Fenton/絮凝工艺深度处理制浆造纸废水的工程应用分析

Application analysis of Fenton/flocculation process for advanced treatment of pulp and papermaking wastewater

-

摘要: 以某制浆造纸厂生化出水Fenton/絮凝深度处理工艺长期运行数据为依据,系统分析了H2O2、废酸液(FeSO4含量约8%)、硫酸铝、PAM及氧化钙等处理药剂用量与水量、进水负荷和COD去除量之间的关系。结果表明, H2O2、废酸液、硫酸铝、PAM及氧化钙的单位水量平均投加量分别为0.05、2.18、0.07、0.0075和0.27 kg/m3,而去除单位COD的药剂平均消耗量分别为0.20、8.48、0.27、0.029和1.06 kg/(kg COD);H2O2、废酸液、硫酸铝和氧化钙的用量随进水负荷的增大而增加,而PAM随进水负荷的变化较小。H2O2和FeSO4的投加摩尔比(MH2O2/Fe2+)主要集中在1.0~2.0之间,其中在1.0~1.6之间的累积频率达到93%。该工艺的出水COD和SS分别为65~100 mg/L和20~30 mg/L,达到《制浆造纸工业水污染物排放标准》(GB 3544-2008)排放要求。废水深度处理成本约为1.01元/m3,其中药剂费用约0.58元/m3,占56.98%。Abstract: The relation of H2O2, waste acid (8% FeSO4), Al2(SO4)3, PAM, CaO and treatment capacity, influent load, COD removal were analyzed based on the long term operation date of a Fenton/flocculation process used for advanced treatment of pulp and papermaking wastewater. The average dosages of H2O2, waste acid, Al2(SO4)3, PAM and CaO to unit volume of wastewater were 0.05 kg/m3,2.18 kg/m3,0.07 kg/m3,0.0075 kg/m3 and 0.27 kg/m3, respectively,and the average reagent consumption of COD removed were 0.20 kg/(kgCOD),8.48 kg/(kgCOD),0.27 kg/(kgCOD),0.029 kg/(kgCOD) and 1.06 kg/(kgCOD), respectively. The dosages of H2O2, waste acid, Al2(SO4)3 and CaO increased with the increase of influent load, but PAM had no significant change. The molar ratio of H2O2/Fe2+ (MH2O2/Fe2+) was about 1.0~2.0, and the cumulative frequency of MH2O2/Fe2+ between 1.0 and 1.6 was about 93%. The effluent COD and SS were 65~100 mg/L and 20~30 mg/L, respectively, and met the Discharge Standard of Water Pollutants for Pulp and Paper Industry (GB 3544-2008).The treatment cost of the advanced process was about 1.01 yuan/m3, in which the chemical cost was 0.58 yuan/m3 and accounted for 56.98%.

-

Key words:

- pulp and papermaking wastewater /

- Fenton oxidation /

- flocculation /

- advanced treatment

-

矿产资源开发与利用一直以来都是世界各国发展的重要基础[1]。随着国家发展以及工业进步,我们对矿产资源的需求也越来越大,矿产资源开采活动也越来越频繁[2]。但矿产资源的开采往往伴随着生态环境破坏,这其中包括植被破坏、表土剥离、重金属污染、尾矿堆存等[3]。

尾矿作为选矿后留下的固体废物其主要矿物成分为碳酸盐类和硅酸盐类,具有颗粒细小多为砂质、有机质极低、重金属毒性高且易扩散、微生物少、植被难以定殖等特点[4-6]。针对上述特点,目前尾矿的生态修复多采用“改良剂-微生物-植物”体系进行尾矿生态修复[7]。这种修复策略对重金属污染防治作用分为重金属稳定固化和植物吸收,通过有机质的引入为植物生长提供养分以及利用其中的官能团对重金属进行螯合等作用,在实现生态覆绿的同时防治重金属污染[8]。而植物能否定殖成功的关键点就在于重金属的毒性作用和有机质、氮、磷、钾等营养元素,因此探究尾矿生态修复过程中养分以及重金属的变化尤为重要。

本研究通过盆栽实验模拟尾矿生态修复过程,旨在诠释有机酸淋洗和菌棒有机质添加的情况下尾矿中养分和重金属的变化情况及作用机理,为尾矿生态修复工程提供依据。

1. 材料与方法

1.1 实验材料

实验尾矿选自云南省昆明市东川区铜尾矿,为海相砂岩型铜矿,主要矿物为白云石、石英、方解石、钠长石等[9]。其尾矿为砂质,养分较低,主要重金属为铜、锌、铁、锰。添加的废菌棒(以下简称菌棒)为福建古田县购买的茶树菇、滑子菇、银耳废菌棒堆肥发酵制成。具体理化性质见表1。

表 1 铜尾矿和菌棒基本理化性质Table 1. Basic physicochemical properties of copper tailings and edible fungi residue供试材料 pH 电导率/(us·cm−1) 有机质/(g·kg−1) 碱解氮/(mg·kg−1) 速效磷/(mg·kg−1) 速效钾/(mg·kg−1) 铜/(mg·kg−1) 锌/(mg·kg−1) 铁/(mg·kg−1) 锰/(mg·kg−1) 铜尾矿 9.43 139.00 5.27 0.57 0.35 55.64 531.70 38.00 1 415.00 3 506.00 菌棒 7.11 — 38.83 1 266.80 152.13 128.75 — — — — 选用的有机酸改良剂包括柠檬酸(C6H8O7)、草酸(C2H2O4)、醋酸(C2H4O2)、酒石酸(C4H6O6)、抗坏血酸(C6H8O6),纯度为分析纯,有机酸从上海麦克林生化科技股份有限公司购买。有机酸的官能团能够与重金属结合形成较为稳定的配合物,从而降低重金属的毒性作用[10]。植物选择种植高羊茅,草种从宿迁绿芃种业科技有限公司购买。使用的微生物菌肥为硅酸盐细菌,菌肥从北海亦强生物科技有限公司购得,其活菌数≥1.0×1010 g−1。

1.2 实验方法

本研究结合前人实验方法[11],采用盆栽实验进行,尾矿重量为1 kg每盆,然后配制浓度为0.1 mol·L−1的5 种有机酸淋洗剂对尾矿分别进行淋洗,有机酸选取浓度参考吴俭[10]相关研究结果而确定,由于尾矿本身为碱性所以无需进行pH回调,反应放置1 个月后取样用于重金属和养分等分析(以上部分称之为处理前),之后向其中加入菌棒50 g以及将1 g微生物菌肥混匀,同时向每盆中均匀撒入高羊茅种子50 颗,待发芽后拔除多余高羊茅每盆保留25 株,每组设置4 个平行,同时设置对照组。培养3 个月后收集尾矿样品和植物样品进行分析(以上部分称之为处理后),将其实验前后数据进行对比,观察添加菌棒前后的变化。实验组:C(草酸淋洗)、U(醋酸淋洗)、N(柠檬酸淋洗)、J(酒石酸淋洗)、K(抗坏血酸淋洗)。对照组:T1(无有机酸淋洗,无发酵菌棒添加)、T2(无有机酸淋洗)。

1.3 分析方法

采用pH计(pHS-3C,上海雷磁科学仪器有限公司)测定尾矿pH,固液比为1∶5。采用电导率仪(DDS-11A,上海雷磁科学仪器有限公司)测定尾矿EC,固液比为1∶5。采用SEM-EDS(Sigma 300,德国ZEISS公司)观察不同有机酸淋洗及菌棒添加后尾矿中元素分布。

养分测定:有机质采用“水合热重铬酸钾氧化-比色法”在559 nm波长处用紫外分光光度计(EVOLUTION 201,安捷伦科技有限公司)测定;碱解氮采用碱解扩散法测定;速效磷采用碳酸氢钠法在700 nm波长处用紫外分光光度计测定;速效钾采用乙酸铵浸提法在火焰原子吸收光度计(TAS-990,北京普析通用仪器有限责任公司)测定。

重金属测定:铜、锌、铁、锰总量采用混合酸溶法在火焰原子吸收光度计上测定;重金属化学形态采用BCR顺序提取法测定;有效态采用DTPA浸提法测定;植物中的重金属采用高氯酸+硝酸消化测定[12]。

1.4 数据处理与风险评价

采用生态风险指数(ecological risk index,ERI),评价重金属环境风险;风险评价编码法(risk assessment code,RAC)以重金属形态为对象评价重金属污染风险;次生相与原生相比值(rations of secondary phase and primary phase,RSP)来评价其污染风险等级。数据处理采用SPSS.26进行单因素方差分析(P<0.05)和邓肯检验(P<0.05),评价各处理组间pH、电导率(electric conductivity,EC)、养分、重金属等的显著性差异。

2. 结果与讨论

2.1 有机酸淋洗和菌棒添加对尾矿pH、EC的影响

pH作为环境中的关键参数,土壤中无数物质的化学反应都与其有关,并且它直接或间接影响着植物生长发育,过酸和过碱的环境都不适宜植物生长[13-14]。这样的情况也同样适用于生态修复的尾矿基质中,因此,将尾矿基质维持在微酸性至微碱性是生态修复的重要基础。而EC则是代表着尾矿中可溶性盐的浓度,其浓度过高会形成反渗透和离子胁迫,会引起植物损伤和抑制植物生长[15]。有机酸淋洗和菌棒添加情况下尾矿的pH和EC变化情况见表2。

表 2 不同有机酸淋洗下及菌棒添加前后尾矿pH和EC值Table 2. pH and EC values of copper tailings treated with different organic acids washing and edible fungi residue before and after addition组别 pH EC/(us·cm−1) 处理前 处理后 处理前 处理后 T1 8.38±0.233d 7.61±0.028c 189.00±18.384c 115.95±8.980b T2 8.80±0.007c 7.65±0.007c 165.85±11.101c 86.52±5.550cd U 9.80±0.084ab 7.71±0.084bc 289.00±89.095ab 99.00±3.111bc N 9.91±0.049ab 7.77±0.042b 297.50±6.363ab 99.05±2.050bc J 9.79±0.091ab 7.78±0.028b 382.50±7.778a 182.95±8.555a C 10.01±0.007a 7.94±0.035a 301.50±36.062ab 106.95±5.020b K 9.71±0.000b 7.89±0.056a 286.00±5.656b 89.30±8.909cd 注:同列数据后不同小写字母表示差异显著(P<0.05)。 与对照组相比,在未添加菌棒及植物种植前(处理前),有机酸淋洗下尾矿pH均有不同程度的上升,这可能是因为有机酸加速了矿物的溶解释放Na+、K+、Ca2+等离子以及硅酸盐水解释放的OH−有关[13,16],其中C组pH上升最明显。而在添加菌棒和植物种植以后(处理后)pH均有不同程度的降低,与对照组T1相比,在添加了菌棒的情况下pH降低更为显著,降低范围从1.15~2.14不等。这是可能因为微生物介导的有机质分解和植物根系分泌产生的有机酸所致,然而这些有机酸的产生并没有像之前一样引起pH的上升,这可能是因为植物及微生物的引入能够调控自身对Na+、K+、Ca2+等离子的吸收等,使周围环境pH保持在适宜生长的范围内[17]。

EC在处理前组内的变化趋势和原因与pH相似,均是在有机酸淋洗情况下EC值要显著高于对照组,主要是因为有机酸的淋洗溶解矿物释放大量元素所致。处理后与处理前相比,EC降低了79.33~199.55 us·cm−1,说明添加菌棒有机质能够显著降低EC值,这是因为有机质中含有大量的羧基等能够增加土壤胶体吸附Ca2+、K+等盐基离子的能力,从而降低可溶性盐离子[18]。通过以上分析,可以发现菌棒的引入能够大幅度降低尾矿pH和EC值,改变尾矿盐碱度,为植物生长提供良好的基础条件,加快植物定殖。

2.2 有机酸淋洗和菌棒添加对尾矿中养分的影响

土壤养分作为植物生长的必须物质,当养分不足时,会严重影响植物生长发育。例如,当有机质缺乏时会影响土壤团聚性,使土壤板结等,进而导致植物呼吸作用和养分吸收减弱;当缺氮时,会导致植株矮小、植物细胞壁变薄,容易受病菌感染等;当缺钾时,会降低植物体内酶活性;当缺磷时,会影响植物光合作用、蛋白质合成等正常生命代谢活动[19]。由于菌棒本身含有的氮磷钾远高于尾矿,因此菌棒的添加在一定程度上会使得尾矿中的养分提高,根据实验条件计算可知,理论上有机质增加1.59 g·kg−1,碱解氮、速效磷、速效钾分别增加60.29、7.22、3.47 mg·kg−1。然而,研究结果表明,当向尾矿中添加菌棒后,有机质、碱解氮、速效磷、速效钾均显著高于理论升高值,具体结果见表3。

表 3 不同有机酸淋洗下及菌棒添加前后尾矿养分值Table 3. Nutrient contents of copper tailings treated with different organic acids washing and edible fungi residue before and after addition组别或标准 有机质/(g·kg−1) 碱解氮/(mg·kg−1) 速效磷/(mg·kg−1) 速效钾/(mg·kg−1) 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 T1 5.28±0.21bc 7.99±0.38b 0.49±0.05d 11.57±1.87d 1.39±0.12bc 3.15±0.47c 66.62±1.78bc 70.49±2.81e T2 6.11±0.20a 20.08±1.39a 3.24±0.12a 105.06±6.79bc 2.67±0.16a 11.94±0.73a 63.39±3.31c 115.72±5.55d U 5.48±0.46abc 21.18±3.58a 0.57±0.17cd 114.57±3.13a 2.50±0.27a 11.96±0.37a 65.81±1.67bc 137.03±7.53bc N 5.95±2.30ab 23.32±4.90a 0.14±0.03e 97.04±2.00c 1.37±0.07bc 12.23±0.62a 72.25±3.09a 121.20±5.04cd J 5.45±0.27abc 17.53±1.42a 2.15±0.17b 99.90±1.91c 1.55±0.33bc 11.82±0.82a 68.69±1.88ab 161.65±6.59a C 5.17±0.23c 18.63±2.12a 0.84±0.04c 110.10±2.06ab 1.13±0.11c 9.81±0.58b 68.73±1.88ab 113.46±5.35d K 5.12±0.03c 18.70±1.37a 2.01±0.12b 102.69±2.05bc 1.67±0.10b 12.42±0.76a 68.35±3.57ab 145.17±8.56b 绿化种植土壤肥力技术要求 20~80 40~200 5~60 60~300 注:同列数据后不同小写字母表示差异显著(P<0.05)。 从表中可以发现,在添加菌棒的情况下(处理后)T2、U、N,有机质均达到绿化种植土壤肥力技术要求,J、C、K虽然略低于绿化种植土壤肥力技术要求,但也远高于未添加菌棒的组别;碱解氮、速效磷、速效钾则是在添加菌棒后所有组别均达到了绿化种植土壤肥力技术要求。其中,有机质N处理组最高,23.32 g·kg−1,U处理组次之,21.18 g·kg−1;碱解氮U处理组最高,114.57 mg·kg−1,C处理组次之,110.10 mg·kg−1;速效磷K处理组最高,12.42 mg·kg−1,N处理组次之,12.23 mg·kg−1;速效钾J处理组最高,161.65 mg·kg−1,U处理组次之,137.03 mg·kg−1;有机质、碱解氮、速效磷的提高一方面是菌棒自身其养分较高,更重要的可能是由于菌棒的添加给微生物提供了生存条件,微生物通过对菌棒的分解转化使得尾矿中养分进一步升高[20]。钾的提高可能是添加的硅酸盐菌所致,由于菌棒的添加为硅酸盐细菌生长繁殖提供充足的碳源,使得硅酸盐菌大量繁殖,硅酸盐细菌又称解钾细菌,能够破坏矿物晶格释放其中的钾元素[21]。而在(处理前)组别中,由于尾矿本身养分低,因此在有机酸淋洗下无明显变化;在(处理后)组别中可以发现向添加菌棒的情况下不同有机酸淋洗组之间养分的变化情况同样不大,说明有机酸淋洗对尾矿养分变化影响较小。综上所述,菌棒的添加能够大幅度改善尾矿养分情况,解决尾矿生态修复过程中由于养分缺乏导致的植物矮小易死亡等问题。

2.3 有机酸淋洗和菌棒添加对尾矿重金属形态影响及风险评价

重金属作为尾矿的主要特征污染物,一方面会对周边土壤和水环境造成严重污染,一方面也会因为对植物的毒性作用造成尾矿生态修复工程难度增加[22]。重金属主要是在细胞和分子层面对植物产生毒性作用改变植物生理循环,例如使酶失活、破坏细胞膜细胞壁的完整性、蛋白质变性、诱导活性氧的产生以及与植物中某些生物分子结合[23]。

1)重金属化学形态变化。将尾矿中的重金属向更稳定的形态转化,减弱其迁移能力和毒性作用是尾矿生态修策略的1 种。ASEMOLOYE等[24]和CAI等[25]研究发现菌棒可以作为重金属钝化剂,结合和固定土壤中的重金属,能够促进重金属向活性较低的化学形态转化。因此,本研究通过引入有机酸和菌棒,利用其含有丰富的官能团及配位体对重金属进行螯合,以此来探究尾矿中重金属化形态的变化情况,具体结果见图1。

从图中可以发现,在添加菌棒前(处理前),不同有机酸处理均能够降低Cu的弱酸提取态及还原态,可氧化态则是U、J、C、K处理组略微升高,T2和N组略微降低,以及提高其残渣态占比。在弱酸提取态中U处理组效果最好,与T1相比降低了7.3%;还原态中则是K处理组效果最好,与T1相比降低了5.78%;可氧化态中与T1相比J处理组升高最多(4.1%);残渣态中K处理组效果最好,与T1相比升高了12.64%。对Zn的弱酸提取态则是在N、J、C组处理下有所降低,N处理组降低最多(2.73%),U和K两组处理有所升高,K处理组升高最多(12.29%);还原态在5 组有机酸处理下有不同程度降低;而对可氧化态和残渣态的变化不大。总体上说,有机酸处理对Zn的化学形态影响较低。Fe和Mn在有机酸处理下化学形态变化则是不明显。综上所述大部分有机酸处理均能降低重金属的弱酸提取态和可还原态,Cu和Zn受有机酸影响程度要大于Fe和Mn。

当向有机酸处理后的尾矿中添加菌棒(处理后),由于向尾矿中添加的菌棒重量占比远远小于尾矿,因此菌棒添加引起的物理稀释忽略不计。从图中可以发现Cu和Fe的弱酸提取态占比进一步减少,与处理前相比Cu的弱酸提取态占比从41.39%~34.06%降低至22.57%~18.54%;Fe弱酸提取态占比从10.08%~5.78%降低至2.18%~1.72%;Mn弱酸提取态占比从15.70%~13.88%降低至11.95%~10.52%;而对Zn弱酸提取态的影响则是不明显,与处理前相比略微有升高。可还原态Cu和Fe的变化情况与弱酸提取态相似,与处理前相比Cu的可还原态占比整体上从10.66%~4.88%降低至7.44%~6.21%;Fe可还原态占比从12.29%~10.00%降低至8.77%~8.08%;Zn可还原态占比略微有所降低,从7.15%~4.23%降低至5.12%~3.43%;Mn可还原态处理前后变化则是不明显。4 种重金属的可氧化态处理前后变化情况与弱酸提取态和可还原态变化情况有所不同,菌棒添加对4 种重金属的可氧化态均影响较小。Cu可氧化态占比略微有所降低,整体上从23.80%~19.12%降低至20.15%~17.44%;Fe可氧化态占比整体上从2.12%~2.72%升高至2.80%~4.45%;而Zn和Mn的可氧化态整体上则是变化不明显。残渣态占比则是除了Zn略微有所降低外,整体上从77.80%~62.40%降低至75.49%~71.22%,其余3 种重金属均有不同程度升高,Cu残渣态占比整体上从37.08%~28.77%升高至54.62%~50.59%,这也说明了菌棒的添加大幅提高了Cu的残渣态;Fe残渣态占比整体从80.03%~77.04%上升至86.79%~85.11%;Mn残渣态占比整体从84.72%~82.87%上升至87.99%~86.42%。通过对添加菌棒前后重金属各个化学形态对比分析可以知道,除了Zn外,菌棒的添加会降低Cu、Fe、Mn的弱酸提取态及可还原态占比,增加残渣态占比,使其向更稳定低毒的形态转变。

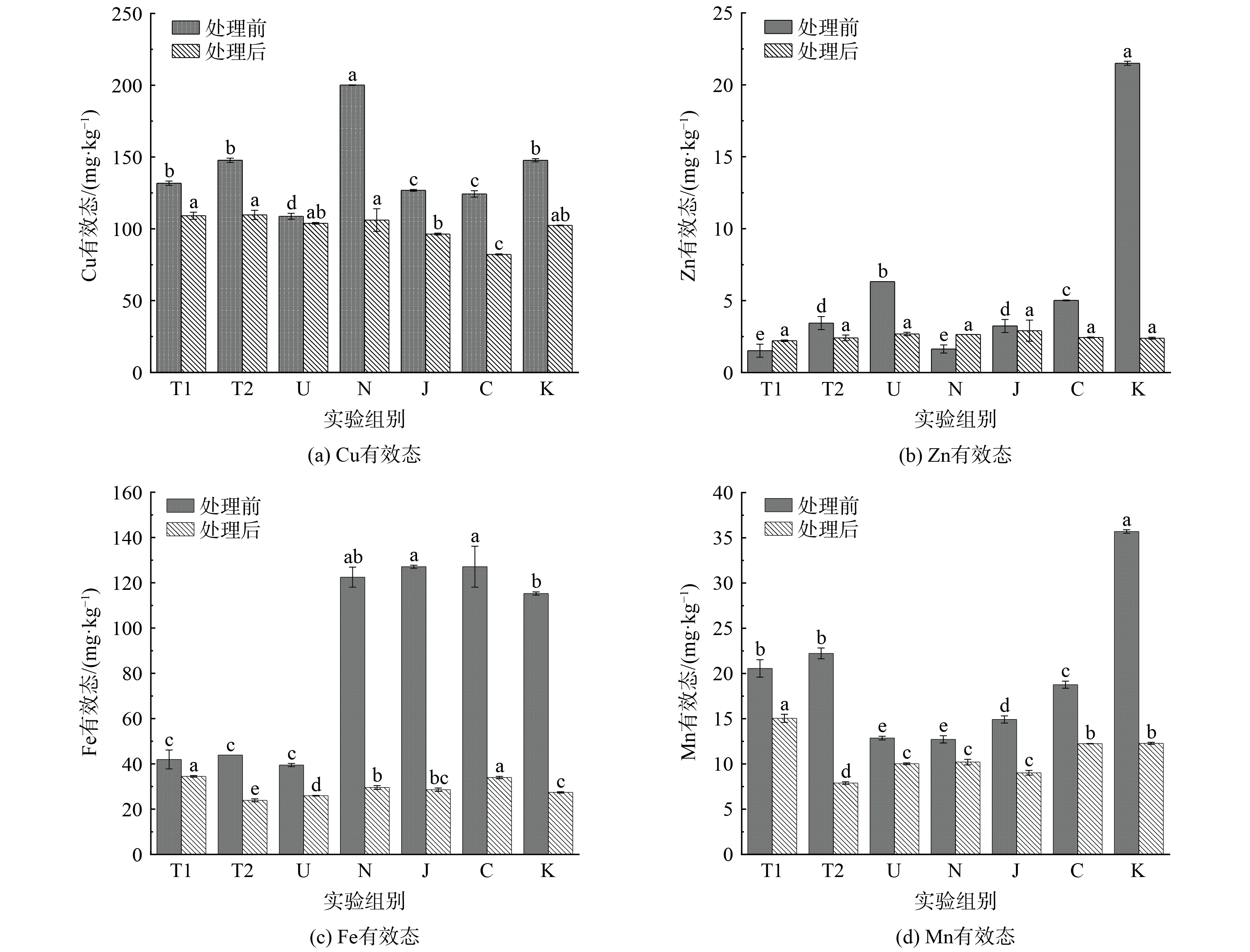

2)重金属有效态和植物吸收变化。重金属有效态作为植物可以吸收利用的形态与植物的生长发育息息相关[26],因此,关注其变化也是在尾矿生态修复工程中十分必要的。有机酸淋洗和菌棒添加对尾矿中Cu、Zn、Fe、Mn有效态的影响情况见图2。

在处理前的组别中,与T1、T2相比大部分有机酸淋洗有助于Cu的有效态减少,但N组除外,这可能是由于柠檬酸的酸化作用所致[27]。而Zn有效态则是在大部分有机酸的淋洗下表现出升高的趋势,其中K组尤为明显,这可能与Zn在尾矿中的存在形式有关,导致有机酸对Zn主要是解吸作用[28]。Fe的有效态在N、J、C、K,4组有机酸酸处理下显著升高,这可能是有机酸诱导的含Fe矿物溶解[29]。Mn的有效态变化情况与Zn相似,均是在K处理组最高。在处理后的组别中,可以发,当菌棒添加后4 种重金属的有效态均要明显低于处理前组别,这可能是因为在植物根系及微生物的作用下,菌棒被逐渐分解形成的腐殖质中含有大量羧酸、羟基、多糖等官能团与重金属络合以及有机物代谢过程的副产物使得铁锰氧化物增加进而加强了对重金属的吸附作用[30-32]。

图3则是表示不同有机酸处理下及菌棒添加后(处理后)植物地上和地下部分植中重金属的质量分数,从图中可以发现,T1与其他组相比:在添加菌棒后植物地上和地下部分中Cu的质量分数显著降低,T2与其他有机酸处理组相比则是变化不明显,这说明有机酸对植物吸收重金属的影响小于菌棒添加的影响;植物对Zn和Mn的吸收则无论是菌棒添加还是有机酸淋洗情况下均变化不明显;对Fe的吸收地下部分在菌棒添加后显著上升,地上部分则是有机酸淋洗的组别吸收较高。图4为尾矿的EDS图谱及Cu、Zn、Fe、Mn的元素分布图,结果表明,在添加菌棒的尾矿中,绝大部分组别的Cu、Zn、Fe、Mn均有不同程度降低,从元素分布图也能看出相较于T1,其他组别4 种元素分布相对较少。EDS图谱结果也表明植物对重金属的吸收情况,并且与上述重金属的化学形态和有效态的变化情况基本符合,也证实了上述中给出的有关重金属变化的结果。

3)重金属环境风险评价。由于各种重金属风险评价方法差异较大,各有优缺点,因此本研究采用RAC、ERI、RSP,3 种评价方法对有机酸和菌棒处理下的重金属进行风险评价,对比各种方法下重金属污染风险等级[33-35]。

RAC法主要是通过重金属中的弱酸提取态在总量中的占比对环境风险进行评级,其公式为式(1)。

RAC=CF1CF1+CF2+CF3+CF4×100% (1) 式中:RAC为尾矿中重金属风险指数;

CF1 CF2 CF3 CF4 ERI通常是以重金属活性较高的有效态与重金属总量之比来评价重金属风险等级,其公式为式(2)。

ERI=CbsCs×100% (2) 式中:ERI为尾矿中重金属生态风险指数;

Cbs Cs RSP是指次生相(除残渣态)重金属形态与原生相(残渣态)重金属比值来评价其污染风险等级,其公式为式(3)。

RSP=MsecMprim (3) 式中:RSP为尾矿中重金属污染程度;

Msec Mprim 3 种方法评价等级划分标准见表4,Cu、Zn、Fe、Mn风险评价分别见表5、6、7、8。

表 4 RAC、ERI、RSP法评价标准Table 4. Evaluation criteria of RAC, ERI and RSP methods等级 RAC ERI RSP RAC值 划分标准 ERI值 划分标准 RSP值 划分标准 1 RAC<1% 无风险 ERI<1% 无风险 RSP≤1 无污染 2 1%≤RAC<10% 低风险 1%≤ERI<10% 低风险 1<ERI≤2 轻度污染 3 10%≤RAC<30% 中风险 10%≤ERI<30% 中风险 2<ERI≤3 中度污染 4 30%≤RAC<50% 高风险 30%≤ERI<50% 高风险 ERI>3 重度污染 5 RAC≥50% 极高风险 ERI≥50% 极高风险 — — 表 5 不同有机酸淋洗及菌棒添加后尾矿中Cu的RAC、ERI、RSP法等级风险评价Table 5. RAC, ERI and RSP grade risk assessment of Cu in tailings treated with different organic acids washing and after edible fungi residue was added组别 RAC值 RAC评价等级 ERI值 ERI评价等级 RSP值 RSP评价等级 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 T1 41.36%±1.12%a 49.91%±0.53%a 高风险 高风险 26.91%±0.73%c 20.53%±0.23%a 中风险 中风险 2.53±0.67a 4.15±0.96a 中度污染 重度污染 T2 38.24%±0.44%bc 22.57%±0.97%b 高风险 中风险 29.12%±0.04%b 22.81%±1.04%a 中风险 中风险 2.10±0.10ab 0.93±0.22b 中度污染 无污染 U 34.06%±0.49%d 18.53%±0.27%b 高风险 中风险 21.59%±0.60%d 21.17%±0.00%a 中风险 中风险 1.73±0.01b 0.83±0.03b 轻度污染 无污染 N 40.15%±2.15%ab 20.05%±4.88%b 高风险 中风险 39.30%±1.14%a 21.43%±6.80%a 中风险 中风险 2.02±0.28ab 0.87±0.26b 中度污染 无污染 J 38.36%±1.11%bc 22.60%±0.39%b 高风险 中风险 26.07%±1.54%c 20.69%±0.17%a 中风险 中风险 2.30±0.05ab 0.97±0.05b 中度污染 无污染 C 37.20%±0.72%c 22.93%±0.96%b 高风险 中风险 25.12%±0.55%c 17.95%±0.78%a 中风险 中风险 2.21±0.20ab 0.92±0.00b 中度污染 无污染 K 37.34%±0.69%c 19.93%±0.40%b 高风险 中风险 29.69%±0.46%b 22.58%±0.09%a 中风险 中风险 1.78±0.10b 0.88±0.08b 轻度污染 无污染 注:同列数据后不同小写字母表示差异显著(P<0.05)。 表 6 不同有机酸淋洗及菌棒添加后尾矿中Zn的RAC、EIR、RSP法等级风险评价Table 6. RAC, ERI and RSP grade risk assessment of Zn in tailings treated with different organic acids washing and after edible fungi residue was added组别 RAC值 RAC评价等级 EIR值 EIR评价等级 RSP值 RSP评价等级 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 T1 13.79%±4.79%b 12.79%±1.97%b 中风险 中风险 4.15%±1.31%e 6.93%±0.22%a 低风险 低风险 0.38±0.11b 0.30±0.02b 无污染 无污染 T2 12.22%±1.95%b 14.47%±0.58%ab 中风险 中风险 9.77%±1.49%cd 7.44%±1.00%a 低风险 低风险 0.37±0.04b 0.35±0.01ab 无污染 无污染 U 14.66%±0.94%b 15.85%±2.42%ab 中风险 中风险 17.42%±1.11%b 8.79%±0.05%a 中风险 低风险 0.35±0.04b 0.38±0.05ab 无污染 无污染 N 10.97%±1.90%b 14.95%±0.28%ab 中风险 中风险 4.50%±1.12%e 8.85%±0.08%a 低风险 低风险 0.28±0.02b 0.35±0.02ab 无污染 无污染 J 11.52%±0.61%b 13.66%±0.66%ab 中风险 中风险 9.17%±2.01%d 8.41%±2.33%a 低风险 低风险 0.29±0.03b 0.32±0.02b 无污染 无污染 C 11.48%±0.78%b 16.46%±0.57%a 中风险 中风险 12.67%±0.83%c 7.83%±0.18%a 中风险 低风险 0.29±0.04b 0.40±0.00a 无污染 无污染 K 26.08%±0.28%a 14.61%±1.68%ab 中风险 中风险 49.94%±0.57%a 7.01%±0.54%a 高风险 低风险 0.60±0.02a 0.33±0.03ab 无污染 无污染 注:同列数据后不同小写字母表示差异显著(P<0.05)。 表 7 不同有机酸淋洗及菌棒添加后尾矿中Fe的RAC、EIR、RSP法等级风险评价Table 7. RAC, ERI and RSP grade risk assessment of Fe in tailings treated with different organic acids washing and after edible fungi residue was added组别 RAC值 RAC评价等级 EIR值 EIR评价等级 RSP值 RSP评价等级 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 T1 6.24%±0.15%c 17.61%±1.73%a 低风险 中风险 0.30%±0.03%b 0.25%±0.00%a 无风险 无风险 0.25±0.00b 0.46±0.04a 无污染 无污染 T2 5.59%±0.26%c 1.72%±0.31%b 低风险 低风险 0.31%±0.01%b 0.17%±0.00%c 无风险 无风险 0.25±0.01b 0.15±0.00b 无污染 无污染 U 6.59%±0.09%c 1.76%±0.02%b 低风险 低风险 0.28%±0.00%b 0.18%±0.00%bc 无风险 无风险 0.24±0.00b 0.16±0.00b 无污染 无污染 N 8.07%±1.18%b 1.88%±0.21%b 低风险 低风险 0.90%±0.02%a 0.21%±0.01%b 无风险 无风险 0.26±0.02ab 0.16±0.00b 无污染 无污染 J 9.47%±0.11%a 1.77%±0.06%b 低风险 低风险 0.94%±0.02%a 0.20%±0.01%b 无风险 无风险 0.28±0.01ab 0.16±0.01b 无污染 无污染 C 5.78%±0.13%c 1.98%±0.14%b 低风险 低风险 0.94%±0.07%a 0.24%±0.00%a 无风险 无风险 0.26±0.00ab 0.17±0.00b 无污染 无污染 K 10.08%±0.42%a 2.18%±1.68%b 中风险 低风险 0.87%±0.02%a 0.19%±0.00%bc 无风险 无风险 0.29±0.01a 0.17±0.00b 无污染 无污染 注:同列数据后不同小写字母表示差异显著(P<0.05)。 表 8 不同有机酸淋洗及菌棒添加后尾矿中Mn的RAC、EIR、RSP法等级风险评价Table 8. RAC, ERI and RSP grade risk assessment of Mn in tailings treated with different organic acids washing and after edible fungi residue was added组别 RAC值 RAC评价等级 EIR值 EIR评价等级 RSP值 RSP评价等级 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 处理前 处理后 T1 14.92%±0.38%ab 16.10%±0.10%a 中风险 中风险 0.58%±0.03%c 0.46%±0.02%a 无风险 无风险 0.19±0.00ab 0.22±0.00a 无污染 无污染 T2 14.97%±0.34%ab 11.64%±0.63%bc 中风险 中风险 0.63%±0.02%b 0.24%±0.00%e 无风险 无风险 0.19±0.01ab 0.15±0.00bc 无污染 无污染 U 13.88%±0.06%b 11.08%±0.03%cd 中风险 中风险 0.37%±0.00%e 0.30%±0.00%cd 无风险 无风险 0.18±0.00b 0.14±0.00bcd 无污染 无污染 N 14.82%±1.13%ab 11.09%±0.46%cd 中风险 中风险 0.36%±0.00%e 0.31%±0.00%c 无风险 无风险 0.19±0.01ab 0.14±0.00bcd 无污染 无污染 J 15.03%±0.11%ab 11.00%±0.31%cd 中风险 中风险 0.44%±0.00%d 0.27%±0.01%d 无风险 无风险 0.19±0.00ab 0.14±0.00cd 无污染 无污染 C 15.70%±0.15%a 11.95%±0.23%b 中风险 中风险 0.55%±0.01%c 0.38%±0.00%b 无风险 无风险 0.20±0.00a 0.15±0.00b 无污染 无污染 K 14.56%±0.44%ab 10.52%±0.01%d 中风险 中风险 1.03%±0.00%a 0.36%±0.01%b 低风险 无风险 0.18±0.00ab 0.13±0.00d 无污染 无污染 注:同列数据后不同小写字母表示差异显著(P<0.05)。 从表5中可以发现,利用3 种评价方法对尾矿中的Cu污染进行评价时,RAC方法显示在未添加菌棒的处理前组别中Cu污染评价等级均为高风险,但在添加菌棒的处理后组别中Cu污染等级均降为中风险;ERI方法显示虽然在处理前和处理后组别均为中风险,但是在添加菌棒的处理后组相比于处理前组别其ERI值均有显著降低;RSP方法评价Cu污染等级显示在未添加菌棒的处理前组别中为轻度污染和中度污染,而在添加菌棒的处理后组别中均变为无污染。在T1组别中,也就是未添加菌棒情况下种植植物会增加RAC和RSP值,RAC评价中从处理前的41.36%增加至处理后的49.91%;RSP评价中更是从2.53增加至4.15,污染等级从中度变为重度。相比于菌棒添加,有机酸淋洗对Cu污染风险的影响就小的很多,无论是在处理前还是处理后组别中,不同有机酸处理虽然对RAC、ERI、RSP的值有变化但对评价等级几乎没影响。

从表6中可以发现,利用3种方法对Zn污染进行评价时,RAC方法评价在未添加菌棒的处理前组别中为中风险,虽然在添加菌棒的处理后组别中RAC值有所升高,但评价等级仍然为中风险;ERI方法处理前组别为高、中、低风险,处理后组别均降为低风险;对RSP评价无明显影响,处理前后组别均为无污染。而有机酸淋洗除了对处理前组别ERI评价等级有影响外(K组对EIR评价影响最大),对其他方法评价等级均没有显著的影响。

从表7、8中发现,与Cu和Zn不同的是,Fe和Mn虽然3种评价方法的值处理后组别相比于处理前组别均有降低,但其评价等级几乎没变化。同样,在不同有机酸处理下,Fe和Mn的评价值和评价等级也无明显变化。通过对4 种重金属的风险评价分析,可以发现无论是有机酸处理下还是添加菌棒对Cu和Zn的影响要大于Fe和Mn,其次,在Cu和Zn的风险等级评价中可以发现,添加菌棒的作用要大于有机酸淋洗的作用。

3. 结论

1)尾矿pH和EC受有机酸处理和菌棒添加的显著影响,菌棒添加下,pH降低了1.15~2.14,EC降低了79.33~199.55 us·cm−1。

2)尾矿中的养份受到菌棒添加的显著影响。在菌棒添加下养分显著增加,基本达到绿化种植土壤肥力技术要求。

3)除Zn外,有机酸淋洗和菌棒添加均能降低其余3 种重金属的弱酸提取态,增加残渣态。重金属形态受菌棒添加的影响要大于有机酸,对Cu的影响最大。

-

[1] 王庆, 丁原红, 马英华, 等. MBBR法深度处理造纸中段废水的工程应用. 中国给水排水, 2009, 25(14): 72-74, 78 Wang Q., Ding Y. H., Ma Y. H., et al. Application of MBBR process in papermaking middle-stage wastewater treatment. China Water & Wastewater, 2009, 25(14): 72-74, 78 (in Chinaese) [2] 刘剑玉, 汪晓军, 陈彦. 臭氧预氧化-BAF深度处理造纸废水. 中国造纸, 2009, 28(9): 36-38 Liu J. Y., Wang X. J., Chen Y. Advanced treatment of paper mill wastewater by ozone pre-oxidation and biological aerated filter processes. China Pulp & Paper, 2009, 28(9): 36-38 (in Chinaese) [3] 何仕均, 李坤豪, 谢雷, 等. γ辐射/生物处理工艺处理草浆中段废水的研究. 中国给水排水, 2009, 25(7): 69-72 He S. J., Li K. H., Xie L., et al. Study on treatment of straw-pulp middle-stage wastewater by γ-radiation and biological treatment process. China Water & Wastewater, 2009, 25(7): 69-72 (in Chinese) [4] 刘丽, 罗松柏, 谢智华. 水解酸化/曝气/气浮/Fenton工艺处理造纸废水. 中国给水排水, 2011, 27(10): 73-75 Liu L., Luo S. B., Xie Z. H. Hydrolysis acidification/biolak/air flotation/fenton process for treatment of papermaking wastewater. China Water & Wastewater, 2011, 27(10): 73-75 (in Chinese) [5] Lin S. H., Lo C. C. Fenton process for treatment of desizing wastewater. Water Research, 1997, 31(8): 2050-2056 [6] Xu X. R., Li H. B., Wang W. H., et al. Degradation of dyes in aqueous solutions by the Fenton process. Chemosphere, 2004, 57(7): 595-600 [7] 许燕, 王征. 多种强化混凝技术在制浆造纸废水深度处理中的应用探讨. 工业水处理, 2010, 30(7): 15-18 Xu Y., Wang Z. Approach to the application of several enhanced coagulation technologies to advanced treatment of pulp & papermaking wastewater. Industrial Water Treatment, 2010, 30(7): 15-18 (in Chinese) [8] Torrades F., Saiz S., García-Hortal J. A. Using central composite experimental design to optimize the degradation of black liquor by Fenton reagent. Desalination, 2011, 268(1-3): 97-102 [9] 朱亦仁, 鲁玲, 李爱梅, 等. Fe2+/H2O2法处理草浆纸厂废水的影响因素研究. 环境污染治理技术与设备, 2006, 7(7): 91-95 Zhu Y. R., Lu L., Li A. M., et al. Study on influencing factors in treating paper making wastewater by Fe2+/H2O2 system. Techniques and Equipment for Environmental Pollution Control, 2006, 7(7): 91-95 (in Chinese) [10] Martinez N., San S., Fernández J. F., et al. Pre-oxidation of an extremely polluted industrial wastewater by the Fenton's reagent. Journal of Hazardous Materials, 2003, 101(3): 315-322 [11] Zhou L., Hu J. X., Zhong H., et al. Study of phenol removal using fluidized-bed Fenton process. Chemical Engineering Research and Design, 2012, 90(3): 377-382 [12] Meric S., Kap tan D., Ölmez T. Color and COD removal from wastewater containing Reactive Black 5 using Fenton's oxidation process. Chemosphere, 2004, 54 (3): 435-441 [13] 刘千钧, 袁斌, 伍红, 等. Fenton法深度处理制浆造纸综合废水实验研究. 造纸科学与技术, 2009, 28(4): 57-59 Liu Q. J., Yuan B., Wu H., et al. Advanced treatment of pulping and papermaking effluent by Fenton process. Paper Science & Technology, 2009, 28(4): 57-59 (in Chinese) [14] Neyens E., Baeyens J. A review of classic Fenton's peroxidation as an advanced oxidation technique. Journal of Hazardous Materials, 2003, 98(1-3): 33-50 [15] Jiang C. C., Pang S. Y., Ouyang F., et al. A new insight into Fenton and Fenton-like processes for water treatment. Journal of Hazardous Materials, 2010, 174(1-3):813-817 [16] 张金玲, 于军亭, 张帅. 芬顿法深度处理造纸废水. 水资源与水工程学报, 2011, 22(3): 154-156 Zhang J. L., Yu J. T., Zhang S. Advanced treatment of papermaking wastewater by Fenton method. Journal of Water Resources and Water Engineering, 2011, 22(3): 154-156 (in Chinese) [17] 翟阳. 新标准下制浆造纸工业废水处理应对措施与深度处理工程案例. 中华纸业, 2011, 32(16): 13-15 Zhai Y. Measures and advanced treatment engineering cases of pulping and papermaking industry wastewater under new standard. China Pulp & Paper Industry, 2011, 32(16): 13-15 (in Chinese) [18] 陈楠, 陈永利, 刘新亮, 等. Fenton法深度处理制浆中段废水的工程应用. 中国造纸, 2009, 28(10): 59-62 Chen N., Chen Y. L., Liu X. L., et al. Engineering application of Fenton advanced oxidation process for washing and bleaching effluent treatment. China Pulp & Paper, 2009, 28(10): 59-62 (in Chinese) [19] 左晨燕, 何苗, 张彭义, 等. Fenton 氧化/混凝协同处理焦化废水生物出水的研究. 环境科学, 2006, 27(11): 2201-205 Zuo C. Y., He M., Zhang P. Y., et al. Study on Fenton oxidation cooperated with coagulation of biologically treated coking wastewater. Environmental Science, 2006, 27(11): 2201-205 (in Chinese) -

点击查看大图

点击查看大图

计量

- 文章访问数: 2184

- HTML全文浏览数: 1257

- PDF下载数: 1177

- 施引文献: 0

DownLoad:

DownLoad: