全文HTML

1 实验部分

1.1 原材料与试剂

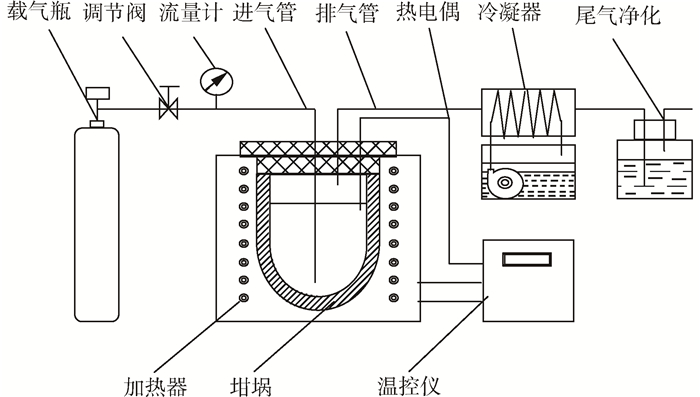

1.2 实验装置

Fig. 1 Schematic of molten salt process experiment

1.3 实验过程

1.4 分析方法与主要仪器

2 结果与讨论

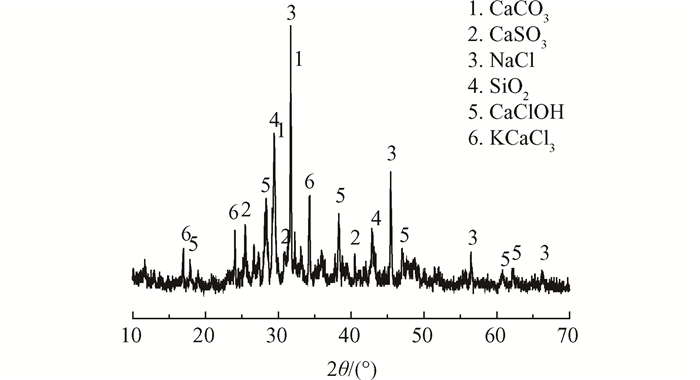

2.1 原始飞灰基本特性检测

2.1.1 原始飞灰组成与溶解、熔化特性

Table 1 Main chemical elements mass fraction of MSWI fly ash

Table 1 Main chemical elements mass fraction of MSWI fly ash

| % | |

| 元素 | 质量分数 |

| Cl | 29.6 |

| Ca | 36.2 |

| Si | 3.35 |

| Al | 5.25 |

| S | 5.59 |

| Na | 6.81 |

| K | 5.73 |

Table 2 Amount of loss and amount of water-soluble matter of fly ash at different temperatures treatment

Table 2 Amount of loss and amount of water-soluble matter of fly ash at different temperatures treatment

| 处理温度/℃ | 可溶物/% | 烧失量/% | 总失重率/% |

| 100 | 40.4 | 0 | 40.4 |

| 800 | 31.25 | 12.3 | 43.55 |

| 1 000 | 20.55 | 31.35 | 51.9 |

| 1 200 | 3.25 | 39.85 | 53.15 |

| 1 400 | 0 | 44.85 | 44.85 |

| 1 450 | 0 | 50.85 | 50.85 |

Fig. 2 Schematic of XRD patterns of original fly ash

Table 3 Oxide composition mass fraction of MSWI fly ash

Table 3 Oxide composition mass fraction of MSWI fly ash

| % | |

| 氧化物 | 质量分数 |

| CaO | 67.17 |

| MgO | 3.39 |

| SiO2 | 9.50 |

| Al2O3 | 13.69 |

| Fe2O3 | 1.91 |

2.1.2 原始飞灰重金属浸出特性

Table 4 Heavy metal ion leaching concentration of MSWI fly ash and standard limits

Table 4 Heavy metal ion leaching concentration of MSWI fly ash and standard limits

| μg·L-1 | |||||

| 项目 | Cr | Cu | Zn | Cd | Pb |

| 原始飞灰 | 209.4 | 6 498 | 21 970 | 1 819 | 1 936 |

| HJ/T 300-2007限值 | 4 500 | 40 000 | 100 000 | 150 | 250 |

2.2 氯化钠熔盐处置飞灰后重金属离子浸出特性

2.2.1 热处理温度和添加氯化钙对氯化钠熔盐中飞灰重金属挥发特性

Table 5 Heavy metal leaching concentration of MSWI fly ash treated at different temperatures in sodium chloride molten salt by adding calcium chloride

Table 5 Heavy metal leaching concentration of MSWI fly ash treated at different temperatures in sodium chloride molten salt by adding calcium chloride

| 温度/℃ | CaCl2与NaCl重量比 | 重金属浸出浓度/(μg·L-1) | |||

| Cu | Zn | Cd | Pb | ||

| 900 | 0:1 | 129.5 | 1 056 | 115.3 | 1 072 |

| 1:9 | 30.7 | 451 | 26.6 | 177.5 | |

| 950 | 0:1 | 252.2 | 410 | 329.7 | 881.1 |

| 1:9 | 336.6 | 227.7 | 201.1 | 379.2 | |

| 1 000 | 0:1 | 478.5 | 423.6 | 102.2 | 495.3 |

| 1:9 | 496.3 | 952.2 | 109.6 | 179.7 | |

| 原始飞灰 | 6 498 | 21 970 | 1 819 | 1 936 | |

2.2.2 盐灰比和热处理气氛对飞灰重金属挥发特性的影响

Table 6 Heavy metal ions leaching concentration at different salts fly ash ratios under reducing atmosphere

Table 6 Heavy metal ions leaching concentration at different salts fly ash ratios under reducing atmosphere

| 实验条件 | 重金属离子浸出浓度/(μg·L-1) | ||||||

| 盐灰重量比 | 石墨/g | Cr | Cu | Zn | Cd | Pb | |

| 1:2 | 1.0 | 157.9 | 128.1 | 2 081 | 15.9 | 326.3 | |

| 1:6 | 1.0 | 95.1 | 514.7 | 4 979 | 53.6 | 1 045 | |

| 1:10 | 1.0 | 71.1 | 32.2 | 790.2 | 16.5 | 225.6 | |

Table 7 Heavy metal ions leaching concentration at different salts fly ash ratios under oxidizing atmosphere

Table 7 Heavy metal ions leaching concentration at different salts fly ash ratios under oxidizing atmosphere

| 实验条件 | 重金属离子浸出浓度/(μg·L-1) | ||||||

| 灰盐重量比 | 石墨/g | Cr | Cu | Zn | Cd | Pb | |

| 1:2 | 0 | 622.5 | 1 275 | 6 409 | 285.2 | 984.2 | |

| 1:6 | 0 | 92.3 | 1 428 | 7 497 | 323.6 | 1 328 | |

| 1:10 | 0 | 71.7 | 1 041 | 13 580 | 497.0 | 1 274 | |

2.2.3 高氯化钙含量熔盐处置飞灰后重金属离子浸出特性

Table 8 Heavy metal ions leaching concentration for MSWI fly ash treatment with high calcium chloride content in molten salt

Table 8 Heavy metal ions leaching concentration for MSWI fly ash treatment with high calcium chloride content in molten salt

| 实验条件 | 重金属离子浸出浓度/(μg·L-1) | ||||||||

| CaCl2与NaCl比值 | 灰盐比 | 温度/℃ | 石墨/g | Cr | Cu | Zn | Cd | Pb | |

| 1:1 | 1:10 | 1 000 | 1.0 | 62.80 | 69.40 | 493.90 | 2.10 | 49.90 | |

| 2:1 | 1:10 | 1 000 | 1.0 | 189.00 | 2 251 | 3 328 | 194.30 | 33.00 | |

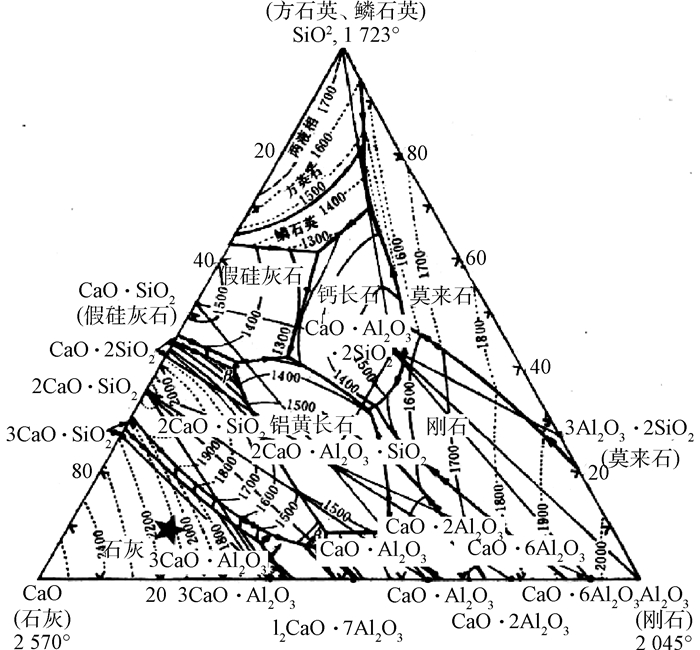

2.3 熔盐处置飞灰灰渣晶体矿物组成与胶凝特性

2.3.1 飞灰渣的矿物组成

Fig. 3 XRD patterns of waste after MSWI fly ash treated by melton salt process

Fig. 3 XRD patterns of waste after MSWI fly ash treated by melton salt process

2.3.2 飞灰渣的火山灰胶凝特性

Table 9 Cementitious characteristics after MSWI fly ash treated by melton salt process

Table 9 Cementitious characteristics after MSWI fly ash treated by melton salt process

| MPa | ||

| 项目 | 抗折强度 | 抗压强度 |

| 空白组 | 5.3 | 15.5 |

| 30%灰渣粉 | 5.0 | 15.3 |

3 结论

致谢: 长安大学西部矿产资源与地质工程教育部重点实验室的何克、谭细娟老师提供了等离子质谱测试,在此表示感谢。

下载:

下载: