在锥体上端跟随气旋重新进入内筒,这会对锥斗上端的颗粒运动产生干扰;除尘器D的气流在通过挡板的开孔后,继续旋转,至滤袋区后,直线上升。气流分布不均会缩短滤袋的使用寿命、增加清灰难度[12],除尘器C的导流板均匀气流的效果较好。

-

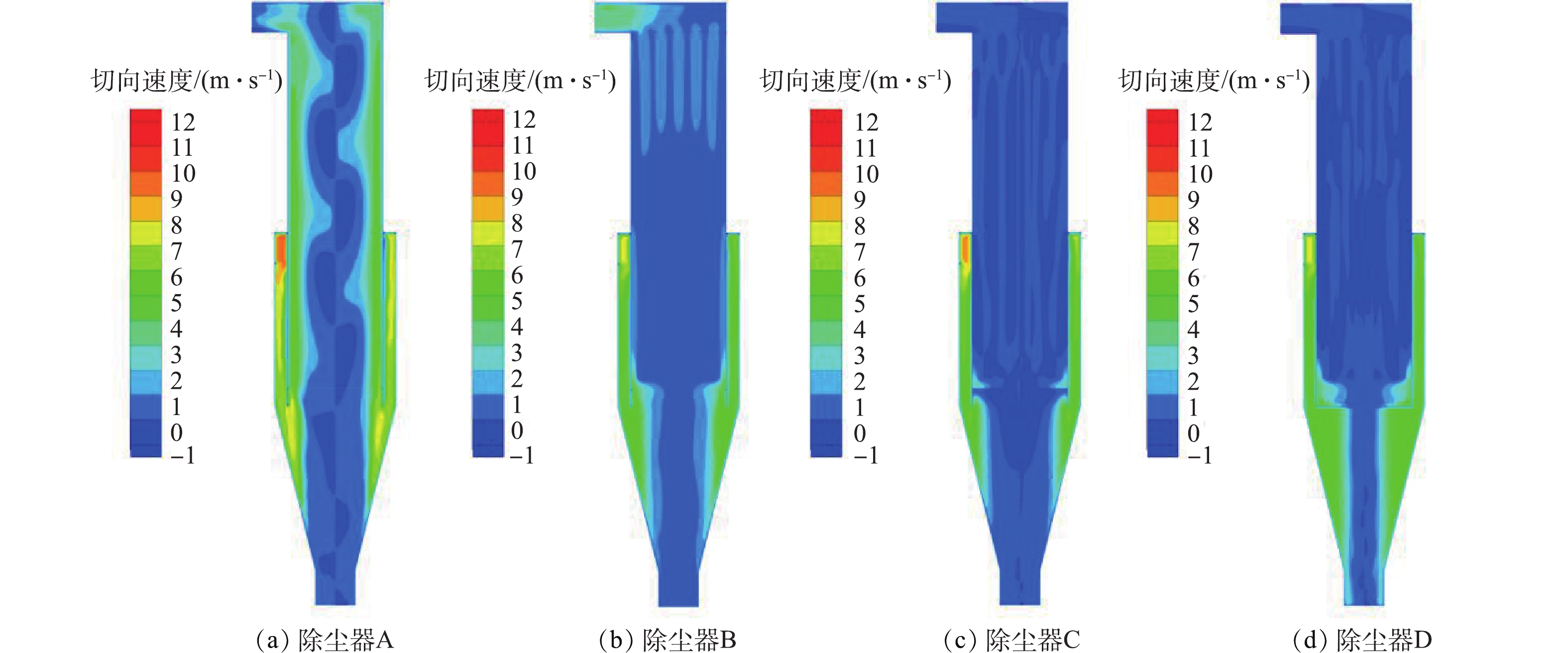

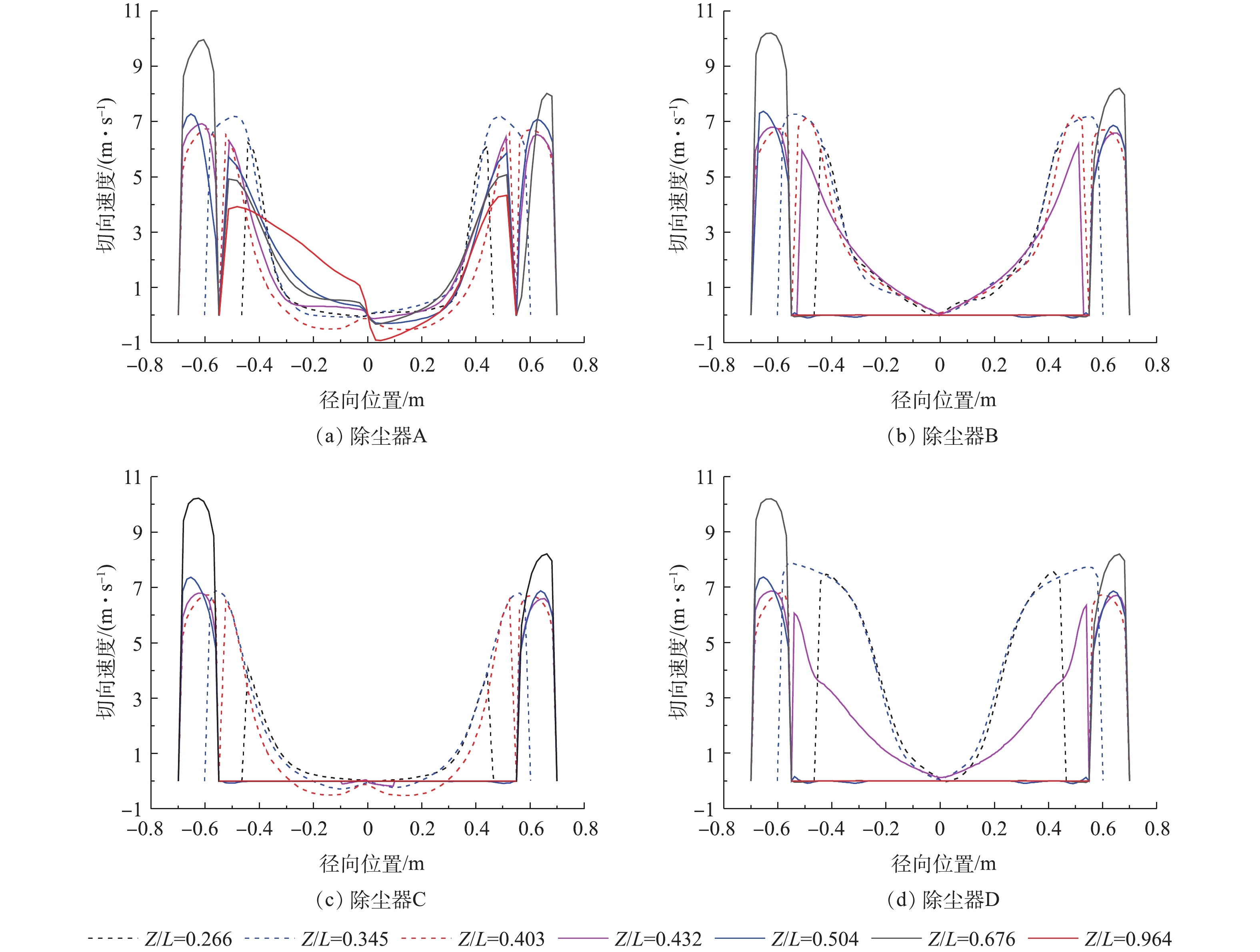

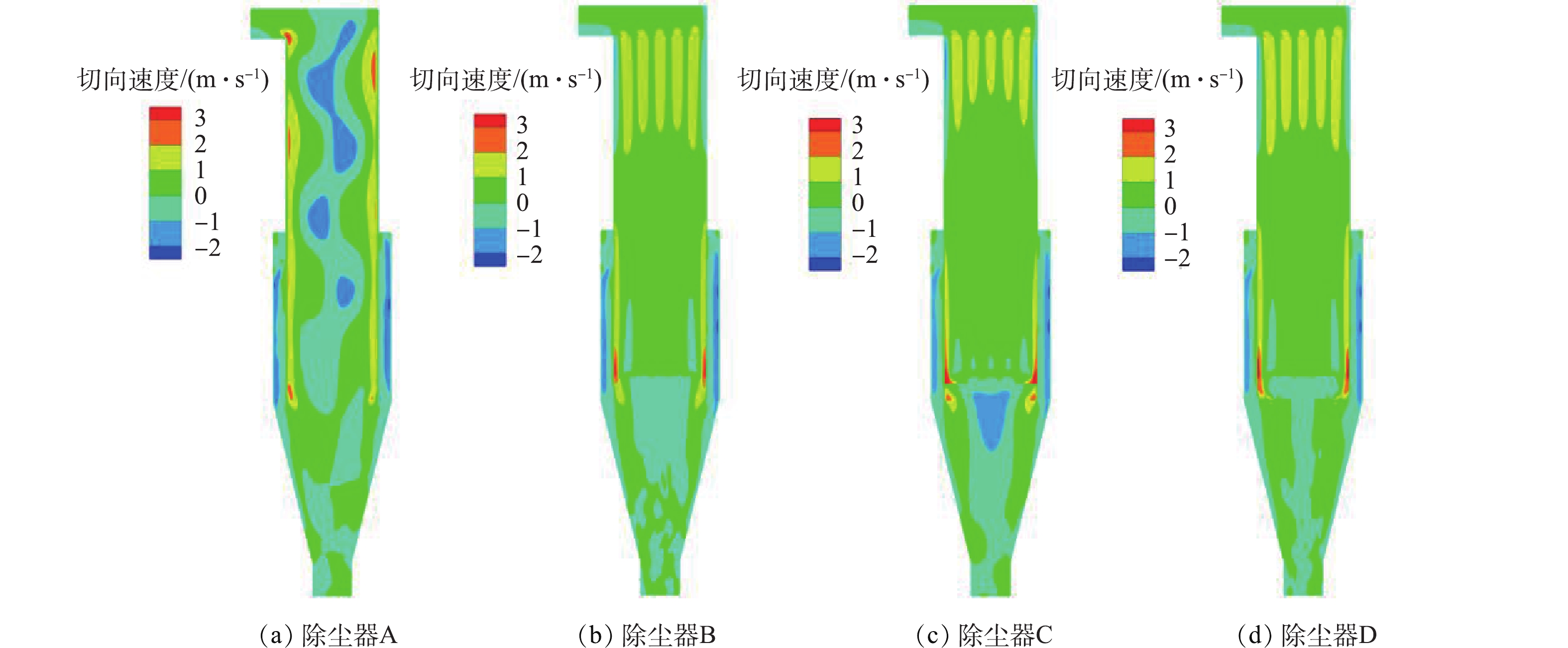

图6和图7为除尘器A、B、C、D在y=0截面和参考截面的切向速度分布。在旋流速度的3个分量中,切向速度占主导,颗粒随气流高速旋转,在离心力的作用下被抛向壁面,从而与气体分离。切向速度在外筒和锥斗内表现为典型的双涡结构,被称作兰金涡旋[1]。最大切向速度出现在外筒顶端且接近入口风速,在轴向上变化很小,这在其他研究中也有类似的报道[13-14]。在图7中,除尘器C的导流板下方出现了逆向旋流,这在图5中表现为绕过导流板进入锥体后又返回内筒的气流。在内筒入口截面,除尘器C达到的最高切向速度低于除尘器B,而除尘器D的切向速度稳定为0。这是由于除尘器C的导流板使旋流开始向中间扩散,除尘器D的开孔挡板迫使气流只能从开孔中穿过。在气流将要进入滤袋前的区域,除尘器B、D表现为旋流,而除尘器C的旋流消失,切向速度接近0,气流流速稳定,这能使滤袋的寿命更长。

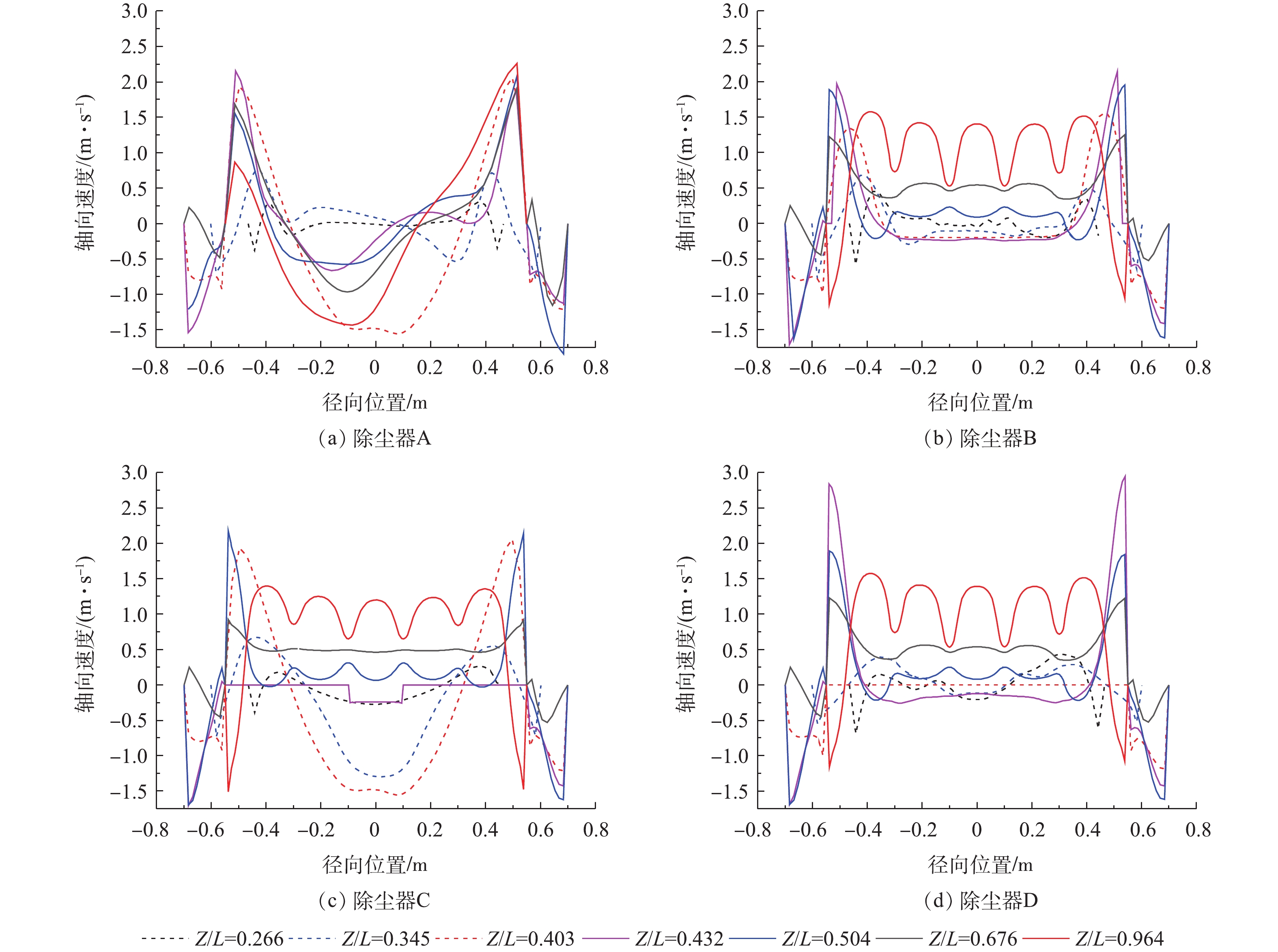

图8和图9为除尘器A、B、C、D在y=0截面和参考截面的轴向速度。轴向速度也是影响除尘器去除率的重要因素。轴向气流主要包括除尘器壁面附近向下的气流和核心处向上且夹带部分颗粒的气流。在除尘器B、C、D中,受滤袋影响,还出现了从内筒下方到排尘口的向下气流,这与SON等[2]的研究结果相近。而在除尘器C的导流板下方附近,这股气流更为强烈。在外筒顶端存在少量轴向速度向上的气流,这是由于此处流动缓慢、静压较低,因而气流会流向低压区域,形成纵向涡旋,部分颗粒随着气流在此处形成死循环[15];在锥斗段,除尘器B的锥斗下方出现许多上下反复波动的干扰旋流的小型纵向涡旋,在排尘口附近,涡旋依旧存在,二次夹带使底部的粉尘重新进入除尘器,这些情况在除尘器C、D内得到改善。气流在除尘器B、C、D的内筒上端内壁面附近转变为向下的轴向速度,这是由气流撞到花板而向下流动导致的。滤袋内部轴向速度高于滤袋外部轴向速度,随着高度的增加,整体的轴向速度也在增大。除尘器C在滤袋内外侧轴向速度差较小,除尘器D在滤袋区域整体的轴向速度较低,这表明导流板有利于滤袋区域气流的平稳流动,开孔挡板能够降低滤袋区域气流流速。

-

图10为除尘器A、B、C、D在y=0截面和Z/L=0.676(进口处)截面的静压图。静压主要受除尘器结构的影响,外筒和锥斗内静压变化相似:在入口夹角处最大,由壁面向中心不断递减,在轴向上的变化远小于径向。在内筒中,滤袋外的静压在除尘器C内呈现在径向上由外往内、在轴向上由两端向中间逐渐减小的趋势,在除尘器B、D内,则在轴向上两端略高;滤袋内的静压在除尘器C呈现与滤袋外部区域一样的变化趋势,在除尘器B、D中表现较为稳定。除尘器内静压变化趋势的不同导致滤袋内外侧压差的不同,在滤袋内外侧压差的变化顺序为除尘器C<除尘器D<除尘器B,同时除尘器C滤袋中部的滤袋内外侧压差比滤袋两端的滤袋内外侧压差降低了近50%。滤袋内外侧静压差的降低意味着过滤阻力降低,这样有利于过滤和节能。

由图5~图10可知,除尘器C的流场分布最为均匀。同时发现,除尘器A中存在一股向下内旋,其旋流轴线不断在除尘器轴线两侧偏移,气体不断相互挤压,这可能导致除尘器结构不稳定[16],而设置了滤袋的复合除尘器则不存在这种情况。

-

除尘器的压降是进口与出口之间的压差。压降的变化会对除尘器能耗产生影响,图11反映了除尘器A、B、C、D在入口风速为8~16 m·s−1时的压降变化情况。在图11的入口风速范围内,除尘器B、C、D的压降为200~800 Pa。入口风速提高引起涡流强度的增大,这会加大流体之间以及流体与除尘器之间的摩擦,从而导致压力损失增加[17],无滤袋的除尘器A压降远低于除尘器B、C、D。在速度较低时,除尘器B、C的压降相近,除尘器D的压降略低。随着入口风速的增加,除尘器D的开孔挡板和除尘器B锥斗下方较多的二次流导致的压力损失不断增大,除尘器B、D的压降逐渐高于除尘器C。

-

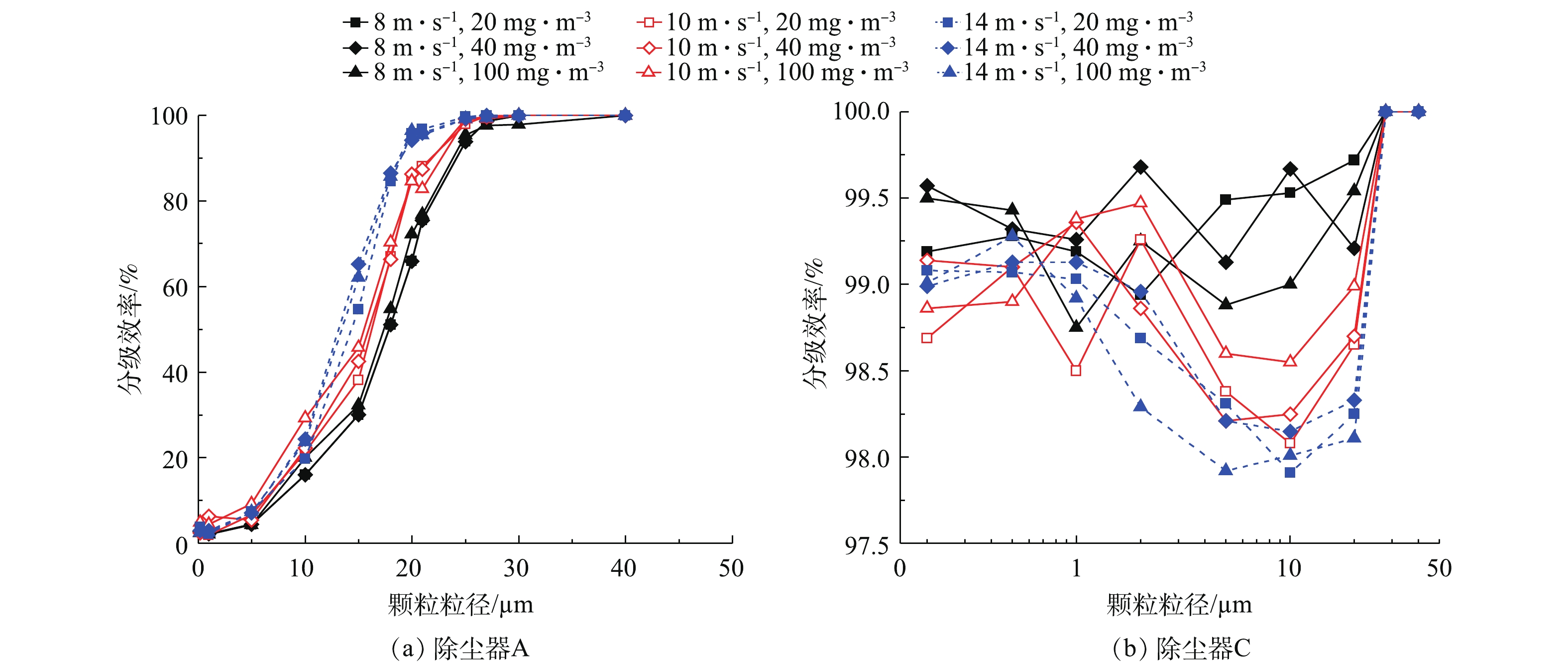

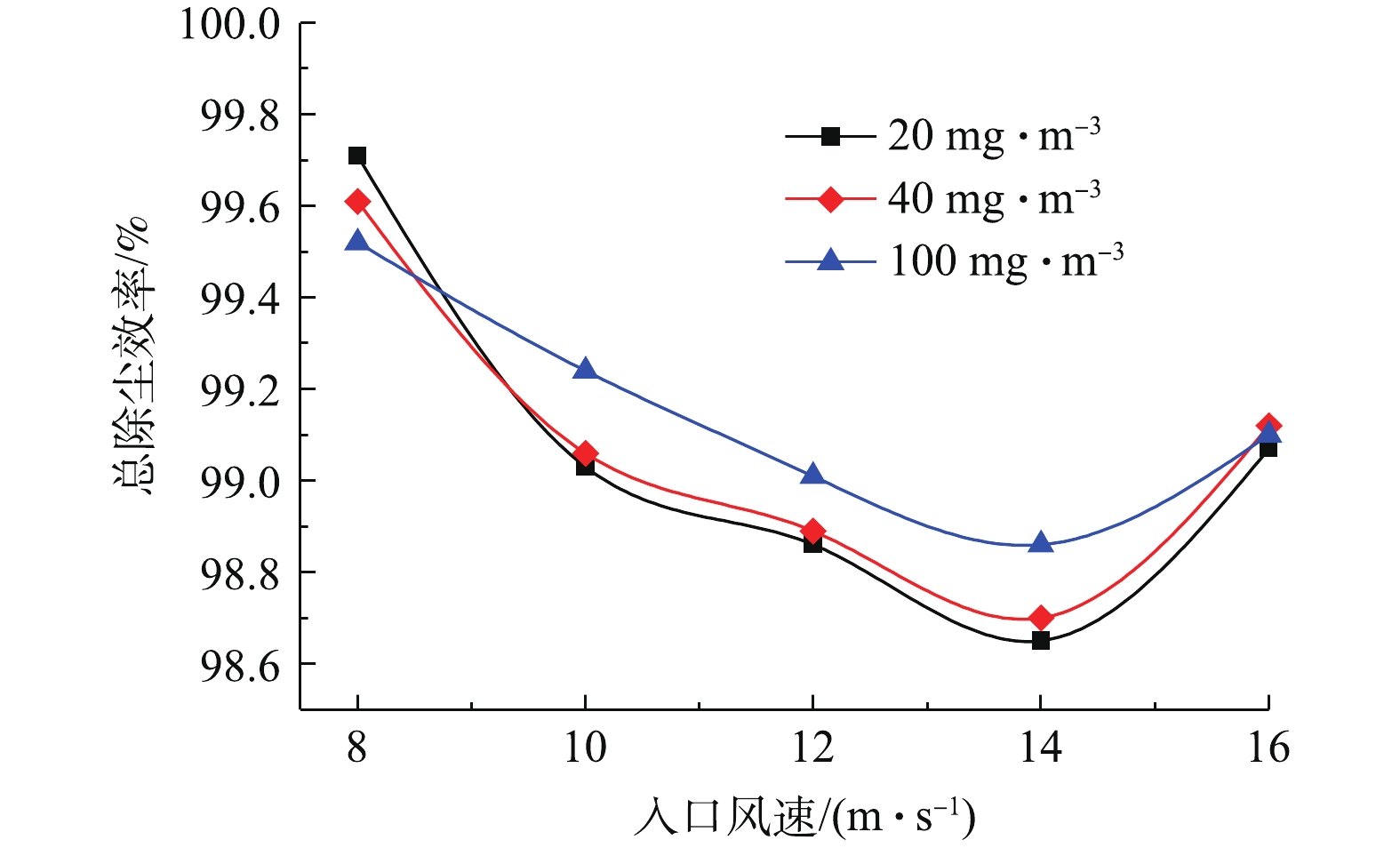

考虑到超低排放的要求,把本研究的复合除尘器用作二级除尘使用,设置了3个入口粉尘浓度(即上一级净化装置的出口浓度)。图12反映了除尘器A、C在入口风速分别为8、10、14 m·s−1,入口粉尘浓度分别为20、40、100 mg·m−3时的分级效率,图13反映了除尘器C在不同入口风速下,入口粉尘浓度分别为20、40、100 mg·m−3时的总除尘效率。

除尘器A的分级效率曲线近S形,其切割粒径为14~19 μm。对于粒径<15 μm的颗粒,去除率低于60%;对于粒径>25 μm的颗粒,去除率高于90%。滤袋的各种过滤效应对于不同粒径的粉尘作用效果不同[18],因此,对于粒径<30 μm的颗粒,除尘器C的去除率为97.8%~99.5%;对于粒径>30 μm的颗粒,除尘器C可以完全捕集。对比除尘器A、C对各粒径颗粒的去除率可推断,除尘器C内粒径>25 μm的颗粒基本被外部的旋风除尘器去除,剩下的较细颗粒物则进入内筒,被滤袋过滤。粉尘浓度增高时,对应的去除率也较高,这是由于颗粒存在团聚效应,高浓度下形成更多易于被去除的颗粒团[19]。入口风速增大(8~14 m·s−1)时,颗粒受到的离心力相应变大,除尘器A的各粒径粒子去除率则增高,由于过滤速度提高不利于滤袋的运行[20],故导致除尘器C的总除尘效率和各粒径粒子去除率降低;当入口风速增加到16 m·s−1时,外部结构去除了更多的颗粒,除尘器C的总除尘效率略微提高。综上所述,低入口风速下总除尘效率和细微颗粒去除率更高,能耗也较低。通过模拟可以看到,在入口风速为14 m·s−1、粉尘浓度为20 mg·m−3时,除尘器C的除尘效率最低,为98.6%,对应的出口浓度为0.28 mg·m−3,可以满足超低排放的要求。

2.1. 气流流线

2.2. 速度

2.3. 静压

2.4. 入口速度与压降

2.5. 分级效率和总除尘效率

-

1)在滤袋前设置导流板有利于气流在内筒中分布均匀、流速平缓,能够降低滤袋内外侧压差,并且在入口风速较高的情况下,能够减少压降,降低能耗。

2)旋风-滤袋复合除尘器能够降低滤袋负荷,延长滤袋寿命。除尘器C对各粒径颗粒的去除率高于97.8%,总除尘效率高于98%,可作为超低排放目标的二级除尘使用。粉尘浓度的变化对除尘效率影响较小,低入口风速下总除尘效率和细微颗粒的去除率更高,能耗也较低。

3)气流对外围滤袋下端的冲击较高,对滤袋上端也存在一定冲击,因此,可以进一步采取措施加固滤袋两端,如更换或者外部包裹多孔陶瓷等耐磨坚固的滤料。

下载:

下载: