-

伴随着国内原油品质逐渐降低,氢燃料电池的高速发展,以及人们对环境保护意识的增强等,氢气的需求正在迅速增加。低浓度含氢废气中存在一定比例的氢气以及N2、CH4、CO2等其他气体,直接作为燃料进行管网燃烧,不仅未能高效利用,还会对环境产生较大污染。因此,最适宜的途径是从现有的含氢废气中高效地回收氢气和其他气体[1-2]。目前,变压吸附(pressure swing adsorption,PSA)工艺已广泛应用于含氢气体处理中,其设备简单,提纯纯度高,易于自动化;吸附剂通常以颗粒状或柱状堆积于固定床吸附塔中,在交变压力下,尺寸较小的吸附剂粒子间相互摩擦严重,随气流逸失或堵塞孔道,而采用较大尺寸的颗粒又增加了分子向内扩散的时间,增大吸附剂的库存量,且导致装置能量利用效率低[3-5]。

沸石分子筛具有比表面积大、孔径均一、可再生等特点,可用于筛分不同尺寸的流体分子[6-8]。其中有效孔径为0.5 nm的5A沸石分子筛被广泛应用于工业含氢气体的变压吸附提纯过程[9-11]。结构化5A分子筛吸附剂是一种具有复合结构的吸附材料,克服了传统分子筛吸附剂的不足[12-13],可避免在交变压力下分子筛粒子间的磨损,提供了适用于高频操作的高表面活性通道,极大地提高了吸附材料的传质速率,有利于开发更紧凑的吸附装备[12-14]。LARA等[15]采用土聚凝胶-热转化(GGTC)结合浸涂法,ERIK等[16]采用水热合成法,均在氧化铝基体表面制备出沸石分子筛涂层,用于气体的分离提纯,但涂层厚度较薄,气体吸附量较低;ASIER等[17]采用浸涂法和水热合成法分别在不锈钢网上制备沸石分子筛涂层,研究结果表明浸涂法具有较大的负载量,但其与基体结合强度较弱;RYAN等[18]采用干喷、湿淬纺丝法制备出沸石分子筛内芯,醋酸纤维素外护套的双层中空纤维管,在循环变压吸附中,产品的纯度可达99.2%,表现出优异的气体分离性能。为提高吸附材料强度、分子筛负载量以及材料在吸附分离时的传质特性,本研究以泡沫镍金属为基体,采用浸渍提拉工艺制备结构化5A分子筛吸附材料,优化了制备工艺参数,并对其性能进行了评价。

-

泡沫镍(厚0.6 mm,孔隙率96%);5A分子筛原粉,平均粒径约3 μm;对比样5A分子筛球,平均粒径1 mm;可溶性淀粉,主要成分为玉米粉;酸性硅溶胶,固含量30%,化学纯;纳米氧化铝溶胶,固含量20%,化学纯;聚乙二醇(PEG),相对分子质量2 000;氢氧化钠,分析纯;乙醇,分析纯;丙酮,分析纯。

-

1)泡沫镍预处理:将泡沫镍薄片分别在丙酮、无水乙醇、去离子水中超声洗涤15 min,在60 ℃的质量分数为10%的氢氧化钠溶液中碱洗30 s,经60 ℃的热水冲洗30 s,然后放入沸水中处理3 min,吹干。

2) 5A分子筛浆液的制备:为获得结合性能良好的分子筛涂层,优选出可溶性淀粉为造孔剂,聚乙二醇为分散剂,硅溶胶和铝溶胶为黏结剂,去离子水作为溶剂,经球磨混合30 min,获得5A分子筛浆液。

3) 5A分子筛涂覆:采用浸渍提拉法在泡沫镍薄片上浸涂分子筛浆液,设置提拉速度为20 mm·min−1,浸渍提拉完成后,置于自制的全自动旋转仪上,设置旋转速度为5 r·min−1,并在60 ℃温度下缓慢烘干,然后置于马弗炉中焙烧2 h。

-

采用日本日立公司的S-4800型场发射扫描电子显微镜对样品表面和断面形貌进行观察;采用珀金埃尔默仪器(上海)有限公司的TGA-4000热重分析仪对样品热稳定性进行分析;采用英国牛津仪器公司的D/max2550V型X射线粉末衍射仪对样品进行定性分析;采用美国麦克仪器有限公司的TriStar II 3flex型比表面积及孔径分析仪测定样品的比表面和孔径分布及N2吸附-脱附等温线。

-

采用超声振荡法对结构化5A分子筛进行结合强度测试。样品置于丙酮溶液中,超声波振荡器振荡频率为40 kHz,测试时间为30 min,抽真空烘干后称量。根据超声振荡前、后质量差计算质量损失率,计算方法见式(1)。

式中:W为样品质量变化量;Q为样品质量损失率;M为样品超声振荡前重量,N为样品超声振荡后的重量,X为基体(泡沫镍)重量。

-

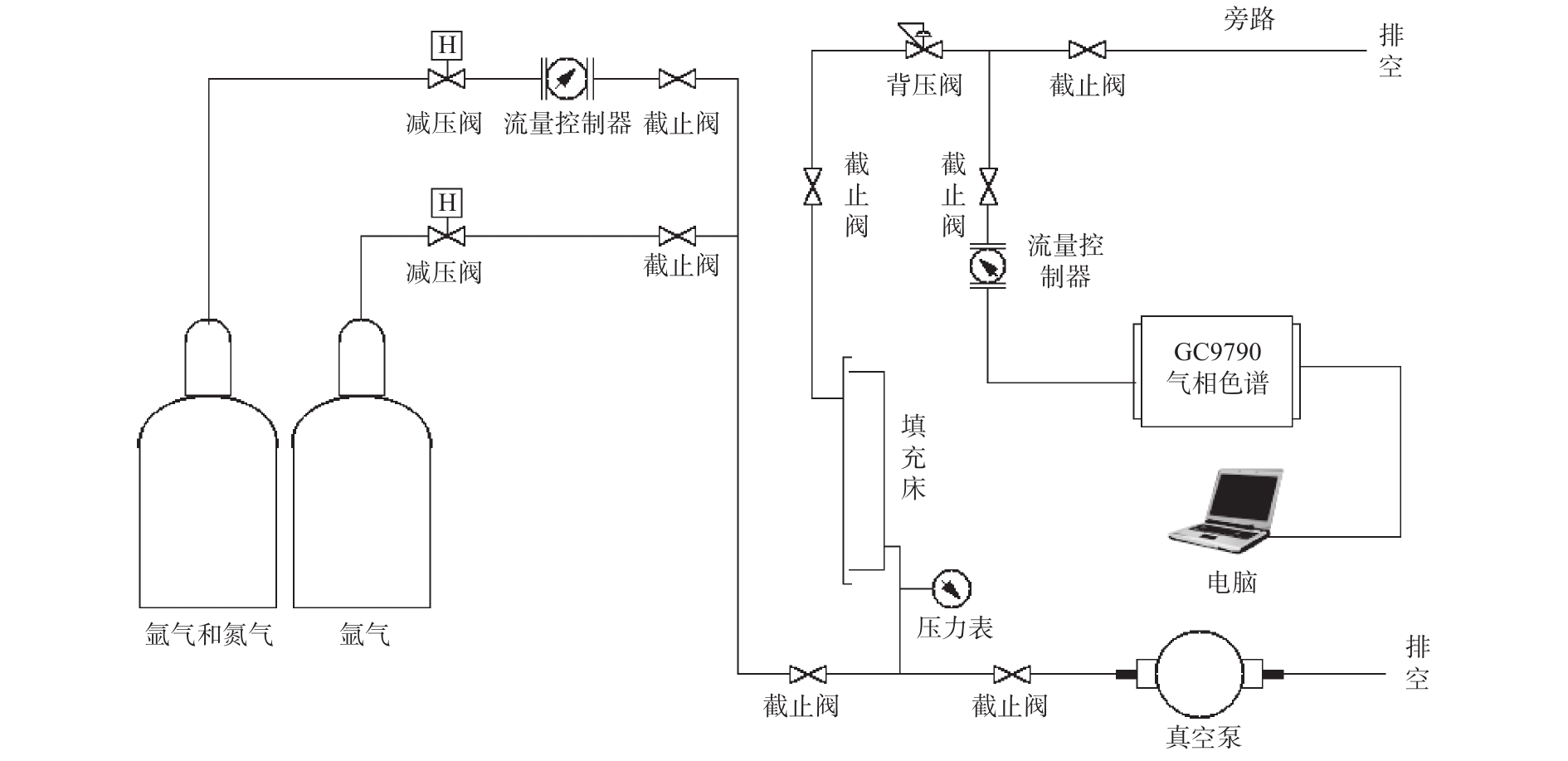

穿透曲线测定实验装置如图1所示,装置由气源、吸附实验、气体成分分析部分组成。实验中气源部分有2块质量流量控制器,分别控制充压氦气和由体积分数为75%的H2与25%的N2组成的混合气的气体流量,吸附实验是将混合气通入填充床进行吸附,填充床为200 mm×50 mm×10 mm的不锈钢槽,槽内装填若干片结构化的吸附材料或球状吸附剂。在分析气体成分时,将填充床出口气体通入GC9790气相色谱(填充相TDX01),采用TCD检测器在线测试气体各组分浓度。

根据氮气穿透时间、标气中氮气含量以及尾气中氮气含量,利用式(2)计算样品的N2吸附容量。

式中:q为吸附材料对氮气的累计吸附容量,mmol·g−1;p为吸附压力,MPa;v为混合气体流过填充床的线速度,cm·s−1;

τ 为临界穿透时间,min;C0、C为标气及尾气中氮气的平均浓度,10−6。实验中以C>1×10−6作为穿透临界时间点;m为填充床中吸附材料填充量,g;常数6.1为填充床参数常量,由实验填充床计算获得。 -

1)形貌分析。泡沫镍和结构化5A分子筛吸附材料的形貌如图2所示。图2(a)为泡沫镍表面SEM图,可以看出,泡沫镍具有明显的三维孔结构,其特殊的结构为5A分子筛浆液的附着提供支撑,极高的孔隙率有利于提高浆液的附着量。图2(b)和图2(c)分别为结构化5A分子筛吸附材料表面显微照片和SEM图,可以看出,泡沫镍基体镶嵌于分子筛层中,并与镍骨架紧密接合,且吸附材料表面均匀分布着利于气体扩散的细微孔隙。图2(d)和图2(e)分别为结构化5A分子筛断面SEM图和断面局部放大SEM图,可以看出,经焙烧,断面处金属镍骨架包埋在分子筛层中,分子筛颗粒间通过黏结剂桥接作用紧密结合在一起,有利于提高吸附材料整体的机械性能。

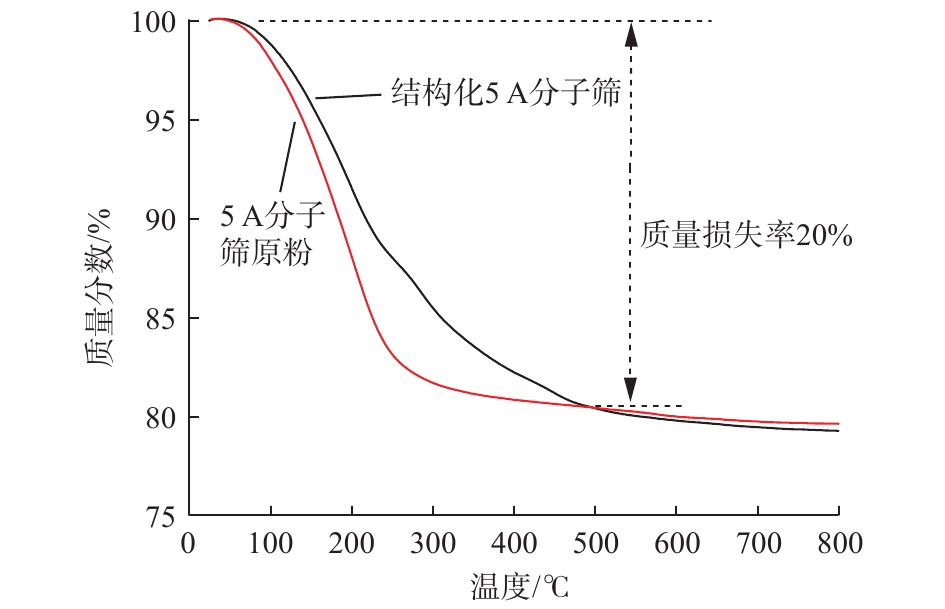

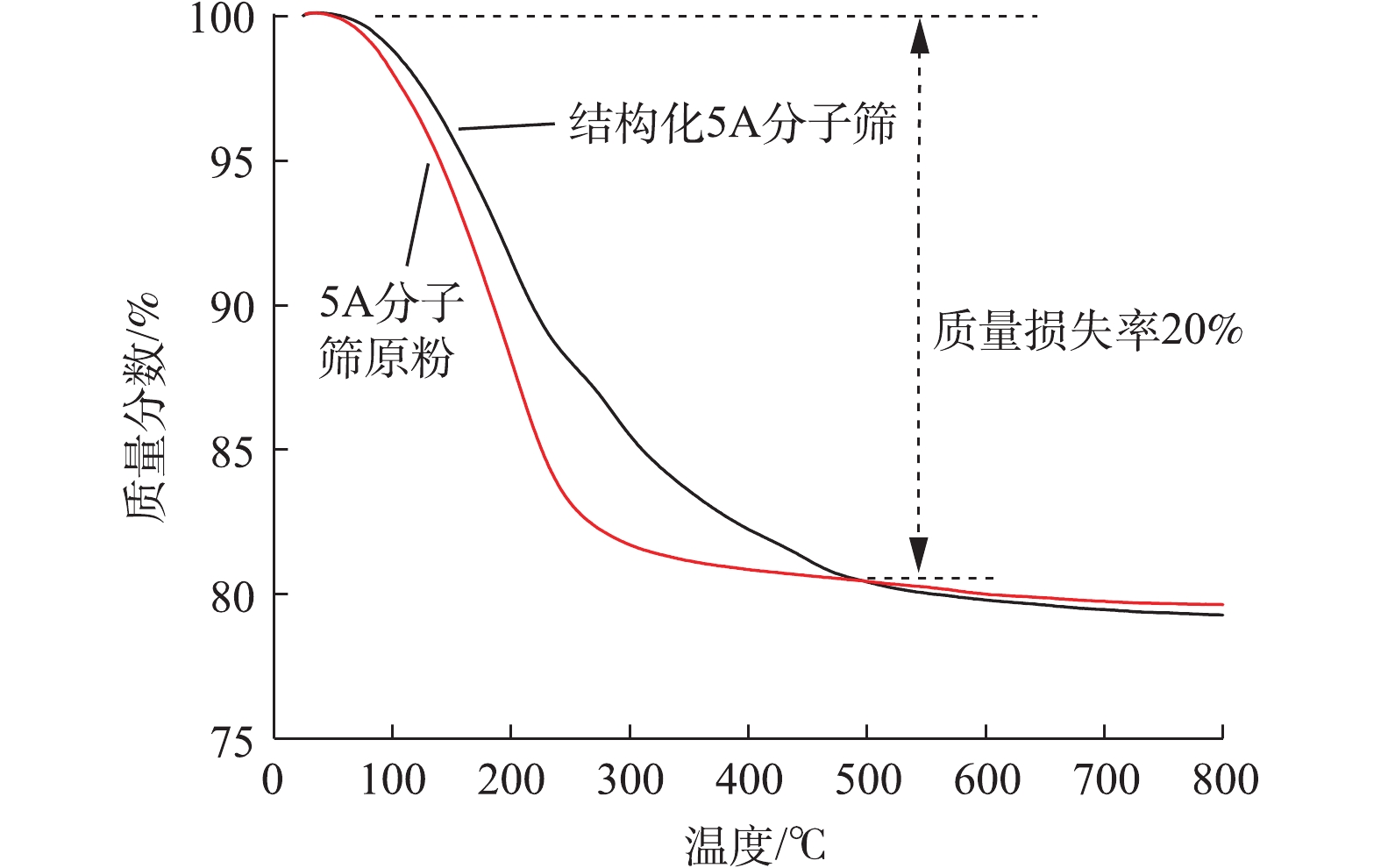

2)热重分析。图3为550 ℃焙烧后获得的结构化5A分子筛和5A分子筛原粉的热重分析曲线,可以看出,两者的失重率相当,均在20%左右。100 ℃左右的质量损失主要是由物理吸附在5A分子筛颗粒表面的吸附水脱除造成的;100~500 ℃质量损失为5A分子筛颗粒上化学吸附的结合水和结构水,以及残余的沸石水的脱除;当温度高于500 ℃时,结构化5A分子筛及其原粉质量均保持不变。由此可见,制备的结构化5A分子筛中无残余的分散剂和造孔剂,且具有良好的热稳定性。

-

1)焙烧温度对结构化5A分子筛性能的影响。图4为不同焙烧温度下结构化5A分子筛XRD图。可以看出,在不同焙烧温度时,特征衍射峰位置基本相同,均没有出现明显不同的衍射峰。焙烧温度在550~650 ℃时,结构化5A分子筛的X射线特征衍射峰位置和相对强度与5A分子筛原粉基本一致;焙烧温度为750 ℃时,某些晶面的长程有序性变差,相对于5A分子筛原粉,特征衍射峰变宽;焙烧温度达到850 ℃时,结构化5A分子筛无尖锐的X射线特征衍射峰,晶型结构完全发生改变,呈无定型态。这说明焙烧后分子筛浆料中的PEG和可溶性淀粉均已被去除,浆液中少量的黏结剂未对5A分子筛原粉的结构产生破坏,并且其衍射峰强度很低。在焙烧温度升高过程中,高温促使分子筛晶粒细化,颗粒结晶度变差,当焙烧温度达到850 ℃时,5A分子筛的孔道坍塌,晶型结构转变成无吸附性能的无定型态。

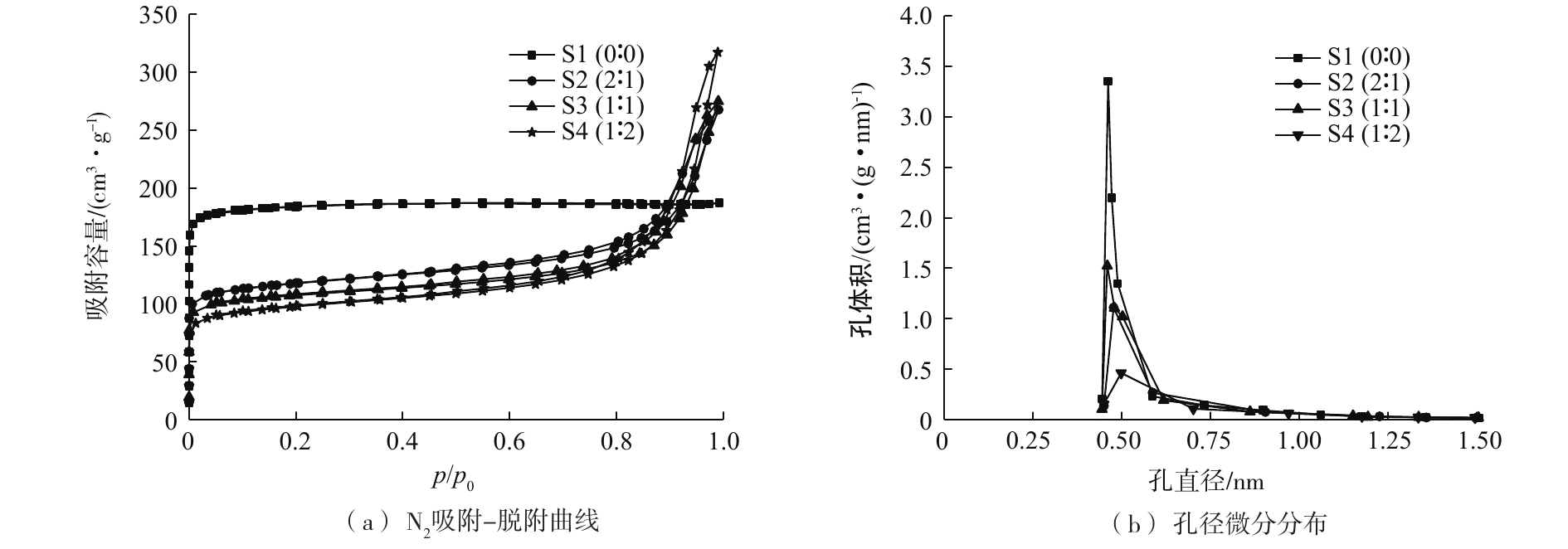

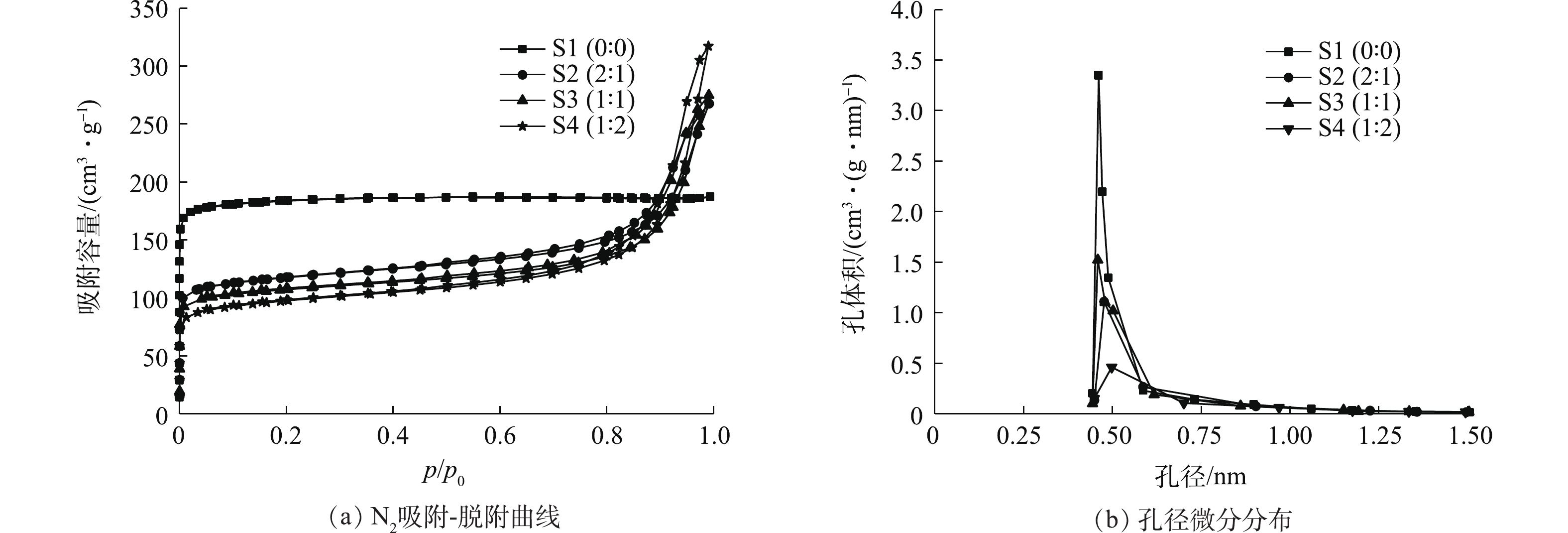

2)硅/铝溶胶固含量比对结构化5A分子筛性能的影响。图5为不同硅/铝溶胶固含量比下经550 ℃焙烧后获得的结构化5A分子筛的N2吸附-脱附曲线及孔结构参数,其中S1(0∶0)为5A分子筛原粉,S2(2∶1)、S3(1∶1)和S4(1∶2)中w(硅溶胶)∶w(铝溶胶)分别为2∶1、1∶1和1∶2。从图5(a)可以看出,5A分子筛原粉的吸附-脱附曲线为Ⅰ型。加入硅溶胶和铝溶胶后,结构化5A分子筛吸附材料的吸附-脱附曲线属于Ⅰ+Ⅳ型。这说明5A分子筛原粉为孔道特征规则的微孔,而结构化5A分子筛为微孔和介孔并存的复杂性孔道。从图5(b)可以看出,5A分子筛原粉和结构化5A分子筛的孔径均集中于0.5 nm(5A)位置。随着硅/铝溶胶比值的减小,集中于0.5 nm处的孔体积呈先增大后减小的趋势。当硅/铝溶胶固含量比为1∶1时,结构化5A分子筛吸附材料在0.5 nm孔径位置孔体积最大。通过分析认为:当硅/铝溶胶固含量比较大时,分子筛浆液黏度较小,与分子筛骨架同种电性的硅胶粒子在一定范围内形成硅胶膜包裹分子筛颗粒,阻碍气体分子进入分子筛孔道;当硅/铝溶胶固含量比较小时,酸性的硅溶胶较少,在与弱碱性的铝溶胶混合后,分子筛浆液pH增大,促使溶胶转变为凝胶,导致浆液中5A分子筛原粉未被完全分散开,产生团聚,致使部分分子筛颗粒未完全起到吸附作用;当硅/铝溶胶固含量比为1∶1时,分子筛浆液的pH偏弱酸性,浆液中的颗粒物可以均匀地分散在水溶液中,焙烧后分子筛颗粒分布均匀。

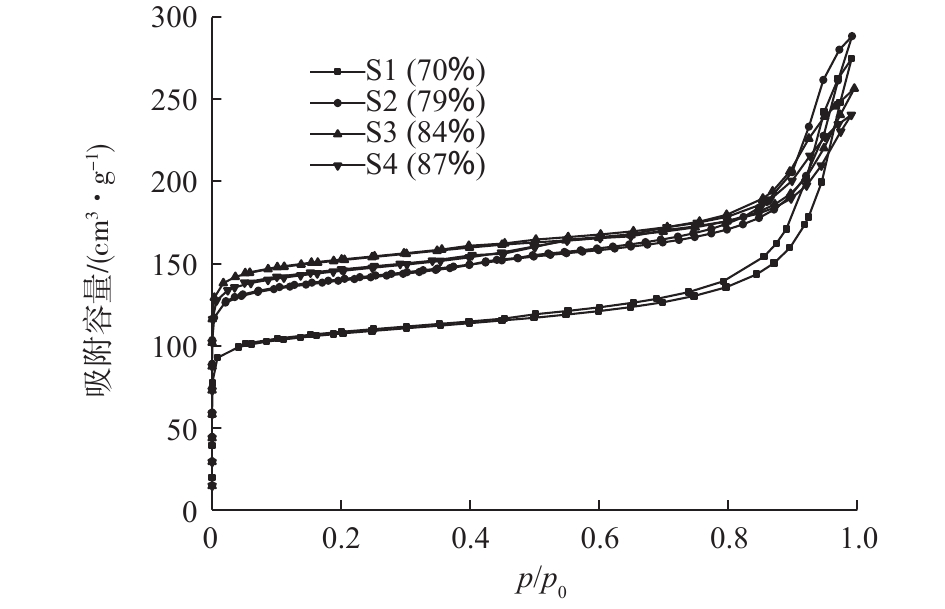

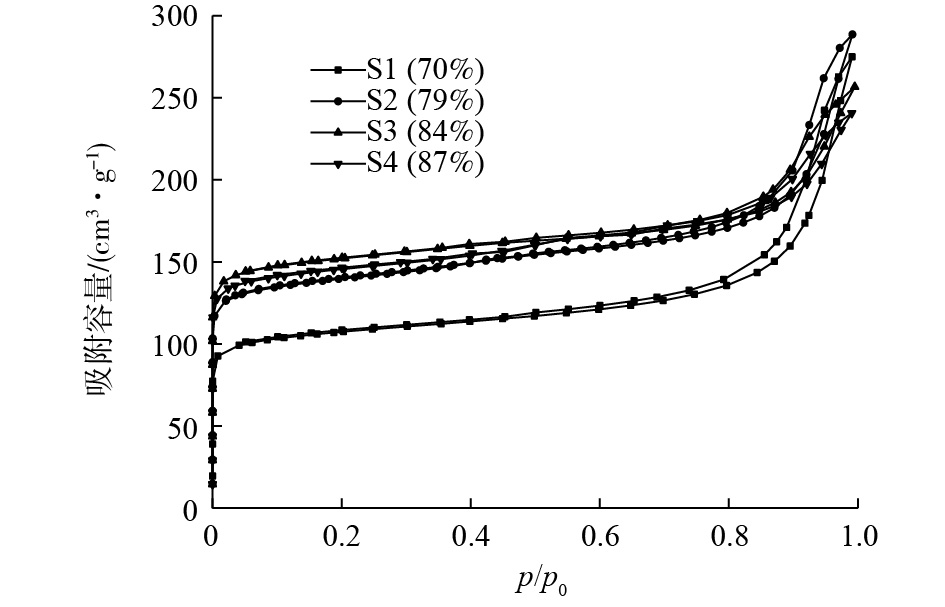

3)分子筛原粉固含量对结构化5A分子筛性能的影响。图6为不同5A分子筛原粉固含量下经550 ℃焙烧后获得的结构化材料的N2吸附-脱附曲线。从图6可以看出,样品S1(70%)、S2(79%)、S3(84%)、S4(87%)均为Ⅰ型和Ⅳ型组成的混合型吸附-脱附曲线。在较低相对压力下,吸附量迅速上升,而后出现饱和;在中等相对压力下,吸附曲线的吸附支和脱附支在一定相对压力范围内不重合,分离形成环状;在较高相对压力区域没有表现出明显的饱和,为典型的H1型回滞环。这一现象通常归因于在中孔吸附材料上发生了毛细管冷凝[19-20]。这进一步证实样品为微孔和介孔并存结构,且介孔的孔径分布均匀,均为两端开口的圆筒状孔。另外,随着5A分子筛原粉固含量的增加,单位吸附材料的吸附量增加,其原因可能是分子筛原粉固含量较少时,包裹在分子筛颗粒表面的高温黏结剂在一定程度上会阻碍气体分子进入分子筛孔道,不利于吸附传质;增大5A分子筛原粉固含量,分子筛颗粒表面的黏结剂由包裹状态逐渐转变为部分黏连,气体分子可以顺利地进入分子筛孔道。

表1为不同5A分子筛原粉固含量对结构化吸附材料孔径结构及结合性能的影响。可以看出,随着分子筛原粉固含量的增加,样品的BET比表面(SBET)、微孔比表面积(Smic)及微孔孔容(Vmic)均不断增加,外比表面积(Sext)先增大后保持不变,且当5A分子筛原粉固含量由70%增加到79%时,这一变化尤为明显。这一现象与前面黏结剂包裹分子筛原粉颗粒的分析推断相印证。实验也表明,不断增大5A分子筛原粉固含量,分子筛层脱落率Q增大较为明显,因此,在浆料配制时,分子筛原粉加入量须兼顾结构化5A分子筛吸附材料的比表面积大及结合强度高的要求。

-

以N2和H2的混合气为原料,模拟工业含氢废气,分析经550 ℃焙烧后获得的结构化分子筛的N2吸附性能。所采用的实验温度为298 K,柱前压为0.4 MPa,气体流速为1.2 cm·s−1,分别测量5A分子筛球和工艺参数优化后的结构化5A分子筛吸附材料对N2的吸附穿透曲线,结果如图7所示。根据实验穿透曲线,分别计算出吸附材料对N2的工作吸附容量,如表2所示。由图7可以看出,结构化分子筛的穿透曲线形状比分子筛球的更陡峭,且前沿的波幅更短,说明结构化5A分子筛吸附材料具有更小的传质区与传质阻力。产生上述不同的原因是,结构化5A分子筛是以泡沫镍金属为基体,整体厚度小于分子筛球粒径,其气体的传质区间相较于5A分子筛球更短;造孔剂的分解逸失产生丰富的大孔孔道,为气体分子扩散提供了较大的流动通道。由表2可以看出,在相同测试条件下,由于存在基体等非有效吸附成分,单位质量结构化吸附材料的N2吸附量降低,但有效吸附质(5A分子筛原粉)的吸附量与分子筛球相比,仅降低8.6%,表明结构化工艺对分子筛的吸附量影响较小。

-

1)以泡沫镍为基体制备出结构化5A分子筛吸附材料。泡沫镍骨架镶嵌于分子筛层中,并与分子筛层相互封锁,结合强度高,结构化吸附材料涂层脱落率可低于1%。

2)在550~650 ℃焙烧温度下,可保持5A分子筛晶型结构完整,随着温度的升高,5A分子筛结构被破坏。结构化5A分子筛吸附材料随着硅/铝溶胶固含量比的降低,材料吸附性能下降,当硅/铝溶胶固含量比为1∶1时,吸附材料微孔孔体积最大。随着5A分子筛原粉固含量的增加,结构化材料吸附性能逐渐提高,但结合强度降低。

3)结构化5A分子筛中微孔和介孔并存,具有较高的单位质量吸附量,且与球状吸附剂相比,结构化吸附材料具有更小的传质区与传质阻力,表现出优异的吸附特性。

泡沫镍负载5A分子筛结构化吸附材料的制备及性能

Preparation and properties of structured adsorbent materials with foam nickel loaded with 5A molecular sieve

-

摘要: 以泡沫镍金属为基体,制备结构化5A分子筛吸附材料,探讨了焙烧温度、硅/铝溶胶固含量比、5A分子筛原粉固含量对结构化5A分子筛性能的影响。采用SEM、TG、XRD、BET、超声振荡等分析方法对样品进行了微观组织结构和结合强度的分析和表征;采用H2和N2的混合气体为吸附质进行了N2在结构化材料中的吸附穿透曲线测定。结果表明,具有较高强度的泡沫镍骨架包埋于分子筛层中,且结构化吸附材料中微孔和介孔并存。在焙烧温度为550~650 ℃时,5A分子筛可较好地保持原有晶型结构;硅/铝溶胶固含量比为1∶1时,结构化5A分子筛微孔孔体积最大;分子筛原粉固含量为79%时,结构化5A分子筛质量损失率仅为0.75%。结构化5A分子筛具有较高的吸附容量,可达544 m2·g−1。与球状吸附剂相比,结构化吸附材料具有更小的传质区与传质阻力。Abstract: Structured 5A molecular sieve adsorbent was prepared with foam nickel as matrix. The effects of calcination temperature, solid content ratio of silicon/aluminum sol and raw powder content of 5A molecular sieve on the properties of structured 5A molecular sieves were discussed. The microstructure and bonding strength of the samples were analyzed and characterized by SEM, TG, XRD, BET, ultrasonic vibration. The adsorption breakthrough curves of N2 in the structured material were measured by using the mixed gas of H2 and N2 as the adsorbate. The results show that the foam nickel skeleton with high strength was embedded in the molecular sieve layer, and the micropores and mesopores coexisted in the structured adsorbent material. 5A molecular sieve could maintain its original crystal structure at the calcination temperature up to 550~650 ℃. The structured 5A molecular sieve had the largest microporous volume when the solid content ratio of silicon/aluminum sol was 1∶1. The mass loss rate of structured 5A molecular sieve was less than 0.75% when the raw powder content of molecular sieve was 79%. The structured 5A molecular sieve had appreciable adsorption capacity up to 544 m2·g−1. Compared to the spherical adsorbent, the structured adsorption material had smaller mass transfer zone and mass transfer resistance.

-

Key words:

- 5A molecular sieve /

- loading /

- structuration /

- adsorption material

-

伴随着国内原油品质逐渐降低,氢燃料电池的高速发展,以及人们对环境保护意识的增强等,氢气的需求正在迅速增加。低浓度含氢废气中存在一定比例的氢气,以及N2、CH4、CO2等其他气体,直接作为燃料进行管网燃烧,不仅未能高效利用,还会对环境产生较大污染。因此,最适宜的途径是从现有的含氢废气中高效地回收氢气和其他气体[1-2]。目前,变压吸附(pressure swing adsorption,PSA)工艺已广泛应用于含氢气体处理中,其设备简单,提纯纯度高,易于自动化;吸附剂通常以颗粒状或柱状堆积于固定床吸附塔中,在交变压力下,尺寸较小的吸附剂粒子间相互摩擦严重,随气流逸失或堵塞孔道,而采用较大尺寸的颗粒又增加了分子向内扩散的时间,增大吸附剂的库存量,且导致装置能量利用效率低[3-5]。

沸石分子筛具有比表面积大、孔径均一、可再生等特点,可用于筛分不同尺寸的流体分子[6-8]。其中有效孔径为0.5 nm的5A沸石分子筛被广泛应用于工业含氢气体的变压吸附提纯过程[9-11]。结构化5A分子筛吸附剂是一种具有复合结构的吸附材料,克服了传统分子筛吸附剂的不足[12-13],可避免在交变压力下分子筛粒子间的磨损,提供了适用于高频操作的高表面活性通道,极大地提高了吸附材料的传质速率,有利于开发更紧凑的吸附装备[12-14]。LARA等[15]采用土聚凝胶-热转化(GGTC)结合浸涂法,ERIK等[16]采用水热合成法,均在氧化铝基体表面制备出沸石分子筛涂层,用于气体的分离提纯,但涂层厚度较薄,气体吸附量较低;ASIER等[17]采用浸涂法和水热合成法分别在不锈钢网上制备沸石分子筛涂层,研究结果表明浸涂法具有较大的负载量,但其与基体结合强度较弱;RYAN等[18]采用干喷、湿淬纺丝法制备出沸石分子筛内芯,醋酸纤维素外护套的双层中空纤维管,在循环变压吸附中,产品的纯度可达99.2%,表现出优异的气体分离性能。为提高吸附材料强度、分子筛负载量以及材料在吸附分离时的传质特性,本研究以泡沫镍金属为基体,采用浸渍提拉工艺制备结构化5A分子筛吸附材料,优化了制备工艺参数,并对其性能进行了评价。

1. 材料与方法

1.1 材料与试剂

泡沫镍(厚0.6 mm,孔隙率96%);5A分子筛原粉,平均粒径约3 μm;对比样5A分子筛球,平均粒径1 mm;可溶性淀粉,主要成分为玉米粉;酸性硅溶胶,固含量30%,化学纯;纳米氧化铝溶胶,固含量20%,化学纯;聚乙二醇(PEG),相对分子质量2 000;氢氧化钠,分析纯;乙醇,分析纯;丙酮,分析纯。

1.2 结构化5A分子筛吸附材料制备

1)泡沫镍预处理:将泡沫镍薄片分别在丙酮、无水乙醇、去离子水中超声洗涤15 min,在60 ℃的质量分数为10%的氢氧化钠溶液中碱洗30 s,经60 ℃的热水冲洗30 s,然后放入沸水中处理3 min,吹干。

2)5A分子筛浆液的制备:为获得结合性能良好的分子筛涂层,优选出可溶性淀粉为造孔剂,聚乙二醇为分散剂,硅溶胶和铝溶胶为黏结剂,去离子水作为溶剂,经球磨混合30 min,获得5A分子筛浆液。

3)5A分子筛涂覆:采用浸渍提拉法在泡沫镍薄片上浸涂分子筛浆液,设置提拉速度为20 mm·min−1,浸渍提拉完成后置于自制的全自动旋转仪上,设置旋转速度为5 r·min−1,并在60 ℃温度下缓慢烘干,然后置于马弗炉中焙烧2 h。

1.3 样品的表征方法

采用日本日立公司的S-4800型场发射扫描电子显微镜对样品表面和断面形貌进行观察;采用珀金埃尔默仪器(上海)有限公司的TGA-4000热重分析仪对样品热稳定性进行分析;采用英国牛津仪器公司的D/max2550V型X射线粉末衍射仪对样品进行定性分析;采用美国麦克仪器有限公司的TriStar II 3flex型比表面积及孔径分析仪测定样品的比表面和孔径分布及N2吸附-脱附等温线。

1.4 结合强度测试

采用超声振荡法对结构化5A分子筛进行结合强度测试。样品置于丙酮溶液中,超声波振荡器振荡频率为40 kHz,测试时间为30 min,抽真空烘干后称量。根据超声振荡前后质量差计算质量损失率,见式(1)。

Q=M−NN−X×100% (1) 式中:W为样品质量变化量;Q为样品质量损失率(%);M为样品超声振荡前重量,N为样品超声振荡后的重量,X为基体(泡沫镍)重量。

1.5 穿透曲线测定及吸附容量计算

穿透曲线测定实验装置如图1所示,由气源、吸附实验、气体成分分析部分组成。实验中气源部分有2块质量流量控制器,分别控制充压氦气和由体积分数为75%的H2与25%的N2组成的混合气的气体流量,吸附实验是将混合气通入填充床进行吸附,填充床为200 mm×50 mm×10 mm的不锈钢槽,槽内装填若干片结构化的吸附材料或球状吸附剂。气体成分分析是将填充床出口气体通入GC9790气相色谱(填充相TDX01),采用TCD检测器在线测试气体各组分浓度。

根据氮气穿透时间、标气中氮气含量以及尾气中氮气含量,利用如下公式计算样品的N2吸附容量:

q=6.1Pvτ(Co−C)×10−6m (2) 式中:q为吸附材料对氮气的累计吸附容量,mmol·g−1;P为吸附压力,MPa;v为混合气体流过填充床的线速度,cm·s−1;

τ 为临界穿透时间,min;C0、C为标气及尾气中氮气的平均浓度,10−6。实验中以C>1×10−6作为穿透临界时间点;m为填充床中吸附材料填充量,g;常数6.1为填充床参数常量,由实验填充床计算获得。2. 结果与讨论

2.1 结构化5A分子筛的表征

2.1.1 形貌分析

泡沫镍和结构化5A分子筛吸附材料的形貌如图2所示。图2(a)为泡沫镍表面SEM图,可以看出,泡沫镍具有明显的三维孔结构,其特殊的结构为5A分子筛浆液的附着提供支撑,极高的孔隙率有利于提高浆液的附着量。图2(b)和图2(c)分别为结构化5A分子筛吸附材料表面显微照片和SEM图,可以看出,泡沫镍基体镶嵌于分子筛层中,并与镍骨架紧密接合,且吸附材料表面均匀分布着利于气体扩散的细微孔隙。图2(d)和图2(e)分别为结构化5A分子筛断面SEM图和断面局部放大SEM图,可以看出,经焙烧,断面处金属镍骨架包埋在分子筛层中,分子筛颗粒间通过黏结剂桥接作用紧密结合在一起,有利于提高吸附材料整体的机械性能。

2.1.2 热重分析

图3为550 ℃焙烧后获得的结构化5A分子筛和5A分子筛原粉的热重分析曲线,可以看出,两者的失重率相当,均在20%左右。100 ℃左右的质量损失,主要是由物理吸附在5A分子筛颗粒表面的吸附水脱除造成的;100~500 ℃质量损失为5A分子筛颗粒上化学吸附的结合水和结构水,以及残余的沸石水的脱除;当温度高于500 ℃时,结构化5A分子筛及其原粉质量均保持不变。由此可见,制备的结构化5A分子筛中无残余的分散剂和造孔剂,且具有良好的热稳定性。

2.2 工艺参数对结构化5A分子筛性能的影响

2.2.1 焙烧温度对结构化5A分子筛性能的影响

图4为不同焙烧温度下结构化5A分子筛XRD图。可以看出,在不同焙烧温度时,特征衍射峰位置基本相同,均没有出现明显不同的衍射峰。焙烧温度在550~650 ℃时,结构化5A分子筛的X射线特征衍射峰位置和相对强度与5A分子筛原粉基本一致;焙烧温度为750 ℃时,某些晶面的长程有序性变差,相对于5A分子筛原粉,特征衍射峰变宽;焙烧温度达到850 ℃时,结构化5A分子筛无尖锐的X射线特征衍射峰,晶型结构完全发生改变,呈无定型态。这说明焙烧后分子筛浆料中的PEG和可溶性淀粉均已被去除,浆液中少量的黏结剂未对5A分子筛原粉的结构产生破坏,并且其衍射峰强度很低。在焙烧温度升高过程中,高温促使分子筛晶粒细化,颗粒结晶度变差,当焙烧温度达到850 ℃时,5A分子筛的孔道坍塌,晶型结构转变成无吸附性能的无定型态。

2.2.2 硅/铝溶胶固含量比对结构化5A分子筛性能的影响

图5为不同硅/铝溶胶固含量比下经550 ℃焙烧后获得的结构化5A分子筛的N2吸附-脱附曲线及孔结构参数,其中S1(0:0))为5A分子筛原粉,S2(2:1)、S3(1:1)和S4(1:2)中w(硅溶胶):w(铝溶胶)分别为2:1、1:1和1:2。从图5(a)可以看出,5A分子筛原粉的吸附-脱附曲线为Ⅰ型。加入硅溶胶和铝溶胶后,结构化5A分子筛吸附材料的吸附-脱附曲线属于Ⅰ+Ⅳ型。这说明5A分子筛原粉为孔道特征规则的微孔,而结构化5A分子筛为微孔和介孔并存的复杂性孔道。从图5(b)可以看出,5A分子筛原粉和结构化5A分子筛的孔径均集中于0.5 nm(5A)位置。随着硅/铝溶胶比值的减小,集中于0.5 nm处的孔的孔体积呈先增大后减小的趋势。当硅/铝溶胶固含量比为1:1时,结构化5A分子筛吸附材料在0.5 nm孔径位置孔体积最大。通过分析认为:当硅/铝溶胶固含量比较大时,分子筛浆液黏度较小,与分子筛骨架同种电性的硅胶粒子,在一定范围内形成硅胶膜包裹分子筛颗粒,阻碍气体分子进入分子筛孔道;当硅/铝溶胶固含量比较小时,酸性的硅溶胶较少,在与弱碱性的铝溶胶混合后,分子筛浆液pH增大,促使溶胶转变为凝胶,导致浆液中5A分子筛原粉未被完全分散开,产生团聚,致使部分分子筛颗粒未完全起到吸附作用;当硅/铝溶胶固含量比为1:1时,分子筛浆液的pH偏弱酸性,浆液中的颗粒物可以均匀地分散在水溶液中,焙烧后分子筛颗粒分布均匀。

2.2.3 分子筛原粉固含量对结构化5A分子筛性能的影响

图6为不同5A分子筛原粉固含量下经550 ℃焙烧后获得的结构化材料的N2吸附-脱附曲线。从图6可以看出,样品S1(70%)、S2(79%)、S3(84%)、S4(87%)均为Ⅰ型和Ⅳ型组成的混合型吸附-脱附曲线。在较低相对压力下,吸附量迅速上升,而后出现饱和;在中等相对压力下,吸附曲线的吸附支和脱附支在一定相对压力范围内不重合,分离形成环状;在较高相对压力区域没有表现出明显的饱和,为典型的H1型回滞环。这一现象通常归因于在中孔吸附材料上发生了毛细管冷凝[19-20]。这进一步证实样品为微孔和介孔并存结构,且介孔的孔径分布均匀,均为两端开口的圆筒状孔。另外,随着5A分子筛原粉固含量的增加,单位吸附材料的吸附量增加,其原因可能是分子筛原粉固含量较少时,包裹在分子筛颗粒表面的高温黏结剂在一定程度上会阻碍气体分子进入分子筛孔道,不利于吸附传质;增大5A分子筛原粉固含量,分子筛颗粒表面的黏结剂由包裹状态逐渐转变为部分黏连,气体分子可以顺利地进入分子筛孔道。

表1为不同5A分子筛原粉固含量对结构化吸附材料孔径结构及结合性能的影响。可以看出,随着分子筛原粉固含量的增加,样品的BET比表面(SBET)、微孔比表面积(Smic)及微孔孔容(Vmic)均不断增加,外比表面积(Sext)先增大后保持不变,且当5A分子筛原粉固含量由70%增加到79%时,这一变化尤为明显。这一现象与前面黏结剂包裹分子筛原粉颗粒的分析推断相印证。实验也表明,不断增大5A分子筛原粉固含量,分子筛层脱落率Q增大较为明显,因此,浆料配制时分子筛原粉加入量需兼顾结构化5A分子筛吸附材料的比表面积大及结合强度高的要求。

表 1 5A分子筛原粉固含量对吸附材料孔结构及结合强度的影响Table 1. Effect of 5A molecular sieve content on pore structure and bonding strength of adsorbent样品号 分子筛原粉固含量/% SBET/(m2·g−1) Smic/(m2·g−1) Sext/(m2·g−1) Vmic/(cm3·g−1) Q/% S1 70 414 326 88 0.128 0.54 S1 79 544 437 108 0.170 0.75 S1 84 554 451 103 0.174 3.39 S1 89 569 466 103 0.180 5.42 2.3 结构化5A分子筛吸附材料吸附性能

以N2和H2的混合气为原料,模拟工业含氢废气,分析经550 ℃焙烧后获得的结构化分子筛的N2吸附性能。所采用的实验温度为298 K,柱前压为0.4 MPa,气体流速为1.2 cm·s−1,分别测量5A分子筛球和工艺参数优化后的结构化5A分子筛吸附材料对N2的吸附穿透曲线,结果如图7所示。根据实验穿透曲线,分别计算出吸附材料对N2的工作吸附容量,如表2所示。由图7可以看出,结构化分子筛的穿透曲线形状比分子筛球的更陡峭,且前沿的波幅更短,说明结构化5A分子筛吸附材料具有更小的传质区与传质阻力。产生上述不同的原因是,结构化5A分子筛是以泡沫镍金属为基体,整体厚度小于分子筛球粒径,其气体的传质区间相较于5A分子筛球更短;造孔剂的分解逸散,产生丰富大孔孔道,又为气体分子提供了较大的流动通道。由表2可以看出,在相同测试条件下,由于存在基体等非有效吸附成分,单位质量结构化吸附材料的N2吸附量降低,但有效吸附质(5A分子筛原粉)的吸附量与分子筛球相比,仅降低8.6%,表明结构化工艺对分子筛的吸附量影响较小。

表 2 不同5A分子筛吸附材料结构形式填充床上的N2吸附性能Table 2. Adsorption properties of N2 on packed bed with different 5A molecular sieve adsorbent structure样品 填充柱长/cm 柱前压/MPa 透过时间/min 吸附量/(mmol·g−1) 有效成分吸附量/(mmol·g−1) 5A分子筛球 20 0.4 22 0.81 0.81 结构化5A分子筛 20 0.4 14 0.50 0.74 3. 结论

1)以泡沫镍为基体制备出结构化5A分子筛吸附材料。泡沫镍骨架镶嵌于分子筛层中,并与分子筛层相互封锁,结合强度高,结构化吸附材料涂层脱落率可低于1%。

2)在550~650 ℃焙烧温度下,可保持5A分子筛晶型结构完整,随着温度的升高,5A分子筛结构被破坏。结构化5A分子筛吸附材料随着硅/铝溶胶固含量比的降低,材料吸附性能下降,当硅/铝溶胶固含量比为1:1时,吸附材料微孔孔体积最大。随着5A分子筛原粉固含量的增加,结构化材料吸附性能逐渐提高,但结合强度降低。

3)结构化5A分子筛中微孔和介孔并存,具有较高的单位质量吸附量,且与球状吸附剂相比,结构化吸附材料具有更小的传质区与传质阻力,表现出优异的吸附特性。

-

表 1 5A分子筛原粉固含量对吸附材料孔结构及结合强度的影响

Table 1. Effect of 5A molecular sieve content on pore structure and bonding strength of adsorbent

样品号 分子筛原粉固含量/% SBET/(m2·g−1) Smic/(m2·g−1) Sext/(m2·g−1) Vmic/(cm3·g−1) 脱落率/% S1 70 414 326 88 0.128 0.54 S2 79 544 437 108 0.170 0.75 S3 84 554 451 103 0.174 3.39 S4 89 569 466 103 0.180 5.42 表 2 不同5A分子筛吸附材料结构形式填充床上的N2吸附性能

Table 2. Adsorption properties of N2 on packed bed with different 5A molecular sieve adsorbent structure

样品 填充柱长/cm 柱前压/MPa 透过时间/min 吸附量/(mmol·g−1) 有效成分吸附量/(mmol·g−1) 5A分子筛球 20 0.4 22 0.81 0.81 结构化5A分子筛 20 0.4 14 0.50 0.74 -

[1] 卫建军, 刘永忠, 张亮, 等. 炼油厂中含氢气体排放的最小化与废氢资源化处置方案研究[J]. 炼油技术与工程, 2010, 40(9): 16-20. doi: 10.3969/j.issn.1002-106X.2010.09.004 [2] 李建勋, 李顺德. 炼油厂从含氢气体中回收利用氢气的方案探讨[J]. 甘肃科技纵横, 2014, 43(7): 32-34. doi: 10.3969/j.issn.1672-6375.2014.07.012 [3] 郭海亮. 固态吸附剂的探究[J]. 中国石油和化工标准与质量, 2014, 34(6): 269. doi: 10.3969/j.issn.1673-4076.2014.06.249 [4] ARISTOV Y, RETUEEIA G, CACEIOLA G, et al. A family of new working materials for solid sorption air conditioning systems[J]. Applied Thermal Engineering, 2002, 22(2): 191-204. [5] ICHIURA H, KUBATA Y, WU Z H, et al. Preparation of zeolite sheet using a papermaking technique[J]. Journal of Materials Science, 2001, 36(4): 913-917. doi: 10.1023/A:1004851101749 [6] 唐静思.低硅铝比ZSM-48分子筛的合成与表征[D].太原: 太原理工大学, 2016. [7] WEUTKAMP J. Zeolites and catalysis[J]. Solid State Ionics, 2000, 131(1/2): 175-188. [8] 王豪, 杨清, 吴雁, 等. 分子筛吸附法脱除废水中的聚丙烯酰胺[J]. 环境工程学报, 2015, 9(3): 1289-1296. doi: 10.12030/j.cjee.20150350 [9] 陈翔. 多级孔道5A分子筛的合成及吸附性能研究[D].上海: 华东理工大学, 2016. [10] XIAO Q, XU X M, NA L. Breakthrough analysis for adsorption of phosphine on 5A molecular sieve[J]. Chemical Engineering & Technology, 2011, 34(1): 140-145. [11] NAN S, QUAN P, ZHANG H, et al. Enhanced thermal conductivity of 5A molecular sieve with BNs segregated structures[J]. Advanced Engineering Materials, 2018, 20(2): 1700745. doi: 10.1002/adem.201700745 [12] DENIS C, DAVID G D, LES J.Rotary pressure swing adsorption apparatus: US6406523B1[P]. 2002-06-18. [13] BOWIE G K, DENIS J C.Pressure swing adsorption with axial or centrifugal compression machinery: US6488747B1[P]. 2002-11-03. [14] BOWIE G K, DAVID G D, CHRISTOPHER R M, et al. Modular pressure swing adsorption apparatus: US7094275 B2[P]. 2006-08-22. [15] LARA M, TORRES R, GUTIERREZ A, et al. Separation of CO2 and N2 with a lithium-modified silicalite-1 zeolite membrane[J]. International Journal of Greenhouse Gas Control, 2012, 10(10): 494-500. [16] ERIK S, SIMON B, DANIL K, et al. MFI membranes for separation of carbon dioxide from synthesis gas at high pressures[J]. Journal of Membrane Science, 2015, 486: 132-137. doi: 10.1016/j.memsci.2015.03.041 [17] ASIER E, PALPMA N, LUCIANO C, et al. Deposition of zeolitic coatings onto fecralloy microchannels-washcoating vs in situ growing[J]. Microporous and Mesoporous Materials, 2009, 123(1/2/3): 113-122. [18] RYAN P L, NAOKI B, DHAVAL A B. Thermally moderated hollow fiber sorbent modules in rapidly cycled pressure swing adsorption mode for hydrogen purification[J]. International Journal of Hydrogen Energy, 2012, 37(20): 15227-15240. doi: 10.1016/j.ijhydene.2012.07.110 [19] SING K S W, WILLIAMS R T. Physisorption hysteresis loops and the characterization of nanoporous materials[J]. Adsorption Science Technolgy, 2004, 22(10): 773-782. doi: 10.1260/0263617053499032 [20] 张云林, 刘晓鹏, 王树茂, 等. 碱处理对5A分子筛孔结构和氢气吸附行为的影响[J]. 材料科学与工程学报, 2014, 32(6): 840-844. -

下载:

下载: