常州某纺织园印染废水处理工艺改造研究

A study of dyeing wastewater treatment technology in Changzhou textile park

-

摘要: 常州某纺织园印染废水厂,由于原有深度处理工艺中混凝沉淀与活性炭吸附运行费用高、产生的污泥量大等缺点,拟进行工艺改进,本研究采用改性磁粉/ClO2氧化协同深度处理代替原有深度处理工艺,连续运行结果表明,当电磁体装置中调节废水pH为4左右、磁粉投加量为10 g/L、ClO2投量为60 mL/L,先吸附20 min,然后ClO2氧化8 min,处理后的废水COD<20 mg/L,色度<30倍,低于江苏省地方标准太湖地区城镇污水处理厂及重点工业行业主要污染物排放限值的排放要求,且工艺经济合理。Abstract: This research is about a printing and dyeing wastewater treatment plant in Changzhou, which has some disadvantage, such as high operating cost of coagulation and sedimentation and activated carbon, large quantity of sludge, and so on. As a consequence, this advanced treatment process needs to be improved. Modified magnetic powder/ClO2 oxidation process is studied to replace the old advanced treatment process. The continuously results show that when pH is about 4, dosage of modified magnetic powder is 10 g/L, dosage of ClO2 is 60 mL/L, adsorption time is 20 min, and then oxidation time of using ClO2 is 8 min, the treated effluent COD<20 mg/L, color<30. The quality of effluent is lower than limits for dyeing wastewater of Jiangsu Taihu area sewage treatment plants, and the process is economic and reasonable.

-

实验室危险废物是指在生产、研究、开发、教学和环境检测 (监测) 活动中,化学和生物实验室产生的废物,包括无机废液、有机废液,废弃化学试剂,及含有或直接沾染危险废物的实验室检测样品、废弃包装物、废弃容器、清洗杂物和过滤介质等[1]。实验室产生的废液等若随意处理会造成下水道的腐蚀或影响人体健康,甚至会引发爆炸、火灾等安全事故[2],生物实验室废物产生的包装物、容器和吸附介质等还可能沾染有害微生物,如具有感染性的病原微生物等,若不妥善处理,可能导致严重的健康问题[3]。

近年来,我国科技实力伴随经济发展同步壮大,在科技活动主体的研发活动投入持续增加,研发经费规模持续扩大。2021年研究与试验发展 (R&D) 经费达2.79×1012 元,为2000年的31倍,2001-2021年年均增幅达到18.1%。同时,2018-2021年间,我国研究与试验发展 (R&D) 经费投入占GDP比重不断提高,由2018年的2.19%增加至2021年的2.44%。“十四五”规划提出,全社会研发经费投入年均增长要大于7%,基础研究经费投入占研发经费投入比重提高到8%,实验室危险废物产生量随着全社会研发经费的增加亦与日俱增[4-5],实验室危险废物管理引发公众关注。以北京市为例,可获取统计数据的12家产废单位实验室废物产生量由2014年的708.76 t增加至2018年的972.11 t[6],增长了近40%。我国新修订并于2020年9月生效实施的新《固体废物污染环境防治法》[7]第七十三条明确要求,各级各类实验室及其设立单位应当加强对实验室产生的固体废物的管理,其中属于危险废物的,应当按照危险废物管理。随着我国固体废物环境污染防治工作的不断深入,实验室危险废物环境管理的现实需求日益迫切。

本研究在我国实验室危险废物产生量预测的基础上,总结了我国实验室危险废物管理现状和存在的问题,提出了完善相应管理工作的建议,以期为我国实验室危险废物管理提供参考。

1. 数据与方法

1.1 实验室危险废物产生量预测

目前,国内外针对废物产生量的预测主要采用时间序列分析、回归分析和灰色模型等数理统计方法,根据人口总量和社会经济总产值等社会经济特征进行预测[8-9]。其中,灰色系统预测模型(Grey Model,GM),主要基于关联度收敛原则进行废物产生量预测,能够实现在基础产生数据较少的情况下较好地模拟废物产生量变化趋势[10],是相关预测研究较为常用的方法之一[11]。本文在北京市研究与试验发展 (R&D) 经费预测基础上,根据调研获取的实验室危险废物产生量与R&D经费的产废强度关系,预测北京市实验室危险废物产生量。首先,建立R&D经费随时间变化的一阶灰色预测模型GM (1,1) ,确定北京市R&D经费预测模型方程。GM (1,1) 模型构建见式 (1) 。

x0(k)+az(1)(k)=b (1) 通过最小二乘法求解参数

a b ˆx(1)(t+1)=(x(0)(1)−ba)e−at+ba,t=1,2,...,n (2) 式中:

x(0)(1) ˆx(1)(t+1) t+1 ˆx(0)(t+1)=ˆx(1)(t+1)−ˆx(1)(t),t=1,2,...,n (3) 式中:

ˆx(0)(t+1) t+1 ˆx(1)(t) t 基于此,预测近10年北京市实验室危险废物产生量,预测方法见式 (4) 。

Qn(t+1)=ˆx(1)(t+1)×k,t=0,1,2... (4) 式中:

Qn(t+1) t+1 ˆx(1)(t+1) k 1.2 数据来源

实验室危险废物产生源分散,且各单位产生量小,统计困难。目前,我国尚无公开的实验室危险废物产生量的统计数据,国内外针对实验室危险废物产生量预测的研究也较少。本研究基于北京市危险废物转移联单数据,筛选了项目期内 (2014-2017年) 可连续获取实验室危险废物联单信息的12家危险废物产生量最大的科研机构,调研收集了其实验室危险废物转移量作为产生量,并以此作为预测模型的基础参数。将收集到的数据与相应产废单位同时期R&D经费投入情况相结合,计算该时间范围内的平均产废强度关系,用于预测北京市实验室危险废物的产生量。

1.3 政策分析

本研究结合实验室危险废物相关内容,查找国家和地方、高校和企业实验室管理政策文件和相关举措。针对国家和地方出台的17项政策文本进行分析并找出各项政策针对实验室危险废物的切入点和欠缺点;同时,对39所“985”工程高校、116所“211”工程高校和6个地 (园) 区小微企业的实验室危险废物管理政策和举措进行调查,并对比分析高校和企业在收集处理实验室危险废物全过程中的优缺点。

2. 结果与讨论

2.1 实验室危险废物产生量预测

2.1.1 实验室危险废物产废强度

根据前述调研和计算,结果显示,2014-2017年间北京市研究所涉产废单位实验室危险废物收集量呈逐年递增趋势 (表1) ,结合同期相应R&D经费,计算得出平均产废强度为6.89×10−8 t∙元−1。鉴于本研究调研的研究机构大部分为综合性高校,因此本研究在当前可获取的数据条件下,据此作为北京市实验室危险废物产生量预测时的强度参数。

表 1 北京市部分研究机构实验室危险废物产生量 (2014-2017年)Table 1. Volume of laboratory hazardous waste generation in major generator in Beijing from 2014 to 2017年份 实验室危险废物产生量/t R&D经费值/(×108 元) 实验室危险废物产废强度/(×10−8 t∙元−1) 2014 708.76 96.96 7.31 2015 814.13 92.97 8.76 2016 748.18 131.53 5.69 2017 777.0 133.68 5.81 实验室危险废物收集率方面,北京市2018年收集单位数量较2017年增加44.1%,收集覆盖范围和收集成效逐渐提高。同时,2018年北京市实验室危险废物收集量近40 00 t,较2017年增加35.7%。此外,采用前述方法,结合北京市R&D经费情况和危险废物产生量预测,估算结果显示2018年北京市实验室危险废物收集率约27%。鉴于北京市自2016年出台《北京市实验室危险废物污染防治技术规范》[12],逐步规范实验室危险废物管理,收集率显著高于全国同期其他省市。

2.1.2 R&D经费预测

根据2014-2020年北京市R&D经费,采用公式统计值拟合出2021-2030年北京市R&D经费预测值,将原始数据代入GM (1,1) 模型,见式 (5) 。

ˆx(1)(t+1)=10874.5e0.1154t−9605.7,t=0,1,2... (5) 式中:

ˆx(1)(t+1) 式 (5) 表示以R&D经费值为数值的累加序列,t=0时计算得到的值代表基准年的R&D经费值,t=n时计算得到的是基准年至基准年+n年间R&D经费累积值。2021-2030年北京市R&D经费预测值见表2。

表 2 2021-2030年北京市R&D经费预测值Table 2. Forecast value of Beijing R&D funds from 2021 to 2030年份 预测值/ (×108 元) 年份 预测值/ (×108 元) 2021 2 661.76 2026 4 748.96 2022 2 988.51 2027 5 331.92 2023 3 355.37 2028 5 986.46 2024 3 767.27 2029 6 721.34 2025 4 229.73 2030 7 546.43 预测结果通过模型精度进行检验,由表3可以看出,预测值与实际值间的残差波动较小,在-6.06~5.53之间,经计算得出预测值与实际值之前的关联度R=0.97>0.5,模型精度满足要求。同理,计算得到小误差概率P=1>0.95,方差比值C=0.21<0.35,当P>0.95,C<0.35时,判断预测精度等级为好[13]。

表 3 2014-2020年北京市R&D经费模型检验Table 3. Beijing R&D funds model test from 2014 to 2020年份 实际值/(×108 元) 预测值/(×108 元) 绝对误差 残差/% 2014 1 268.8 1 268.8 0 0 2015 1 384.0 1 330.2 53.8 3.89 2016 1 484.6 1 492.7 -8.1 -0.55 2017 1 579.7 1 675.5 -95.8 -6.06 2018 1 870.8 1 880.3 -9.5 -0.51 2019 2 233.6 2 110.0 123.6 5.53 2020 2 326.6 2 368.3 -41.7 -1.79 2.1.3 实验室危险废物产生量

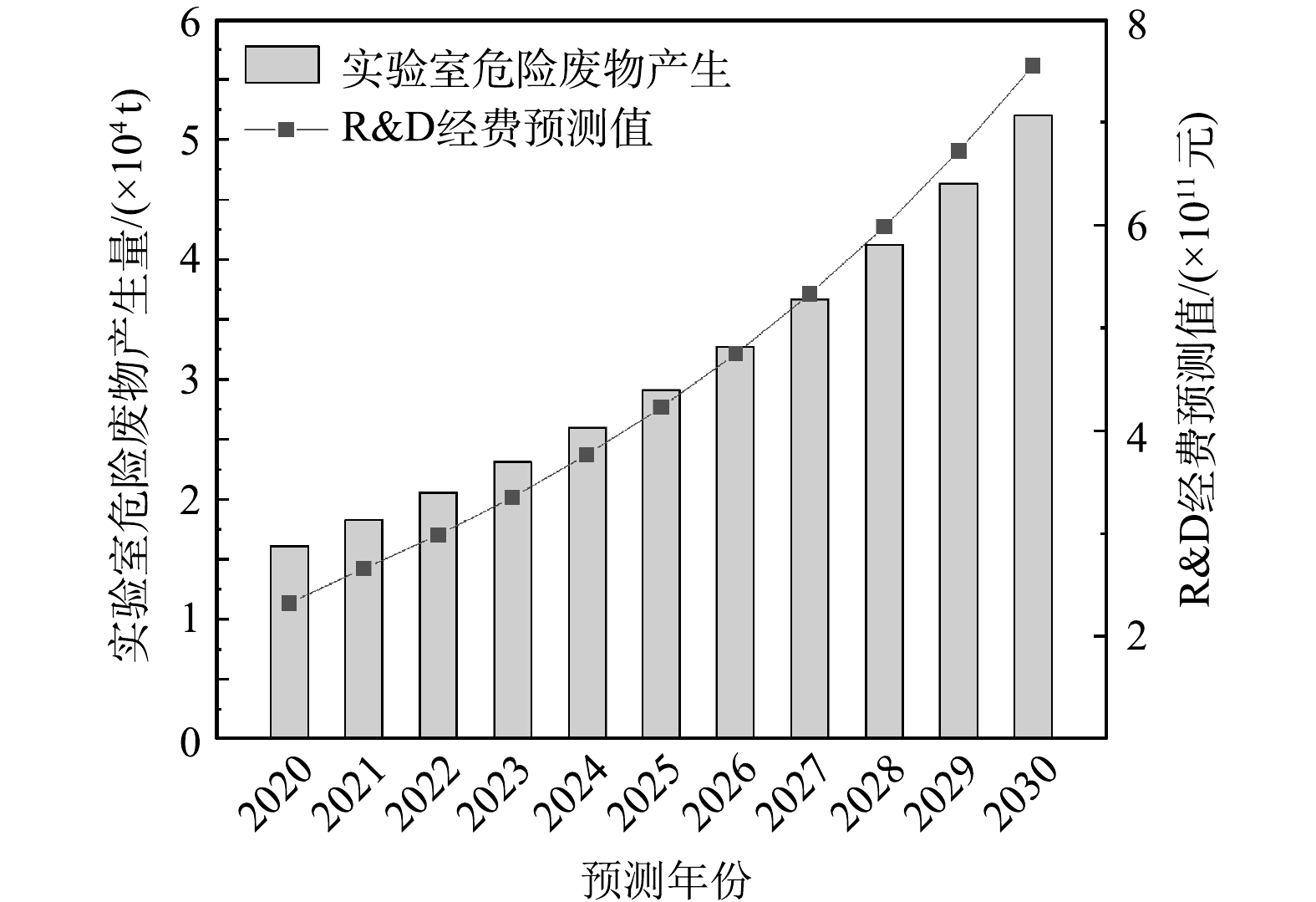

将产废强度和北京市R&D经费预测值代入式 (4) 中,预测结果如图1所示。可见,随着R&D经费值增加,预期北京市实验室危险废物产生量呈明显上升趋势,其中2020年和2021年北京市实验室危险废物产生量预计分别为1.61×104和1.83×104 t,2025年和2030年分别为2.91×104和5.20×104 t,较2021年产生量分别增长为59%和184%。同时,采用该方法和参数对全国实验室危险废物产生量进行简单地预测,结果显示,2025年和2030年产生量分别可达133.17×104和231.16×104 t。

北京市2016-2018年实验室危险废物收集率从15%增长至27%,平均增长率约为4%,预计2021年收集率约为39%。根据北京市2021年统计年鉴公布的北京市2020年危险废物产生量为24.97×104 t,北京市实验室产生的危险废物量约占北京市所有危险废物量的6.4%,随着产生量的增长及收集率的增高,实验室危险废物也将成为北京市危险废物管理中非常重要的类别。探索建立实验室废物收集及处理处置机制,规范化管理实验室危险废物且有法可依是目前更迫切需要解决的问题。本研究以北京市实验室危险废物产生量为基础数据,研究预测北京市产生量,是本研究的初步结果。目前针对各地区及全国实验室危险废物产生量有较少的研究,因此预测存在一定的局限性和不确定性。北京市汇集了众多高校和科研机构,相对于全国其他地区,较具有代表性和典型性。本研究采用的预测方法和预测对象与蔡彬等[10]原理相同,建议后续同类研究中可以将其他相关影响因素加入到预测中来,在统计学中获得更加准确的结论与数据。

2.2 实验室危险废物管理政策

2.2.1 国外政策

国外重视实验室危险废物管理,出台了一系列法规和管理政策。美国联邦法规[14] (第40篇第262部分第K子部分) 制定了适用于实验室危险废物产生者的要求,对每月产生实验室危险废物量少于100 kg的极小规模生产者采取豁免机制。美国大部分高校设有EHS (环境、健康、安全) 部门,为学校各实验室和研究中心提供有关环境和安全方面的服务,并承担环境监督与管理的职责[15-17]。日本大多数高校依据国家颁布的《废弃物管理和清扫法》[18]制定其针对实验室危险废物的管理指南,对实验室危险废物的管理流程和方法进行详细说明。部分高校专门设立“环境保护中心”,负责制定管理标准及注意事项,对收集的实验室危险废物在单位内部处理处置、检测排水及其他环保事项 (宣传、培训等) [19]。

2.2.2 国家和地方政策

随着实验室危险废物产生量的增多,我国对实验室危险废物管理越来越重视。我国自2004年就开始出台实验室管理文件,但主要针对生物类实验室及高校实验室排污管理。原国家环保总局发布了《关于加强实验室类污染环境监管的通知》[20],提出禁止将废弃药品转移给不具备污染治理条件的企业、单位或个人使用,禁止随意丢弃有毒有害废物及废液,防止实验室类污染危害环境,损害人体健康的原则性要求。同年,国务院发布了《病原微生物实验室生物安全管理条例》[21],提出了对病原微生物将实行分类管理,对实验室实行分级管理的总体要求。相关政策未针对实验室危险废物提出明确管理规定和要求,导致实验室危险废物的分类收集、贮存、运输、处置等操作流程缺乏专门的管理规范。

2005年,教育部和原国家环保总局发布了《关于加强高等学校实验室排污管理的通知》[22],提出了实验室科研教学活动中产生和排放的废气、废液、固体废物等严格按照主管部门申报登记、收集、运输和处置,实验室危险废物的暂存、交换、运送和处置应严格执行危险废物转移联单制度的要求。该通知构建了高校实验室排污监管制度,启动了高校实验室危险废物规范化管理工作。2006年,原国家环保总局发布了《病原微生物实验室生物安全环境管理办法》[23],提出了建立健全病原微生物实验室废水、废气和危险废物污染防治管理的规章制度。2008年,国家质量监督检验检疫总局和国家标准化管理委员会发布了《实验室生物安全通用要求》[24],主要对生物安全实验室以及动物生物安全实验室安全管理,明确各部门责任、严格危险废物的处理处置,防止污染环境。相关政策和标准针对生物实验室安全管理,提出了具体要求,以降低实验室安全管理存在的隐患。

2008年,原环境保护部、国家发展改革委和公安部发布了《国家危险废物名录》[1],在2005年《关于加强高等学校实验室排污管理的通知》[22]基础上,进一步明确了在科研教学活动中产生的应参照危险废物进行管理的实验室固体废物,具体为“在研究、开发和教学活动中,化学和生物实验室产生的废物” (HW49,废物代码900-047-49) 。2016年,教育部发布了《关于集中开展教育系统危险化学品安全专项整治的通知》[25],要求教育部门及各类学校建立完善实验用废弃危化品处置备案制度,联系有资质的危化品处置企业尽快将高校积压的危废品予以分批处理,并逐步建立高校和危废处置企业长期合作、定向处理机制,加强了学校对危险化学品安全隐患的排查治理和监督管理能力,整治了安全管理工作的薄弱环节。2021年国务院办公厅发布《强化危险废物监管和利用处置能力改革实施方案》[26],鼓励在有条件的高校集中区域开展实验室危险废物分类收集和预处理示范项目建设。该方案为进一步完善危险废物监管体制机制,建立安全监管与环境监管联动机制提供了保障措施,为逐渐完善危险废物收集处理设施提供了依据。2022年生态环境部办公厅发布《关于开展小微企业危险废物收集试点的通知》[27],主要针对危险废物产生量较小的企业,还包括科研机构和学校实验室等社会源开展试点收集,要求小微企业按照高标准、可持续的原则,明确收集单位责任,强化收集过程环境监管,加强收集单位的培训及宣传等工作,为后续加强小微企业危险废物污染防治,防范小微企业危险废物环境风险,推动各地完善小微企业危险废物收集建设具有重要意义。具体管理政策见表4。

表 4 我国在实验室安全管理等方面管理政策Table 4. Management policies in laboratory safety management in China文件名称 发布日期 发布单位 《关于加强实验室类污染环境监管的通知》[20] 2004年2月 原国家环保总局 《病原微生物实验室生物安全管理条例》[21] 2004年11月 国务院 《关于加强高等学校实验室排污管理的通知》[22] 2005年7月 教育部和原国家环保总局 《病原微生物实验室生物安全环境管理办法》[23] 2006年5月 原国家环保总局 《国家危险废物名录》[1] 2008年8月 (2021年更新) 原环境保护部、国家发展和改革委员会和公安部 《实验室生物安全通用要求》[24] 2008年12月 国家质量监督检验检疫总局和国家标准化管理委员会 《关于集中开展教育系统危险化学品安全专项整治的通知》[25] 2016年5月 教育部 《强化危险废物监管和利用处置能力改革实施方案》[26] 2021年5月 国务院办公厅 《关于开展小微企业危险废物收集试点的通知》[27] 2022年2月 生态环境部办公厅 根据国家颁布的政策法规文件,目前有10个省市及地区出台了相关的实验室危险废物管理办法、污染防治技术规范、技术指南等。10个省份的政策都明确了高校及科研机构等产废单位实验室废物的管理,强化了源头管理问题。北京、四川、山东和湖南明确了分类、投放、暂存、收运、贮存、处置利用过程的技术要求,详细的指明处理处置各项要求;浙江、江苏、上海、重庆市渝北区和广东省东莞市指出了责任主体,更加明确责任分工;四川和浙江强调了危险废物的源头控制要求,最大限度的减少了实验室危险废物的产生。全国其他省份应尽快制定出相关文件,加强实验室产废单位的规范化管理。具体内容见表5。

表 5 我国10省市出台的实验室废物政策及内容介绍Table 5. Introduction of laboratory waste policies and contents issued by 9 provinces and cities in China地区 文件名称 北京市 北京市危险废物污染环境防治条例[28] 四川省 四川省实验室危险废物污染防治技术指南 (试行) (川环发〔2017〕73号) [29] 浙江省 关于进一步加强实验室废物处置监管工作的通知[30] 福建省 关于进一步规范学校实验室废弃物处置工作的通知 (闽环保土〔2018〕24号) [31] 山东省 山东省实验室废弃物环境管理暂行办法 (鲁环发〔2009〕5号) 湖南省 关于印发《湖南省实验室危险废物环境管理指南》的通知 (湘环发〔2021〕12号) [32] 江苏省 关于进一步加强实验室危险废物管理工作的通知 (苏环办〔2020〕284号) [33] 关于加强全省高校实验室危险废物收集处置工作的通知 (苏教办科函〔2020〕31号) [34] 上海市 关于进一步加强实验室危险废物管理工作的通知 (沪环土〔2020〕270号) [35] 重庆市渝北区 关于加强实验室危险废物管理的通知 (渝北环发〔2020〕64号) [36] 广东省东莞市 关于加强实验室危险废物环境管理工作的通知[37] 2.2.3 企事业单位管理政策

1) 高校。我国部分高校根据《关于加强高等学校实验室排污管理的通知》[22]要求,制定了有关实验室废物的管理办法、条例等。也有高校将实验室废物的管理列入到《实验室安全管理办法》中进行统一规定。在调查的29个省市区中,39所“985”工程高校中85%以上制定了实验室危险废物相关管理办法,116所“211”工程高校中60%以上制定了实验室危险废物管理办法,其他普通高校制定管理办法的占比较低。

目前高校对实验室危险废物的处理处置并没有明确的统一方法,陈璐等[15]在2017年调研的高校实验室中,只有36%的调研单位对废弃物进行细致分类;有28%的高校建立了分类管控的废弃物仓,对不同种类的废弃物进行全时监控管理;有78%的调研单位在实验室废物后期清运处置中与已有专业资质的第三方机构进行合作。

从全国高校出台的相关实验室危险废物方面的管理办法看出,我国一部分高校对实验室危险废物比较重视。1) 大部分主要的产生源在教学实验、科学研究等环境类、生物类、化工类专业的实验室。2) 一部分学校设有专门负责实验室废物管理的部门,以学校、学院、实验室三级管理体制,学院是实验室危险废物的主管部门,学校是监督、检查的归口部门。3) 一部分学校以“谁购买,谁保管,谁使用,谁负责”的原则进行管理。4) 高校在教学中产生的危险废物处置费用由学校承担,科研产生的危险废物处置费用暂由学校承担,再依据学校成本分担机制的推进,逐步过渡到由科研项目承担;而有的学校则是学院承担一部分,剩下的由学校来承担;有的学校则由课题组全额承担;一些普通高校科研经费少,没有太多经费投入到处置费用中。5) 一部分学校定期对全校危险废物进行回收、转移、处置,在收集时填写好台账信息,并且由有资质的公司进行预约回收、转移、处置。

2) 产业园区。实验室危险废物不仅在高校教学中产生,研究和开发活动中也会产生。实验室危险废物产生量少且产生来源分散,具有小微企业产废的特点,同时,很多小微企业管理政策涉及到实验室危险废物的管理,表6中列举出产业园区中小微企业的实验室危险废物相关政策文件。

表 6 我国小微企业危险废物管理政策Table 6. Hazardous waste management policy of small and micro enterprises in China上海市2019年发布了《上海市产业园区小微企业危险废物集中收集平台管理办法》[38],分别从管理职责、危险废物管理台账、危险废物运输和转移联单制度、危险废物源头管理、信息报送及罚则等方面详细制定了本办法。其中,以下几点突出显示其在责任机制等方面的管理制度:1) 在管理职责中,各部门分别履行各自的责任,要求各区生态环境局监管频次不少于1年10次;2) 主要收集贮存危险废物年产生量小于10 t的小微企业所产生的危险废物和废荧光灯管、废铅蓄电池等社会源危险废物;3) 鼓励产业园区开展收集贮存转运设施的规划与建设;4) 危险废物收集贮存转运设施建立危险废物出入库管理台账。上海市产业园区危险废物收集平台的建立,使小微产废企业的危险废物在产业园区层面得以得到有效收集,使平台将小微企业危险废物纳入合规渠道,避免其向其它渠道流失,在产废企业与处理企业之间构筑了园区的缓冲区间,也使上海市危险废物管理体系更具韧性与弹性[40]。

山东2019年发布了《山东省生态环境厅关于开展危险废物集中收集贮存转运试点的指导意见》[39],仅限收集年产生危险废物50 t以下的企业、实验室危险废物产生单位、机动车维修拆解单位和垃圾分类后产生的家庭源危险废物。江苏宿迁、江西南昌、浙江温州及福建宁德根据当地实际情况管理小微企业危险废物,逐渐完善产业园区危险废物收集平台。

2.3 我国实验室危险废物问题分析

1) 管理政策欠缺。我国没有针对实验室危险废物管理方面的具体政策,只有2个环保总局和教育部下发的通知。未加大对实验室危险废物的监督管理,未确定具体的责任机制,不能按规定将实验室危险废物交由有资质的处置单位定时定点处置。在《医疗废物管理条例》[41]中,仅对医学科研和教学等相关活动中产生感染性废物的管理依据此条例执行。在《实验室生物安全通用要求》[23]中对生物实验室废物处理没有专门的管理要求[14]。高校实验室归口管理职能部门混乱,缺乏有效的监督管理机制[42]。而对于小微企业,存在环保技术人员缺乏等现象,导致产生的实验室危险废物管理意识薄弱,无法达到危险废物规范化管理的相关要求[43]。

2) 收运处置困难。目前高校危险废物种类繁多、分布散且呈周期性产生,即使部分学校制定了相关管理规定,却依然存在收集难、贮存难、运输难、处置难等问题。调研发现,由于处置单位收运不及时,大多数产废单位都面临着较大的危险废物暂存或贮存压力,产废量较小的实验室在收运处置前长期堆存危险废物且不能及时处理,产生了一定的安全及环境风险。而处置单位对于未达到收运量的实验室收取同样的费用,导致一些小微企业面临处置费用高的问题,进而降低了对危险废物处理处置的积极性。实验室危险废物在运输时,必须使用危险品车辆运输,但部分高校位于城区,导致危险品车辆禁区通行难[44]。同时,由于产废单位贮存空间有限,运输单位能力不足,处置单位地域分配不均衡,导致多数产废单位的实验室危险废物积压严重。实验室危险废物在产生到收运处置全流程中,各方面都存在着安全及环境风险。

3) 环保意识不足。我国大部分高校在教学、科学研究过程中,需要大量的化学药品,但大部分化学药品及试剂未得到充分的利用,有的化学药品会长时间放置,不仅会产生安全隐患,而且造成了浪费。高校中实验室的分类收集已经有一定基础,但在一些普通高校,环保意识落后、专业化水平低、实验室设备陈旧落后、教学和科研经费少。这就导致了在处理实验室危险废物时,直接倒入下水道、只做简单处理排放、不分类直接倒入废液桶等一系列管理、监督不到位的问题。产业园区从业人员对危险废物的管理认识匮乏,企业员工在填写危险废物进出库记录中,存在危险废物类别出入库数量不一致、个别类别无入库却有出库现象[40]。

3. 建议

1) 明确实验室危险废物责任主体、形成管理机制及指南。实验室危险废物规范管理的机构占比较低,各行业主管部门 (教育、科技、卫健、市场监管等) 应协同生态环境部,指导各自负责的单位 (中小学及高等院校、科研院所、医疗机构、企业) 开展实验室危险废物管理工作,包括制度制定、人员培训等,形成生态环境部门和行业主管部门分工协作、齐抓共管的工作格局。各高校、科研机构或其他产业园区可以在申请项目时,将处理实验室危险废物的经费纳入到预算中,适时制定对收集处理不及时的机构实施相应的处罚。“无废城市”试点期间将高校及科研机构实验室废物等社会源废物处理纳入建设指标中,应加快管理机制研究,推进“无废城市”建设。

2) 建立高校定时定点回收处理、小微企业豁免相结合的收集体系。高校建立贮存设施,将单位内部实验室危险废物应分类收集,将不含危险物质或可自行无害化处理的实验室废物按照一般固体废物处置,切实做到源头减量。按规定分类后,分别放入不同容器中,由有资质的公司进行定时定点收集运输,并鼓励试剂生产厂家执行生产者责任延伸制,主动与产废单位建立沟通渠道,回收废旧试剂和空瓶。产废单位开展区域实验室危险废物收集试点,建立集中贮存设施,鼓励积极探索预处理方案,将实验室危险废物作破碎、压块、沥干、同质废液混合等处理,进一步做到实验室危险废物减容,降低贮存压力和处置单位的处理压力。产业园区小微企业,如每月实验室危险废物产生量少于100 kg的机构,或产生低风险类实验室危险废物的,如废弃药品、油漆、含汞灯管、铅蓄电池等,可以探索实行特定环节豁免管理机制。

3) 加强高校实验室危险废物管理能力建设。产废单位专人负责实验室药品及试剂的使用,以及危险废物的产生、分类、投放、暂存、收运、贮存、利用处置等环节的监管,并建立专业管理团队,明确组织构架,保证实验室危险废物各个环节都有相应的责任人。高校或其他机构在上课或实验操作前,指导教师或专业人员应向学生或实验人员介绍实验室内仪器及药品的使用,加强学生及实验人员对危险废物的分类和处理的培训,增强主管教师和学生的实验室危险废物环境管理意识。学校可以将实验室危险废物管理纳入学生和科研助理的实验室准入考核内容,教师在评定职称时将实验室安全纳入到评定范围内。

-

点击查看大图

点击查看大图

计量

- 文章访问数: 1988

- HTML全文浏览数: 1170

- PDF下载数: 1063

- 施引文献: 0

DownLoad:

DownLoad: