全文HTML

1 实验部分

Table 1 Preparation condition of biomass char

Table 1 Preparation condition of biomass char

| 样品编号 | 制备种类 | 制备粒径/μm | 制备温度/℃ | 制备氧气浓度/% | 制焦率/% |

| WS-1 | 核桃壳 | >106且 < 150 | 600 | 3 | 20.99 |

| WS-2 | 核桃壳 | >150且 < 270 | 600 | 3 | 21.77 |

| WS-3 | 核桃壳 | >270 | 600 | 3 | 23.02 |

| CH-1 | 椰壳 | >150且 < 270 | 600 | 0 | 19.62 |

| CH-2 | 椰壳 | >150且 < 270 | 600 | 3 | 21.26 |

| CH-3 | 椰壳 | >150且 < 270 | 600 | 5 | 21.66 |

| CC-1 | 玉米芯 | >150且 < 270 | 1 000 | 3 | 17.75 |

| CC-2 | 玉米芯 | >150且 < 270 | 800 | 3 | 20.09 |

| CC-3 | 玉米芯 | >150且 < 270 | 600 | 3 | 24.01 |

| CS-1 | 棉花秆 | >150且 < 270 | 600 | 3 | 22.89 |

2 结果与分析

2.1 生物质种类对生物焦吸附汞特性的影响

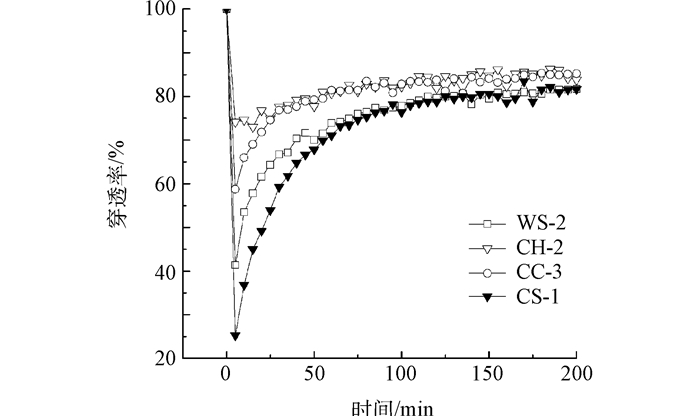

Fig. 1 Breakthrough curves of biomass char with different species

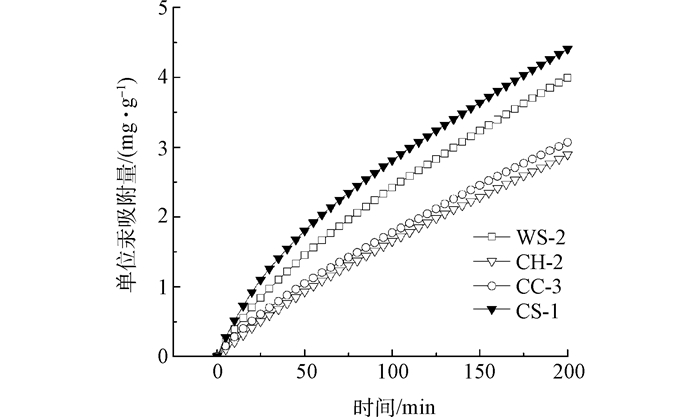

Fig. 2 Adsorption capacity curves of biomass char with different species

| η=CoutCin×100% | (1) |

| q=[∫ti01−CiCinqvdt]Cin/m≈n∑i=0(1−Ci+Ci+12Cin)qvΔtCin/m | (2) |

Table 2 Proximate analyses of biomass

Table 2 Proximate analyses of biomass

| % | ||||

| 生物质 | Vad | FCad | Mad | Aad |

| WS | 79.50 | 12.77 | 7.40 | 0.32 |

| CH | 70.61 | 17.19 | 11.88 | 0.31 |

| CC | 74.31 | 17.84 | 6.02 | 1.82 |

| CS | 77.83 | 16.16 | 3.94 | 2.06 |

| 注:下标ad表示空气干燥基。 | ||||

Fig. 3 TGA curves of four biomass

Table 3 Pore structure parameter of biomass char with different species

Table 3 Pore structure parameter of biomass char with different species

| 样品编号 | 平均孔直径/nm | 出现概率最大的孔径/nm | BET比表面积/(m2·g-1) | 累积孔体积/(cm3·g-1) | 累积孔面积/(m2·g-1) | 相对比孔容积/% | 分形维数 | ||

| 微孔 | 介孔 | 大孔 | |||||||

| WS-2 | 2.407 | 18.384 | 404.98 | 0.098 4 | 126.75 | 6.09 | 90.39 | 3.52 | 2.695 9 |

| CH-2 | 2.709 | 17.784 | 174.39 | 0.058 4 | 81.96 | 10.27 | 81.23 | 8.51 | 2.351 2 |

| CC-3 | 4.036 | 68.226 | 0.51 | 0.065 3 | 0.51 | 0 | 95.49 | 4.51 | 2.907 5 |

| CS-1 | 4.695 | 20.306 | 153.24 | 0.119 1 | 44.63 | 0.84 | 93.08 | 6.08 | 2.903 8 |

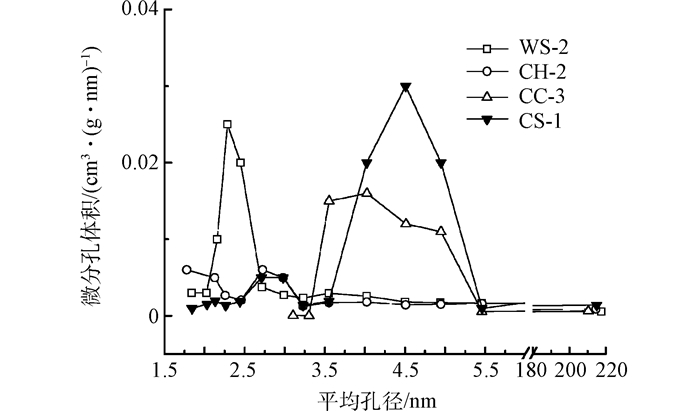

Fig. 4 Differential pore volume of biomass char with different species

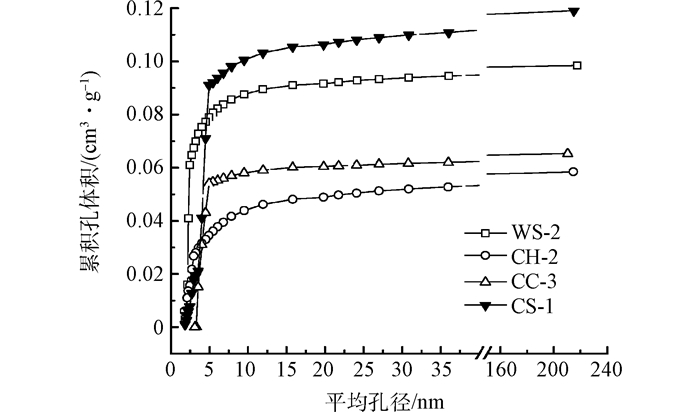

Fig. 5 Cumulative pore volume of biomass char with different species

| ln(V/Vm)=(DS−3)ln(ln(p0/p))+C | (3) |

2.2 制备粒径对生物焦汞吸附特性的影响

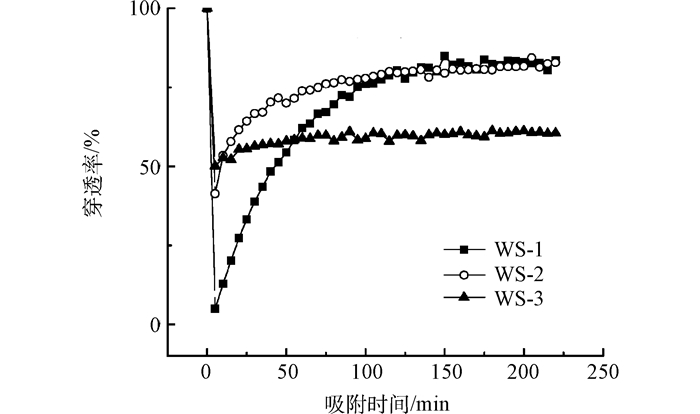

Fig. 6 Breakthrough curves of biomass char with different particle size

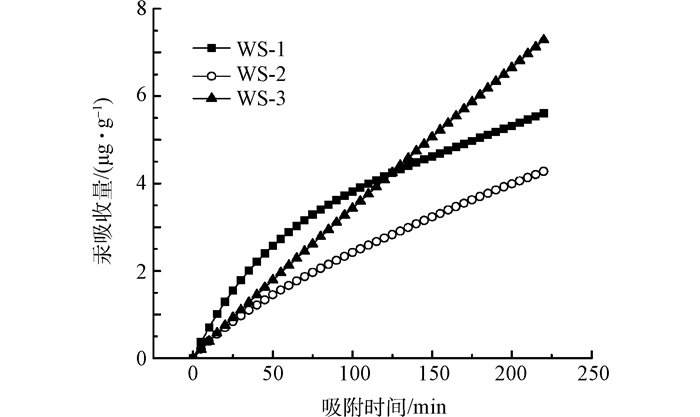

Fig. 7 Adsorption capacity curves of biomass char with different particle size

Table 4 Pore structure parameter of biomass char with different particle size

Table 4 Pore structure parameter of biomass char with different particle size

| 样品编号 | 平均孔直径/nm | 出现概率最大的孔径/nm | BET比表面积/(m2·g-1) | 累积孔体积/(cm3·g-1) | 累积孔面积/(m2·g-1) | 相对比孔容积/% | 分形维数 | ||

| 微孔 | 介孔 | 大孔 | |||||||

| WS-1 | 2.303 | 17.277 | 413.32 | 0.128 6 | 92.37 | 5.75 | 88.16 | 6.09 | 2.905 0 |

| WS-2 | 2.407 | 18.384 | 404.98 | 0.098 4 | 126.75 | 6.09 | 90.39 | 3.52 | 2.695 9 |

| WS-3 | 5.651 | 19.676 | 439.65 | 0.151 4 | 283.85 | 3.34 | 95.03 | 1.63 | 2.900 9 |

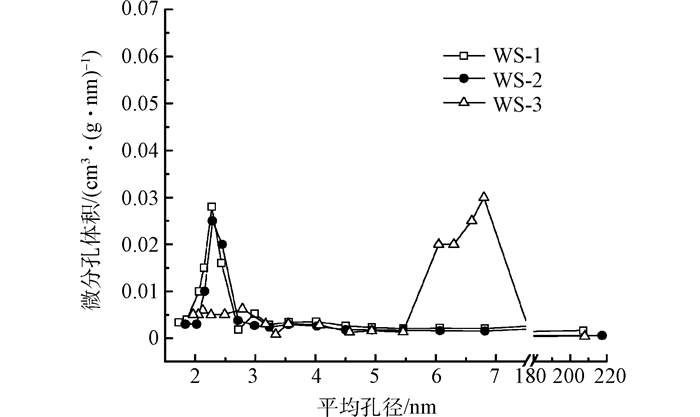

Fig. 8 Differential pore volume of biomass char with different particle size

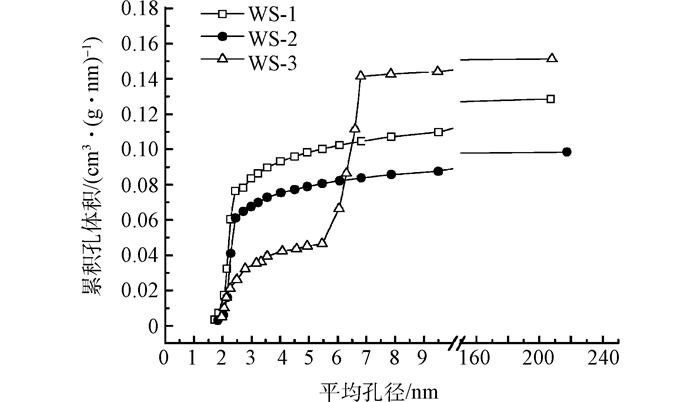

Fig. 9 Cumulative pore volume of biomass char with different particle size

2.3 制备温度对生物焦汞吸附特性的影响

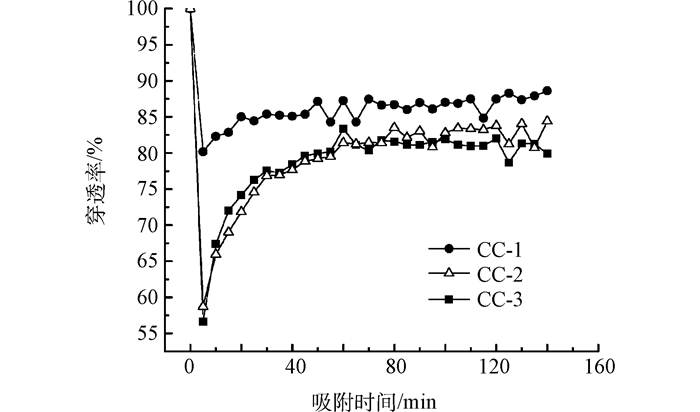

Fig. 10 Breakthrough curves of biomass char with different preparation temperature

Fig. 10 Breakthrough curves of biomass char with different preparation temperature

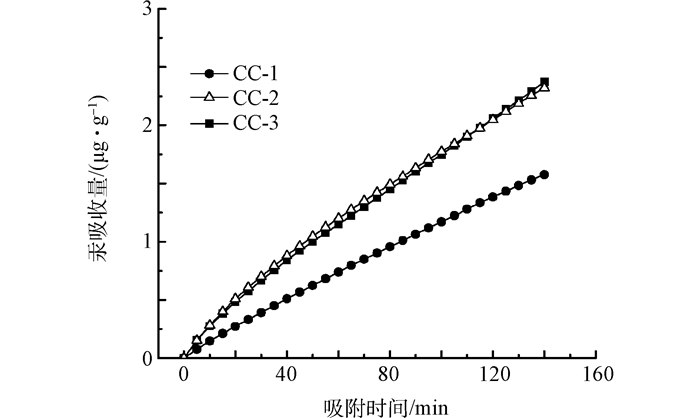

Fig. 11 Adsorption capacity curves of biomass char with different preparation temperature

Fig. 11 Adsorption capacity curves of biomass char with different preparation temperature

Table 5 Pore structure parameter of biomass char with different preparation temperature

Table 5 Pore structure parameter of biomass char with different preparation temperature

| 样品编号 | 平均孔直径/nm | 出现概率最大的孔径/nm | BET比表面积/(m2·g-1) | 累积孔体积/(cm3·g-1) | 累积孔面积/(m2·g-1) | 相对比孔容积/% | 孔隙丰富度Z | 分形维数 | ||

| 微孔 | 介孔 | 大孔 | ||||||||

| CC-1 | 8.354 | 49.501 | 0.24 | 0.040 9 | 0.19 | 0 | 84.09 | 15.91 | 5.762 5 | 2.332 5 |

| CC-2 | 13.219 | 78.682 | 0.42 | 0.054 1 | 0.29 | 0 | 94.34 | 5.66 | 7.790 3 | 2.678 9 |

| CC-3 | 4.036 | 68.226 | 0.51 | 0.065 3 | 0.51 | 0 | 95.49 | 4.51 | 7.849 9 | 2.907 5 |

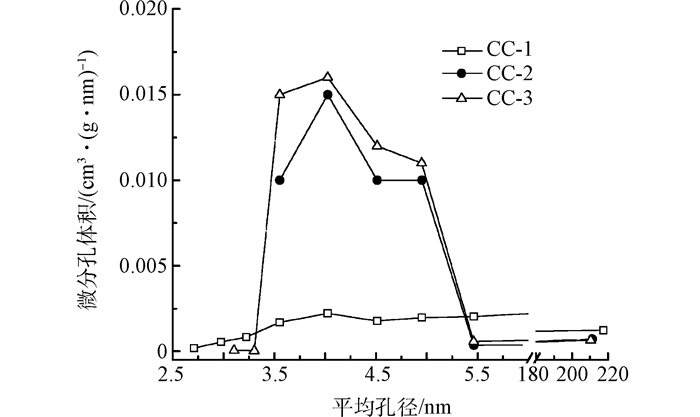

Fig. 12 Differential pore volume of biomass char with different preparation temperature

Fig. 12 Differential pore volume of biomass char with different preparation temperature

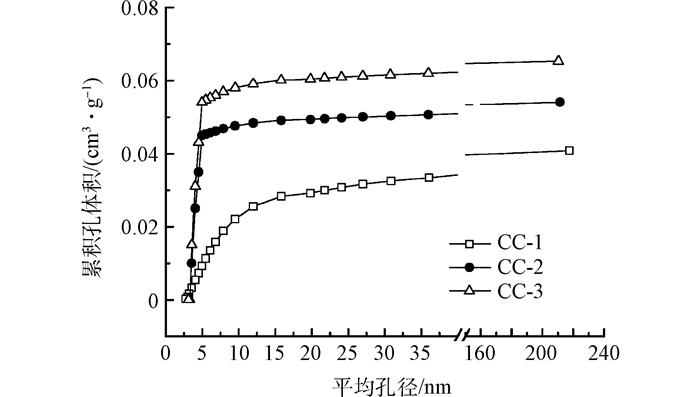

Fig. 13 Cumulative pore volume of biomass char with different preparation temperature

Fig. 13 Cumulative pore volume of biomass char with different preparation temperature

| Z=S0V0 | (4) |

2.4 制备氧气浓度对生物焦汞吸附特性的影响

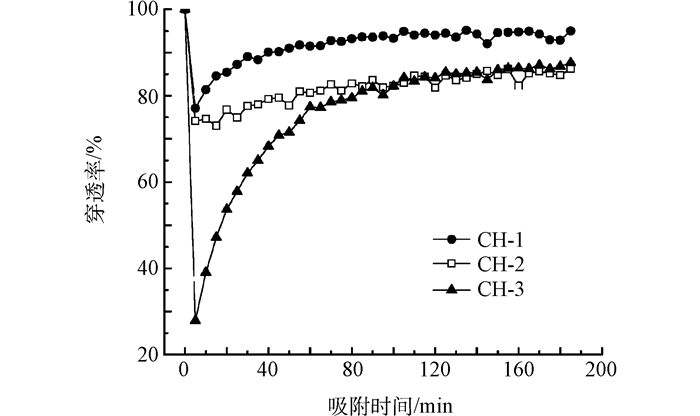

Fig. 14 Breakthrough curves of biomass char with different preparation oxygen concentration

Fig. 14 Breakthrough curves of biomass char with different preparation oxygen concentration

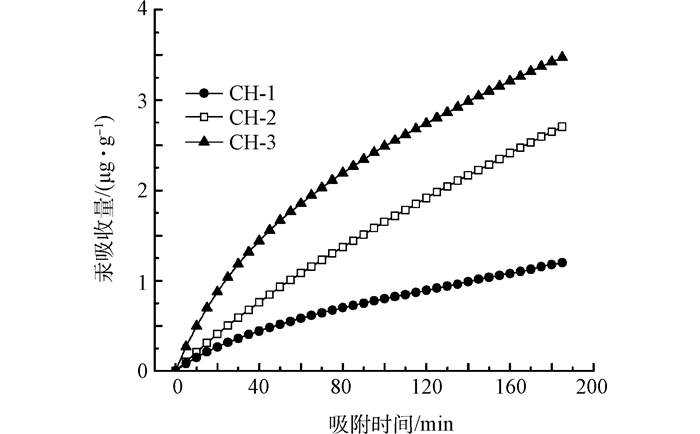

Fig. 15 Adsorption capacity curves of biomass char with different preparation oxygen concentration

Fig. 15 Adsorption capacity curves of biomass char with different preparation oxygen concentration

Table 6 Pore structure parameter of biomass char with different preparation oxygen concentration

Table 6 Pore structure parameter of biomass char with different preparation oxygen concentration

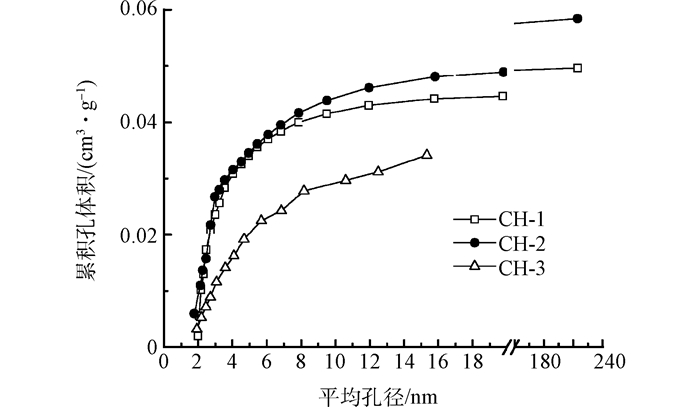

| 样品编号 | 平均孔直径/nm | 出现概率最大的孔径/nm | BET比表面积/(m2·g-1) | 累积孔体积/(cm3·g-1) | 累积孔面积/(m2·g-1) | 相对比孔容积/% | 分形维数 | ||

| 微孔 | 介孔 | 大孔 | |||||||

| CH-1 | 2.862 | 19.779 | 301.23 | 0.049 6 | 97.48 | 4.03 | 90.81 | 5.16 | 2.906 7 |

| CH-2 | 2.709 | 17.784 | 174.39 | 0.058 4 | 81.96 | 10.27 | 81.23 | 8.51 | 2.351 2 |

| CH-3 | 6.282 | 17.096 | 205.47 | 0.039 8 | 26.53 | 8.01 | 87.06 | 4.93 | 2.878 3 |

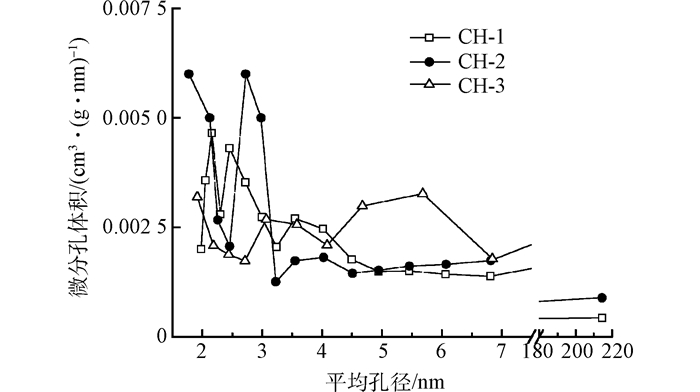

Fig. 16 Differential pore volume of biomass char with different preparation oxygen concentration

Fig. 16 Differential pore volume of biomass char with different preparation oxygen concentration

Fig. 17 Cumulative pore volume of biomass char with different preparation oxygen concentration

Fig. 17 Cumulative pore volume of biomass char with different preparation oxygen concentration

2.5 生物焦汞吸附特性的动力学研究

| q=qe(1−e−tk1) | (5) |

| q=q2ek2t1+qek2t | (6) |

| q=kidt12+C | (7) |

| q=1βln(t+t0)−1βln(t0) | (8) |

Table 7 Fitting parameters of biomass chars with different preparation condition

Table 7 Fitting parameters of biomass chars with different preparation condition

| 样品 | 准一级动力学方程 | 准二级动力学方程 | 颗粒内扩散方程 | 耶洛维奇方程 | |||||||||||

| R2 | k1 | qe | R2 | k2 | qe | R2 | kid | c | R2 | α | β | ||||

| WS-1 | 0.994 9 | 0.010 7 | 5.915 6 | 0.997 4 | 1.06×10-3 | 8.262 1 | 0.995 7 | 0.411 | -0.405 7 | 0.999 5 | 0.085 8 | 0.381 0 | |||

| WS-2 | 0.997 8 | 0.004 6 | 6.615 6 | 0.998 3 | 2.79×10-7 | 10.676 | 0.993 4 | 0.341 | -0.898 4 | 0.998 8 | 0.033 3 | 0.239 3 | |||

| WS-3 | 0.999 9 | 0.000 5 | 69.266 | 0.999 9 | 2.60×10-6 | 116.76 | 0.970 5 | 0.734 7 | -3.374 | 0.999 9 | 0.035 2 | 1.57×10-2 | |||

| CH-1 | 0.999 7 | 0.002 9 | 6.536 8 | 0.998 5 | 1.52×10-4 | 11.312 | 0.997 4 | 0.258 3 | -0.831 7 | 0.996 8 | 0.019 8 | 0.206 9 | |||

| CH-2 | 0.999 4 | 0.005 3 | 3.945 9 | 0.999 8 | 1.39×10-3 | 4.855 2 | 0.997 9 | 0.101 3 | -0.194 5 | 0.998 5 | 0.012 7 | 1.024 | |||

| CH-3 | 0.999 9 | 0.010 8 | 3.874 1 | 0.999 9 | 1.50×10-3 | 5.577 7 | 0.996 6 | 0.283 3 | -0.361 0 | 0.999 3 | 0.053 3 | 0.538 4 | |||

| CC-1 | 0.999 1 | 0.000 6 | 29.586 | 0.999 1 | 5.70×10-6 | 55.679 | 0.966 7 | 0.370 1 | -1.680 6 | 0.999 1 | 0.017 7 | 3.83×10-2 | |||

| CC-2 | 0.999 8 | 0.002 4 | 5.448 2 | 0.999 8 | 1.31×10-4 | 10.093 | 0.979 3 | 0.165 3 | -0.475 5 | 0.999 9 | 0.013 4 | 0.214 7 | |||

| CC-3 | 0.997 4 | 0.003 7 | 5.814 8 | 0.998 2 | 2.32×10-4 | 9.782 9 | 0.997 6 | 0.263 1 | -0.751 0 | 0.988 6 | 0.022 8 | 0.247 8 | |||

| CS-1 | 0.996 8 | 0.007 6 | 8.654 8 | 0.995 4 | 6.46×10-4 | 4.953 2 | 0.998 4 | 0.352 4 | -0.667 9 | 0.998 0 | 0.048 3 | 0.335 9 | |||

百度学术

百度学术

下载:

下载: