-

随着燃煤电厂节能减排改造工程的升级,超低排放技术得到快速地推广与应用[1]。然而在超低排放条件下如何准确测量颗粒物浓度,对超低排放改造工程进行有效评价是目前亟待解决的问题。颗粒物浓度的测试方法包括在线监测和手工测试,在线监测设备的校准可通过光学原件校准,但其偏差较大[2-3]。相关标准及方法规定采用手工测试方法对在线监测设备进行校准和验收[4-5],因此,颗粒物手工测试方法已成为设备是否达到超低排放的主要评判手段[6]。但测试结果往往易受复杂的烟气条件、测试方法、仪器、滤膜、操作人员等因素影响而存在差异,这直接影响设备的最终评价结果。

目前,国内外针对可吸入颗粒物采样器已经建立计量标准和方法[7-9]。其基本原理是由标准粒子发生器产生一定粒径单分散的标准粒子,并使之在测试区域均匀分布后,在一定环境条件及时间内,用滤膜捕集进入粒子分离器前后的标准粒子,用天平称重后,确定滤膜上粒子的质量及浓度[10]。还有的颗粒物检定装置以米氏散射为理论基础,将光度法和粒子计数法相结合,通过激光功率的切换实现对颗粒物粒径和浓度的监测[11]。这些方法建立在实验室环境条件下,未模拟实际烟气的温度、湿度和酸性气体,并不适用于低浓度颗粒物手工法测试。近年来,环境保护部结合国外测试标准[12-14],制定了适合我国的低浓度颗粒物测试标准[15],规范了低浓度颗粒物手工测试方法,但对低浓度颗粒物测试方法尚未建立相关的计量标准和装置。本研究根据国家相关测试标准,研制了一台量值可溯源的低浓度颗粒物测试校准装置[16](以下简称校准装置),并对该校准装置的给料发生装置、SO3发生装置、空气加热器、蒸气发生器和在线监测等主要单元进行了详细阐述、性能评价和实际应用,以期为低浓度颗粒物的手工测试及在线监测的准确性提供技术参考。

-

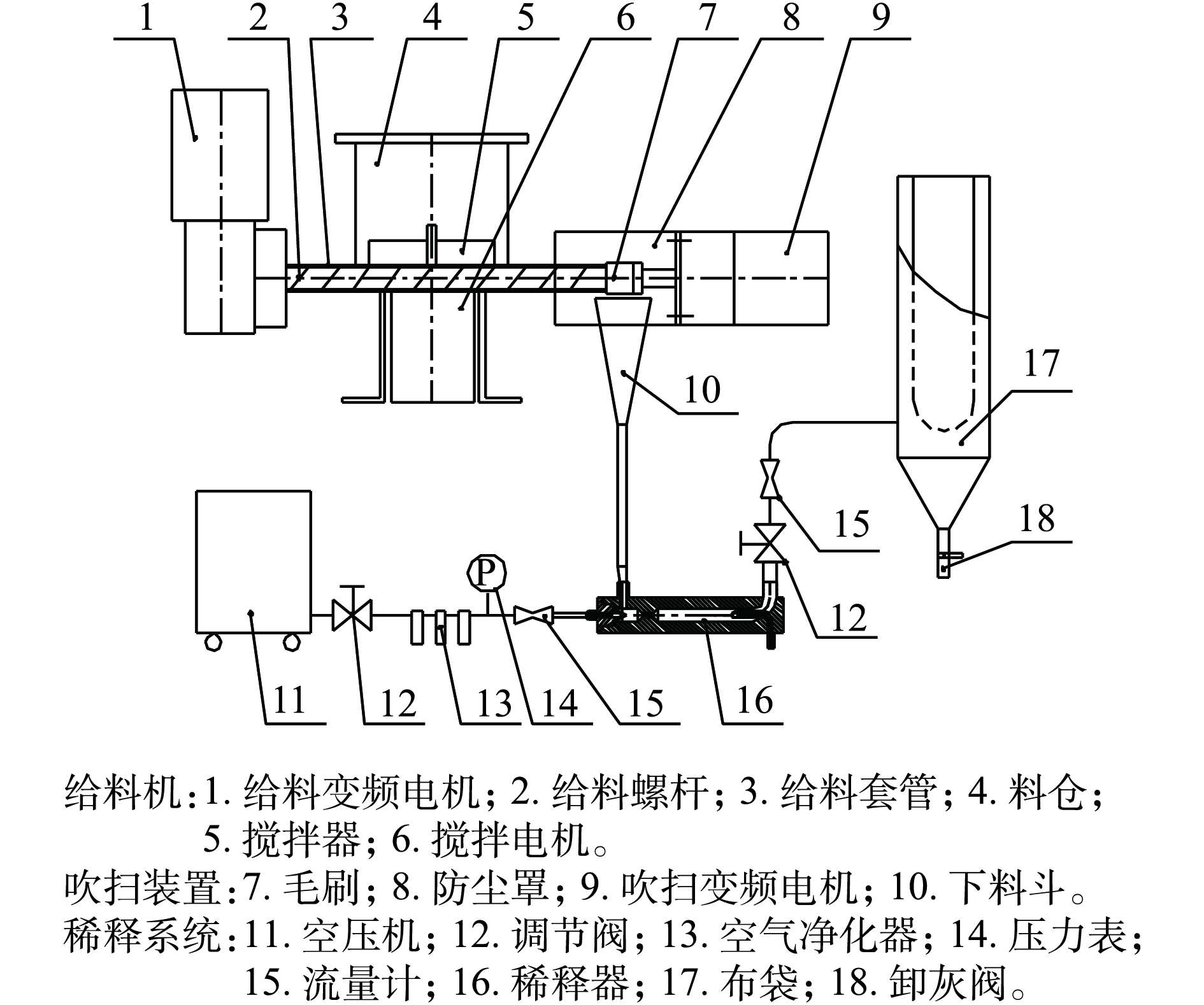

给料发生装置为自主研发,主要包括给料机、吹扫装置、稀释系统等3部分,给料发生装置如图1所示。其工作原理是:给料机通过搅伴器将颗粒物搅拌进给料螺杆,给料螺杆在给料变频电机的带动下将颗粒物输送至出料口,由变频电机控制的毛刷对出料口出来的颗粒物实施刮扫,使颗粒物由团状或块状变成粉末状,稳定均匀地将颗粒物吹扫进下料斗;稀释器[17]在空压机的作用下,使压缩空气通过稀释器环形喷射孔进入稀释器内腔,环形喷射孔与进料口相连接,压缩空气高速通过环形喷射孔时在进料口产生负压,诱导下料斗中的颗粒物从进料口通过喷射孔进入稀释器内腔,再与洁净空气充分混合;混合后含有颗粒物的气流以稳定的稀释比[18]分别进入稀释器的2个口(1个为需求气出口,另1个为多余气出口),经多余气出口排出的大部分颗粒物通过布袋进行回收,需求气出口与校准装置连接,实现连续不断地给料。

-

管道包括风机前和风机后2部分。风机前管道包括进入空气加热器的进风管和连接空气加热器与风机的管道。进风管的管径与空气加热器接口尺寸相同,进风口设有集流器和过滤器。连接空气加热器与风机的管道呈“n”字型布置,管径为180 mm,为玻璃钢材质,有50 mm厚的保温层。距空气加热器出口200 mm处设有粉尘给料口。在“n”字型2个弯头内按等分原则各布置1块导流板。距导流板末端100 mm处,依次设有SO3和蒸气的接入点。手工法测试位置布置在距蒸气接入点大于6倍当量直径,距下游弯头大于3倍当量直径[19]的位置,颗粒物和温湿度在线监测分别安装在手工法测试位置上游200 mm和下游100 mm位置。

风机后的管道有尘酸回收装置和连接风机与尘酸回收装置的管道,为玻璃钢材质。连接风机与尘酸回收装置的管道为方管,断面尺寸为200 mm×215 mm。尘酸回收装置的长×宽×高为654 mm×600 mm×1 000 mm,内部装有350 mm高的液体,液体可采用水或其他碱性液体,具有自动补充液体功能,进入回收装置管道应伸入液体表面50~100 mm。

-

在确定管道管径后,根据设计的烟气流速和管道布置计算风机风量和系统阻力,并预留10%~20%的余量,确保风机能够完全满足实验要求。由于管道中烟气具有一定的温度、颗粒物和酸性气体,采用耐温的玻璃钢材质的变频离心式风机,布置在手工测试位置后,确保烟道内保持负压,烟气不外冒。

-

空气加热器主要是将环境中的空气加热到所需的烟气温度。由于SO3反应炉和蒸气发生器进入校准装置的温度分别可达260 ℃和100 ℃,所以加热功率宜以饱和湿烟气的温度50 ℃来计算。加热功率主要包括空气升温热损失、流量补充热损失、管道和保温散热损失等,热损失与介质的重量和比重、温升和升温时间有关。经过计算并预留余量后,最大加热功率为20 kW。

-

SO3发生装置[20]是通过V2O5与SO2标气高温反应生成SO3气体,并根据实际需要的SO3浓度、反应炉催化效率、SO2标气质量浓度和烟气流量,调节通入反应炉的SO2标气流量,然后采用控制冷凝法[21-22]等速采集SO3,用铬酸钡分光光度法[23]分析硫酸根含量,结合所抽取的采样体积计算SO3浓度。反应炉与校准装置之间伴热管应加热至260 ℃[24],SO2标气的质量浓度为228.57 g·m−3,在SO3通入校准装置前,应先对反应炉进行硫平衡实验。

-

在蒸气发生器选型时,首先根据VATSALA软件计算由环境湿度加热到设计温度的饱和湿度,烟气流量所需的加水量为89.45 g·m−3,然后按最大烟气流量计算单位时间的加水量为79.60 kg·h−1,预留一定余量后,计算蒸气发生器的加热功率为72 kW。

-

在线监测包括颗粒物和温湿度在线监测,其中颗粒物在线监测采用英国的PCME实时监测[25],是基于颗粒物对激光的前向散射的特性设计而成的[26],温湿度采用HMT330型VATSALA温湿度传感器实时监测。控制系统集成了变频风机、空气加热器、给料发生装置、SO3发生装置、蒸气发生器等,操作简单方便。建成后的校准装置如图2所示。

-

表1和图3给出了给料发生装置通过滤筒每隔1 min连续采集60个样品的给料量和给料稳定均匀性。由表1和图3可知,当给料频率分别为12、20、30、40 Hz时,给料量分别为1.9、3.3、4.8、6.9 g·h−1,给料稳定均匀性分别为6.9%、5.5%、7.9%、6.9%。最低给料量仅为1.9 g·h−1,且给料稳定均匀性小于8%,满足校准装置的给料要求[27]。

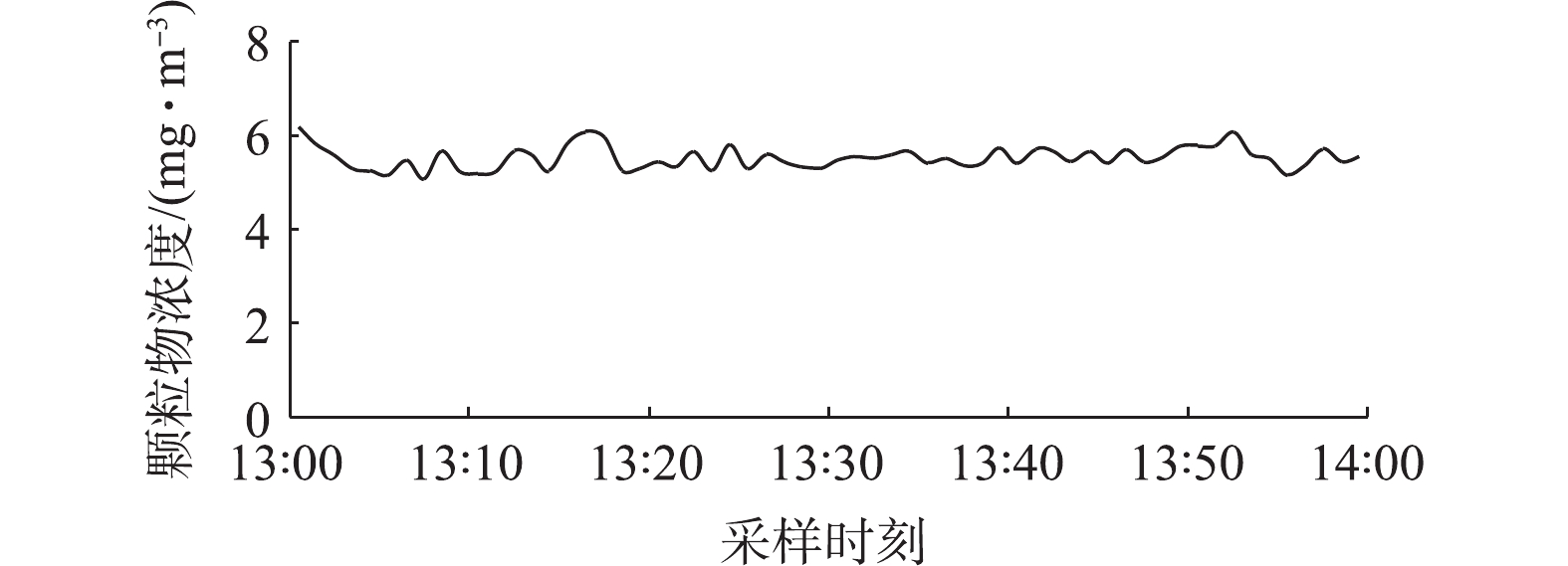

图4给出了在饱和湿烟气条件下在线颗粒物浓度为5.50 mg·m−3时1 h的颗粒物在线监测分布曲线。由图4可知,在线颗粒物浓度为5.50 mg·m−3时,稳定均匀性只有4.4%。这说明给料发生装置的给料是稳定均匀的,校准装置所提供的颗粒物浓度校准可靠性高。

-

采用圆管和方管在“n”字型2个弯头处,在未设置导流板、按等分原则布置1块和2块导流板、按不等分原则布置2块导流板时,通过CFD分析计算,圆管测试位置的流场分布均匀性分别为10.0%、7.4%、8.2%、8.1%,方管测试位置的流场分布均匀性分别为11.0%、7.9%、8.3%、8.1%。同样的导流板布置圆管的流场要优于方管,在“n”字型2个弯头处按等分原则布置1块导流板的流场最优。

-

校准装置在饱和湿烟气条件下,通入 SO3发生装置的SO2标气质量浓度为228.57 g·m−3,流量为0.35 L·min−1时,3个样品的SO3浓度分别为6.52、5.94、5.79 mg·m−3,平均为6.08 mg·m−3,样品相对标准偏差为6.34%。通入校准装置的SO3浓度要高于一般脱硫后的SO3浓度,说明校准装置可稳定提供与实际烟气相近浓度的酸性气体。

-

图5为校准装置在烟气温度为50 ℃和60 ℃时所对应的烟气湿度。由图5可知,烟气温度为60 ℃时,烟气绝对湿度为26.2%;烟气温度为50 ℃时,烟气绝对湿度为13.3%,2个温度点的烟气相对湿度均在100%以上,这说明烟气进入了饱和状态。通过以上测试与分析表明,该装置可模拟现场高湿度、低温度、酸性气体等工况,同时提供稳定、均匀、浓度低的颗粒物输出,为低浓度颗粒物测试准确性提供技术参考。

-

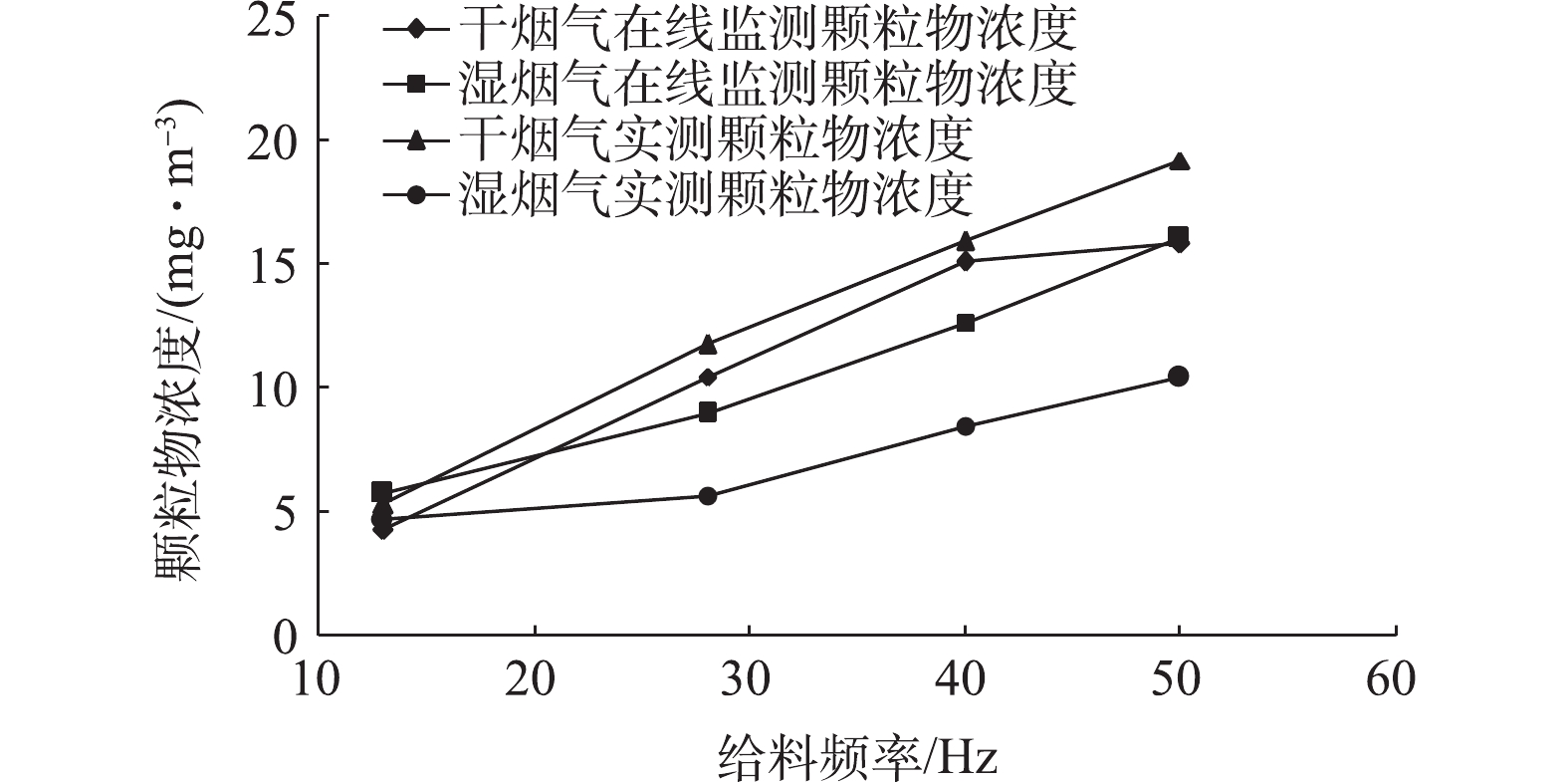

表2和表3给出了校准装置在模拟低温电除尘器后干烟气和湿法脱硫后饱和湿烟气的不同颗粒物浓度的测试结果。由表2和表3可知,在干烟气和饱和湿烟气条件下,不同颗粒物浓度的全程序空白样浓度均小于实测颗粒物浓度的10%[15],说明测试的样品均有效;实测颗粒物浓度随给料频率的升高而增大,且样品平行性较优。

图6给出了校准装置在干烟气和湿烟气条件下实测不同颗粒物浓度分布曲线和在线监测颗粒物浓度分布曲线。由图6可知,干烟气和湿烟气实测颗粒物浓度按多项式回归后的方程式(如式(1)和式(2)所示)计算,r分别为0.999 9、0.993 2,按照选定显著性水平α和观测点数目n减去2的数值(自由度),可在相关系数临界值表中查出相应临界值r0分别为0.999(α=0.001)、0.990(α=0.01)。根据实验数据计算出的相关系数r≥r0,那么给料发生装置的给料频率与干烟气和湿烟气颗粒物浓度存在很好的线性关系,而且可信度分别高达99.9%、99.0%,可作为校准装置标准曲线对颗粒物浓度进行校准。如果按照线性回归,那么r分别为0.997 8、0.968 0,其可信度分别为99.0%、95.0%,要比按式(1)和式(2)计算的可信度低,所以在低浓度颗粒物标定时,其校准因子推荐按多项式回归进行计算设置。

式中:x为给料频率,Hz;y为颗粒物浓度,mg·m−3。

在同样给料频率时,实测的湿烟气颗粒物浓度要比干烟气的低,在给料频率为13 Hz时,低了10.8%,随着给料频率升高至28 Hz,降低幅度上升至52.1%,之后趋于平缓,这主要是由于校准装置的管径小,在饱和湿烟气条件下,喷入的水蒸气大,致使一些颗粒物被吸附在管壁上,在低给料量时,影响较小,随着给料量的增加,吸附越明显,到达一定的给料量后,吸附量基本稳定。

由图6还可知,颗粒物在线监测校准因子按y=3.5x−0.5设置后,在干烟气时,在线监测的颗粒物浓度仍比实测值低,在给料频率≤40 Hz时,两者基本平行,给料频率>40 Hz时,两者明显拉开;在湿烟气时,在线监测的颗粒物浓度反而比实测值高,随着给料频率的升高,其增加的颗粒物浓度也越多,最终接近干烟气的在线值。这说明,在干烟气和湿烟气条件下,颗粒物在线监测校准因子是不一样的,在湿烟气时要小些。其出厂标定的校准因子y=x与实际的差异较大,反映了颗粒物在线监测设备出厂标定的准确度较差。

-

1)通过对校准装置进行性能评价,表明该装置可模拟现场高湿度、低温度、酸性气体等工况,同时提供稳定、均匀、浓度低的颗粒物输出,为低浓度颗粒物测试准确性提供技术支撑。

2)通过对校准装置不同颗粒物浓度的测试与回归分析,给出了干烟气和饱和湿烟气2条颗粒物浓度标准曲线,结果表明可信度高,可作为校准装置标准曲线对颗粒物浓度进行校准,且装置操作简单方便,运行稳定可靠。

3)在线监测结果表明,在颗粒物浓度较低时,颗粒物在线监测设备出厂标定的准确度较差,校准因子应根据不同烟气环境校准装置实际测试结果进行标定。

4)校准装置可模拟现场复杂烟气条件,对超低排放颗粒物浓度的测试准确性进行验证,同时还可以对不同的测试方法和在线监测设备等进行校准。

燃煤烟气低浓度颗粒物测试校准装置的研制与应用

Development and application of test calibration device for low concentration particulate matter in coal-fired flue gas

-

摘要: 在超低排放条件下,如何准确测量颗粒物浓度是非常关键的技术问题。根据HJ 836-2017等相关测试标准,研制了量值可溯源的低浓度颗粒物测试校准装置,详细说明了校准装置的主要单元和性能评价,并在实际中进行验证。结果表明,校准装置的颗粒物浓度随给料频率的升高而增大,且样品平行性较优;给料频率与干烟气和湿烟气颗粒物浓度存在很好的线性关系,可信度高,可作为校准装置标准曲线对颗粒物浓度进行校准;在线监测低浓度颗粒物标定时,推荐采用多项式回归进行计算设置;在干烟气和湿烟气条件下,颗粒物在线监测校准因子不一样,出厂标定的准确度较差。该装置可提供高湿度、低温度和酸性烟气条件下的稳定均匀和可信度高的低浓度颗粒物输出,可用于模拟现场复杂烟气条件,为验证低浓度颗粒物的手工测试及在线监测的准确性提供参考。Abstract: Under ultra-low emission conditions, how to accurately measure low-concentration particulate matter has become a key technical issue. According to the test standards of HJ 836-2017, a low-concentration particle test calibration device with traceable value was developed. The main units and performance evaluation of the calibration device were elaborated, which was also applied in practice. The application results show that the particle concentration of the calibration device increased with the increase of the feed frequency, and the result parallelism of the samples was better. The feeding frequency had a good linear relationship with the particle concentration in dry flue gas and wet flue gas, which showed high credibility and could be used as a calibration device standard curve to calibrate the particle concentration. The polynomial was recommended for the calculation and installation when on-line monitoring was used to calibrate low concentration particulate matter. Under dry and wet flue gas conditions, the calibration factors for on-line monitoring particulate matter were different, and the accuracy of factory calibration was poor. The device could provide stable, uniform and reliable output of low concentration particulate matter under high humidity, low temperature and acid flue gas conditions, which could be used to simulate the complicated flue gas condition in the field, and provide technical reference for the accuracy in verifying the manual testing and on-line monitoring particulate matter with low concentration.

-

表 1 给料发生装置的给料量和给料稳定均匀性

Table 1. Feed quantity, stability and uniformity of the feeding device

给料频率/Hz 给料量/(g·h−1) 给料稳定均匀性/% 12 1.9 6.9 20 3.3 5.5 30 4.8 7.9 40 6.9 6.9 表 2 干烟气下颗粒物浓度

Table 2. Particle concentration under dry flue gas condition

给料频率/Hz 烟气温度/℃ 烟气湿度/% SO3浓度/(mg·m−3) 烟气流量/(m3·h−1) 实测颗粒物浓度/(mg·m−3) 样品平行性/% 全程序空白样/(mg·m−3) 在线监测颗粒物浓度1)/(mg·m−3) 13 90 5.37 4.86 563 5.30 4.73 0.31 4.23 28 90 5.40 4.92 556 11.75 6.75 0.46 10.43 40 90 5.37 4.43 567 15.88 4.23 0.09 15.03 50 90 5.30 4.91 557 19.18 4.49 0.40 15.80 注:1)颗粒物在线监测校准因子按y=3.5x−0.5设置。 表 3 湿烟气下颗粒物浓度

Table 3. Particle concentration under wet flue gas condition

给料频率/Hz 烟气温度/℃ 烟气湿度/% SO3浓度/(mg·m−3) 烟气流量/(m3·h−1) 实测颗粒物浓度/(mg·m−3) 样品平行性/% 全程序空白样/(mg·m−3) 在线监测颗粒物浓度1)/(mg·m−3) 13 50 13.80 6.15 445 4.72 0.03 0.04 5.72 28 50 13.70 6.82 441 5.63 1.67 0.17 8.89 40 50 13.80 6.09 449 8.45 3.84 0.06 12.61 50 50 13.50 6.59 445 10.41 2.03 0.06 15.97 注:1)颗粒物在线监测校准因子按y=3.5x−0.5设置。 -

[1] 中国环境保护产业协会电除尘委员会. 燃煤电厂烟气超低排放技术[M]. 北京: 中国电力出版社, 2015. [2] 崔云寿. 烟气浊度在线监测的校准[J]. 电力科技与环保, 2001, 17(4): 43-45. doi: 10.3969/j.issn.1674-8069.2001.04.013 [3] 纵宁生, 张晏, 陈书建. 烟气浊度在线监测仪校准中应注意的几个问题[J]. 电力科技与环保, 2003, 19(3): 57-59. doi: 10.3969/j.issn.1674-8069.2003.03.019 [4] 环境保护部. 固定污染源废气(SO2、NOx、颗粒物)排放连续监测系统技术要求及检测方法: HJ 76-2017[S]. 北京: 中国环境科学出版社, 2017. [5] BUTTERFIELD D, QUINCEY P. Measurement science issues relating to PM10 and PM2.5 airborne particles[EB/OL]. [2018-10-10]. http://publications.npl.co.uk/npl_web/pdf/as15.pdf, 2007. [6] 梁云平. 固定源低浓度颗粒物监测技术现状与思考[J]. 中国环境监测, 2013, 29(5): 161-164. doi: 10.3969/j.issn.1002-6002.2013.05.034 [7] 刘运席, 陈旭, 杨复沫, 等. 新型多级冲击采样器切割粒径的标准粒子实验分析[J]. 环境工程学报, 2006, 7(5): 138-141. doi: 10.3969/j.issn.1673-9108.2006.05.032 [8] WANG X, CHANCELLOR G, EVENSTAD J, et al. A novel optical instrument for estimating size segregated aerosol mass concentration in real time[J]. Aerosol Science and Technology, 2009, 43(9): 939-950. doi: 10.1080/02786820903045141 [9] HELLERZEISLER S F, ONDOV J M, ZEISLER R. Collection and characterization of a bulk PM2.5 air particulate matter material for use in reference materials[J]. Biological Trace Element Research, 1999, 71-72: 195-202. doi: 10.1007/BF02784205 [10] 刘俊杰, 张文阁. 可吸入颗粒物采样器准确性计量检测方法的设计及研究[J]. 中国粉体技术, 2006, 12(5): 5-8. doi: 10.3969/j.issn.1008-5548.2006.05.002 [11] 吴芳. 颗粒物发生装置与检定系统研究[D]. 杭州: 浙江大学, 2015. [12] ISO. Stationary source emissions-determination of mass concentration of particulate matter(dust) at low concentrations-manual gravimetric method: ISO12141-2002[S]. BSI Standards Publication, 2002. [13] ASTM. Standard test method for determination of mass concentration of particulate matter from stationary sources at low concentrations(manual grvimetric method): ASTM D 6331-2014[S]. American Society for Testing and Materials, 2014. [14] BS EN. Stationary source emissions. Determination of low range mass concentration dust. Manual gravimetric method: BS EN 13284-1-2017[S]. BSI Standards Publication, 2017. [15] 环境保护部. 固定污染源废气低浓度颗粒物的测定重量法: HJ 836-2017[S]. 北京: 中国环境科学出版社, 2017. [16] 郭俊, 杨丁, 叶兴联, 等. 用于标定低浓度颗粒物测试方法准确性的测试校准装置: ZL201721869892.4[P]. 2017-12-27. [17] 李兴华, 段雷, 郝吉明, 等. 固定燃烧源颗粒物稀释采样系统的研制与应用[J]. 环境工程学报, 2008, 28(3): 458-463. [18] AHLVIK P, NTZIACHRISTOS L, KESKINEN J, et al. Real time measurements of diesel particle size distribution with an electrical low presser impactor: NO 980410[R]. Washington DC: SAE International, 1998: 10-20. [19] 国家环境保护局. 固定污染源排气中颗粒物测定与气态污染物采样方法: GB/T 16157-1996[S]. 北京: 中国环境科学出版社, 1996. [20] 杨丁, 陈威祥, 郑芳, 等. 一种三氧化硫采样测试系统的校验方法和装置: ZL201410401789.1[P]. 2014-08-14. [21] 中华人民共和国国家质量监督检验检疫总局. 燃煤烟气脱硫设备性能测试方法: GB/T 21508-2008[S]. 北京: 中国环境科学出版社, 2008. [22] EPA. Determination of sulfuric acid mist and sulfur dioxide emissions from stationary sources. EPA Method 8-1990[S]. U. S. Environmental Protection Agency, 1990. [23] 国家环境保护总局. 水质硫酸盐的测定 铬酸钡分光光度法(试行): HJ/T 342-2007[S]. 北京: 中国环境科学出版社, 2007. [24] WILLIAM E F, PETER M W, JOHN P G, et al. Identification of (and responses to) potential effects of SCR and wet scrubbers on submicron particulate emissions and plume characteristics[R]. Alabama: Environmental Protection Agency, 2004: 1-81. [25] CHENG H H. Field comparison of real-time PM2.5 readings from a beta gauge monitor and a light scattering method[J]. Aerosol and Air Quality Research, 2007, 7(2): 239-250. doi: 10.4209/aaqr.2007.01.0002 [26] JUERGEN K, INGO S, KLAUS S. Scattered light range of view measurement apparatus: 7414703 B2[P]. 2008-08-19. [27] MAYNARD A D, KENNY L C, BALDWLN P E J. Development of a system to rapidly measure sampler penetration up to 20μm aerodynamic diameter in calm air, using the aerodynamic particle sizer[J]. Journal Aerosol Science, 2016, 30(9): 1215-1226. 期刊类型引用(3)

1. 刘越,石川,马金元,罗娟,王凯军. 不同预处理对超磁分离污泥水解产酸效果的影响研究. 中国沼气. 2022(01): 3-10 .  百度学术

百度学术

2. 宋新新,刘杰,林甲,李佳,李传举,江瀚,王洪臣,伊锋. 碳中和时代下我国能量自给型污水处理厂发展方向及工程实践. 环境科学学报. 2022(04): 53-63 .  百度学术

百度学术

3. 贺聪慧,王祺,梁瑞松,王凯军. 磁强化处理技术在城市污水处理中的研究与应用进展. 环境科学学报. 2021(01): 54-69 .  百度学术

百度学术

其他类型引用(1)

-

下载:

下载: