内浮顶油罐具有拱顶罐与浮顶罐的双重优点,既减少油品损耗,又减轻油气污染,往往用于成品油和高质量油品的储存

[1]。浮盘与罐壁间的边圈密封随服役时间延长而逐渐老化甚至损坏,导致液面与气体空间接触,加速油品蒸发。油品蒸发造成资源浪费和油品质量下降。美国石油学会公布了最新浮顶罐损耗公式AP-42,新公式认为外界风对内浮顶罐边圈密封损耗的影响不显著,故将风速设为0

[2],但对于设备老旧、管理不善的部分油库可能并不适用

[3]。SHARMA等

[4]对放置在地上和地下2种卧式储油罐中的15种汽油进行了小呼吸蒸发损耗实验,根据油品温度、蒸气压和储罐温度、留空高度以及储存时间等易获取的参数,回归了损耗计算式,与AP-42公式有区别。TAMADDONI等

[5]实验研究了油轮装载原油时的VOCs (volatile organic compounds)排放特点,以及油气组分各比例、温度、压力、装船条件、装油时间等因素对排放的影响。OKAMOTO等

[6-8]研究了汽油、煤油蒸气压、蒸发速率和闪点等物性参数变化,并拟合了相应公式,但尚需针对储罐工作特点研究其损耗机理。ZHU等

[9]实测了开口玻璃瓶中93号汽油质量、雷特蒸气压、黏度、油气中非甲烷总烃含量、油气各组分浓度等参数随蒸发过程的变化情况,发现各参数变化幅度不尽相同,且主要发生在初始阶段,拟合的质量损耗曲线成对数律关系。赵晨露等

[10]数值模拟了5 000 m

3内浮顶罐,发现罐壁通气孔(以下简称壁孔)储罐与罐顶通气孔(以下简称顶孔)储罐内具有不同气流分布,前者易使油气大范围扩散。吴宏章等

[11]采用自制实验平台研究了罐内油气浓度、分子扩散、热扩散和对流扩散等因素对蒸发损耗的影响,结果表明内浮顶罐“小呼吸”损耗主要受热扩散的影响。张有渝等

[12]对壁孔和顶孔做了分析比较,认为后者能提高油罐储油容积和经济效益;孟琳等

[13]在生产现场也以提高储油容积的角度,采用了顶孔设计。生产实际中,内浮顶油罐往往受风环境影响,外界风自由出入通气孔势必带来油气损耗。上述研究均未考虑气孔和浮盘位置变化对损耗量和罐内气流分布的影响,对其损耗机理的认识尚不深入和全面。本文通过自制1 000 m

3内浮顶罐缩比模型,研究了气窗和浮盘位置变化对通气孔流向、罐内风速、蒸气浓度和蒸发损耗量的影响。

1 材料与方法

采用自制内浮顶油罐模型进行实验,罐模型根据内浮顶储罐系列和相关设计规范

[14]由1 000 m

3内浮顶罐按1:32比例缩小制成(见

图 1),该缩比保证油罐处于风扇风速场中,便于测点在罐内布置。储罐放在阴凉空阔且通风良好的室内,近似模拟恒温环境(13 ℃)。储罐直径344 mm,浮盘与罐壁间距6 mm,罐壁高度395 mm,顶盖高度41 mm。罐内气体空间直接与边圈处储液接触。罐壁顶部和罐顶边缘各自沿圆周均匀分布4个通气孔(沿逆时针方向分别编号B-1~B-4和D-1~D-4)。顶盖中央开测试孔,对罐内不同高度取气,经气相色谱仪分析得出罐内不同高度处蒸气浓度。热线风速计探头插入罐内不同高度处测得风速。电子天平测得蒸发损耗量。正己烷组分单一,挥发性能适中,作为本实验储液。用大型风扇模拟外界风,扇叶直径大于罐高度与宽度,在某截面位置风速均匀稳定(4.36 m·s

-1)。该风扇获得的流场曾用于本团队其他课题,模拟风场情况与现场实际情况较符合,考虑到现有实验条件,本实验亦采用该风扇模拟外界风。

图1 实验装置示意

Fig. 1 Schematic diagram of experimental set-up

为观察壁孔和顶孔气流方向,将细软棉线一端粘在气孔内侧,若观察气流流入罐内,则另一端露在气孔外并恰好与气孔边缘接触;若观察气流流出罐外,则将另一端与气孔边缘内侧接触。打开风扇,用高速照相机拍摄棉线摆动情况,重复观察5次以上;调整浮盘位置后按同样方法继续观察。从低到高共选取4个浮盘位置(浮盘距罐底分别为88、176、264、312 mm),每个浮盘位置对应壁孔和顶孔2种气孔形式。第1个测点距离浮盘10 mm,后续测点距离均为40 mm的整数倍,最后一个测点紧贴罐顶中心。每一种工况下每一种数据均至少测量3次,排除错误或偏差过大数据,将剩下3次数据求平均值,视为最终数据。

2.1 气孔处气流的进出罐方向

本实验定义穿过B-1和B-3孔的风向为0°风向;罐顶气孔时亦如此。气孔流向观察结果见

表 1。实验亦发现,气流进出罐方向与浮盘高低无关,与气孔位置有关。将风向角偏斜±5°后(见

图 2),气孔流向无任何改变。

表1 气孔处气流方向

Table 1 Airflow direction at vents

表1 气孔处气流方向

Table 1 Airflow direction at vents

| 壁孔编号 |

进出罐方向 |

|

顶孔编号 |

进出罐方向 |

| B-1 |

进 |

|

D-1 |

出 |

| B-2 |

出 |

D-2 |

进(出) |

| B-3 |

进 |

D-3 |

进 |

| B-4 |

出 |

D-4 |

出(进) |

图2 罐顶通气孔偏斜示意

Fig. 2 Rotation of fixed-roof vents

顶孔罐两侧气孔流向随机性地一进一出。当储罐逆时针偏斜5°时,D-2孔流向由外向内,D-4孔流向由内向外;若顺时针偏斜5°,则气流方向相反。

产生上述现象的原因是:壁孔罐空气来流遇到迎风侧B-1孔所在竖直区域后,风速减小,动能转变为静压能,B-1静压强增大;在分割线左侧,气流通道缩小,由伯努利方程知,壁面附近风速增大,静压能转变为动能,B-2和B-4静压强减小。在分割线右侧,气流通道扩大,流速减小,动能转变为静压能,B-3压强增加。从B-1经B-4(和B-2)至B-3区域,静压强由迎风侧最大值降至侧风面最小值,然后在背风侧部分恢复,故在压差的作用下出现上述气孔流向。顶孔罐迎风侧B-1区域静压强大于罐壁上方主流风速静压强,在压差作用下,部分气流沿罐壁向上流动并与主流相遇,随主流向下风向运动。气流惯性以及顶盖边缘处的非流线型使罐壁上移气流未能贴合顶盖边缘,而是从D-1孔上方掠过,将D-1附近气体卷携带走,构成低压区,从而持续从罐内抽吸气体。对于侧风面气孔,以逆时针旋转5°为例,在分割线左侧,弧形顶盖使气流加速,静压强降低;在分割线右侧,气流通道扩大,使静压强增大,最终D-3静压强大于D-1静压强,D-2静压强略大于D-4静压强。

2.2.1 浮盘位置对罐内风速的影响

图 3(a)表示壁孔罐升高浮盘后的风速变化情况。从

图 3(a)可知:浮盘风速略大于罐体中部风速;通气孔以下风速平缓;通气孔以上风速逐渐增大,接近罐顶时风速急剧增大。升高浮盘,浮盘风速均有增加,罐体中部风速略微增大,而罐顶风速减小,但大于浮盘风速。

图3 浮盘位置对罐内气流速度的影响

Fig. 3 Influence of floating-roof height on speed of air-vapor flow in tank

产生上述现象的原因是:迎风侧B-1孔所在竖直区域表面风速并非全部为0,而是在竖直中心偏上某处有速度为0的点,即静压强最大点。该点与罐壁上方主流风速间存在由上向下的压力梯度,同时在B-1孔又存在由内向外的压力梯度,故在2种压力梯度下,气流穿过气孔后紧贴顶盖向B-3孔移动,在B-3孔与进气流碰撞,使竖直方向气流动量减少;继续向下移动冲击浮盘,气流水平方向动量再次减少。气流从B-1孔进入罐内,卷携附近气体沿顶盖向背风侧移动,使附近区域压强降低;背风侧不断有气流涌入,压力升高,故气孔以下气体将从背风侧向迎风侧运动。最终在罐内形成与风向平行,先后经过顶盖、背风侧、浮盘、迎风侧的旋涡,旋涡向侧风面延伸从侧孔流出。据文献[

1]推测,此旋涡会引起边圈密封迎风和背风侧出现压力差,但其值小于外浮顶罐相应压力差值,对于一次气托式弹性填料密封,压力差会引起环形气体空间的对流或局部区域涡流,将加速储液蒸发。升高浮盘后,B-1孔气流穿过的气体空间变小,将剩余更多动量途经浮盘,对浮盘扰动增大;气孔下方气体从背风向迎风侧运动的速度也增大,与B-1孔气流所携卷气体剧烈摩擦和动量交换,使顶盖中心风速减小。

图 3(b)表示顶孔罐逐渐升高浮盘后的风速变化情况。由

图 3(b)可知,气体空间中部风速最低,浮盘和罐顶风速有不同程度提高,紧贴顶盖中心两处风速相等。浮盘升高后附近风速显著增大,气体空间中部风速略有增长,顶盖中心风速逐渐减小。低浮盘时,浮盘风速远小于罐顶风速,随浮盘升高,浮盘风速逐渐接近并超过罐顶中心风速。

产生上述现象的原因是:顶孔罐内气体失去迎风侧壁孔气流强烈冲击后,D-1孔内侧呈低压,D-3孔内侧压力较高,气流从D-3孔进入罐内后不能沿背风侧罐壁向浮盘运动,而是在压力梯度和自身惯性力作用下以近似指向浮盘中心的方向流动,对浮盘中心扰动最明显;气流带动周边气体将罐内气体空间分为前上、后下2个相反旋涡。上部旋涡从浮盘开始,经迎风侧罐壁,在D-1孔抽出部分气体后,沿顶盖返回D-3孔与进罐气流相遇;气体抽出罐外时,D-1孔内侧气流被加速,则经过此处流向顶盖中心的风速略有增加。下部旋涡从浮盘开始,经背风侧罐壁,流向D-3孔与进气流相遇。旋涡向两侧发展,掠过浮盘沿壁面向顶盖流动。上、下旋涡气流在D-3孔附近碰撞后随进气流一并运动。顶孔罐内旋涡速度小于壁孔罐,且背风侧入口气流指向浮盘,故若为气托式边圈密封,则在迎、背风侧不能形成有效压强差,对储液面扰动将大为减少。升高浮盘后,气体空间减小,进气流较易穿过气体空间抵达浮盘,对罐内气体扰动增强;且罐内两旋涡被压缩,加剧了气体动量交换。

2.2.2 气孔位置对罐内风速的影响

图 4表示浮盘位于4种高度时壁孔和顶孔对罐内风速的影响。由

图 4可知,壁孔罐内大部分气体空间风速略大于顶孔罐,当测点靠近罐顶中心时,壁孔罐内风速急剧增大。

图4 气窗位置对罐内气流速度的影响

Fig. 4 Influence of vent location on speed of air-vapor flow in tank

产生上述现象的原因是:绕流作用使空气主流经过顶盖时消耗了部分能量,在D-3孔附近静压强不能全部恢复至主流静压强,故与B-1孔相比,D-3孔对罐内气体空间的扰动作用明显减弱。迎风侧主流经B-1孔直接对顶盖气体强烈扰动,而D-1孔是在排出气体时对顶盖气流轻微扰动。

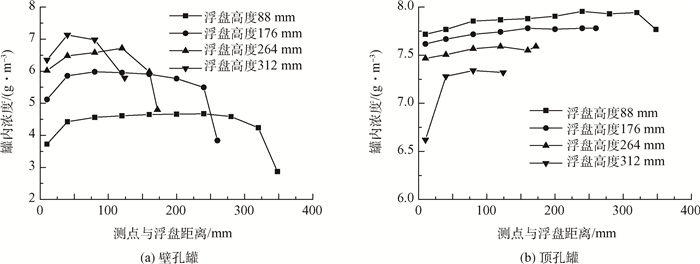

2.3.1 浮盘位置对罐内浓度的影响

图 5(a)表示壁孔罐内气体空间浓度分布情况。由

图 5(a)可知:浮盘和罐顶中心浓度小于分布均匀的中部气体空间浓度;越靠近罐顶,浓度下降越明显,小于浮盘附近浓度。升高浮盘后,浓度分布趋势不变,平均浓度增大;随浮盘升高,浓度值增大的速度变缓。

图5 浮盘位置对罐内浓度的影响

Fig. 5 Influence of floating-roof height on concentration in tank

产生上述现象的原因是:主流风速经B-1孔向罐内注入新鲜空气,大幅降低罐顶气体浓度,空气紧贴顶盖向下风向运动,与周边气体剧烈摩擦,摩擦时产生大量小旋涡,大小不一的旋涡依靠主流提供的能量做无规则脉动,小旋涡耗散消失又重新生成,或汇聚为大旋涡,或碰撞后分裂为更小旋涡,这种无规则运动将携卷涡内气体至别处

[15],加强了空气与罐内蒸气的混合强度。故罐内中部浓度分布均匀;B-1和B-3孔的新鲜空气经背风侧罐壁到达浮盘中心上方使浓度略为降低。浮盘升高后,进罐气流作用在更小的气体空间内,强烈的湍流脉动作用使液面浓度边界层当量膜厚变薄

[3],浓度梯度增大;罐内旋涡经过液面时切应力引起液面振荡,储液分子将有更多动能逸出液面;罐内气体与外界换气量增加,新增风量带走更多蒸气使浓度降低,气体空间与储液面的浓度梯度亦变大,3种因素都将加速储液蒸发。罐内气体浓度增大会抑制储液蒸发,但前两者对蒸发的影响程度随浮盘升高而愈发显著,故浮盘越高,罐内气体浓度越大。

图 5(b)表示顶孔罐浮盘位置变化对罐内浓度的影响。由

图 5(b)可知,气体空间浓度分布较为接近。升高浮盘,罐内浓度略有降低。

产生上述现象的原因是:顶孔罐内两旋涡加强了罐内浓度均匀分布。升高浮盘后,换气量增加,新增风量带走了更多储液蒸气,储液加速蒸发;但蒸发速率小于新风带走蒸气的速率。

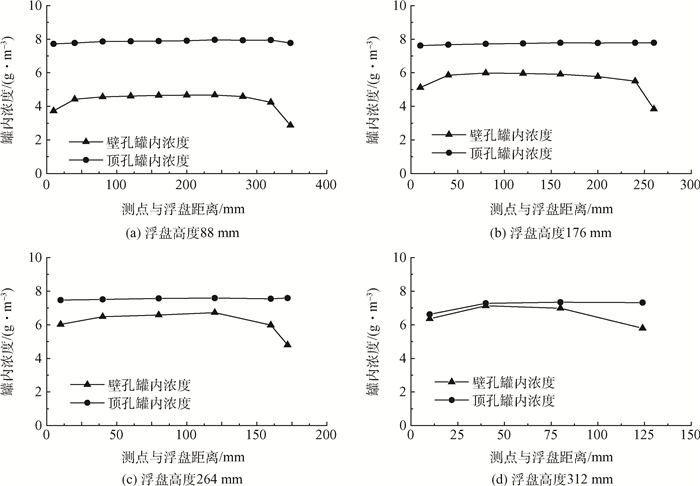

2.3.2 气窗位置对罐内浓度的影响

图 6表示浮盘在不同高度时壁孔和顶孔对罐内浓度的影响。由

图 6可知,顶孔罐内浓度均大于壁孔罐;随浮盘升高,两者间差别缩小,最高浮盘位置时,两者浓度接近。

图6 气窗位置对罐内浓度的影响

Fig. 6 Influence of vent location on concentration in tank

产生上述现象的原因是:相同浮盘位置时,壁孔罐内风速大于顶孔罐,故其换气量比后者多,储液蒸发速率小于空气带走蒸气的速率。浮盘上升后,顶孔罐浓度略有减小,壁孔罐浓度明显增大。

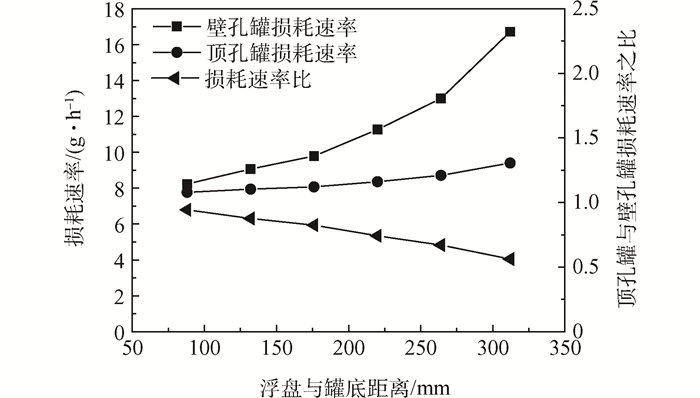

2.4 浮盘与气孔位置对蒸发损耗量的影响

图 7表示改变浮盘和气孔位置后蒸发速率的变化趋势,共6种浮盘位置。从

图 7可知,壁孔罐和顶孔罐随浮盘升高,蒸发速率均增大,蒸发速率增加的幅度也增大,顶孔罐增加幅度小于壁孔罐。低浮盘时,壁孔罐与顶孔罐蒸发速率相差不大,升高浮盘后,两者差别越来越大,顶孔与壁孔的蒸发速率之比越来越小,在最高浮盘处,顶孔罐蒸发速率接近壁孔罐的1/2。

图7 罐顶与罐壁通气孔损耗速率比较

Fig. 7 Comparison of evaporative loss rate in fixed-roof-vent tank with that in shell-vent tank

机理解释见前面各节所述。据此推测,在储油库、炼厂和化工企业等需要储罐改造的现场,若将内浮顶罐的壁孔改造为顶孔,遇外界风扰动时,其损耗速率将减小,可减轻大气污染。此种改造有利于提高罐的容积利用率,提高经济效益,与氮封改造相比,能节省改造工艺和成本。

3 结论

1) 气流进出罐方向与浮盘位置无关,与气孔位置有关,呈现两进两出的特点。

2) 壁孔罐顶盖风速大于浮盘风速,顶盖处储液蒸气浓度小于浮盘处浓度,气体空间中部风速最小,浓度最大;顶孔罐浮盘风速大于顶盖风速,气体空间浓度分布均匀;浮盘升高,罐内风速增大,壁孔罐浓度增大,顶孔罐浓度略有减小。

3) 浮盘升高,损耗速率增大;浮盘移动相同距离,高浮盘比低浮盘损耗速率变化幅度大。顶孔比壁孔能显著减少储液损耗,且浮盘越高,减耗效果越明显。2种气孔位置导致罐内不同气流分布,壁孔罐进气流引起的大旋涡对储液面扰动更强烈,边圈密封压强差更大,使其损耗速率大于顶孔罐。建议将壁孔罐改造为顶孔罐。

4) 建议在API内浮顶罐损耗公式的修订中考虑气窗和浮盘位置的影响。

5) 本文仅研究了特定风速、风向和温度下的储液蒸发扩散规律和损耗机理,后续还将探究泄漏口位置、多种风速、风向角度、气窗数量及其他因素对内浮顶罐蒸发损耗的影响规律和机理。

百度学术

百度学术

下载:

下载: