可用于去除高盐废水中有机污染物的混凝-Fenton氧化联合工艺

Organic pollutant removal from high-salinity wastewater by coagulation-Fenton integrated process

-

摘要: 以某环氧树脂生产厂产生的高盐有机废水为对象,对比研究了Fenton、Fenton-混凝、混凝-Fenton等工艺去除废水中有机污染物的效能。考察了Fenton反应中Fe2+、H2O2投加比、初始pH、反应时间以及混凝反应中混凝剂种类、投加量等参数对处理效果的影响。结果表明:Fenton工艺的最佳条件为亚铁和过氧化氢投加比1:20,投加量分别为25 mmol·L-1和500 mmol·L-1,初始pH 3,反应时间120 min,TOC去除率为62.50%;混凝工艺选择FeSO4混凝剂,投加量为300 mg·L-1,TOC去除率为23.78%;废水经过Fenton-无混凝剂混凝、Fenton-混凝剂混凝、混凝-一级Fenton氧化和混凝-二级Fenton氧化工艺处理,TOC去除率分别为68.32%、71.51%、80.69%和89.27%。

-

关键词:

- 高盐有机废水 /

- Fenton氧化 /

- 混凝-Fenton氧化

Abstract: The removal of organics from high salinity epoxy resin manufacturing wastewater by coagulation and Fenton processes was investigated and compared. The effects of initial pH value, Fenton's reagent or coagulant dosage and reaction time on organics removal were investigated during the oxidation and coagulation processes. Results showed that the optimum conditions for Fenton oxidation were obtained at pH=3 and the mole ratio of Fenton's reagent was n(Fe2+)/n(H2O2)=1:20, Fe2+ dosage of 25 mmol·L-1, and H2O2 dosage of 500 mmol·L-1. The maximum removal efficiency for TOC by Fenton oxidation was 62.50% after 120 min reaction. The removal efficiency of TOC by coagulation process was 23.78% with 300 mg·L-1dosage of FeSO4. The removal efficiencies of TOC in different Fenton and coagulation integrated processes, namely Fenton-coagulation (without addition of coagulant) process, Fenton-coagulation process, coagulation-Fenton oxidation and coagulation-two staged Fenton oxidation process, were 68.32%,71.51%,80.69% and 89.27%, respectively. -

近年来,锑的污染问题日益严重,许多工业过程(如半导体、阻燃剂、合金、催化剂、化工产品等)的生产会向环境中大量的引入锑[1-2],矿山尾矿也是锑污染的主要来源地之一。我国拥有丰富的锑资源,大规模开采的同时也遗留下来大量的废弃尾矿,尾矿中的Sb与Sb化合物随着雨水,地表水浸出,使得矿山排水中含有高浓度的Sb,并通过不断的迁移转化或累积对周围环境和生物造成严重的危害[3]。因此,如何有效地处理含Sb废水一直以来都是各领域所关注的难题。

Sb在水体中常以Sb(Ⅲ)和Sb(Ⅴ)形式存在,其可在不同的pH条件下表现出不同的存在形式[4]。与常规重金属离子不同,Sb在高pH的条件下有着较高的迁移率[5],这一特性使Sb很难通过传统的方法(投加石灰石、白云石)被有效去除。为了解决这一问题,研究人员提出了许多处理锑污染的方法,包括混凝沉淀法[6-7]、膜分离法[8]、微生物法[9]、电化学法[10-11]、离子交换法[12]、吸附法[13-14]等。但是这些方法仍存在操作复杂、工艺成本高、处理浓度低等缺点,无法很好地兼顾对去除效果和二次污染的控制,难以在含锑酸性矿山废水处理中得到广泛推广与应用。据报道[11],Sb(Ⅲ)的毒性的比Sb(Ⅴ)高出10倍以上,因此,将Sb(Ⅲ)转化为Sb(Ⅴ)是实现Sb(Ⅲ)污染控制的一个可行的途径。曹岛等[15]通过H2O2对铜电解液中的Sb(Ⅲ)进行氧化,脱除率可达到68.2%。KONG等[16-17]对黄铁矿(FeS2)在自然酸性环境下发生Fenton反应并有效氧化水体中Sb(Ⅲ)进行了一系列的机理分析与研究。LIU等[11]以FeOCl改性碳纳米管(CNT)滤波器作为功能性阴极,通过流动式电芬顿体系高效地处理300 mL浓度为1 000 μg·L−1的含锑废水,取得了较好的效果。这些研究为我们处理此类废水提供新的方向:通过强氧化性物质(·OH),将Sb(Ⅲ)高效地转化为稳定的高价态,从而降低水体中的毒性,这已成为一种治理酸性矿山废水中Sb(Ⅲ)可行的办法。

本研究设计了一种新型的电芬顿反应器,以酸性矿山废水中的Sb(Ⅲ)为处理目标,考察了各关键参数对去除率的影响,系统地评价了该反应器较传统处理技术的优越性,探讨了其反应机理,并对该反应器在实际废水处理中的应用效果进行了评估,本研究可为含Sb(Ⅲ)酸性矿山废水的处理提供新的解决思路与依据。

1. 材料与方法

1.1 废水与试剂

本研究以湖南某地锑矿浮选废水为例,废水水质:pH=2.4、98.2~102.26 mg·L−1 Sb(Ⅲ)、0.42 mg·L−1 As、0.55 mg·L−1 Fe、0.24 mg·L−1 Mn、0.08 mg·L−1 Cr、0.16 mg·L−1 Zn、30 mg·L−1 COD、3.98 g·L−1

SO2−4 、51 mg·L−1CO2−3 、70 mg·L−1PO3−4 。通过配制模拟含锑废水进行一系列探究。所用试剂(均为分析纯)为酒石酸锑钾(C8H4K2O12Sb2·3H2O,国药)、氯化钾(KCl,国药)、水杨酸(salicylic acid,国药)、苯醌(benzoquinone,国药)、硫酸(H2SO4,国药)、氢氧化钠(NaOH,国药)。实验中所用水均为超纯水(UPH,优普,18.25 MΩ.cm)。1.2 实验装置与步骤

电芬顿反应在有机玻璃(PMMA)材质的圆柱形反应器(D=100 mm, H=150 mm)中进行,实验装置如图1所示。装置阴极由Ti网制成(D=40 mm,H=50 mm),并将活性炭纤维毡(ACF)覆于表面,阳极为Fe电极(10 cm×5 cm),正负极分别通过不锈钢电极夹连接至直流电源(MESTEK DP305)上,通过调节阴极最外端侧到阳极板的距离来控制板间距。配制1 L含100 mg·L−1 Sb(Ⅲ)模拟废水,将阴极浸泡在废水中数小时,直至饱和后取出再用。通入电流开始反应后,通过控制变量法,探究关键参数对去除率的影响,每组实验设置3组平行,在不同的时间段内,提取溶液转移至10 mL取样管中并冷藏。

1.3 样品分析

反应中电流的调控通过直流稳压电源(MASTEK DP305)完成,溶液pH的测定通过pH计(METTLER S220)测定,采用火焰原子吸收法(AA-3800,上海)检测Sb(Ⅲ)和Sb(Ⅴ)的浓度变化。

2. 结果与讨论

2.1 新型电芬顿反应器的优点

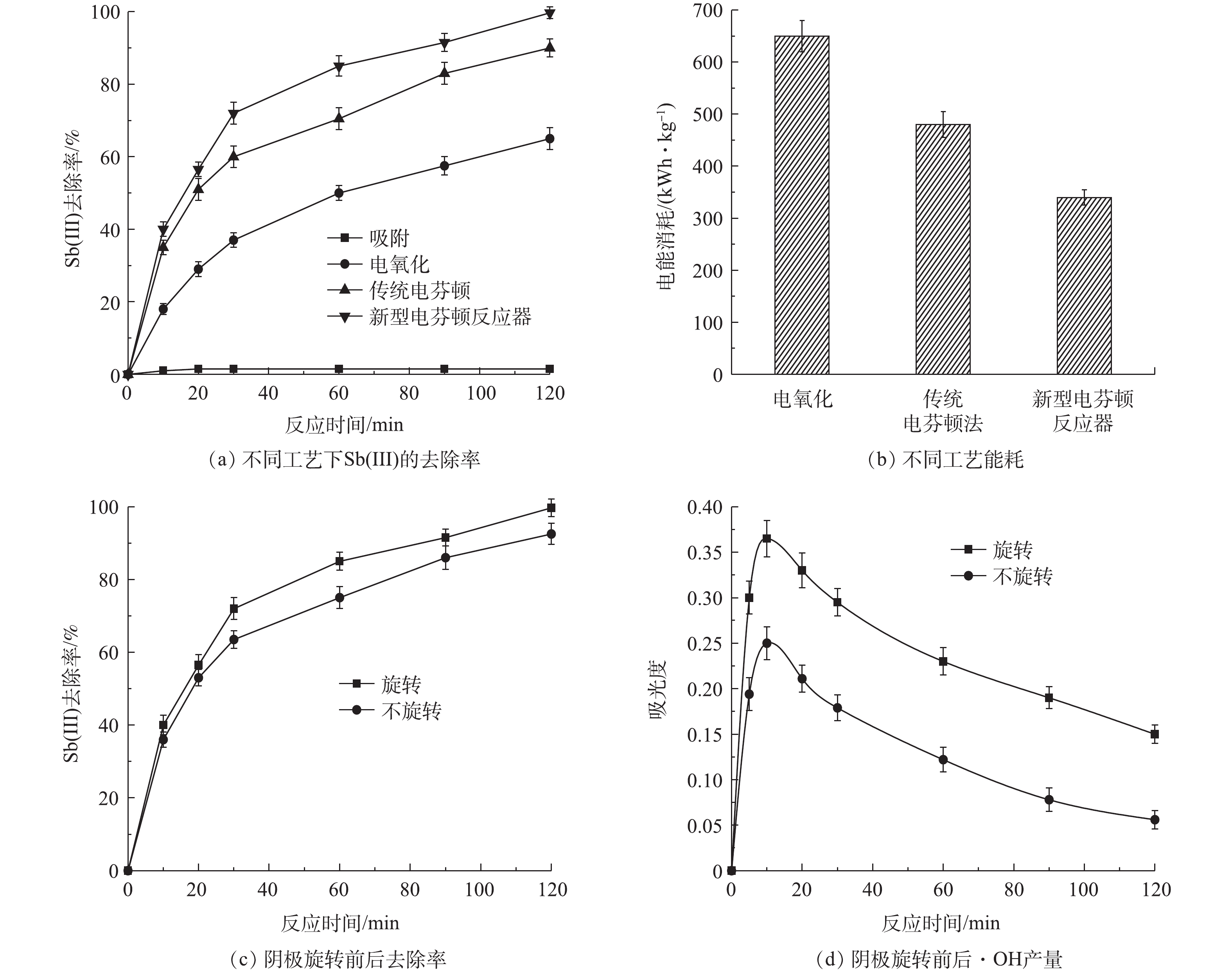

为反映新型电芬顿反应器的效果和优势,对比了不同工艺对Sb(Ⅲ)的处理效果,即吸附、电氧化、传统电芬顿法(10 cm×5 cm ACF作为阴极)的处理效果(见图2)。由图2(a)可知:在吸附条件下,Sb(Ⅲ)的浓度几乎没有变化;在电氧化条件下,Sb(Ⅲ)的去除率约为58%;传统电芬顿法对Sb(Ⅲ)的去除率可以达到90%;而新型电芬顿反应器中Sb(Ⅲ)的去除率可以达到99.7%左右,并且拥有更高的反应速率。此外,处理Sb(Ⅲ)的能耗如图2(b)所示,新型反应器的能耗远小于前二者。这一结果表明,新型电芬顿反应器能够更高效的氧化Sb(Ⅲ),处理效果较其他工艺更好,与其他高级氧化法相比,处理中主要的消耗为电能,这极大地降低了处理成本。

实验考察了阴极旋转在处理过程中起到的作用,结果如图2(c)所示。可以看出,旋转时Sb(Ⅲ)的去除率明显高于未旋转条件下的去除率。以一定量的水杨酸溶液作为羟自由基捕获剂,分别在波长510 nm下对2种条件的电芬顿反应中产生的2,3-二羟基苯甲酸、2,5-二羟基苯甲酸进行检测[18]。可以看出,在旋转条件下,·OH的生成量高于后者(图2(d))。由此可以合理地推测,阴极旋转时可以起到搅拌的作用,同时增强了溶液中的传质速率[19],促进了·OH的产生。此外,通过旋转阴极,使得溶液中的铁絮体沉淀难以附着在ACF表面,使ACF上能够保留更多产生·OH的活性点位[20],进而提升了电芬顿体系的氧化能力。

2.2 操作参数的影响

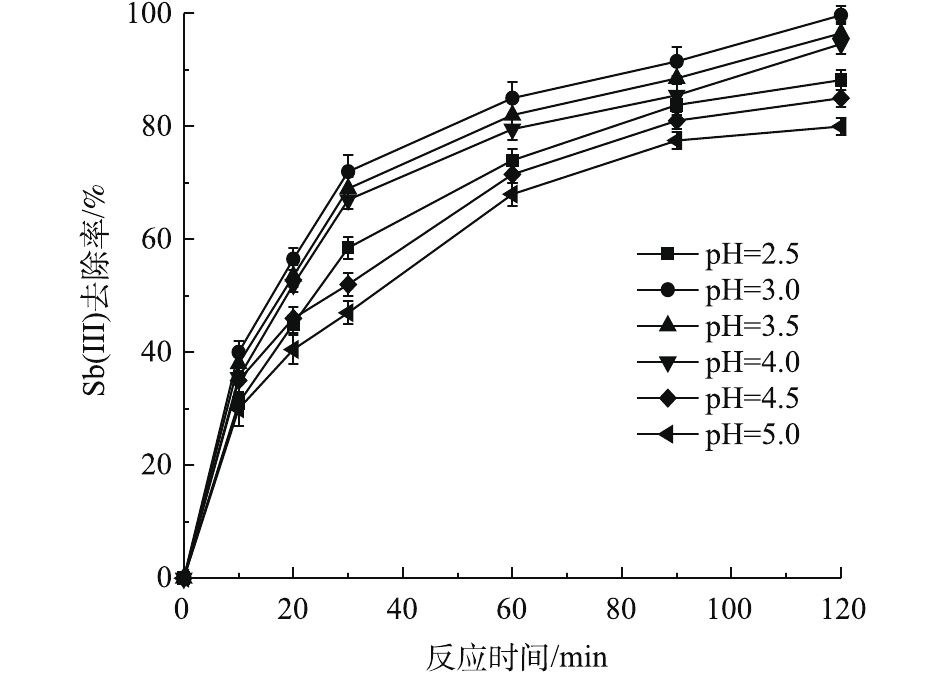

实验考察了初始pH对电芬顿反应的效率的影响。当pH为2.5~5时,pH对废水中Sb(Ⅲ)的去除率的影响结果如图3所示。可以看出:当pH=3时,去除率达到最高,当pH为3.5和4时,去除率稍逊于前者,但仍能保持相当的去除率;但当pH>4时,Sb(Ⅲ)的去除率下降。这是由于:在pH偏低时,H+会与H2O2竞争,阻碍·OH的积累(式(1)),此外,H+还会消耗溶解氧形成H2O[21-22],反应见式(2);而较高的pH条件下,Fe(Ⅱ)易发生水解反应(式(3)),这不利于Fe(Ⅱ)/Fe(Ⅲ)的电化学转化,从而影响了·OH的产生,此外,较高的pH条件同样会抑制H2O2的形成[23-24],反应见式(4)。上述结果表明,在含锑矿山废水呈酸性条件下,该工艺具有较宽的pH适用范围,这可在一定程度上节约成本,不需要花费额外的费用对废水pH进行调节。

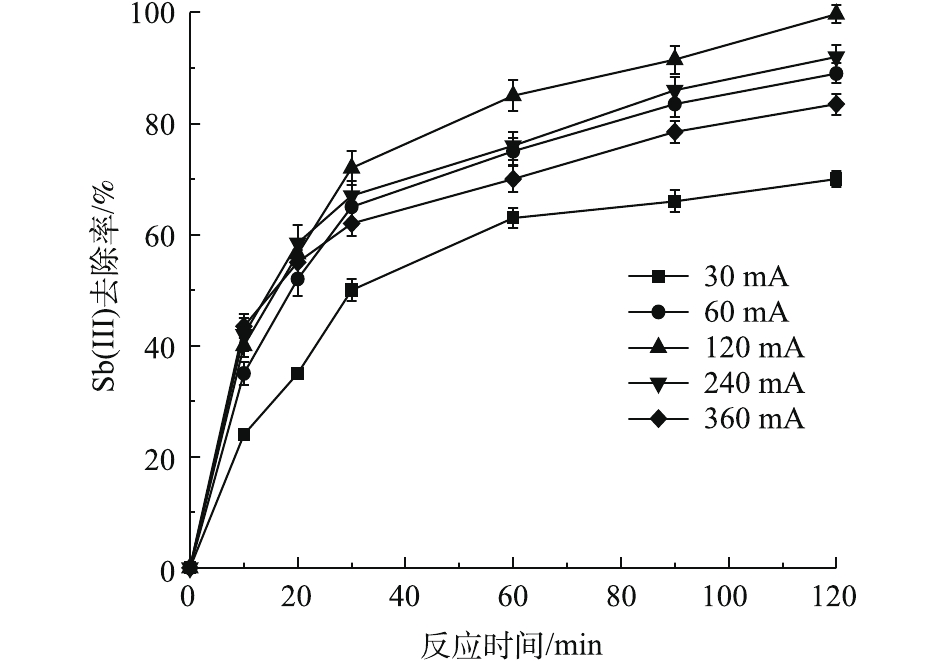

H2O2+2H++2e−→2H2O (1) 4H++O2+4e−→2H2O (2) 4Fe2++10H2O+O2→4Fe(OH)3↓+8H+ (3) H2O2+2OH−→O2+2H2O+2e− (4) 由图4可知,随着初始电流强度(30~360 mA)的上升,Sb(Ⅲ)的去除率呈现先增加后减小的变化趋势。当电流强度为120 mA时(电压为3 V、电流密度为1.91 mA·cm−1),去除率达到99.7%;当施加的电流强度分别增大至240 mA和360 mA时,Sb(Ⅲ)去除率下降(分别为92%和83.5%)。这是由于电芬顿体系的反应速度随着电流强度的上升而上升,但当电流强度过高时,会使电极析氢副反应加剧(式(5)),电流利用效率降低,同时抑制了H2O2在阴极的生成[25-26]。因此,选择电流强度为120 mA,能够最大程度地发挥新型电芬顿反应器的功效。

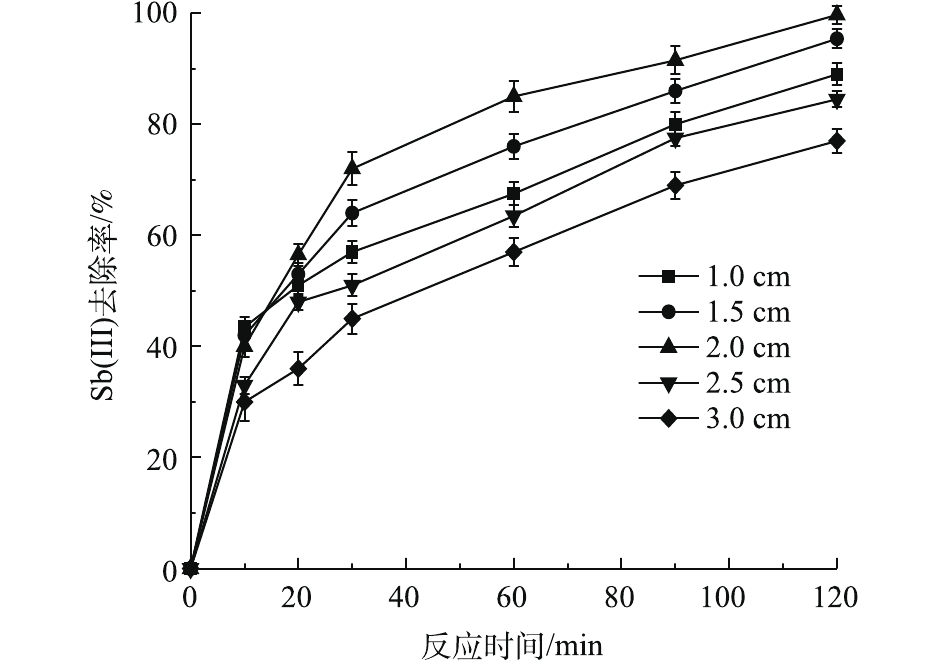

2H++2e−→H2↑ (5) 板间距是决定电芬顿处理效率的重要因素之一。本研究考察了板间距在1~3 cm时对Sb(Ⅲ)的去除率的影响情况,结果如图5所示。由图5可知,当板间距为2 cm时,能够达到对Sb(Ⅲ)最佳去除率。这主要是因为:当板间距过近时,阴阳极上的反应会互相干扰,如Fe(Ⅱ)容易被氧化为Fe(Ⅲ) (式(6)),抑制了Fenton反应的效率,影响·OH的生成[27],此外,被氧化的Sb(Ⅴ)会在阴极被还原为Sb(Ⅲ) (式(7)),这使得去除效果难以达到预期目标。板间距距离较远同样不利于提升处理效率,较远的距离会使极板间电阻增大,阻碍了Fe(Ⅲ)向阴极表面的转移再生[28-29],同时,较远的板间距意味着更大的能耗。因此,最佳板间距确定为2 cm。

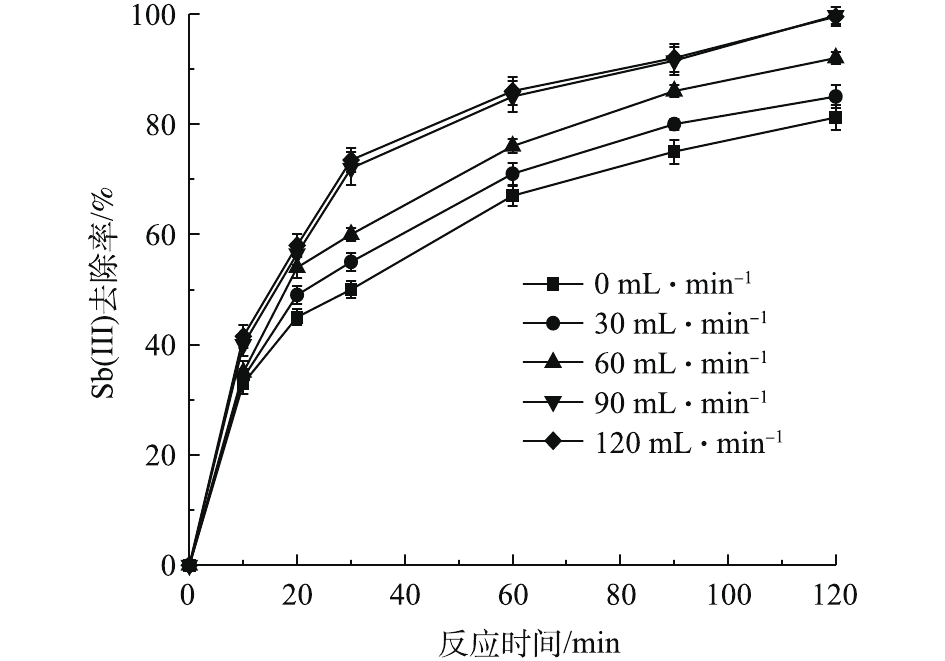

Fe2+−e−→Fe3+ (6) Sb5++2e−→Sb3+ (7) 在电芬顿反应中,曝气速率能够通过影响H2O2的生成效率进而影响整体体系的反应速率[30]。图6反映了不同曝气条件下的Sb(Ⅲ)去除率对比结果。可以看出,在曝气条件下的Sb(Ⅲ)去除率明显高于未曝气条件下的去除率。当曝气速率达到90 mL·min−1时,Sb(Ⅲ)去除率约为未曝气状态的1.3倍,这是由于提升曝气速率能够增加溶液中的溶解氧,有利于H2O2的生成[31-33](式(8))。当曝气速率高于90 mL·min−1时,Sb(Ⅲ)的去除率没有进一步提高,这说明90 mL·min−1的曝气速率可以提供充足的溶解氧。因此,最佳曝气速率选择为90 mL·min−1。

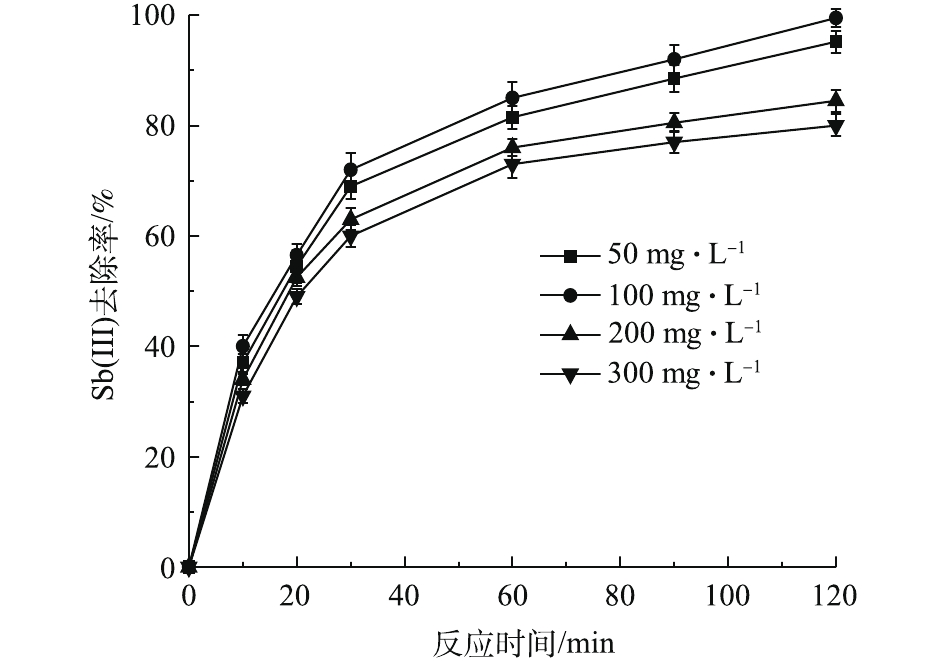

O2+2H++2e−→H2O2 (8) 电解质能够有效加强溶液中的导电性,提高处理效率。本研究考察了不同电解质浓度在含Sb(Ⅲ)实际废水处理中的去除效果,结果如图7所示。通过增加KCl的浓度,观察到去除率有所提高,当电解质浓度100 mg·L−1时,去除率达到99.7%。这是由于KCl作为电解质时,随着电流效率的提升,·OH的生成效率随之提高。此外,KCl作为电解质时,能够消除其他物质作为电解质时的不利影响,如

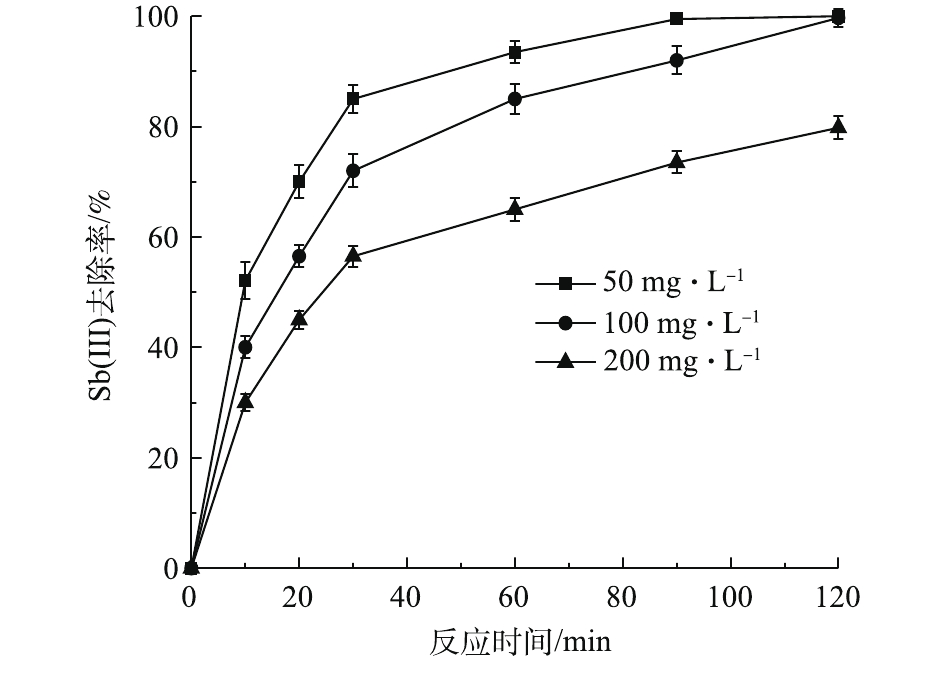

SO2−4 、CO2−3 的存在可能会与溶液中的Ca2+等反应生成沉淀,导致电极钝化,所需能耗上升[27]。溶液中Cl−的存在可能会在电流催化下产生具有氧化性的次氯酸(HOCl),促进了Sb(Ⅲ)/Sb(Ⅴ)的转化。但这并不意味着电解质浓度越高越好,过量的KCl电解质将对·OH起到捕获作用,会使去除率显著地降低(图7)。Sb(Ⅲ)初始浓度是评价新型电芬顿反应器处理效率的重要依据。图8为Sb(Ⅲ)初始处理浓度对电芬顿体系中Sb(Ⅲ)去除率的影响。可以看出,当初始浓度低于100 mg·L−1时,Sb(Ⅲ)的去除率更高,并且反应速率更快。而初始浓度较高时,去除率明显下降。这是由于在一定的电流强度下,电芬顿反应中生成·OH的量是恒定的,低浓度条件下,能够快速将Sb(Ⅲ)氧化至Sb(Ⅴ),而在浓度较高的情况下,中间产物的竞争会使得Sb(Ⅲ)的氧化效率有所降低[34-35]。但总的来说,在高浓度条件下,·OH与Sb(Ⅲ)的碰撞概率增加,从而使得Sb(Ⅲ)的绝对去除率上升。

2.3 Sb(Ⅲ)的去除机理

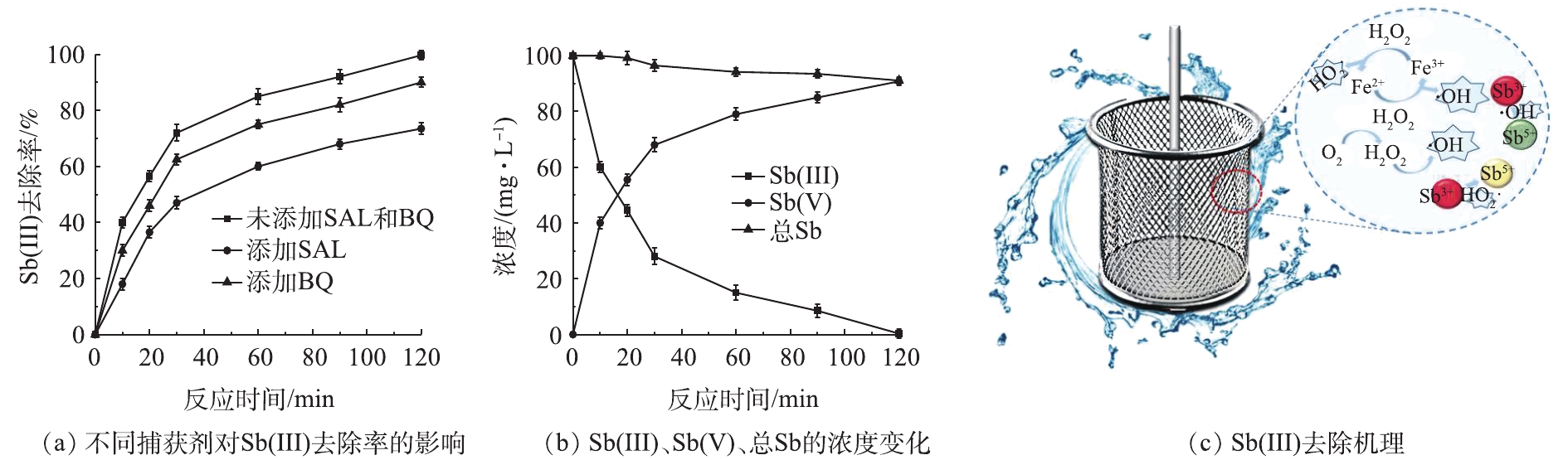

为了探究电芬顿反应对Sb(Ⅲ)的去除机理,设计了一系列的对照实验。通过配制一定量相同浓度的水杨酸(SAL)和苯醌(BQ)溶液,分别投加至溶液中,启动反应,考察Sb(Ⅲ)的去除机理(见图9)。由图9(a)可知,当加入水杨酸作为·OH捕获剂后,Sb(Ⅲ)去除率迅速下降至72.5%。这说明·OH在去除Sb(Ⅲ)的过程中起主要的作用。而除了·OH外,当加入苯醌溶液后,Sb(Ⅲ)去除率下降至90%,这证明过氧化羟自由基HO2·也能对Sb(Ⅲ)/Sb(Ⅴ)的转化起到一定的作用,二者协同作用促进了Sb(Ⅲ)的去除。另外,本研究对阳极的电絮凝作用进行了探讨。在相同浓度的废水中投加0.5 mmol·L−1氯化铁(FeCl3·6H2O),搅拌2 h后,观察到溶液中Sb(Ⅲ)的去除率约为4%,这表明Fe(Ⅲ)在溶液中,除了参与Fenton反应外,还对Sb(Ⅲ)存在一定的凝聚效果。

通过测定废水中Sb类物质浓度随时间的变化,进一步验证Sb(Ⅲ)向Sb(Ⅴ)的转化。如图9(b)所示,反应开始后,Sb(Ⅲ)浓度明显下降,而Sb(Ⅴ)不断上升,这种变化证明了电芬顿体系对Sb(Ⅲ)的氧化能力。在反应终点,总Sb的下降可能是因为一定量的Sb(Ⅴ)在铁絮凝作用下被吸附,以及在阴极表面被还原成Sb。去除过程可以合理地总结为:溶液中的O2在阴极表面还原生成H2O2(式(8)),阳极铁电极氧化产生的Fe(Ⅱ)迅速与H2O2反应产生·OH(式(9)),Fe(Ⅲ)在阴极被还原为Fe(Ⅱ)重新参与Fenton反应,同时会与H2O2反应生成HO2·(式(10)~式(13)),·OH与HO2·协同对Sb(Ⅲ)进行高效氧化(式(14)~式(15)),从而达到对污染物的去除效果(如图9(c)所示)。

Fe2++H2O2→Fe3++·OH+OH− (9) Fe3++e−→Fe2+ (10) Fe3++H2O2→Fe2++HO2⋅+H+ (11) Fe3++HO2⋅→Fe2++O2⋅−+H+ (12) O2⋅−+H+→HO2⋅ (13) ⋅OH+Sb3+→Sb5+ (14) HO2⋅+Sb3+→Sb5+ (15) 2.4 实际废水处理

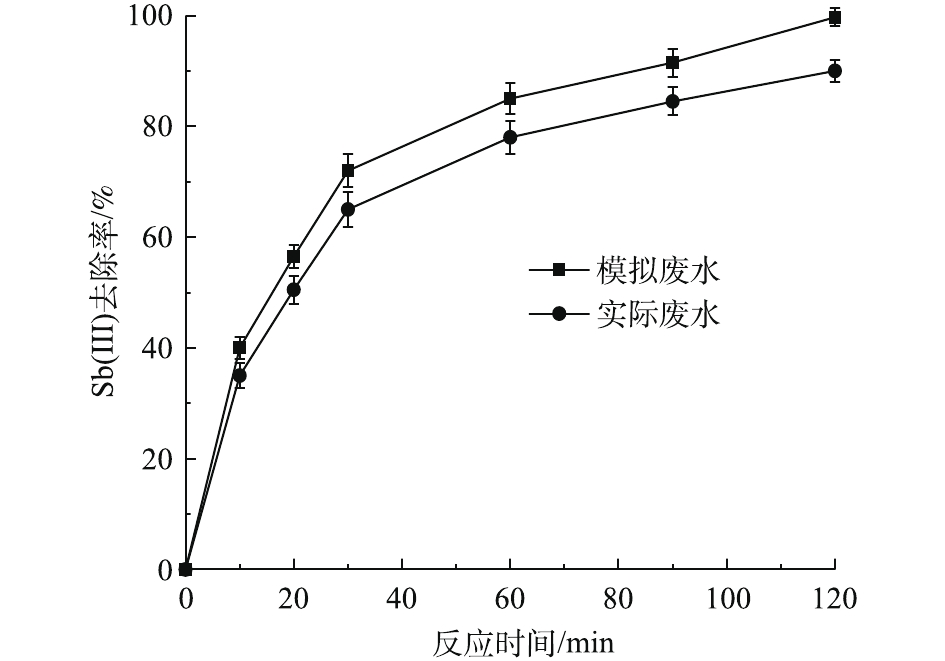

为了验证新型电芬顿反应器在实际废水处理中的可行性,本研究对其在模拟废水与实际废水中的去除率进行了对比,结果如图10所示。可以看出,在最佳反应条件下,实际废水中新型电芬顿反应器对Sb(Ⅲ)的去除率能达到89%,去除率的下降可以用实际废水中其他离子之间对·OH和HO2·的竞争来说明,如Fe(Ⅱ)和As(III)等。此外,溶液中的

CO2−3 、PO2−4 可能在一定程度上对电芬顿体系中Fe(Ⅱ)/Fe(Ⅲ)的循环起到阻碍作用。此结果表明,新型电芬顿反应器在实际废水处理中仍能保持良好的Sb(Ⅲ)去除率,因此,其可以作为一种高效、应用前景广阔的处理酸性矿山废水中Sb(Ⅲ)的技术。3. 结论

1)以电芬顿反应为基础,设计了一种新型阴极旋转式电芬顿反应器,用来处理酸性矿山废水中的Sb(Ⅲ)。相较于传统的电化学处理方法,新型电芬顿反应器处理效率更高,能耗更低。阴极旋转增大了·OH的产量,提升了Sb(Ⅲ)的去除率。

2)·OH和HO2·能够协同作用,共同提高Sb(Ⅲ)的去除效果。在电流强度为120 mA、pH=3、板间距为2 cm、曝气速率为90 mL·min−1、电解质浓度为100 mg·L−1的最佳反应条件下,废水中Sb(Ⅲ)的去除率能够达到99.7%以上。

3)新型电芬顿反应器在实际废水的处理中能够取得很好的效果,Sb(Ⅲ)去除率达到89%以上。

-

[1] 周颖华,丁克鸿.环氧树脂高含盐废水处理及盐的资源化研究[J].河北化工,2012,35(4):46-49 [2] ZHANG W J,YANG X Y,WANG D S,et al.Complete removal of organic contaminants from hypersaline wastewater by the integrated process of powdered activated carbon adsorption and thermal Fenton oxidation[J].Industrial & Engineering Chemistry Research,2013,52(16):5765-5771 [3] 郝明松,周林,邱满意.TOC对离子膜电解槽的影响[J].氯碱工业,2009,45(11):18-20 [4] PIGNATELLO,OLIVEROS E,MACKAY A,et al.Advanced oxidation processes for organic contaminant destruction based on the Fenton reaction and related chemistry[J].Critical Reviews in Environmental Science and Technology,2007,37(3):273-275 [5] PENG S W,ZHANG W J,HE J,et al.Enhancement of Fenton oxidation for removing organic matter from hypersaline solution by accelerating ferric system with hydroxylamine hydrochloride and benzoquinone[J].Journal of Environmental Sciences,2016,41:16-23 [6] GIANG L T, JOSEPH D L, BERNARD L,et al.Effects of chloride and sulfate on the rate of oxidation of ferrous ion by H2O2[J].Water Research,2004,38:2384-2394 [7] 姜妍,蒋林时,苗时雨,等.紫外-Fenton法处理高盐有机废水[J].环境工程学报,2016,10(5):2349-2354 [8] 胡红伟,李晓燕.Fenton催化氧化反应机理及影响因素研究进展[J].科技通报,2012,28(4):220-222 [9] 张英,魏宏斌,卢毅明,等.Fenton氧化法深度处理甲醛废水[J].环境工程学报,2013,7(6):2134-2138 [10] 李再兴,左剑恶,剧盼盼,等.Fenton氧化法深度处理抗生素废水二级出水[J].环境工程学报,2013,7(1):132-136 [11] 黄天寅,李宁,夏四清.混凝工艺去除合流污水中有机物及营养元素[J].环境工程学报,2009,3(4):1579-1584 [12] 杨娟,任源,肖凯军,等.混凝-Fenton氧化-Fe0还原预处理高浓度硝基苯生产废水[J].环境工程学报,2012,6(5):1483-1488 [13] 魏健,范冬琪,宋永会,等.Fenton氧化/混凝沉淀协同处理腈纶聚合废水[J].环境工程学报,2015,9(1):14-18 [14] 梁顺文,叶彬,蒋建国.混凝沉淀-高级氧化联合处理垃圾转运站污水的实验研究[J].环境工程学报,2010,4(8):1759-1764 [15] 朱艳虹,高迎新,杨敏,等.混凝-Fenton法处理采油污水的研究[J].环境污染治理技术与设备,2003,4(4):18-21 [16] 赵大为,邹华,朱琼宇,等.Fenton-混凝法处理苯胺废水[J].环境工程学报,2012,6(11):3942-3946 期刊类型引用(9)

1. 王年禧,霍慧敏,何艺,郑洋,刘研萍,韦洪莲. 化工废盐产生和处理技术研究进展及启示. 环境工程学报. 2024(11): 3149-3156 .  本站查看

本站查看

2. 孙越,张聪慧,白皓,刘鑫,刘思卓. 混凝-异相Fenton工艺处理渗沥液纳滤浓缩液研究. 中国环境科学. 2023(03): 1197-1207 .  百度学术

百度学术

3. 肖芳,廖晓伟,范锐,廖铁,李云龙,曹亮. 天然气净化厂高盐环胺废液处理工艺研究. 天然气与石油. 2023(04): 99-106 .  百度学术

百度学术

4. 刘宇程,杨冰,李沁蔓,马丽丽,李玲丽,陈明燕. Cl~-和pH对高级氧化工艺去除含盐废水中有机物的影响及机理. 环境工程学报. 2021(05): 1487-1499 .  本站查看

本站查看

5. 胡军,员建,宋亚梦. 高级氧化联合处理工艺对高盐难降解有机废水的处理. 天津城建大学学报. 2021(06): 407-411 .  百度学术

百度学术

6. 曹美玲,李海,刘佛财,李丹,钟常明. 高盐有机废水的处理与研究进展. 有色金属科学与工程. 2019(03): 92-98 .  百度学术

百度学术

7. 蒋立先. Fenton—活性炭联合处理酸性高盐有机化工废水. 中国给水排水. 2019(10): 111-114 .  百度学术

百度学术

8. 李俊虎,周珉,王乔,陈春玥. 高盐废水处理工艺最新研究进展. 环境科技. 2018(04): 74-78 .  百度学术

百度学术

9. 姜继平,李玉立,王鹏,王宝玉. 水厂低温低浊排泥水混凝处理工艺设计优化. 净水技术. 2018(08): 61-65 .  百度学术

百度学术

其他类型引用(10)

-

点击查看大图

点击查看大图

计量

- 文章访问数: 3144

- HTML全文浏览数: 2618

- PDF下载数: 612

- 施引文献: 19

下载:

下载: