|

[1]

|

NAZIROˇLU M, Iˇ B, ZGL C.Recovery of N and P from urine by struvite precipitation followed by combined stripping with digester sludge liquid at full scale[J].Water,2013,5(3):1262-1278

|

|

[2]

|

DONOSO-BRAVO A, MAILIER J, MARTIN C, et al.Model selection, identification and validation in anaerobic digestion: A review[J].Water Research,2011,5(17):5347-5364

|

|

[3]

|

王刚.国内外污泥处理处置技术现状与发展趋势[J].环境工程, 2013,1(S1):530-533

|

|

[4]

|

万小春, 董保成, 赵立欣,等.固态物料两相厌氧消化工艺的研究进展[J].中国沼气,2011,9(6):20-23

|

|

[5]

|

WANG A J, LI W W, YU H Q.Advances in biogas technology[M]∥BAI F W,LIU C G,HUANG X,et al.Biotechnology in China III: Biofuels and Bioenergy.Berlin Heidelberg:Springer, 2011:119-141

|

|

[6]

|

POTTS L G A, JOLLY M.Controlling and monitoring anaerobic digesters fed with thermally hydrolysed sludge[J].Water and Environmental Journal,2004,8(2):68-72

|

|

[7]

|

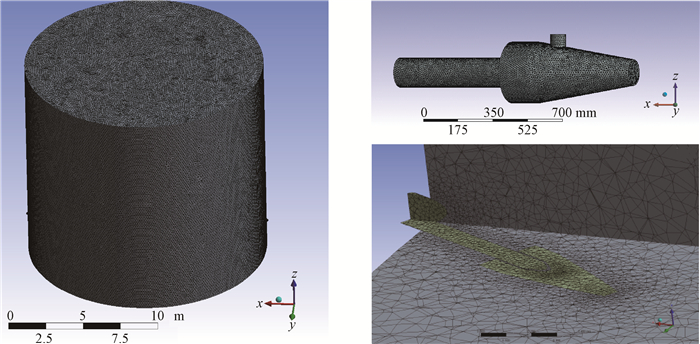

MICALE G,GRISAFI F,RIZZUTI L, et al.CFD simulation of particle suspension height in stirred vessels[J].Chemical Engineering Research and Design,2004,2(9):1204-1213

|

|

[8]

|

COONEY M J, LEWIS K, HARRIS K, et al.Start up performance of biochar packed bed anaerobic digesters[J].Journal of Water Process Engineering,2015,9:7-13

|

|

[9]

|

BLOCKEN B, GUALTIERI C.Ten iterative steps for model development and evaluation applied to computational fluid dynamics for environmental fluid mechanics[J].Environmental Modelling & Software,2012,3(1):1-22

|

|

[10]

|

KARAMA A B, ONYEJEKWE O O, BROUCKAERT C J, et al.The use of computational fluid dynamics (CFD).Technique for evaluating the efficiency of an activated sludge reactor[J].Water Science & Technology,1999,9(10/11):329-332

|

|

[11]

|

HAGUE J, TA C T, BIGGS M J, et al.Small scale model for CFD validation in DAF application[J].Water Science,2001,3(8):167-173

|

|

[12]

|

DANIEL K P, JOEL J D.Modeling of disinfection contactor hydraulics under uncertainty[J].Journal of Environmental Engineerinng,2002,8(11):1056-1067

|

|

[13]

|

LIU J, CRAPPER M, MCCONNACHIE G L.An accurate approach to the design of channel hydraulic flocculators[J].Water Research,2004,8(4):875-886

|

|

[14]

|

KHAN L A, WIVKLEIN E C, TEIXEIRA E C.Validation of a three-dimensional computational fluid dynamics model of a contact tank[J].Journal of Hydraulic Engineering,2006,2(7):741-746

|

|

[15]

|

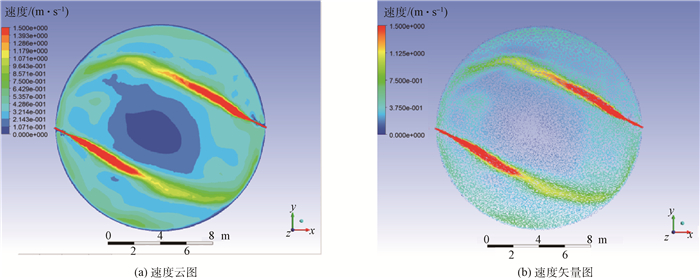

TERASHIMA M, GOEL R, KOMATSU K, et al.CFD simulation of mixing in anaerobic digesters[J].Bioresource Technology,2009,0(7):2228-2233

|

|

[16]

|

MERONER R N, COLORADO P E.CFD simulation of mechanical draft tube mixing in anaerobic digester tanks[J].Water Research,2009,3(4):1040-50

|

|

[17]

|

WU B.CFD analysis of mechanical mixing in anaerobic digesters[J].Transactions of the ASBAE,2009,2(4):1371-1382

|

|

[18]

|

WU B.CFD simulation of mixing in egg-shaped anaerobic digesters[J].Water Research,2010,4(5):1507-1519

|

|

[19]

|

陈庆光,徐忠,张永建.湍流冲击射流流动与传热的数值研究进展[J].力学进展,2002,2(1):92-108

|

|

[20]

|

禹言芳,吴剑华,孟辉波.新型循环射流混合器湍流特性分析[J].过程工程学报,2011,1(1):1-8

|

|

[21]

|

RAHIMI M, PARVAREH A.CFD study on mixing by coupled jet-impeller mixers in a large crude oil storage tank[J].Computers and Chemical Engineering,2007,1(7):737-744

|

|

[22]

|

王乐勤,林思达,田艳丽,等.基于CFD的大流量喷嘴喷射性能研究[J].流体机械,2008,6(11):17-22

|

|

[23]

|

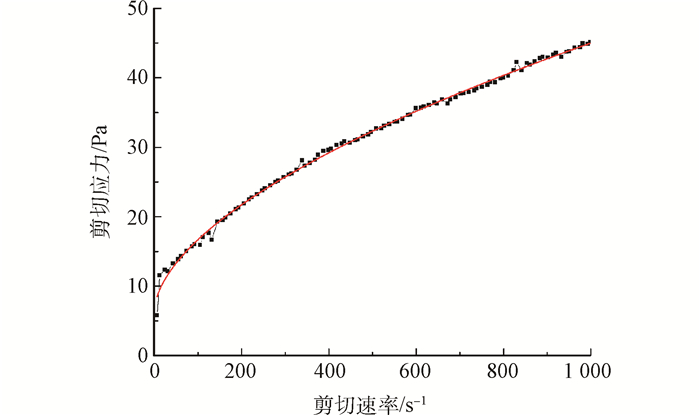

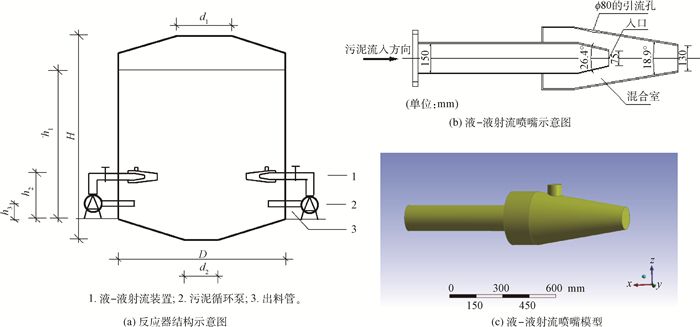

蒋竹荷,曹秀芹,葛芳州,等.基于污泥流变学的射流搅拌混合特性[J].环境工程学报,2016,0(10):5924-5930

|

|

[24]

|

曹秀芹,王鑫,蒋竹荷,等.高含固污泥在热水解-厌氧消化工艺中的流变特性分析[J].环境工程学报,2017,1(4):2493-2498

|

|

[25]

|

ALEXANDRA M M, MARTINEZ T M, VICENTE F M, et al.Modeling flow inside an anaerobic digester by CFD techniques[J].International Journal of Energy & Environment,2011,2(6):963-974

|

|

[26]

|

VESVIKAR M S, ALDAHHAN M.Flow pattern visualization in a mimic anaerobic digester using CFD[J].Biotechnology and Bioengineering,2005,9(3):719-732

|

|

[27]

|

熊向峰, 贾丽娟, 宁平,等.射流搅拌提高牛粪中温厌氧发酵产沼气性能[J].农业工程学报,2015,1(19):222-227

|

百度学术

百度学术

下载:

下载: