高含盐有机废液一般指COD>10 000 mg·L

−1,含盐量>50 000 mg·L

−1的废液

[1],主要来源于制药、农药、煤化工等精细化工行业的盐析、精馏及膜分离等工段,其成分复杂、水质多变、处理难度大

[2]。

目前,国内产废企业大多采用多效蒸发和机械蒸汽再压缩技术(MVR)对废液进行浓缩减量化

[3-5],但多效蒸发及MVR的应用除了需要解决结垢堵塞等问题,同时随着盐浓度增加,溶液沸点升高,从而蒸发效率降低,致使预处理得到的盐仍需进一步干燥

[6]。相较于传统蒸发浓缩装置,滚筒喷雾预浓缩装置集可连续作业、适应性强、结构简单的滚筒干燥

[7]及浓缩效率高、传热效率高的喷雾干燥于一体

[8-9],浓缩条件范围较大。

针对高含盐有机废液资源化利用,整体工艺采用滚筒喷雾预浓缩加圆盘气化脱毒得到工业盐

[10−12],滚筒喷雾预浓缩盐含水率较低,有效减小气化脱毒的能耗,同时还可以保证整套系统的稳定运行。在采用旋转蒸发器验证技术路线可行的基础上,本研究对滚筒喷雾装置应用于高含盐有机废液的安全处置进行探讨,对高含盐有机废液滚筒喷雾预浓缩工艺进行响应面分析,以获得设备运行最佳组合工艺条件,为后续资源化利用奠定理论基础。

1 材料与方法

1.1 实验材料

通过对高含盐有机废液预浓缩小试实验研究,选取苯胺(C

6H

7N微溶于水)及二甘醇(C

4H

10O

3易溶于水)作为有机物改变废液物化性质,以化学需氧量(COD)作为有机物含量指标,小试实验发现苯胺及二甘醇COD可以达到其理论化学需氧量(ThOD)的95%

[13],模拟废液中苯胺与二甘醇配比为3:7。模拟高含盐有机废液以苯胺(分析纯)、二甘醇(分析纯)、氯化钠(优级纯)和超纯水混合而成。

1.2 仪器与设备

滚筒喷雾预浓缩主体装置由一个内部加热的旋转滚筒组成,热源介质为导热油,废液由蠕动泵控制进料,通过喷嘴将高含盐有机废液均匀涂布在热的滚筒表面,基于筒体与料膜传热作用,使料膜内的湿分向外转移

[14−15],当含水率达到要求时,被设在后端的刮刀刮下,与滚筒分离,得到预浓缩盐

[16]。实验中,为分析水气中气体的成分,设计了旁路冷凝液收集瓶及抽气泵,水气采用喷淋水洗后进入活性炭吸附装置。

表1为主要设备及参数,

图1为滚筒喷雾预浓缩实验装置示意图。

表1 主要设备及参数

Table 1 Main equipments and parameters

表1 主要设备及参数

Table 1 Main equipments and parameters

主要设备 | 设备型号及参数 |

超声波清洗机 | E100H,超声频率:37 kHz,功率0.55 kW |

蠕动泵 | BT100-2J,转速范围:0.1~100 r·min−1 |

空气压缩机 | V-0.6/8,功率:4 kW,转速:860 r·min−1 |

油泵 | RY20-20−125,流量:15 m3·h−1,功率0.75 kW |

三相异步电动机 | YX380M2-4,电压:380 V,转速:1 390 r·min−1 |

循环水泵 | SHB-3A,电压:220 V,功率:180 W |

引风机 | DF-2−1,电压:380 V,流量:860 m3·h−1 |

实验室超纯水机 | UP−10A,规格:10 L·h−1 |

箱式气氛炉 | slq1100-30,炉膛尺寸:20 cm×20 cm×30 cm |

图1 实验装置示意图

Fig. 1 Schematic diagram of experimental set-up

图1 实验装置示意图

Fig. 1 Schematic diagram of experimental set-up

1.3 检测分析方法

1)预浓缩盐含水率测定方法。预浓缩盐含水率按《制盐工业通用试验方法水分的测定》(GB/T 13025.3-2012)中规定的灼烧法

[17]测定。

2)预浓缩过程能耗比计算方法。

式中:

λ为干燥水的能耗比,kJ·kg

−1;

CP为导热油在相应温度比热容,kJ·(kg·℃)

−1;

M油为在相应时间内滚筒内通过的导热油质量,kg;

T1为导热油管进口温度,℃;

T0为导热油管出口温度,℃;

M水为在相应时间内所蒸发掉的水分质量,kg。

1.4 实验方法

1.4.1 单因素实验

依据前期小试实验采用旋转蒸发器对3种真实废液(性质见

表2)浓缩,盐分超过97%保留在浓缩液中,证明技术路线可行。因此,在单因素实验中,以NaCl质量分数10%、COD 100 000 mg·L

−1的模拟高含盐有机废液为研究对象,考察自行搭建的滚筒喷雾预浓缩装置中导热油温及滚筒转速对提取浓缩盐与滚筒分离状态效果的影响

[18],导热油温依据有机物沸点确定,滚筒转速设计借鉴滚筒干燥在食品行业应用

[14−16](0.25~1.25 r·min

−1)。

表2 3种真实废液水质特征

Table 2 Characteristics of three kinds of real wastewater

表2 3种真实废液水质特征

Table 2 Characteristics of three kinds of real wastewater

来源 | 含盐量/% | COD/(mg·L−1) | 主要成分 |

化工厂1 | 9.7 | 10 500 | 氯化钠、磷酸二氢钠、甲醇、乙酸钠 |

化工厂2 | 10.4 | 98 020 | 氯化钠、亚硫酸钠、甲苯 |

制药厂3 | 10.8 | 107 950 | 氯化钠、甲醇、聚丙烯酰胺 |

1.4.2 正交实验

选取导热油温和滚筒转速为影响因素,以NaCl质量分数10%、COD 100 000 mg·L−1的模拟高含盐有机废液为研究对象,采用2因素3水平实验方案进行正交实验,以能耗比为评价指标,优化滚筒喷雾预浓缩工艺。

1.4.3 响应面实验

在单因素及正交实验基础上,选取导热油温(A)、滚筒转速(B)、NaCl质量分数(C)、进料COD(D)为考察因子,以含水率(Y1)及能耗比λ(Y2)为响应值,并采用 Design Expert10.0.3软件对实验数据进行统计分析,以获得高含盐有机废液滚筒喷雾预浓缩最佳运行工艺条件。

2 结果与分析

2.1 单因素实验

2.1.1 滚筒转速

在进料相同的情况下,筒体转速越快,料膜厚度越小,利于提高干燥速率,但干燥时间短。考察导热油温为180 ℃,进料COD为100 000 mg·L

−1,NaCl质量分数为10%时,滚筒转速对预浓缩盐状态的影响,结果如

表3所示。

表3 滚筒转速对预浓缩盐状态影响

Table 3 Effect of roller rotating speed on preconcentrated salt state

表3 滚筒转速对预浓缩盐状态影响

Table 3 Effect of roller rotating speed on preconcentrated salt state

滚筒转速/(r·min−1) | 状态效果 |

0.25 | 预浓缩盐流动性好,喷涂厚薄不均匀,颜色白 |

0.50 | 预浓缩盐与刮刀分离状态好,喷涂厚薄较均匀,颜色白 |

0.75 | 预浓缩盐与刮刀分离状态好,喷涂厚薄均匀,颜色白 |

1.00 | 有少量预浓缩盐因含水率高黏附刮刀,喷涂厚薄均匀,颜色浅黄 |

1.25 | 有大量预浓缩盐因含水率高而黏附刮刀,喷涂厚薄均匀,颜色略深 |

表3表明,滚筒转速取0.75 r·min

−1时,预浓缩盐颜色白,喷涂厚薄均匀,易与刮刀分离。随着滚筒转速增加,预浓缩盐颜色变深,黏附刮刀现象越严重。

2.1.2 导热油温度

取滚筒转速0.75 r·min

−1、进料COD100 000 mg·L

−1、NaCl质量分数10%时,考察导热油温对预浓缩盐状态的影响,结果如

表4所示。

表4 导热油温对预浓缩盐状态影响

Table 4 Effect of conduction oil temperature on preconcentrated salt state

表4 导热油温对预浓缩盐状态影响

Table 4 Effect of conduction oil temperature on preconcentrated salt state

导热油温/℃ | 状态效果 |

165 | 预浓缩盐大量堆积在刮刀与滚筒分离处,盐呈黏稠状 |

170 | 预浓缩盐前期干燥状态好,运行一段时间出现黏附刮刀现象,盐呈团聚状 |

175 | 预浓缩盐与刮刀可以正常分离,但盐呈块状 |

180 | 预浓缩盐干燥状态好,盐呈颗粒状 |

185 | 预浓缩盐干燥状态好,盐呈粉状细腻 |

依据

表4中预浓缩盐与刮刀的分离状态及形态,考虑到当盐呈粉状将不利于后端的气化,为保证实验稳定进行,导热油温取180 ℃时,综合性能最佳。

2.2 正交实验

根据单因素实验结果,本研究采用L

9(3

2)正交实验方案,实验设计及结果见

表5。采用spss22.0软件对实验数据进行多因素方差分析,结果表明导热油温和滚筒转速对能耗比均有显著性影响。选取导热油温为180 ℃和滚筒转速为0.75 r·min

−1时,能耗比最小。

表5 正交实验设计及结果

Table 5 Design and results of orthogonal experiment

表5 正交实验设计及结果

Table 5 Design and results of orthogonal experiment

序号 | 因素 | 能耗比/(kJ·kg−1) |

导热油温/℃ | 滚筒转速/(r·min−1) |

1 | 175 | 0.50 | 4 709.65 |

2 | 175 | 0.75 | 4 613.09 |

3 | 175 | 1.00 | 4 591.28 |

4 | 180 | 0.50 | 4 652.88 |

5 | 180 | 0.75 | 4 570.11 |

6 | 180 | 1.00 | 4 583.89 |

7 | 185 | 0.50 | 4 975.44 |

8 | 185 | 0.75 | 4 791.19 |

9 | 185 | 1.00 | 4 821.05 |

2.3 响应面实验

2.3.1 响应面实验设计与结果

根据单因素及正交实验结果,选取导热油温(A)、滚筒转速(B)、NaCl质量分数(C)、进料COD(D)为考察因子,以含水率及能耗比

λ为响应值,采用 Design Expert10.0.3软件中的响应面法( Box-Behnken模型)进行4因素3水平的实验设计(见

表6)。

表6 响应面分析因素与水平

Table 6 Factors and levels of response surface analysis

表6 响应面分析因素与水平

Table 6 Factors and levels of response surface analysis

水平 | 因素 |

导热油温/℃ | 滚筒转速/(r·min−1) | NaCl质量分数/% | 进料COD/(mg·L−1) |

−1 | 175 | 0.50 | 8 | 80 000 |

0 | 180 | 0.75 | 10 | 100 000 |

1 | 185 | 1.00 | 12 | 120 000 |

2.3.2 预浓缩盐含水率响应模型

利用Design Expert10.0.3对

表7实验数据进行多元化回归拟合,得到含水率(

Y1)对导热油温(A),滚筒转速(B),NaCl质量分数(C),进料COD(D)的实际编码值二次多项式回归方程为:

对含水率二次响应方差进行分析,模型平方和为258,均方为18.43,

F值为45.09,

P值<0.000 1,说明回归模型极显著,回归方程在整个回归区域的拟合良好

[19]。多项式模型决定系数

R2=0.978 3,校正后

R2=0.956 6,表明响应值和预测值之间具有较高相关性

[20]。

R2Adj-

R2Pred=0.076<0.2,精密度为24.517>4,变异系数(CV)为2.80%<10%,表明实验的精确度和可信度高

[21]。因此,可以用该模型对高含盐有机废液滚筒喷雾预浓缩效果进行预测。

表7 响应面实验设计和结果

Table 7 Experimental design and results of response surface experiment

表7 响应面实验设计和结果

Table 7 Experimental design and results of response surface experiment

实验序号 | A | B | C | D | Y1/% | Y2/(kJ·kg−1) |

1 | −1 | −1 | 0 | 0 | 22.16 | 4 709.65 |

2 | 1 | −1 | 0 | 0 | 17.26 | 4 975.44 |

3 | −1 | 1 | 0 | 0 | 26.58 | 4 591.28 |

4 | 1 | 1 | 0 | 0 | 18.55 | 4 821.05 |

5 | 0 | 0 | −1 | −1 | 23.14 | 4 536.03 |

6 | 0 | 0 | 1 | −1 | 21.53 | 4 964.51 |

7 | 0 | 0 | −1 | 1 | 28.38 | 4 581.93 |

8 | 0 | 0 | 1 | 1 | 23.86 | 4 912.09 |

9 | −1 | 0 | 0 | −1 | 23.18 | 4 541.08 |

10 | 1 | 0 | 0 | −1 | 16.74 | 4 827.48 |

11 | −1 | 0 | 0 | 1 | 26.89 | 4 579.46 |

12 | 1 | 0 | 0 | 1 | 20.38 | 4 839.31 |

13 | 0 | −1 | −1 | 0 | 22.02 | 4 599.41 |

14 | 0 | 1 | −1 | 0 | 25.52 | 4 615.21 |

15 | 0 | −1 | 1 | 0 | 19.8 | 4 909.86 |

16 | 0 | 1 | 1 | 0 | 23.02 | 4 775.17 |

17 | −1 | 0 | −1 | 0 | 27.08 | 4 431.91 |

18 | 1 | 0 | −1 | 0 | 20.22 | 4 907.24 |

19 | −1 | 0 | 1 | 0 | 24.68 | 4 867.20 |

20 | 1 | 0 | 1 | 0 | 17.21 | 4 898.68 |

21 | 0 | −1 | 0 | −1 | 21.7 | 4 951.38 |

22 | 0 | 1 | 0 | −1 | 23.21 | 4 384.27 |

23 | 0 | −1 | 0 | 1 | 24.05 | 4 529.72 |

24 | 0 | 1 | 0 | 1 | 27.89 | 4 686.85 |

25 | 0 | 0 | 0 | 0 | 23.59 | 4 421.99 |

26 | 0 | 0 | 0 | 0 | 23.19 | 4 538.22 |

27 | 0 | 0 | 0 | 0 | 23.39 | 4 601.94 |

28 | 0 | 0 | 0 | 0 | 22.99 | 4 576.11 |

29 | 0 | 0 | 0 | 0 | 22.86 | 4 511.01 |

利用回归方程系数显著性检验,单因素A、B、C、D和二次项A

2均对模型影响极显著(

P<0.01),而相互作用项AB、CD和二次项D

2达到显著水平(0.01<

P<0.05)。由

F值可以看出,影响预浓缩盐含水率的主次因素依次为导热油温、进料COD、滚筒转速、NaCl质量分数。如

图2和

图3所示,依据含水率回归模型做出AB、CD对含水率影响的响应曲面图和等高线图,可以直观反映各因素对含水率影响的变化趋势。

图2 导热油温和滚筒转速对含水率影响的响应面图及等高线图

Fig. 2 Surface and contour plots for effect of conduction oil temperature and roller rotating speed on water content

图2 导热油温和滚筒转速对含水率影响的响应面图及等高线图

Fig. 2 Surface and contour plots for effect of conduction oil temperature and roller rotating speed on water content

图3 NaCl质量分数和进料COD对含水率影响的响应面图及等高线图

Fig. 3 Surface and contour plots for effect of NaCl thickness and material COD on water content

图3 NaCl质量分数和进料COD对含水率影响的响应面图及等高线图

Fig. 3 Surface and contour plots for effect of NaCl thickness and material COD on water content

图2显示了导热油温和滚筒转速对含水率的影响,等高线图形出现无闭合时,其变化趋势先密后疏表示实验因素对此响应值影响的变化率较为均匀,响应面变化越陡,表示对实验结果的影响越显著

[22]。据此结合

图2等高线先密后疏,响应面变化较陡,说明导热油温和滚筒转速对含水率的影响是均匀、显著的。由

图2可以看出,响应值含水率随着导热油温升高而逐渐降低,且在温度达到180 ℃附近较为明显,随着滚筒转速增加而逐渐增加但影响趋势不大。

图3显示了NaCl质量分数和进料COD对含水率的影响,由

图3可以看出,响应值含水率随着NaCl质量分数增加而逐渐减小,随着进料COD增加而逐渐增加。

2.3.3 预浓缩盐能耗比响应模型

利用Design Expert10.0.3对

表7实验数据进行多元化回归拟合,得到能耗比(

Y2)对导热油温(A),滚筒转速(B),NaCl质量分数(C),进料COD(D)的实际编码值二次多项式回归方程为:

对能耗比二次响应方差进行分析,模型

F值为13.41,

P值小于0.000 1,说明回归模型极显著。该模型决定系数

R2=0.930 6,校正后

R2=0.861 2,两者差异较小,说明回归方程拟合程度较好。

R2Adj−

R2Pred=0.18<0.2,精密度为11.566>4,变异系数(CV)为1.45%<10%,各参数充分表明模型具有较低的变异性,较好的精密度和可信度。对回归模型各项系数进行显著性检验表明,A、B、C、AC、BD、A

2、C

2对响应值能耗比影响极显著,B

2影响显著。因此,依据能耗比回归模型做出AC、BD对能耗比影响的响应曲面图和等高线图,可以直观反映各因素对能耗比影响的变化趋势,其结果如

图4和

图5所示。

图4 导热油温和NaCl质量分数对能耗比影响的响应面图及等高线图

Fig. 4 Surface and contour plots for effect of conduction oil temperature and NaCl thickness on energy consumption ratio

图4 导热油温和NaCl质量分数对能耗比影响的响应面图及等高线图

Fig. 4 Surface and contour plots for effect of conduction oil temperature and NaCl thickness on energy consumption ratio

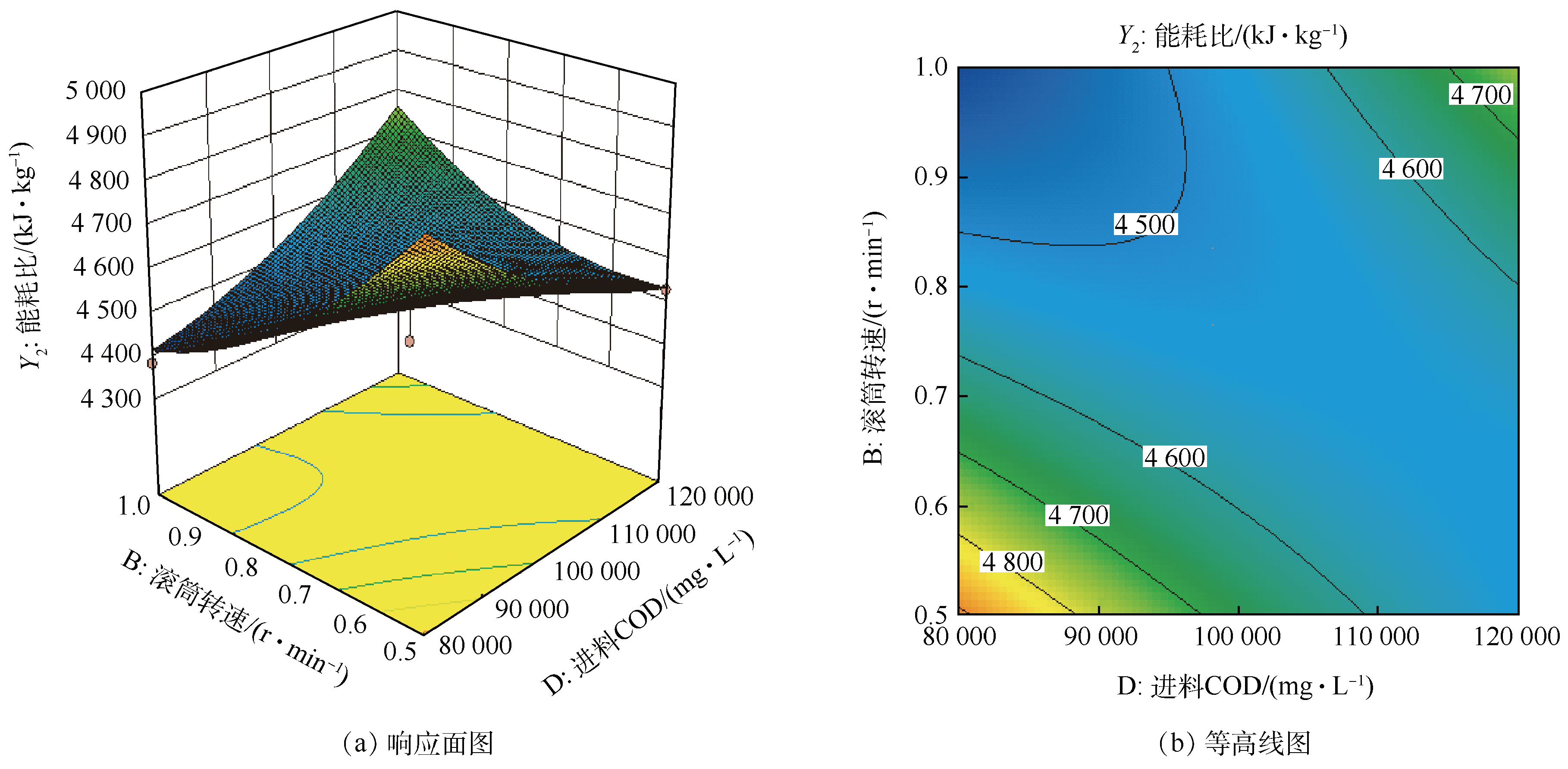

图5 滚筒转速和进料COD对能耗比影响的响应面图及等高线图

Fig. 5 Surface and contour plots for effect of roller rotating speed and material COD on energy consumption ratio

图5 滚筒转速和进料COD对能耗比影响的响应面图及等高线图

Fig. 5 Surface and contour plots for effect of roller rotating speed and material COD on energy consumption ratio

由

图4可知,在NaCl质量分数超过10%时,随着导热油温增加,能耗比先降低后升高;在导热油温高于180 ℃时,随着NaCl质量分数增加,能耗比先降低后升高。但在NaCl质量分数低于10%时,随着导热油温增加,能耗比在导热油温为180 ℃前增加趋于平缓,超过180 ℃后增加较为明显;在导热油温低于180 ℃时,随着NaCl质量分数增加,能耗比在NaCl质量分数为10%前增加趋于平缓,超过10%后增加较为明显。由

图5可知,实验范围内在进料COD及滚筒转速较低时,能耗比随进料COD及滚筒转速的增加而降低;在进料COD及滚筒转速较高时,能耗比随进料COD及滚筒转速的增加而增加。

2.4 响应面实验

依据小试实验中对不同含水率预浓缩盐在同一温度条件气化研究,发现当预浓缩盐含水率过低时,有机物会被预浓缩盐所包裹,在进入二段气化过程难以保证盐的去毒,本研究以5个中心点含水率均值23.20%,以能耗比最低为目标,通过Design Expert10.0.3进行优化条件筛选。结果表明:最佳工艺条件导热油温为179.6 ℃、滚筒转速为1.00 r·min

−1、NaCl质量分数9.07%、进料COD 80 178.67 mg·L

−1。采用最佳条件进行验证实验,将上述条件调整为导热油温为180 ℃、滚筒转速为1.00 r·min

−1、NaCl质量分数9%、进料COD 80 000 mg·L

−1,结果见

表8。

表8 回归方程寻优结果

Table 8 Optimization results of regression

表8 回归方程寻优结果

Table 8 Optimization results of regression

分析值 | 导热油温/℃ | 滚筒转速/ (r·min−1) | NaCl质量分数/% | 进料COD/ (mg·L−1) | 含水率/% | 能耗比/(kJ·kg−1) |

目标值 | 180 | 1.00 | 9 | 80 000 | 23.15 | 4 386.73 |

实测值 | 180 | 1.00 | 9 | 80 000 | 22.46 | 4 573.54 |

相对误差/% | — | — | — | — | 2.97 | 4.26 |

优化目标的实验结果与回归模型预测结果符合(相对误差<5%),表明拟合方程可靠,回归模型可用于指导工程实际应用。

3 结论

1)采用软件Design Expert10.0.3的BBD法对高含盐有机废液滚筒喷雾预浓缩进行模拟,建立含水率及能耗比与各因素多项式模型。通过对模型方差及显著性分析,发现4种因素对含水率影响的主次因素依次为导热油温、进料COD、滚筒转速、NaCl质量分数。而导热油温和滚筒转速、进料COD和NaCl质量分数交互作用对于能耗比具有显著性影响。

2)在保证系统稳定运行的条件下,以能耗比最小为目标值,通过响应面法分析,取最佳工艺条件为导热油温180 ℃、滚筒转速1.00 r·min−1、NaCl质量分数9%、进料COD 80 000 mg·L−1时,含水率预测值23.15%,实测值22.46%,干燥水的能耗比预测值4 386.73 kJ·kg−1,实测值4 573.54 kJ·kg−1。实验结果与预测值拟合良好,可以用于指导实际工程应用。

3)基于当前设备条件,本研究主要针对预浓缩过程水的脱除,后期将通过升级导热油炉使导热油温可以达到260 ℃来对预浓缩过程有机物的迁移转化规律进行探讨,从而为下一步预浓缩盐热解气化提供指导。

下载:

下载: