-

过量的磷是导致水体富营养化的主要原因[1]。有研究[2]表明,若水环境中总磷浓度达到 0.02 mg·L−1,对水体富营养化就起明显促进作用,达到 0.2 mg·L−1,水体就呈富营养状态。因此,在防治水体富营养化问题中控制水体中的磷含量更具有实际意义。现有除磷技术中,吸附法除磷工艺由于其具有高效清洁、可回收磷、可重复利用、工艺简单等优点,具有广泛的应用前景[3]。研究开发经济、高效的除磷技术已成为水污染控制工程研究的重点领域之一。

蒸压加气混凝土(autoclaved aerated concrete, AAC)碎料[4]是一种常见的建筑废料,使用水泥、生石灰、粉煤灰、砂、铝粉等材料,按照蒸压加气混凝土砌块的加工方法,制成建筑用轻质材料——蒸压加气混凝土砌块,进而加工破碎而成。由于蒸压加气混凝土碎料(crushed autoclaved aerated concrete, CAAC)富含钙、铝、铁等氧化物,且多孔、质轻、广泛易得,近年来开始应用在富营养化水体的治理中。LI等[5]和郭杏妹等[6]研究发现,不同浓度的碱改性CAAC的除磷效率大幅提高,其去除率可达98.67%和99.18%。但上述方法存在材料经过碱改性后的碱性残留问题,容易造成新的次生环境污染风险,从而增加了处理成本。而盐改性由于价格低廉、处理量大和去除率高等优点而广泛应用于水处理。有研究[7-9]表明,经铝改性的纳米纤维素、活性炭及水滑石等的除磷效率都有明显提高。

本研究以氯化铝作为改性剂,对蒸压加气混凝土材料进行改性,得到铝改性蒸压加气混凝土(aluminum modified autoclaved aerated concrete,Al-MAAC)材料,并用于低浓度含磷废水的处理中(总磷≤1 mg·L−1),考察除磷效果并确定最优改性条件,在此基础上,揭示除磷机理,以期得到除磷性能更好的材料,为富营养化水体深度除磷材料的选择及应用提供参考。

全文HTML

-

实验中所用的蒸压加气混凝土材料[6]来自广州某建材公司。蒸压加气混凝土碎料由规格不合格或有破损的砌块破碎而成,过200目筛后干燥备用。其余试剂包括结晶氯化铝、钼酸铵、酒石酸锑钾、硫酸、抗坏血酸、磷酸二氢钾,均为分析纯。

-

主要仪器包括上海精科722G型紫外-可见光分光光度计、培英 HZQ-X100恒温振荡器、ZEISS Ultra55 热场发射扫描电子显微镜、BRUKER D8X射线粉末衍射仪及Oxford X-Max 50电制冷X射线能谱仪。

-

将蒸压加气混凝土粉末以一定的比例浸入0.1~1.0 mol·L−1AlCl3溶液中,在25 ℃、180 r ·min−1 下振荡0~3 h,沉淀弃去上清液,反复水洗后,放在干燥箱中烘干,研磨,经200目筛后即得铝改性蒸压加气混凝土碎料除磷材料,记为Al-MAAC。

称取一定质量除磷材料置于250 mL锥形瓶中,加入100 mL初始浓度为1 mg·L−1的磷酸盐水溶液,在水浴振荡器中,于25 ℃恒温振荡0~3 h,取上清液经 0.45 μm 滤膜过滤,测定滤液中磷酸盐的浓度。

-

Al-MAAC对磷的处理量[5]的计算方法见式(1)和式(2),每个处理设3次重复。

式中:Qe为平衡溶液磷的处理量,mg·g−1;Qt为t时刻磷的处理量,mg·g−1;C0、Ce和Ct分别为初始溶液、平衡溶液和t时刻溶液中磷的质量浓度,mg·L−1;V为加入磷溶液的体积,L;W为加入的除磷剂质量,g。

1.1. 实验原料

1.2. 实验装置

1.3. 实验方法

1.4. 分析方法

-

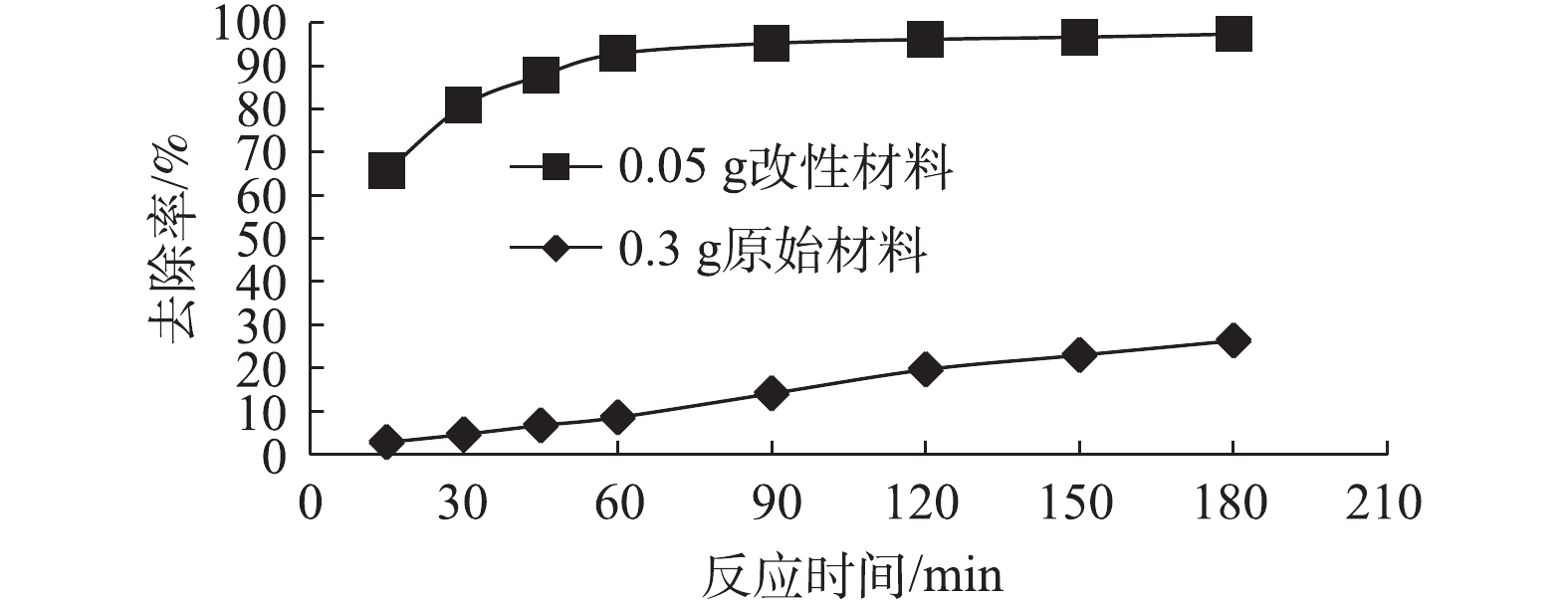

将蒸压加气混凝土粉末以1∶30的比例浸入0.1~1.0 mol·L−1AlCl3溶液中制备除磷材料;取除磷材料0.1 g,在原水磷浓度为1 mg·L−1,温度为25 ℃,反应时间为1 h和2 h,振速为180 r·min−1的实验条件下,考察除磷材料的除磷效果。

如图1所示,2个实验组的结果均表明,当氯化铝溶液浓度为0.2 mol·L−1时,Al-MAAC除磷效果最佳。当反应时间为2 h时,0.2 mol·L−1Al-MAAC的除磷效果为同实验组最佳且达到95.8%,符合预期。当继续增大改性剂溶液浓度,去除率反而下降,可能原因有:1)由于孔隙堵塞,与磷酸盐接触的氢氧化铝减少,导致磷酸盐无法充分与氢氧化铝电离出的铝离子反应;2)磷酸二氢根电离完全时,部分氢氧化铝仅完成一级电离,铝离子量不足导致生成的磷酸铝沉淀减少;3)随着氯化铝溶液浓度的提高,溶液pH降低,不利于改性材料中的含钙组分形成钙磷沉淀,导致总磷去除率降低[10]。

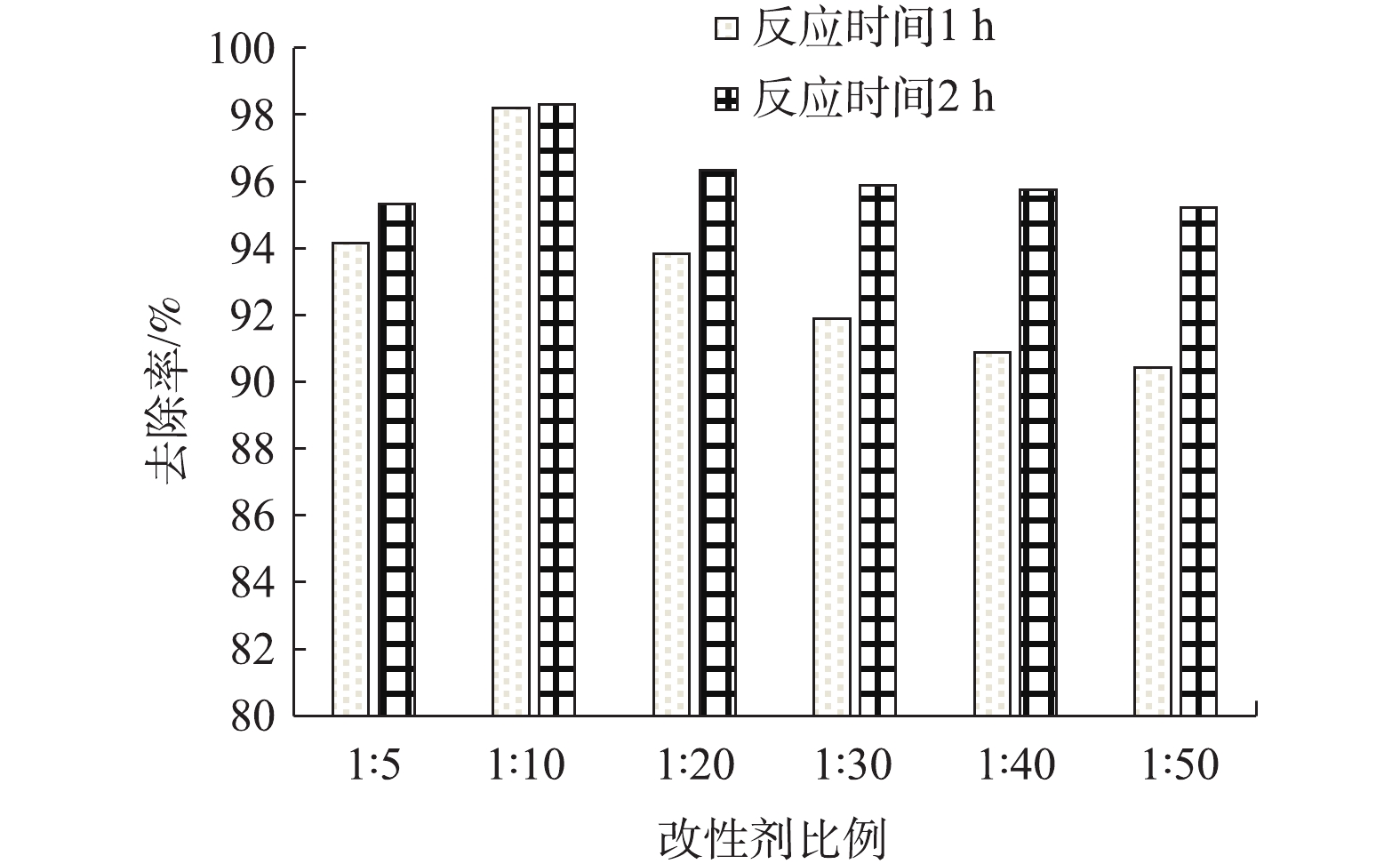

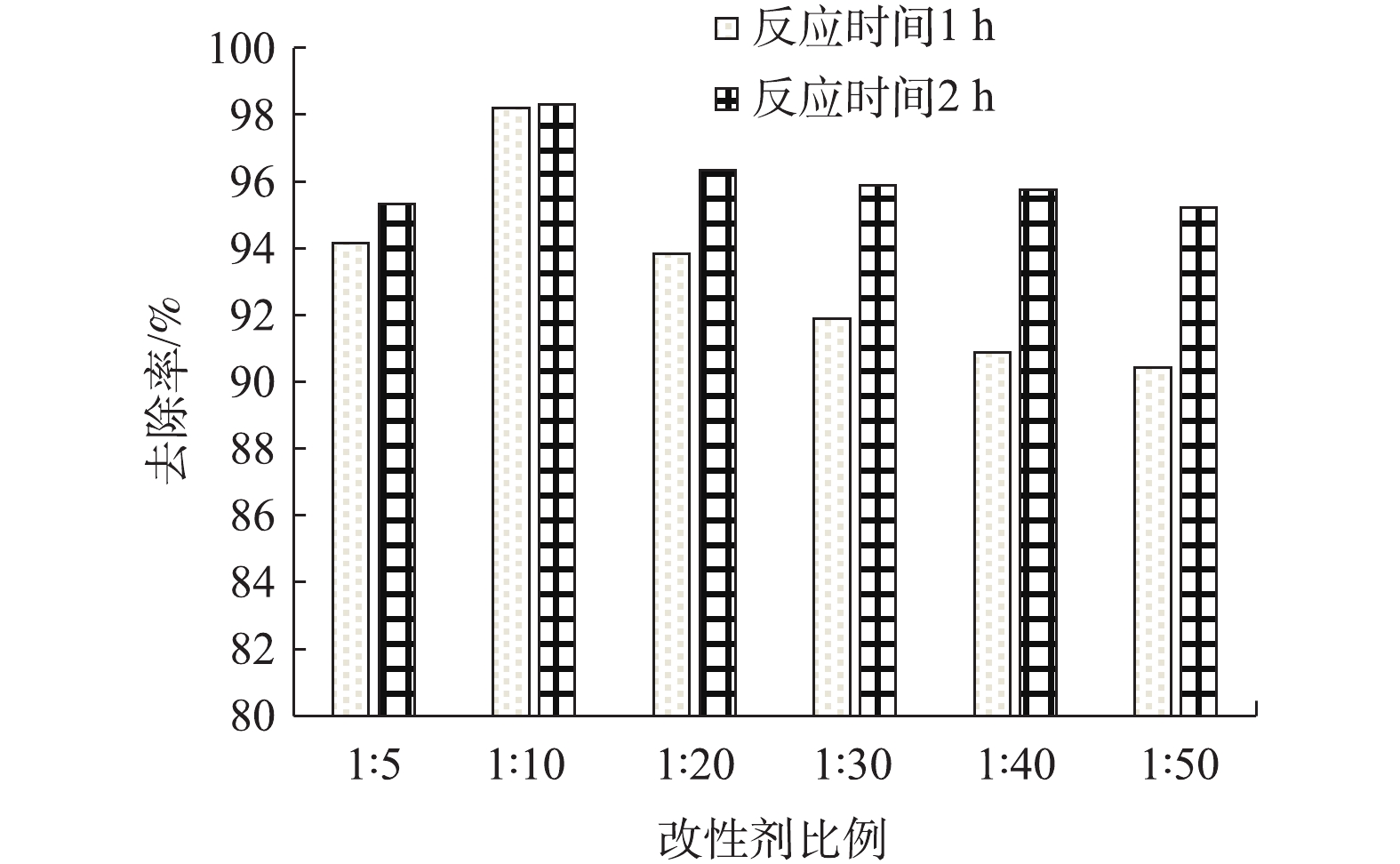

将蒸压加气混凝土粉末以1∶5、1∶10、1∶20、1∶30、1∶40、1∶50的比例浸入0.2 mol·L−1 AlCl3溶液中制备除磷材料;取除磷材料0.1 g,在原水磷浓度为1 mg·L−1,温度为25 ℃,反应时间为1 h和2 h,振速为180 r·min−1的实验条件下,考察除磷材料的除磷效果。

如图2所示,当固液比为1∶10时,2个实验组的除磷效果达到最佳。当提高固液比时,氯化铝溶液体积偏小,可能会因为振荡过程中实际接触时间较短、氯化铝不足量等导致沉淀效果较低。而降低固液比时,同样会继续溶出材料中的部分硅酸钙、硫酸钙和碳酸盐[11]。然而由于氯化铝溶液浓度较低,溶出组分的量和氢氧化铝滞留量有限,因此,新增氢氧化铝的除磷效果劣于溶出组分的除磷效果,总磷去除率降低。

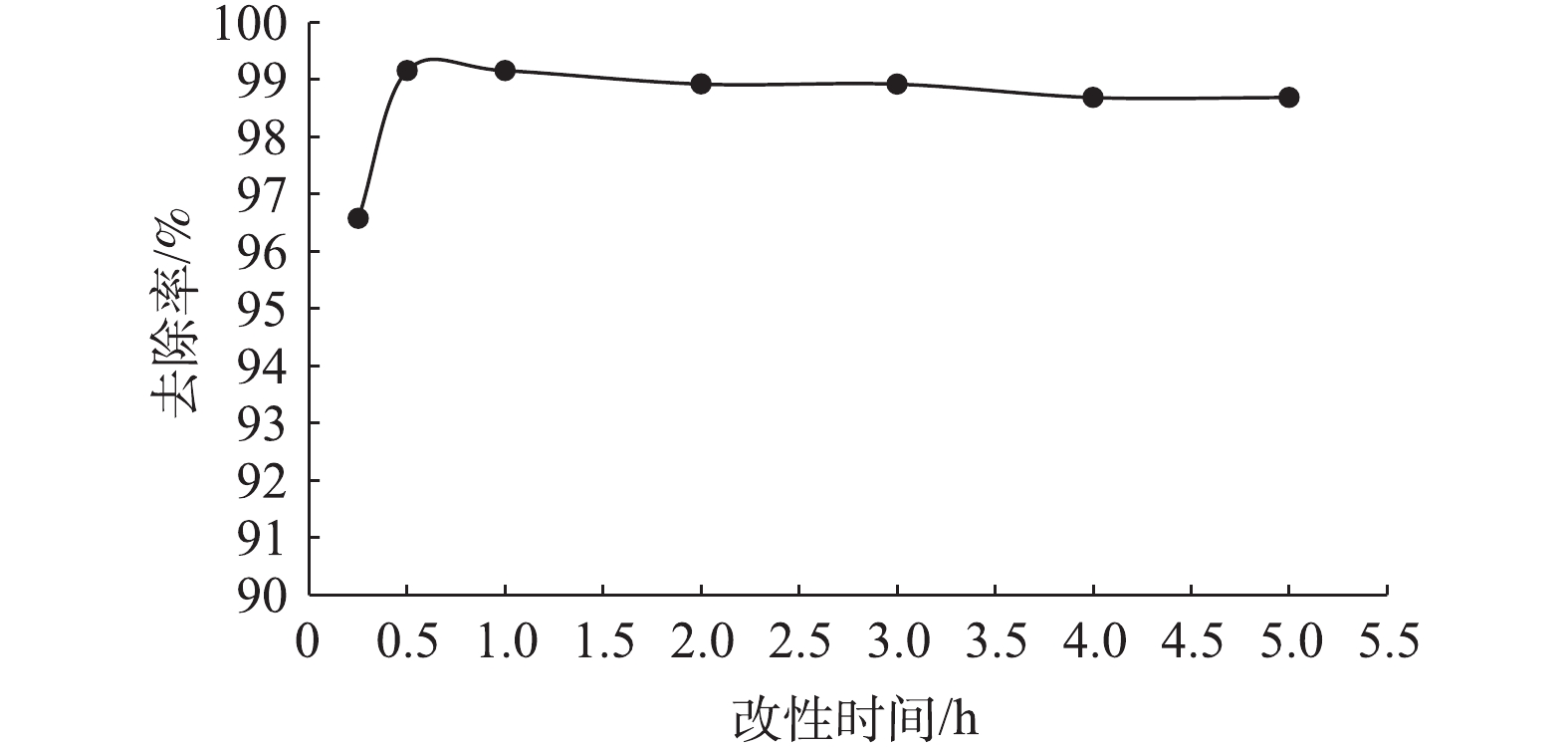

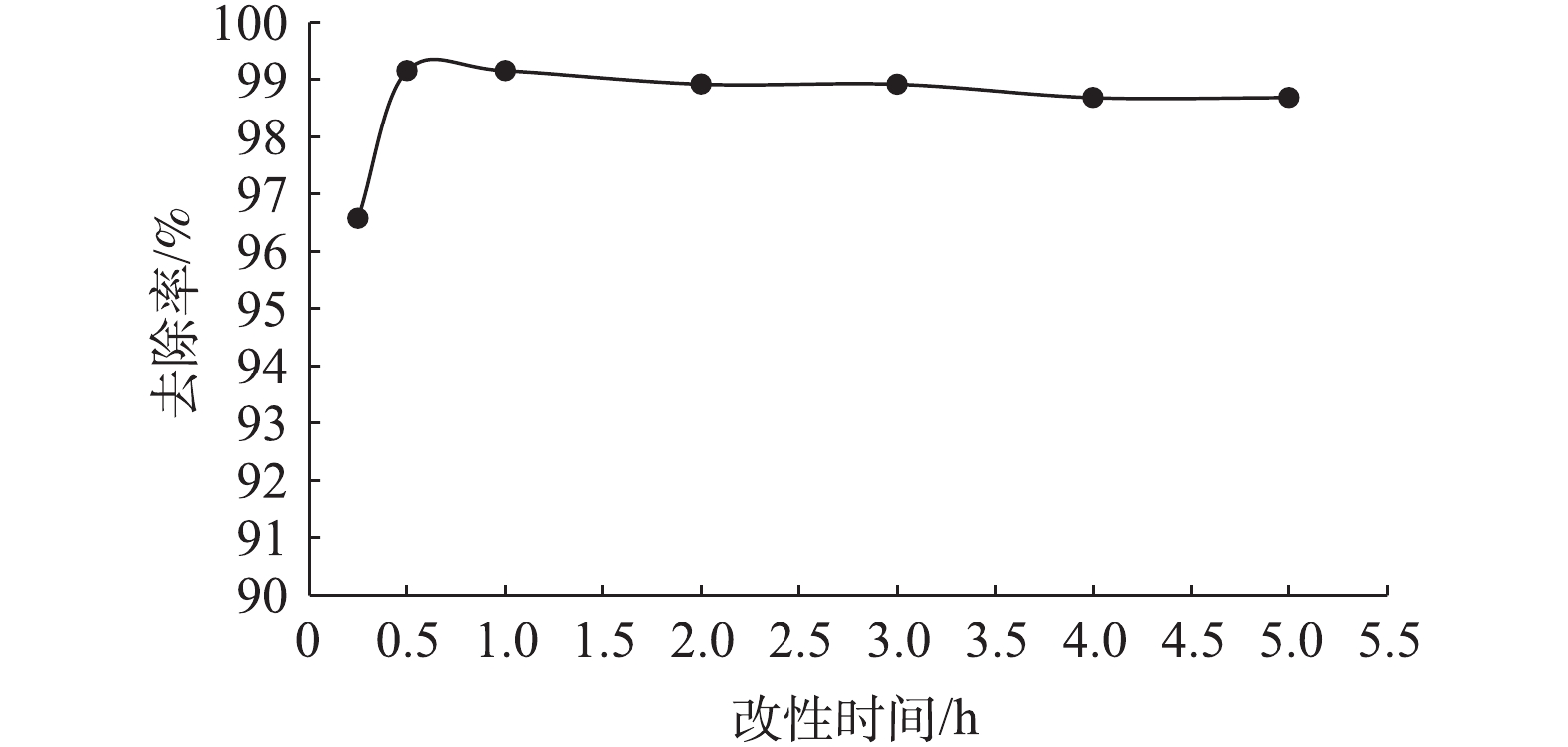

将蒸压加气混凝土粉末以1∶10的比例浸入0.2 mol·L−1AlCl3溶液中制备除磷材料;设置浸渍时间为0.25、0.5、1、2、3、4、5 h,取除磷材料0.1 g,在原水磷浓度为1 mg·L−1,温度为25 ℃,振速为180 r·min−1的实验条件下,考察除磷材料的除磷效果。

如图3所示,浸渍时间为0.25 h的Al-MAAC除磷效果低于平均水平,其余各组除磷效果基本持平,这表明当改性时间不断增加时,其除磷效率不会一直增大,这为改性过程时间控制提供了很好的参考。

-

将蒸压加气混凝土粉末以1∶10的比例浸入0.2 mol·L−1AlCl3溶液中制备除磷材料,并在静态实验中考察除磷材料投加量、反应温度、反应时间和初始磷溶液浓度对除磷效果的影响。

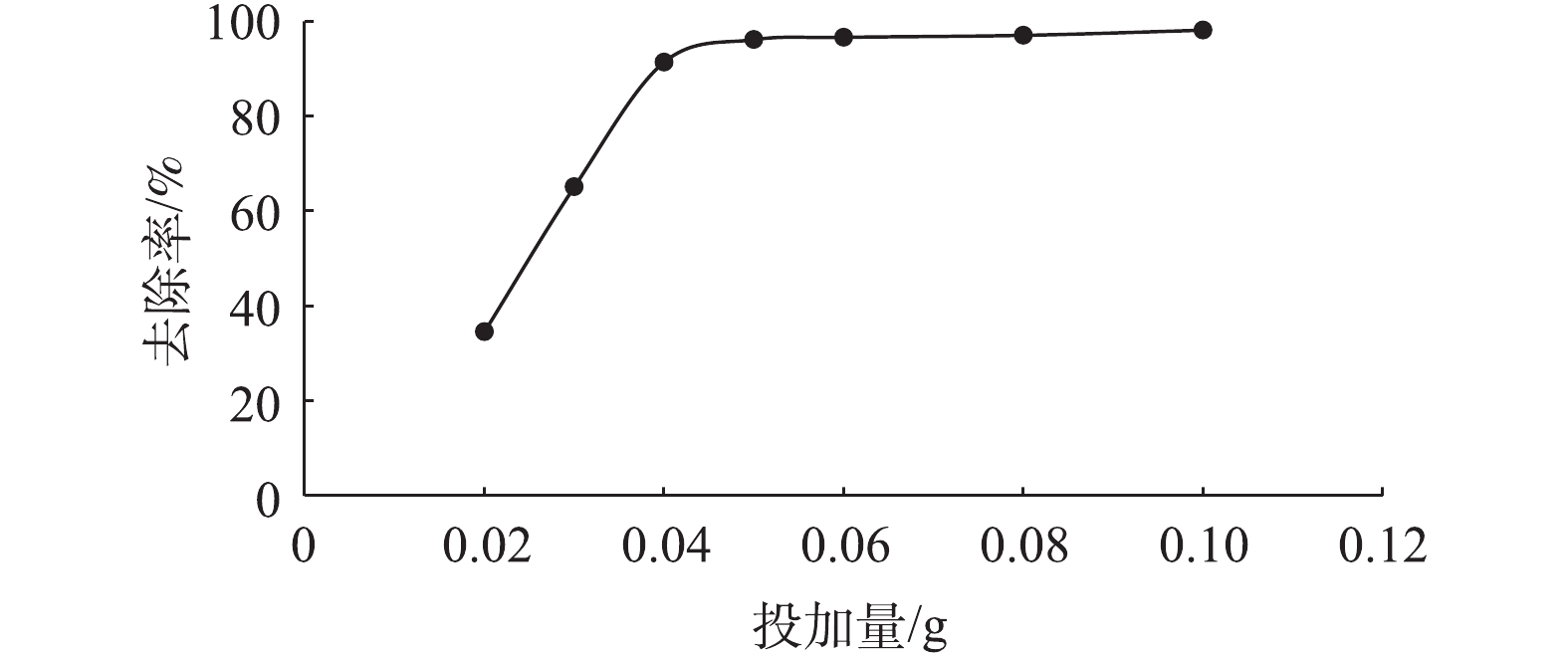

分别取Al-MAAC 0.02、0.03、0.04、0.05、0.06、0.08、0.1 g,在100 mL原水磷浓度为1 mg·L−1,温度为25 ℃,反应时间为2 h,振速为180 r·min−1的实验条件下,考察Al-MAAC投加量对除磷效果的影响。

如图4所示,当投加量为0.5 g·L−1时,磷去除率达到96.1%,与碱改性的CAAC材料相比,要想有同样的去除效果,其用量则须达到10 g·L−1[5-6],可见Al-MAAC的投加量缩减了近20倍,去除率大幅提高。继续增加投加量,对除磷效果影响不大,可能的原因是Al-MAAC对水中正磷酸盐的反应基本达到平衡,此时沉淀反应主要受水中磷酸盐浓度的限制[12],因此,总磷去除率提升较慢。

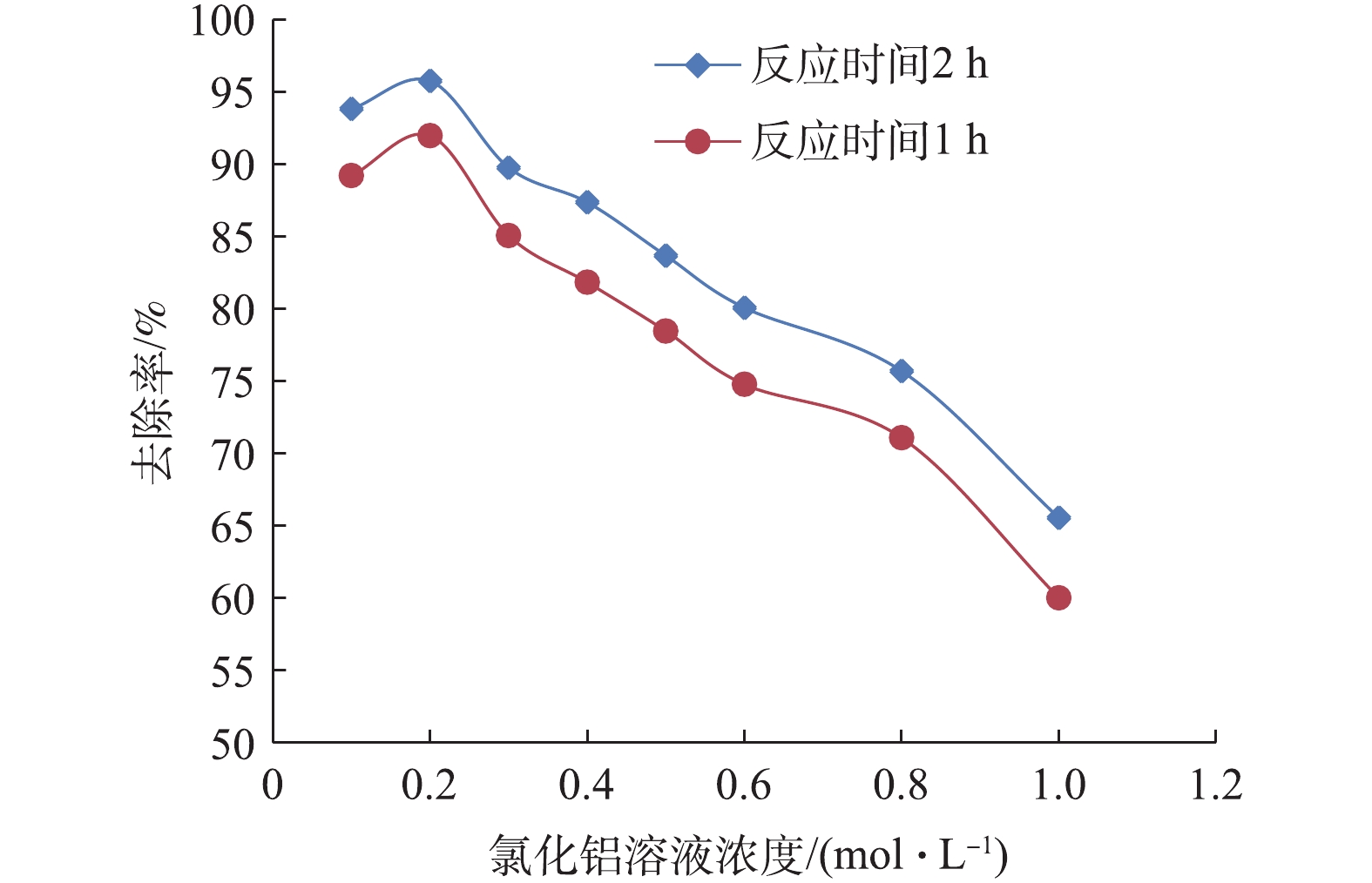

取Al-MAAC 0.05 g,设置反应时间为0.25~3 h 8个梯度,在100 mL原水磷浓度为1 mg·L−1,温度为25 ℃,振速为180 r·min−1的实验条件下,考察反应时间对除磷效果的影响。

如图5所示,反应时间为1.5 h时,Al-MAAC的总磷去除率达到95.2%。1.5 h后,随着反应时间的延长,去除率趋于稳定。综合考虑各因素后,选定1.5 h为最佳反应时间。同时将0.05 g改性材料与0.3 g原始材料的去除效果进行对比,结果发现,其总磷去除率远远低于改性材料,说明使用氯化铝改性CAAC材料是高效可行的,能够达到提升材料除磷性能以及获得经济效益的目的。

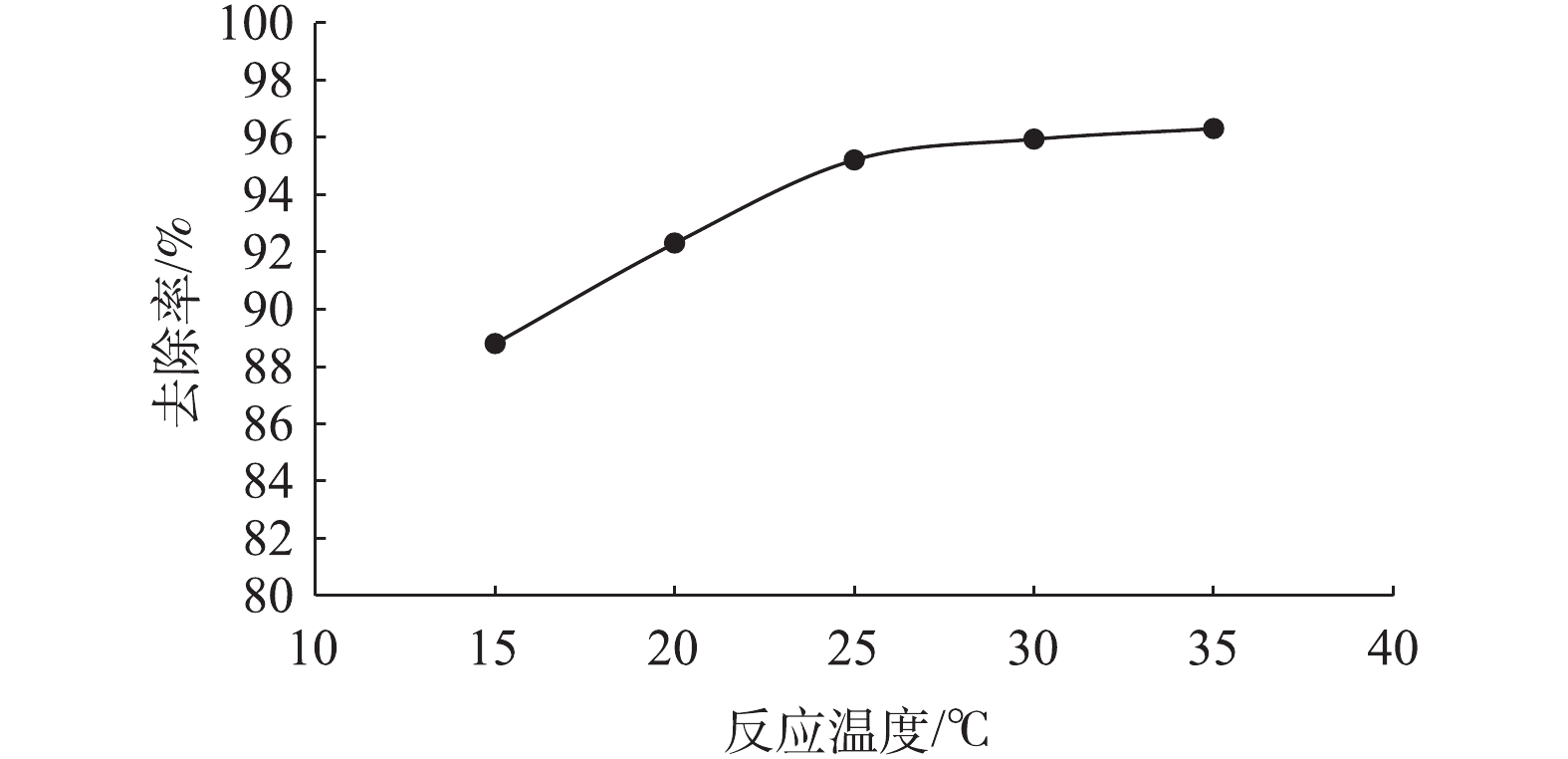

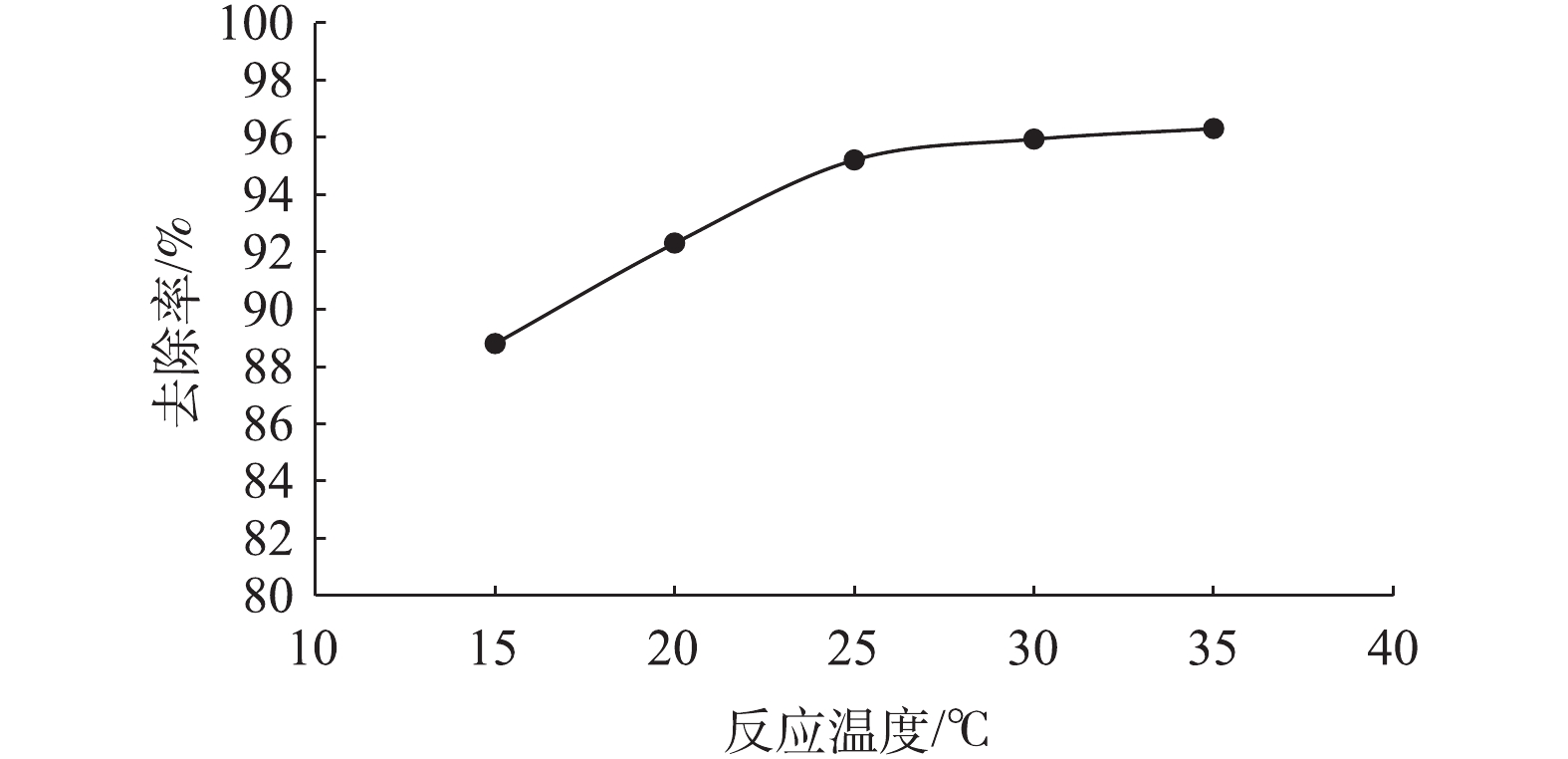

取Al-MAAC 0.05 g,设置反应温度为15、20、25、30、35 ℃,在100 mL原水磷浓度为1 mg·L−1,反应时间为2 h,振速为180 r·min−1的实验条件下,考察反应温度对除磷特性的影响。

如图6所示,磷去除率随反应温度的上升而缓慢上升,在反应温度到达25 ℃后,上升趋势减缓,基本趋于稳定。由此可推断:一方面,综合考虑实验数据和经济效益,Al-MAAC处理含磷废水的最佳反应温度为25 ℃,即常温下可以达到最佳效果;另一方面,该材料处理含磷废水的效果受高温影响小,受低温影响略大,但总体去除率可以保持在较高的水平,因此,具有一定的实用性。主要原因为:1) 提高温度有利于含钙组分结合磷酸根离子形成钙磷沉淀的过程[13],从而提高了总磷去除率;2) 温度提高了磷酸根克服材料表面液膜阻力的扩散能力,有利于磷酸根向材料内部迁移并与铝离子反应[14],有利于提高去除率。

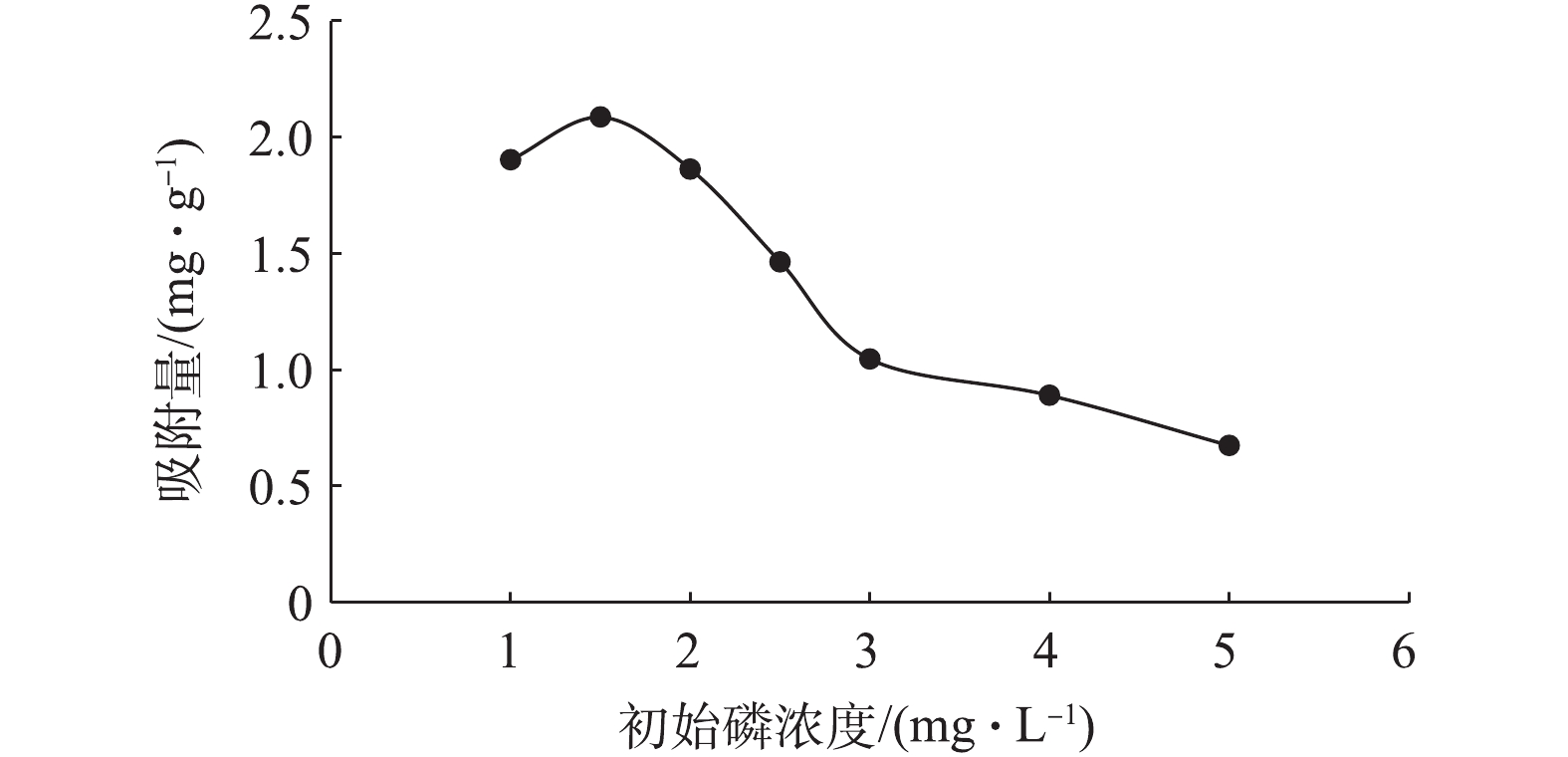

取Al-MAAC 0.05 g,设置100 mL的原水磷浓度分别为1、1.5、2、2.5、3、5 mg·L−1,在温度为25 ℃,反应时间为2 h,振速为180 r·min−1的实验条件下,考察初始磷溶液浓度对除磷效果的影响。

如图7所示,当初始总磷浓度低于2 mg·L−1时,Al-MAAC材料对磷的去除量能维持较高的水平。该特点恰好说明Al-MAAC适合用于深度除磷工艺处理低浓度含磷废水。继续增大初始总磷浓度,材料的除磷效果会有所下降,这可能出于2个方面原因:1)Al-MAAC反应位点有限,无法与过量的磷酸盐发生沉淀反应;2)初始总磷浓度增大时,溶液pH下降,不利于钙磷沉淀的形成[15]。

-

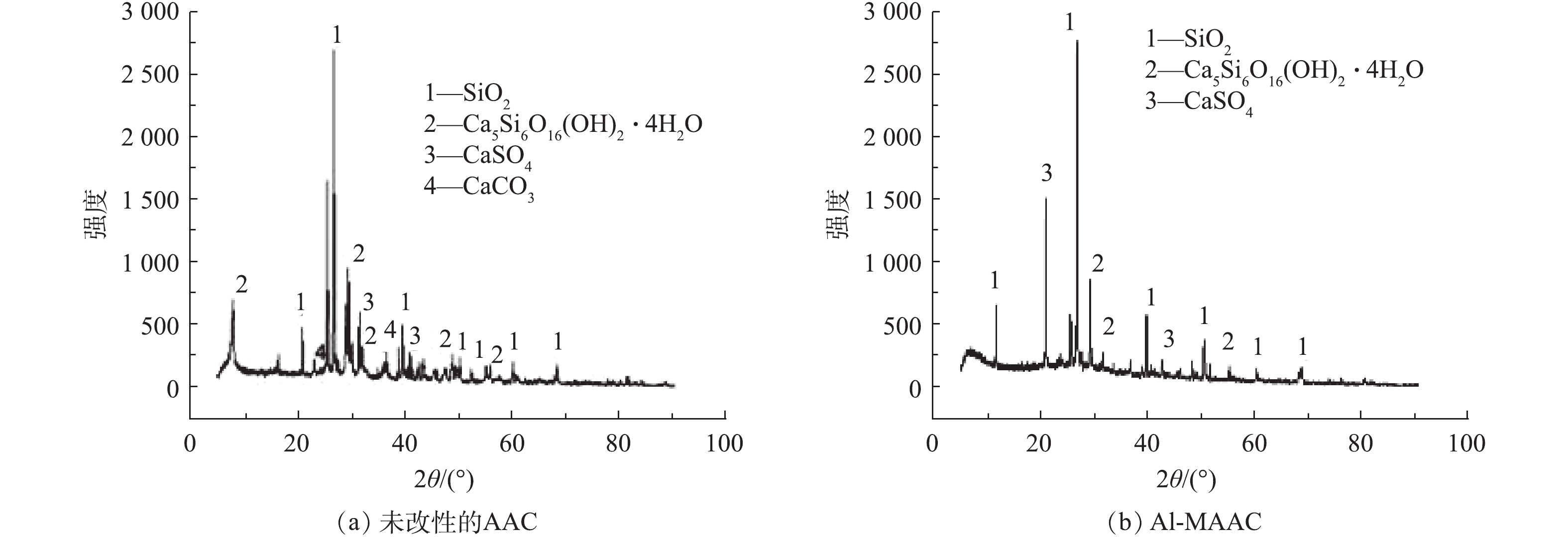

为分析Al-MAAC的晶相及内部结构对除磷效果的影响,本研究对Al-MAAC进行了XRD的表征,并通过表征的结果对Al-MAAC高效除磷原理进行深入分析。

由图8可知,改性前材料中碳酸钙等组分在改性中基本反应完全,而二氧化硅和硫酸钙等组分则没有明显变化。由此推测,合成过程中氯化铝在AAC的表面附着,同时经过AlCl3改性的材料孔道的有效空间得以拓宽,Al-MAAC表面负载了一定的Al3+,它会与水结合生成氢氧化铝,进而与磷酸根离子发生离子交换,生成磷酸盐沉淀[16],最后得以去除。

2.1. Al-MAAC最佳改性条件分析

2.2. Al-MAAC的除磷效果分析

2.3. Al-MAAC的XRD表征

-

1)采用浸渍-焙烧法成功制备铝改性蒸压加气混凝土碎料的最佳制备条件为:固液比10∶1、氯化铝溶液浓度0.2 mol·L−1、浸渍时间0.5 h、搅拌速度180 r·min−1。当初始总磷浓度不超过1 mg·L−1时,在投加量为0.5 g·L−1、反应时间为1.5 h、温度为25 ℃的条件下,磷的去除率可达到96%以上。

2) Al-MAAC相比于碱改性后的材料除磷效果大大提高,并且在处理低浓度含磷废水时,Al-MAAC能避免改性剂残余导致的二次污染问题。

3)经铝改性的AAC材料的除磷机理主要是材料中的Ca5Si6O16(OH)2·4H2O、CaSO4、CaCO3、Al2O3与废水中的

PO3−4 -P反应,生成了以羟基磷灰石为主的钙磷-磷铝共沉淀物,其在重力作用下絮凝沉降,从而加快了除磷过程的实现。

下载:

下载: