-

生物制药废水是一种难处理的高浓度有机废水,具有成分复杂、冲击负荷大、有机物含量高、可生化性差、色度深和毒性强等特点[1]。视生产工艺不同,生物制药废水往往还含有高浓度氨氮。膜生物反应器(membrane bioreactor,MBR)因其具有污泥停留时间长、污泥产量低和出水水质好等优点[2],近年来已成为生物制药废水处理领域的首选工艺之一。然而,膜污染一直是制约MBR工艺广泛应用的主要因素。

已有研究[3]表明,优化操作条件、改善混合液特性和开发膜材料等方法可缓解膜污染进程。其中,添加填料是一种能够快速、有效改善混合液特性并缓解膜污染的方法[4]。HAZRATI等[5]在研究传统MBR(R1)与膜区添加悬浮聚乙烯填料的MBR(R2)对膜污染特征的影响时发现,在反应器运行第95天,R1和R2的跨膜压差(trans-membrane pressure,TMP)分别为12 kPa和5 kPa,滤饼层阻力分别为12.15×1011 m−1和5.83×1011 m−1,污泥颗粒平均粒径分别为44 μm和119 μm。这表明膜区添加填料能够增大污泥粒径,降低滤饼层阻力,进而改善膜污染。RAFIEI等[6]在生物包封膜生物反应器(bio-entrapped membrane bioreactor,BE-MBR)膜区添加聚氨酯填料,发现BE-MBR的膜运行周期为21 d,其溶解性微生物代谢产物(soluble microbial products, SMP)中蛋白质的浓度为33.1 mg·L−1,比传统MBR(conventional membrane bioreactor, CMBR)膜运行周期延长17 d,蛋白质浓度降低164.6 mg·L−1。这表明膜区添加填料能够降低膜表面蛋白质的黏附,延长膜运行周期。朱逸舟等[7]将悬浮聚乙烯填料加入到A2O-MBR的好氧区中,发现有机负荷从0.66 kg·(m3·d)−1增加至1.98 kg·(m3·d)−1时,出水COD、

NH+4 -N和TN浓度均能保持在50、5和15 mg·L−1以下,系统表现出良好的运行稳定性。填料种类及其添加方式对缓解膜污染有重要作用。CHENG等[8]指出,悬浮型填料具有流化效果好、比表面积大、孔隙率高、附着生长的生物量较多、耐受反应器中有毒化合物的能力强等优点,在MBR中应用广泛。宋咏等[9]认为,软质聚氨酯悬浮填料和硬性聚乙烯悬浮填料能够有效降低膜阻力,提高膜组件的过滤性能。现阶段,填料添加方式主要为单一好氧区添加[10]或膜区添加[11],不同添加方式(好氧区和膜区同时添加填料)对污染物去除特征、运行稳定性和膜污染特征的相关研究鲜见报道。本研究旨在开发一种复合型悬浮生物膜强化膜生物反应器(hybrid suspended biofilm enhanced-membrane bioreactor,HSBE-MBR),通过在MBR不同区域(缺氧区、好氧区和膜区)添加悬浮填料,分析典型污染物的去除特征、SMP和胞外聚合物(extracellular polymeric substances,EPS)浓度及其组分变化、污泥粒径分布特征等,研究填料添加方式对处理效果、运行稳定性及膜污染特征的影响,分析膜污染机理,优化填料添加方式,为生物制药废水实现稳定化处理提供参考。

全文HTML

-

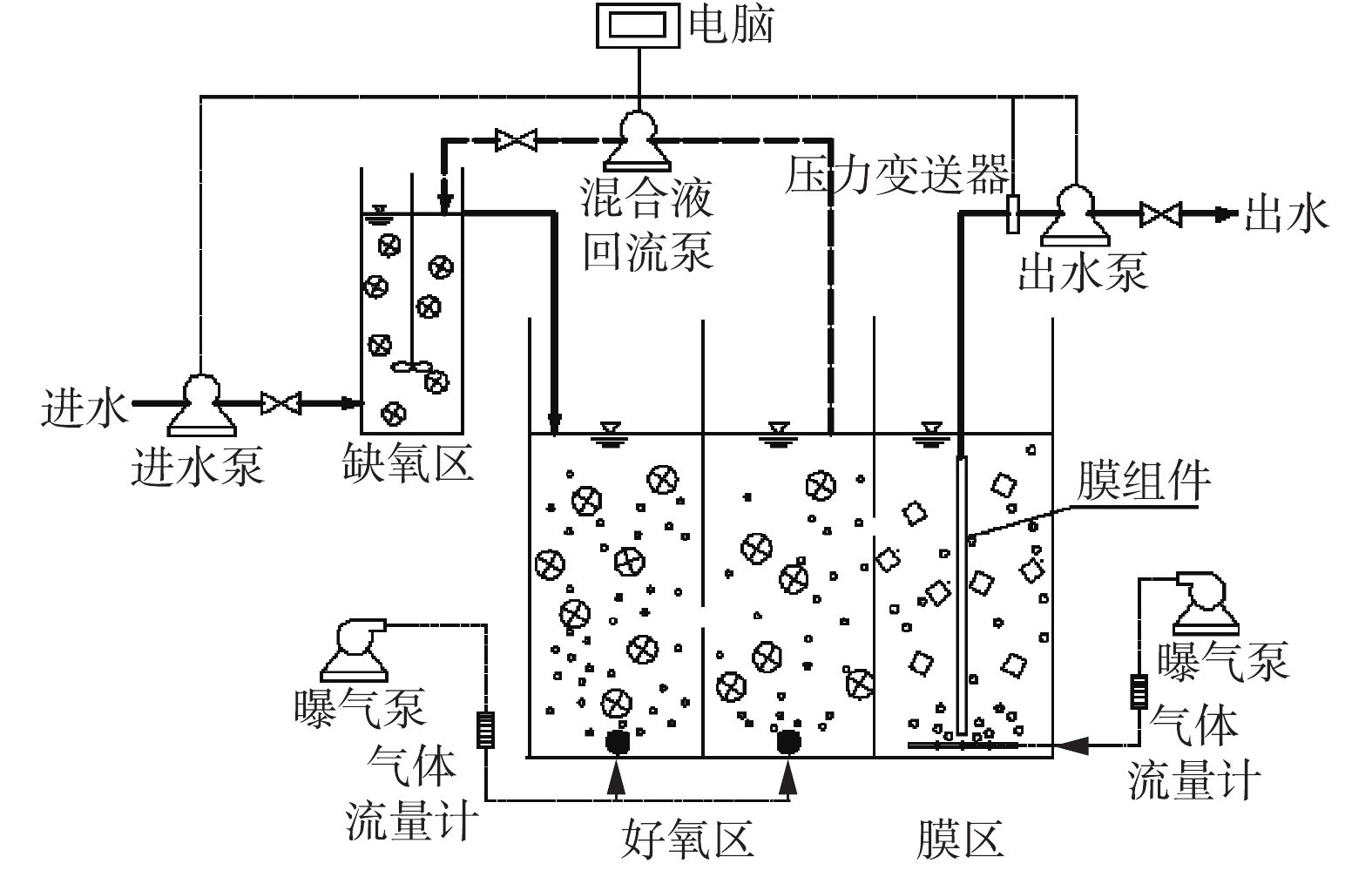

HSBE-MBR总有效容积为60 L,包括缺氧区10 L,好氧区33 L,膜区17 L。膜组件采用平板式微滤膜(Kubota,日本),有效过滤面积为0.11 m2,平均孔径为0.4 μm。在缺氧区设搅拌装置,搅拌强度为10 W·m−3,以保证填料处于悬浮态;好氧区和膜区分别设微孔曝气装置和大气泡曝气装置,曝气强度为2.73 m3·(m2·min)−1,保持溶解氧浓度在2~5 mg·L−1,以实现冲刷膜表面,减缓膜污染并使填料处于悬浮态的目的。出水泵与膜组件之间设压力变送器,用以记录运行过程中TMP的变化,当TMP达到−35 kPa时,系统停止运行。膜组件清洗分为2步:先使用海绵擦拭膜表面进行物理清洗;再将膜组件依次浸泡至0.5%柠檬酸和0.2%次氯酸钠溶液中完成化学清洗,浸泡时间分别为8 h和20 h。HSBE-MBR实验装置如图1所示。

-

本研究选取了2种悬浮生物膜填料,分别为SPR-1型悬浮填料和聚氨酯填料。SPR-1型悬浮填料为直径25 mm,高10 mm的多孔柱体,比表面积为500 m2·m−3,密度为0.96 g·cm−3,生物膜厚度约为0.3~0.5 mm;聚氨酯填料为10 mm×10 mm×10 mm的立方体,孔隙率为98%,密度为0.45 g·cm−3,生物膜厚度约为1~1.5 mm。

HSBE-MBR以连续进水、间歇出水的方式运行,运行/间歇时间为9 min/6 min,水力停留时间(hydraulic retention time,HRT)为72 h,膜通量为12.5 L·(m2·h)−1,混合液回流比为400%。HSBE-MBR按照2种工况运行:在工况1下,在缺氧区和好氧区添加SPR-1型悬浮填料,添加比例为35%(填料体积/各区体积),运行时间为120 d;在工况2下,在缺氧区和好氧区添加SPR-1型悬浮填料,且在膜区添加聚氨酯填料(添加比例为35%),运行时间为173 d。实验原水取自陕西某生物制药厂废水调节池,主要水质指标见表1。

-

TCOD、氨氮(

NH+4 -N)、硝酸盐氮(NO−3 -N)、亚硝酸盐氮(NO−2 -N)、MLSS和MLVSS等常规指标采用文献中的方法[12]测定。膜区样品由膜区污泥混合液在4 000 r·min−1下离心6 min,并取上清液,过0.45 µm滤膜,滤出后得到。SMP、松散结合EPS (loosely bound-EPS, LB-EPS)和紧密结合EPS(tightly bound-EPS, TB-EPS)的提取采用加热法[13],蛋白质和多糖的测定分别采用Folin-酚试剂法[14]和蒽酮-硫酸法[15]。污泥粒径的测定采用激光粒度仪(LS230/SVM+,美国)。SMP和EPS中荧光物质和有机物官能团的测定分别采用荧光分光光度计(excitation-emission matrix, EEM)(F-7000,日本)和傅里叶变换红外光谱仪(fourier transform infrared spectroscopy, FTIR)(IS50,美国)。膜阻力计算方法[16]见式(1)和式(2)。式中:J为膜通量,m3·(m2·s)−1;∆P为膜两侧的压力差,Pa;μ为透过液黏度,Pa·s;Rt为总阻力(当系统TMP达到−35 kPa时进行测定),m−1;Rm为膜固有阻力(膜在清水中测定),m−1;Rp为膜孔阻力(膜去掉滤饼层后在清水中测定),m−1;Rc为滤饼层阻力(由Rt−Rm−Rp计算而得),m−1。

1.1. 实验装置

1.2. 运行条件及实验原水水质

1.3. 测定与分析方法

-

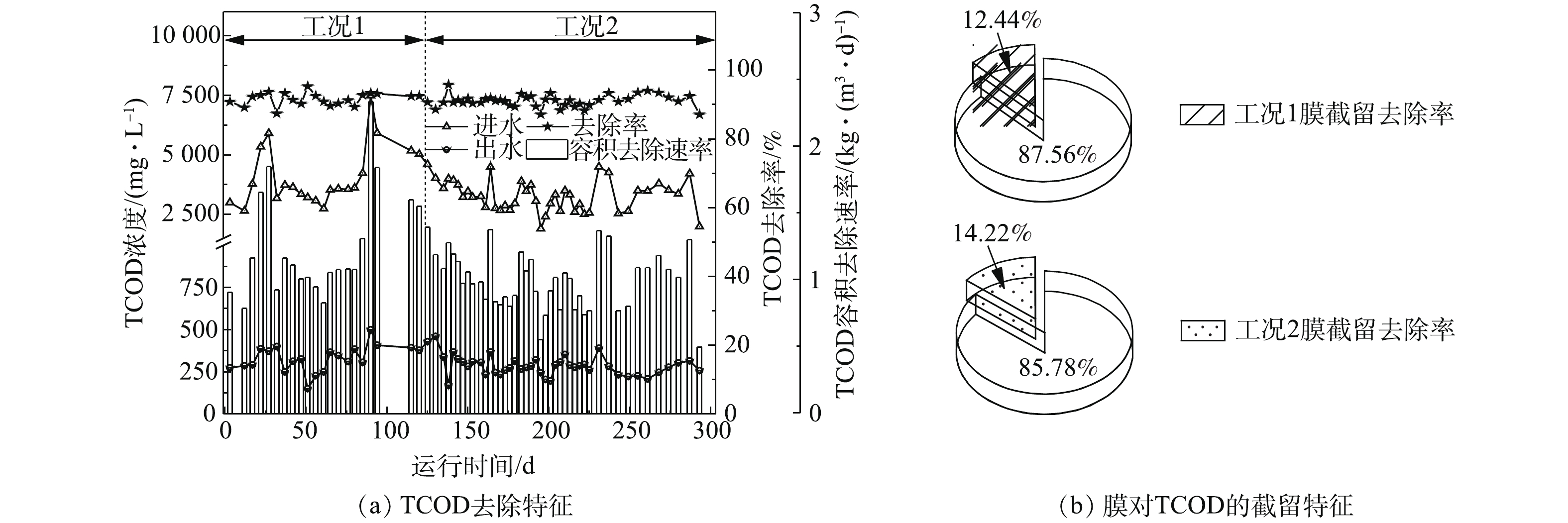

1) TCOD去除特征及运行稳定性。由图2可知:在工况1下,进水TCOD为(4 034.49±1 238.23) mg·L−1,出水TCOD为(327.06±76.26) mg·L−1,其去除率为(91.61±1.84)%,平均容积去除速率为1.24 kg·(m3·d)−1;在工况2下,进水TCOD为(3 317.34±698.34) mg·L−1,出水TCOD为(288.93±59.25) mg·L−1,去除率为(91.09±1.75)%,平均容积去除速率为1.01 kg·(m3·d)−1。上述结果表明:HSBE-MBR出水水质稳定,在其缺氧区、好氧区和膜区添加填料对TCOD的去除率均可达到90%以上,运行稳定性良好;TCOD平均容积去除速率下降了18.54%,其原因在于,工况2中的进水TCOD明显低于工况1。进一步分析发现,在2种工况下,膜对TCOD的去除贡献率分别为(12.44±4.19)%和(14.22±7.59)%,在膜区添加填料后,膜截留对TCOD的去除贡献率略有增加。

KHAN等[17]分别利用CMBR和膜区添加聚氨酯填料的附着型MBR(attached growth MBR,AG-MBR)来处理模拟高强度生活污水的人工合成废水,在进水COD为1 000 mg·L−1的条件下,COD去除率均为90%以上,CMBR与AG-MBR出水COD均保持在20 mg·L−1左右。HU等[10]通过在膜表面设置可拆卸有孔挡板,研究了聚乙烯填料与膜组件直接或间接接触对水质去除作用的不同影响,结果表明,当反应器中的进水COD为280 mg·L−1时,不同条件下的COD去除率均达90%以上,膜区添加填料对TCOD的去除性能无显著影响。由此可知,MBR本身对COD的去除率较高,因此,投加填料后的HSBE-MBR对TCOD去除率的提高并不十分明显。

由图2还可知:在工况1下,TCOD进水平均有机负荷由1.15 kg·(m3·d)−1(第32~85天)升高至2.49 kg·(m3·d)−1(第90天),即在有机负荷提高至2.17倍时,出水TCOD为302.41 mg·L−1和499.19 mg·L−1,对应的去除率为91.21%和93.33%;在工况2下,TCOD进水平均有机负荷由0.88 kg·(m3·d)−1(第216~225天)升高至1.5 kg·(m3·d)−1(第231天),即在有机负荷提高至1.69倍时,出水TCOD为279.41 mg·L−1和389.60 mg·L−1,去除率为89.44%和91.33%。上述结果表明,有机负荷提高至2.17倍(工况1)和1.69倍(工况2)时,出水TCOD去除率均维持在89.44%~93.33%,在2种不同添加方式下,TCOD的去除稳定性均较好。

2)

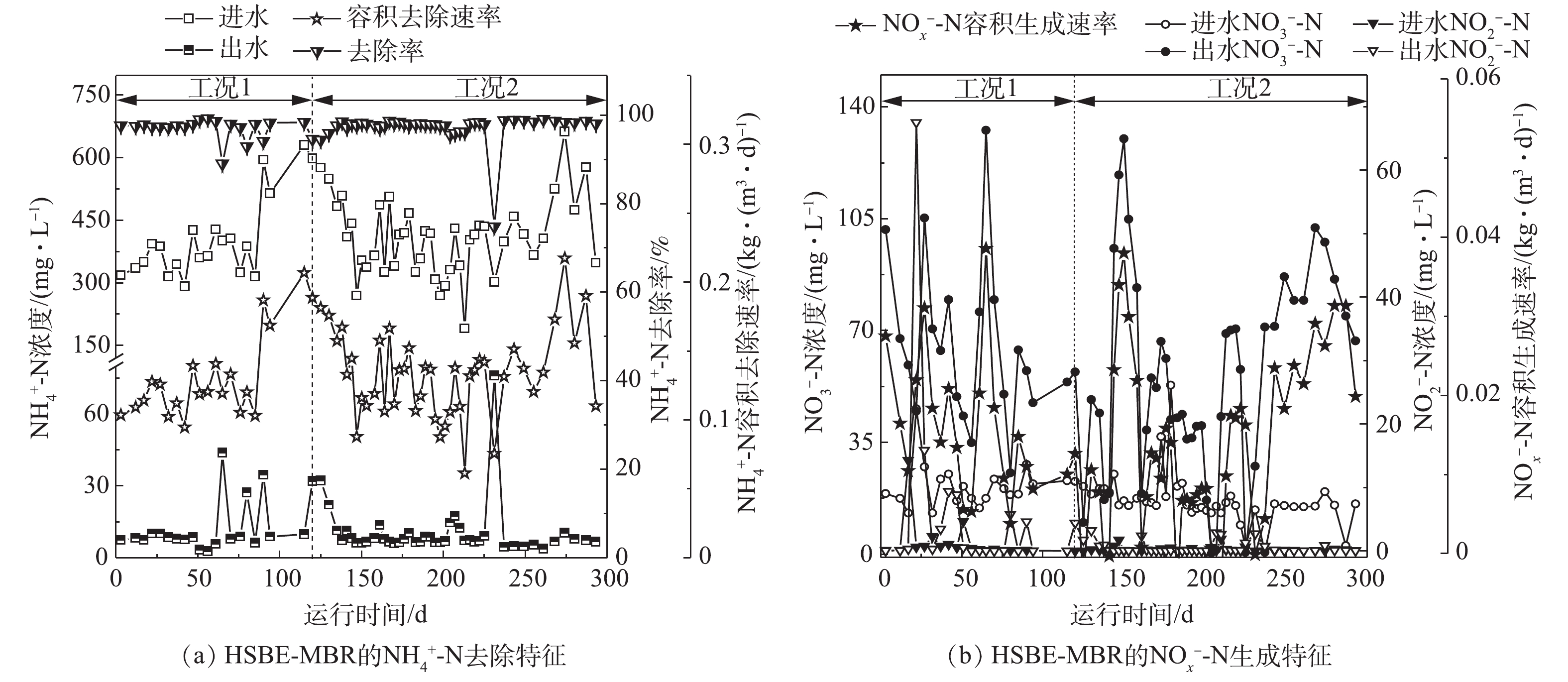

NH+4 -N去除特征、NO−x -N生成特征及运行稳定性。由图3可知:在工况1下,进水NH+4 -N浓度为(394.49±88.55) mg·L−1,出水NH+4 -N浓度为(11.74±10.42) mg·L−1,去除率为(97.08±2.34)%;在工况2下,进水NH+4 -N浓度为(413.13±95.61) mg·L−1,出水NH+4 -N浓度为(10.89±11.63) mg·L−1,去除率为(97.24±3.58)%。在2种工况下,NH+4 -N平均容积去除速率均为0.13 kg·(m3·d)−1。上述结果表明,膜区添加填料对NH+4 -N去除率和平均容积去除速率无显著影响。其原因在于,HSBE-MBR由缺氧区、好氧区和膜区组成,膜的高效截留作用使世代较长的硝化细菌在反应器中充分发挥其作用[18],系统中硝化细菌数量多且活性较高,硝化作用彻底,膜区添加填料并未显著增加硝化细菌的数量。由图3可知:在工况1下,第115天时,进水

NH+4 -N平均浓度由396.95 mg·L−1(第47~94天)增至630.22 mg·L−1,平均浓度提高至1.59倍,但NH+4 -N去除率仍保持稳定(96.51%和98.45%),出水浓度分别为14.36 mg·L−1和9.76 mg·L−1;同样,在工况2下,第274天时,进水NH+4 -N平均浓度由409.23 mg·L−1(第237~268天)升高至662.29 mg·L−1,平均浓度提高至1.54倍,但NH+4 -N去除率仍保持稳定(98.88%和98.43%),出水NH+4 -N浓度分别为4.60 mg·L−1和10.37 mg·L−1。可以看出,在2种不同添加方式下,NH+4 -N的去除稳定性均较好。由图3还可知:在工况1下,出水中

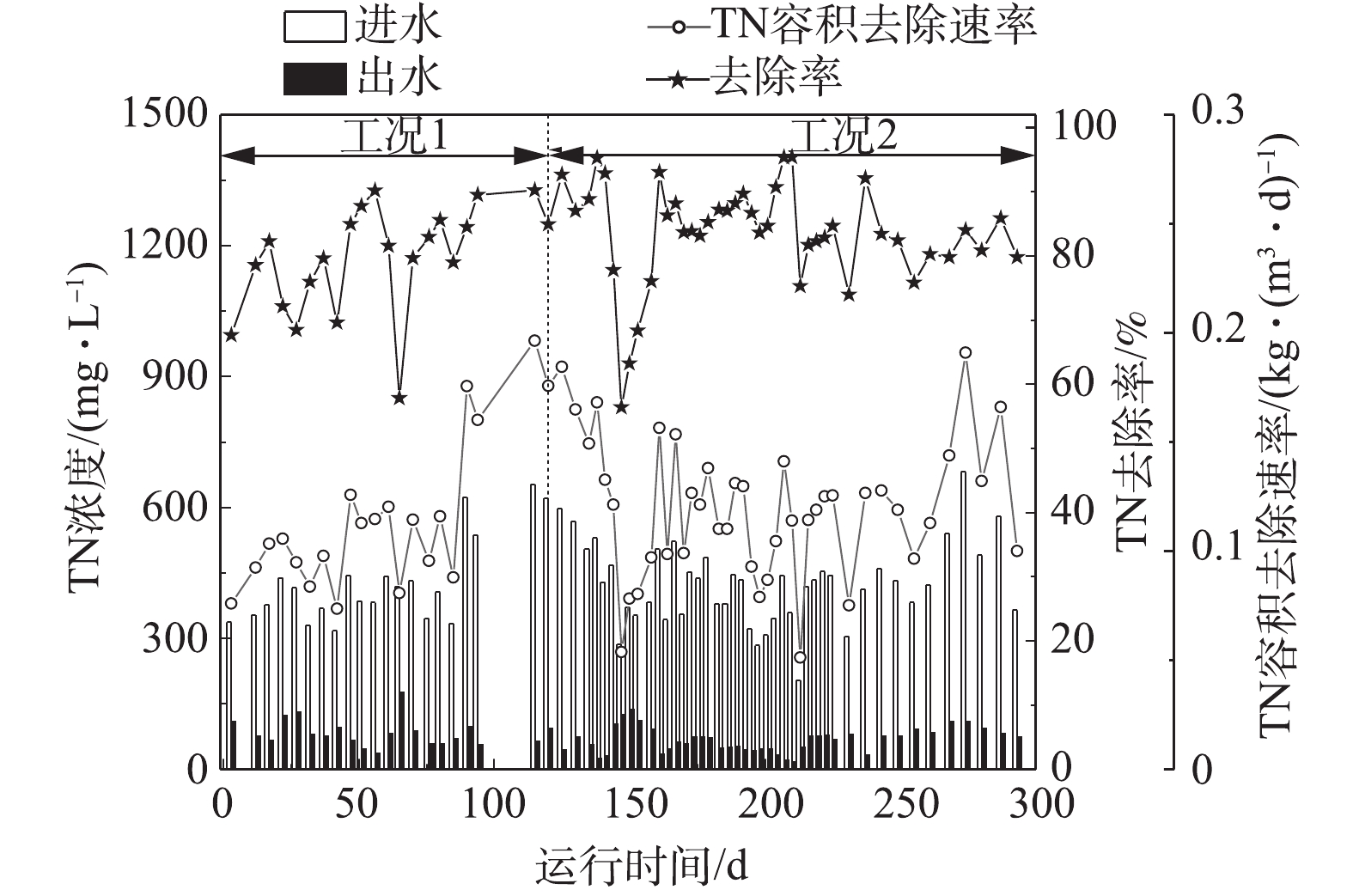

NO−3 -N浓度为(65.29±24.98) mg·L−1,NO−2 -N浓度为(5.85±14.77) mg·L−1,NO−x -N平均容积生成速率为0.02 kg·(m3·d)−1;在工况2下,出水中NO−3 -N浓度为(55.94±31.07) mg·L−1,NO−2 -N浓度为(0.62±1.06) mg·L−1,NO−x -N平均容积生成速率为0.01 kg·(m3·d)−1。上述结果表明,在2种填料添加方式下,出水NO−x -N主要以NO−3 -N形式存在,且膜区添加填料削弱了反应器中NO−x -N的累积。这是因为添加填料后,当溶解氧从填料表面向其内部扩散时,会在其内部形成缺氧微环境,有助于提高反应体系的反硝化能力。与工况1相比,工况2中的出水NO−3 -N浓度减少了16.71%,NO−x -N平均容积生成速率降低了50%。较工况1而言,工况2在膜区添加填料后,除好氧区外,膜区也出现缺氧的微环境,NO−x -N的反硝化效果进一步增强,HSBE-MBR中NO−x -N的累积减弱。3) TN去除特征及运行稳定性。由图4可知:在工况1下,进水TN浓度为(417.08±89.72) mg·L−1,出水TN浓度为(82.87±31.75) mg·L−1,TN去除率为57.84~90.25%,平均去除率为79.40%,平均容积去除速率为0.11 kg·(m3·d)−1;在工况2下,进水TN浓度为(430.34±96.18) mg·L−1,出水TN浓度为(67.45±27.94) mg·L−1,TN去除率为73.95~95.41%,平均去除率为83.66%,平均容积去除速率为0.12 kg·(m3·d)−1。可以看出,工况2中TN去除率和平均容积去除速率分别比工况1提高了4.26%和8.33%。KURITA等[11]通过比对CMBR与在膜区添加悬浮填料的MBR对TN去除性能的影响发现,添加填料后TN去除率为19.2%,与CMBR相比,TN去除率提高了10%以上,TN去除性能明显优于CMBR。NGUYEN等[19]研究发现,膜区添加悬浮填料后,出水TN浓度仅为7.0 mg·L−1,TN去除率可达64.0%。上述结果表明,工况1中的TN去除性能良好,工况2进一步了提高HSBE-MBR的脱氮能力。IVANOVIC等[20]的研究表明,较高的TN去除率主要归因于同步硝化/反硝化作用(simultaneous nitrification/denitrification, SND),而填料表面好氧及内部缺氧的环境,恰好提供了SND需要的良好条件。因此,在好氧区和缺氧区添加填料后,填料SND作用逐渐形成,膜区添加填料后,进一步增大了SND作用发生的体积,使脱氮能力得到强化。

此外,在2种不同添加方式下,MBR对于TN的去除均较为稳定。这表现在第90天时,进水TN平均浓度由393.23 mg·L−1(第51~85天)升高至623.56 mg·L−1,提高至1.59倍,去除率和出水浓度分别为84.48%和96.77 mg·L−1,与之前的80.35%和77.26 mg·L−1相比,基本持平;同样,在第274天时,进水TN平均浓度由424.87 mg·L−1(第225~268天)升高至681.86 mg·L−1,提高至1.60倍,去除率和出水浓度分别为84.03%和108.87 mg·L−1,与之前的82.24%和72.52 mg·L−1相比,基本持平。

-

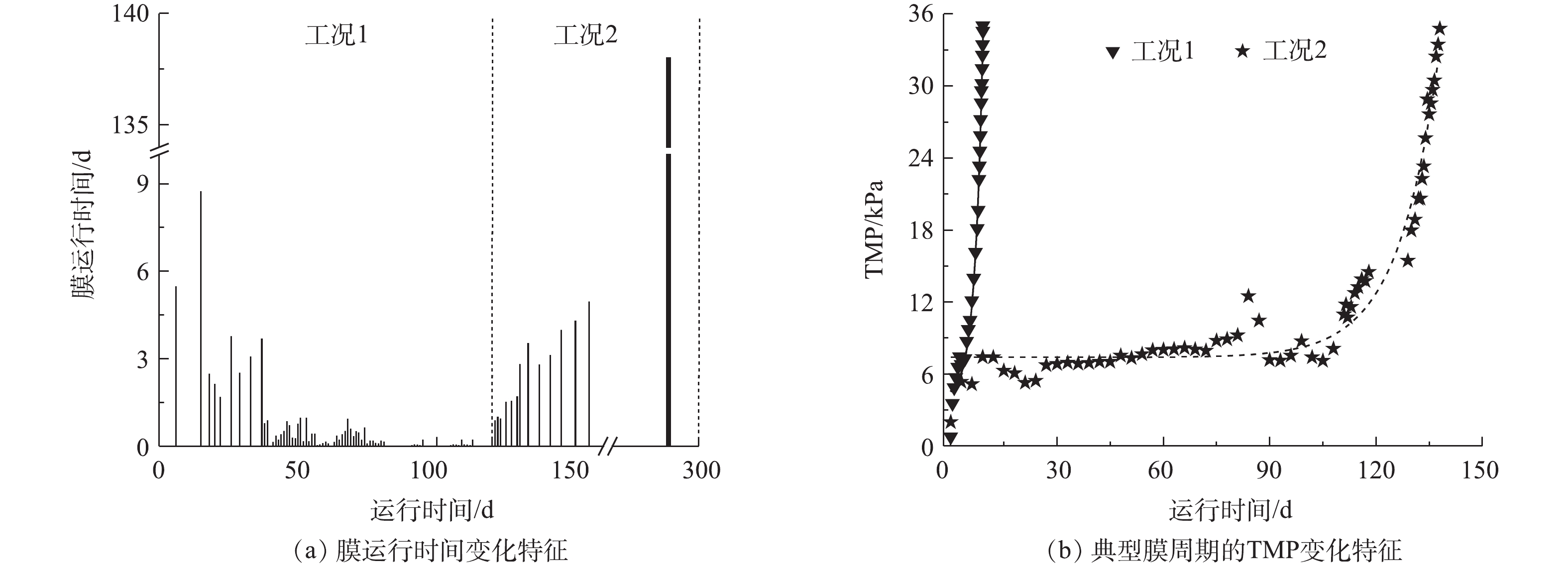

由图5可知:工况1下,膜运行时间为0.02~8.71 d;工况2下,膜运行时间为0.26~138 d。膜区添加填料后,膜运行时间最长可达138 d,比工况1的最长膜运行时间增加15倍。由图5还可知:工况1下,TMP在8.17 d内迅速增加至35 kPa;工况2下,前9 d时,TMP增长较快,由2.01 kPa上升到7.41 kPa,但在第10~110天时,TMP增长缓慢,第111~138天时,TMP从10.72 kPa跃升至35 kPa。因此,膜区添加填料能够显著控制膜污染进程。

由表2可知:在2种工况下,滤饼层阻力(Rc)在总阻力(Rt)中的占比分别为94.7%和90.1%,故总阻力均以滤饼层阻力为主,膜污染机理为滤饼层污染,工况2中的滤饼层阻力占比较工况1下降了4.60%;此外,工况2中的滤饼层阻力较工况1降低了8.07%。上述结果表明,膜区填料对膜表面直接的冲刷作用显著减缓了滤饼层的形成[21],进而增加了膜运行时间。

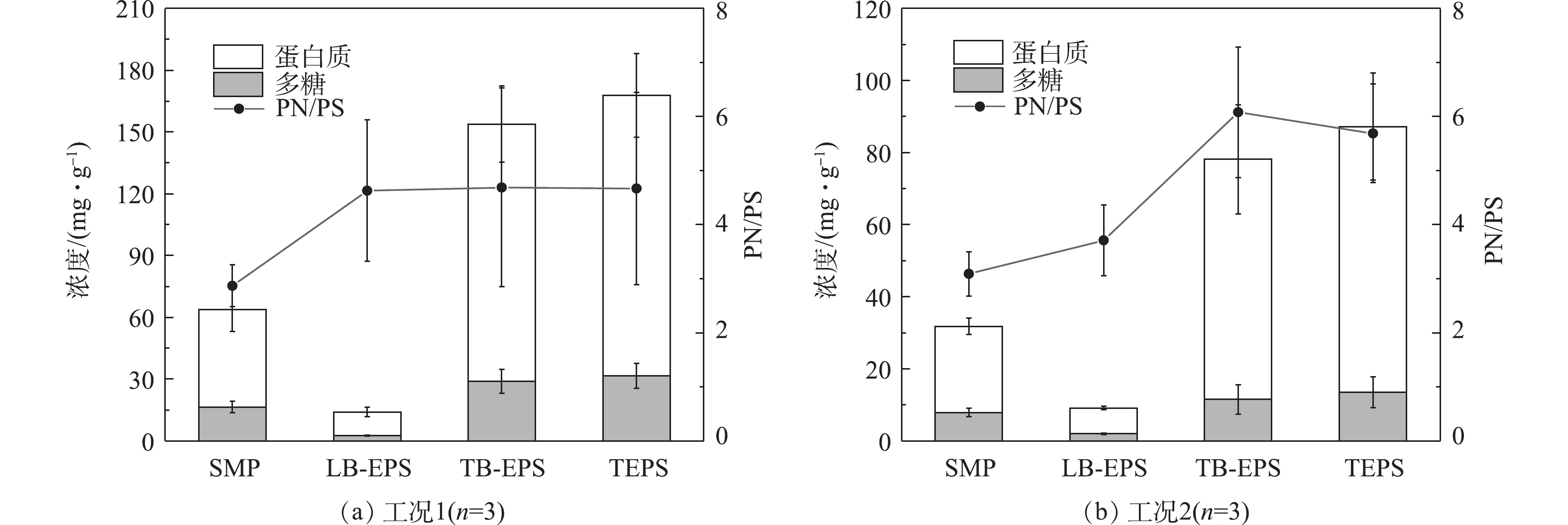

由图6可知:工况1下,SMP、LB-EPS、TB-EPS和TEPS的含量分别为(63.70±12.95)、(13.97±2.03)、(153.82±12.64)和(167.79±12.95) mg·g−1;在工况2下,SMP、LB-EPS、TB-EPS和TEPS的含量分别为(31.77±3.17)、(9.11±0.40)、(78.12±18.92)和(87.22±18.94) mg·g−1,与工况1相比,分别减少50.1%、34.7%、49.2%和48.02%。由此可以看出,HSBE-MBR的主要膜污染物质为SMP和TB-EPS,在膜区添加填料后,SMP、LB-EPS和TB-EPS含量均有所降低。

多糖和蛋白质被认为是组成SMP和EPS的主要成分[22]。由图6还可知:工况2下,SMP、LB-EPS、TB-EPS和TEPS中蛋白质浓度分别为(23.9±2.34)、(7.14±0.49)、(66.6±15.2)和(73.74±14.90) mg·g−1,与工况1相比,分别减少49.5%、37.5%、46.7%和45.90%;工况2下,多糖浓度分别为(7.87±1.24)、(1.96±0.24)、(11.5±4.09)和(13.48±4.29) mg·g−1,与工况1相比,分别减少52.1%、22.7%、60.2%和57.21%。上述结果表明:在2种不同工况下,SMP和EPS中占比最多的组分为蛋白质;多糖是对改善膜污染贡献最大的组分,蛋白质次之。其原因在于,膜区添加填料后附着生物量增大,导致多糖合成量减小。另外,还有一部分多糖会吸附在填料上,使得污泥混合液中的多糖含量显著降低[23]。进一步分析发现,2种工况下,SMP、TB-EPS和TEPS中蛋白质与多糖的比值(protein/polysaccharide, PN/PS)分别从2.87±0.39、4.69±1.78和4.67±1.78增加至3.09±0.41、6.08±1.21和5.69±0.91。膜区添加填料后提高了PN/PS值。HAN等[24]认为,PN/PS增大会增强SMP和EPS的疏水性,从而提高污泥絮体的吸附和沉降性能。因此,膜区添加填料有助于改善污泥混合液性质,进而缓解膜污染。

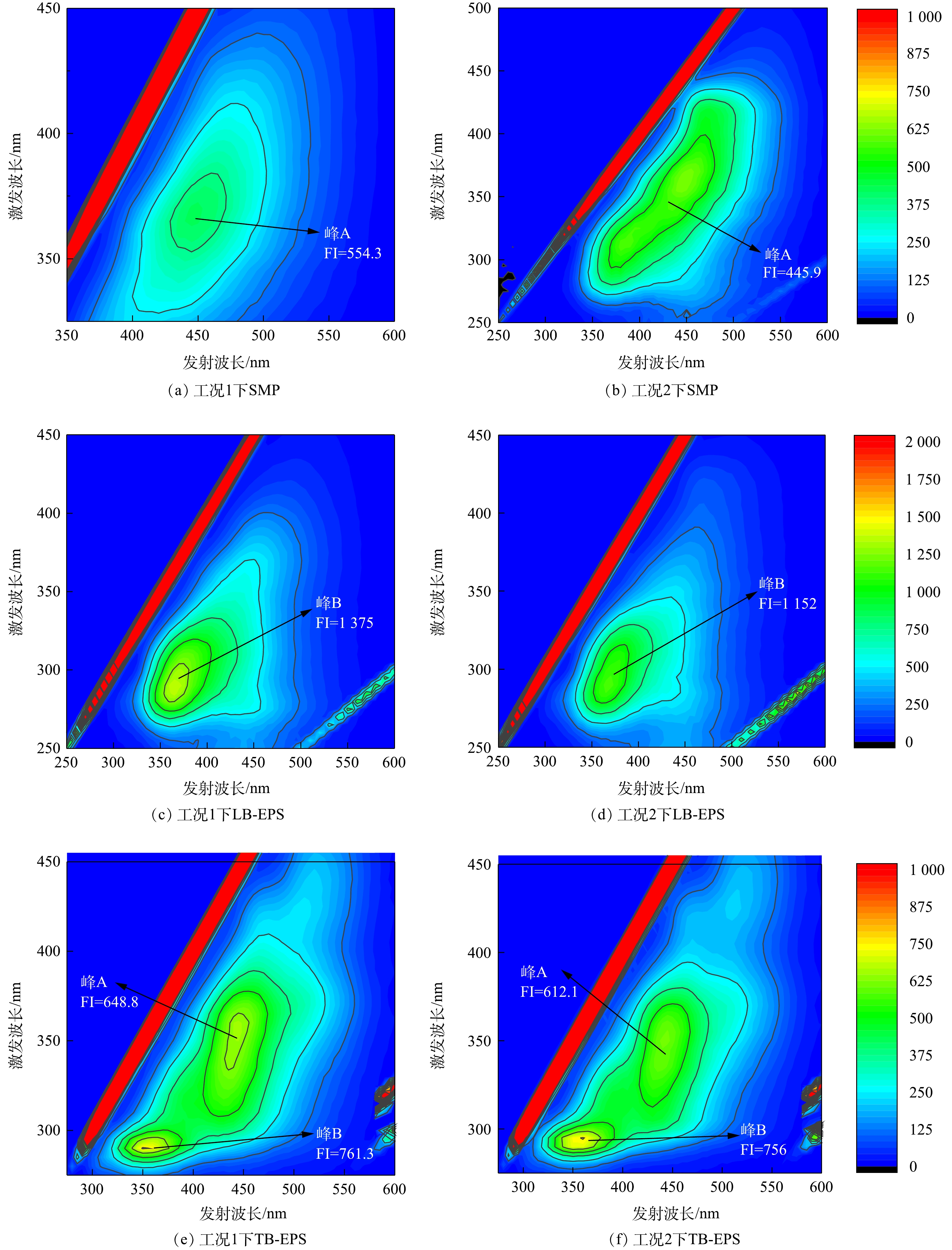

由图7可知,在SMP、LB-EPS和TB-EPS中,共检测到峰A和峰B 2种荧光峰。峰A(Ex/Em=(350~370) nm/(445~455) nm)的荧光主要由腐殖酸产生[25];峰B(Ex/Em=(290~295) nm/(360~365) nm)主要与蛋白质衍生的化合物有关,荧光主要由色氨酸类蛋白质产生[26]。在2种不同工况下,SMP、LB-EPS和TB-EPS的特征峰相似,这是因为2种工况运行的原水水质基本相同[27]。此外,SMP和LB-EPS各检出1种峰,而TB-EPS中同时存在2种峰。由图7还可知:与工况1相比,工况2的SMP中峰A的荧光强度(fluorescence intensity,FI)降低了19.5%;LB-EPS中峰B的FI降低了16.2%;TB-EPS中峰A和峰B的FI分别降低了6%和0.7%。上述结果表明,膜区添加填料有助于降低SMP、LB-EPS和TB-EPS中色氨酸类和腐殖酸类物质的浓度。

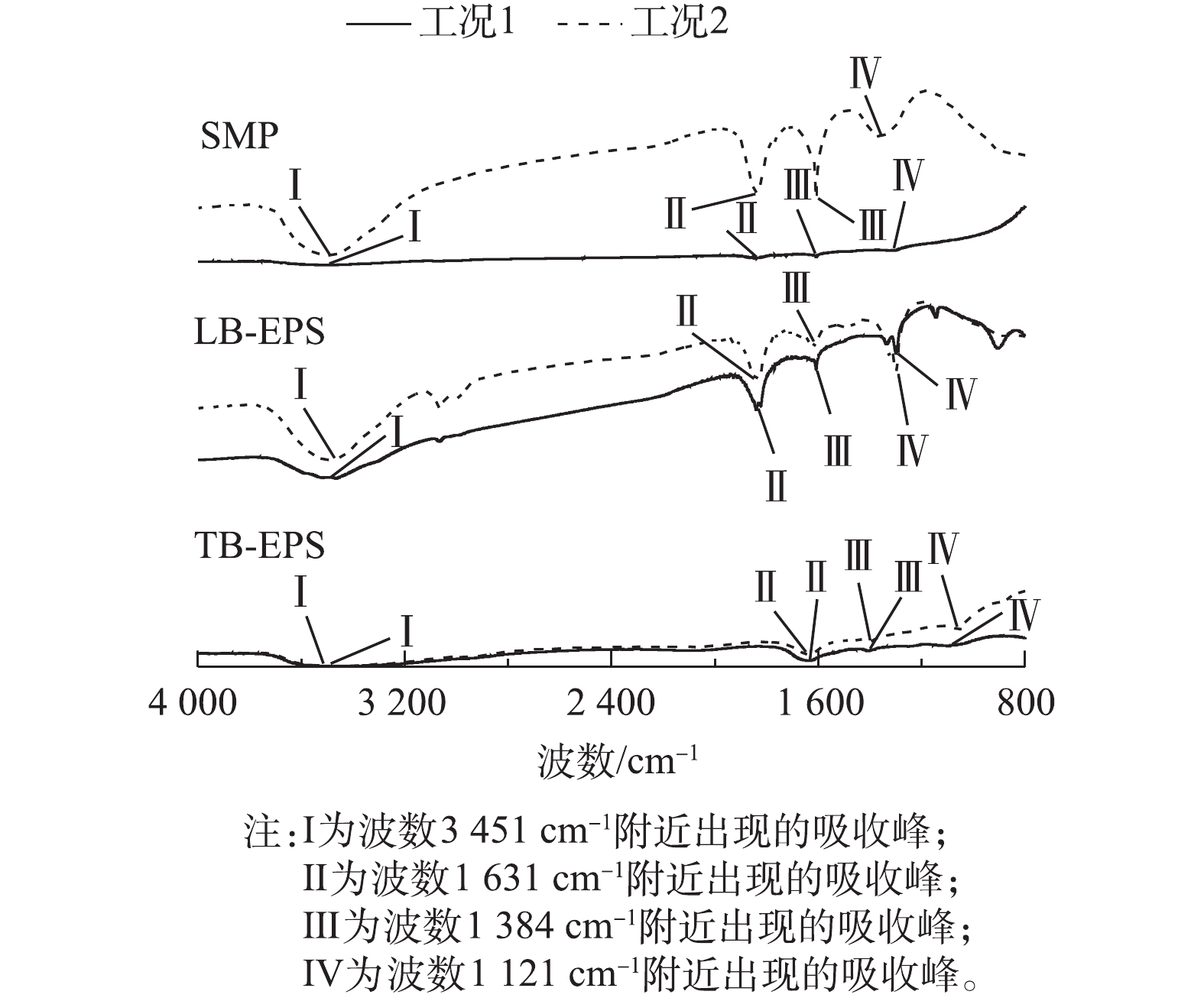

由图8可知,在2种工况下,SMP、LB-EPS和TB-EPS在Ⅳ位置(1 121 cm−1附近)均出现较强的吸收峰。此吸收峰代表C—O的伸缩振动,归属于多糖类物质的吸收峰[28]。此外,在Ⅰ位置(3 451 cm−1附近)、Ⅱ位置(1 631 cm−1附近)和Ⅲ位置(1 384 cm−1附近)也均存在3个吸收峰,分别代表O—H伸缩振动、C=C伸缩振动和C—H弯曲振动,归属于蛋白质类物质吸收峰[1]。上述结果表明,SMP、LB-EPS和TB-EPS的主要成分为多糖和蛋白质。由图8还可知,与工况1相比,工况2中的SMP、LB-EPS和TB-EPS各吸收峰透过率均有所增大,即各吸收峰代表的有机物浓度降低。这表明在膜区添加填料能够降低污泥混合液中SMP、LB-EPS和TB-EPS的含量,进而对减缓膜污染起到积极作用。

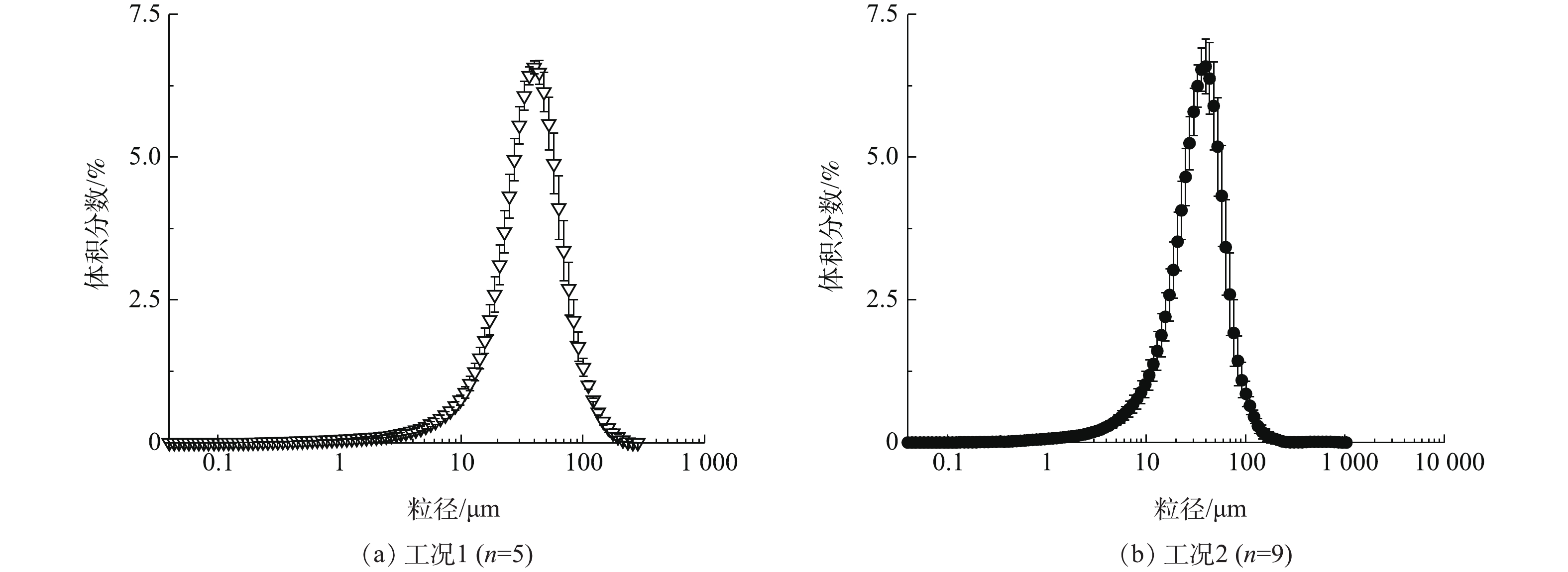

由图9可知:在工况1下,污泥粒径分布在0.04~282.1 μm;在工况2下,污泥粒径分布在0.04~1 143 μm。在2种工况下,污泥平均粒径分别为31.35 μm和34.71 μm,d10分别为12.96 μm和16.07 μm。JIN等[3]认为较高的曝气强度易使污泥颗粒破碎。在本研究中,在膜区添加填料后,实际曝气强度有所降低,有利于提高污泥絮体的团聚能力,从而促进较大污泥颗粒的形成。谢元华等[29]的研究表明,当污泥平均粒径在20~60 μm时,膜过滤阻力随污泥平均粒径减小而增大。在工况2下,污泥平均粒径和d10均有所增大,因此,膜区添加填料减小了膜过滤阻力,进而使膜性能得到了改善。

2.1. 典型污染物去除特征及运行稳定性

2.2. 膜污染特征及膜污染机理解析

-

1) HSBE-MBR在不同填料添加方式下均可稳定运行,且对生物制药废水中TCOD、

NH+4 -N和TN的去除效果良好,在工况1和工况2下的平均去除率分别为91.61%和91.09%、97.08%和97.24%、79.40%和83.66%,膜区添加填料后TN去除率和容积去除速率分别提高了4.26%和8.33%。2) HSBE-MBR的膜污染机理以滤饼层污染为主,填料对膜表面的冲刷使滤饼层阻力降低了8.07%,其在总阻力中的占比降低了4.60%,最长膜运行时长由8.71 d增至138 d。确定最优添加方式为在缺氧区、好氧区和膜区添加填料。

3)膜区添加填料后,污泥混合液的性质得到改善,SMP、LB-EPS和TB-EPS的浓度由分别由(63.70±12.95)、(13.97±2.03)、(153.82±12.64) mg·g−1降低至(31.77±3.17)、(9.11±0.40)、(78.12±18.92) mg·g−1。

4)在膜区添加填料后,污泥平均粒径和d10分别从31.35 μm和12.96 μm增大至34.71 μm和16.07 μm。

下载:

下载: