铁粉还原-Fenton氧化处理络合铜废水的研究

Study on treatment of wastewater containing complex copper by iron powder assisted Fenton

-

摘要: 采用铁粉还原-Fenton氧化工艺处理含络合铜工业废水,研究了联合工艺对络合铜的破络效果,重点考察了常温下H2O2投加量、初始pH值、反应时间、Cu(Ⅱ)初始浓度以及铁粉粒径等因素对该工艺处理效果的影响,同时探讨了相关机理。结果表明:在初始Cu(Ⅱ)浓度为50 mg/L,初始pH=3的体系中,加入过量铁粉,H2O2投加量控制在H2O2∶COD=1.5∶1(质量比),反应30 min后在pH=9的条件下沉淀,废水的COD 去除率为86.5%,Cu(Ⅱ)去除率为99.9%,处理水达到《电镀污染物排放标准》(GB21900-2008)要求。研究还表明:铁粉粒径对处理效率的影响较小,采用工业级铁粉即可达到理想效果。Abstract: Iron powder reduction assisted Fenton oxidization technic was used to treat industrial wastewater containing complex copper. The breaking complexing effect of complex copper in this combined process was investigated, the influence of H2O2 dosage,initial pH,reaction time,initial Cu(Ⅱ) concentration of wastewater, different diameter of iron powder on copper removal efficiency at normal temperatures were discussed, and the possible mechanism was also involved. The result showed that under the 50 mg/L Cu(Ⅱ) concentration when the conditions were controlled as follow: initial pH=3, iron powder was overused, H2O2 dosage was at H2O2∶COD=1.5∶1(mass ratio), reaction time was 30 minutes ,and precipitation pH=9, COD and copper removal rates were 86.5% and 99.9%,respectively, which could meet the new discharge standard of GB21900-2800. And further studies showed that the iron sizes had little effect on treatment efficiency, so using the industrial iron powder could have a good performance.

-

Key words:

- complex copper /

- ethylenediamine tetraacetic acid /

- Fenton oxidization

-

铬是一种易致癌、致突变和高毒性的环境污染物[1],环境中铬含量主要来自于电镀、冶金和制革行业等工业活动废水的排放[2]。铬主要为Cr(Ⅲ)和Cr(Ⅵ),Cr(Ⅲ)可以通过简单加碱沉淀的方法予以去除。相较而言,Cr(Ⅵ)毒性是Cr(Ⅲ)的100倍,且高迁移性使得Cr(Ⅵ)更容易在生物体和人体中积累,对生态环境及人体健康造成了严重的威胁[3-4]。当前含铬废水的处理方法主要有离子交换法[5]、膜分离法[6]和化学还原法[7]等,然而大量实践表明,这些处理方法仍然存在处理费用高和较严重的二次污染问题。目前,高毒性的Cr(Ⅵ)向低毒性的Cr(Ⅲ)转化的高效还原方法,由于降低了其对环境的危害,已成为是含铬废水处理的研究热点之一。高级还原技术(ARPs)是在高级氧化技术(AOPs)基础上发展起来的,区别在于前者可产生还原性自由基,包括水合电子(

e−aq )、原生态氢(H · )和二氧化碳阴离子自由基(CO⋅−2 )等。近年来,对于CO⋅−2 的研究屡有报道[8-9],CO⋅−2 被证实是一种强还原性自由基,氧化还原电位为−1.9 V[10],目前有研究[11-12]表明,CO⋅−2 可以与Hg(Ⅱ)、取代苯化合物[13]、四氯化碳[10]、Cr(Ⅵ)[14]等反应,且均具有较好的还原去除效果。有研究[13]表明,CO⋅−2 产生的主要方法为向AOPs体系中加入甲酸或者甲酸盐,使含有SO⋅−4 、HO · 的氧化性体系转化为还原性体系(如式(1)和式(2)所示),进而对高氧化态的污染物表现出明显的去除效果。JIANG等[15]向过碳酸钠/Fe(Ⅱ)和过氧化钙/Fe(Ⅱ)类芬顿体系中加入HCOOH之后,可以明显降解四氯化碳。REN等[14]在Cr(Ⅵ)、Na2S2O8和HCOO−初始浓度分别为50、30和30 mmol·L−1,反应温度为70 ℃条件下,热活化Na2S2O8/HCOO−体系,反应240 min之后,Cr(Ⅵ)去除率可以达到99%。HO⋅+HCOOH⟶CO⋅−2+H++H2O (1) SO⋅−4+HCOOH→CO⋅−2+2H++SO2−4 (2) 本研究采用紫外(UV)活化过硫酸盐(PS)/甲酸(FA)体系还原高浓度Cr(Ⅵ),利用UV、UV/PS和UV/PS/FA体系对Cr(Ⅵ)还原效果的对比,结合电子自旋共振(ESR)对体系中产生的主要自由基进行了检测分析,研究了UV/PS/FA体系的活化机制及其对Cr(Ⅵ)的还原机制,并考察体系主要反应条件以及复杂水体环境中天然有机物(NOM)、无机阴离子对体系还原Cr(Ⅵ)的影响,以期为高浓度Cr(Ⅵ)还原提供新型高效的、实用性较强的均相光催化处理方法。

1. 材料与方法

1.1 试剂与仪器

丙酮(C3H6O)、硝酸钠(NaNO3)、氯化钠(NaCl)、碳酸氢钠(NaHCO3)、硫酸(H2SO4)、磷酸(H3PO4)、氢氧化钠(NaOH)、甲酸(HCOOH)、二苯碳酰二肼(C13H14N4O)、过硫酸钠(Na2S2O8)均为分析纯;重铬酸钾(K2Cr2O7)为优级纯;腐植酸(黄腐酸FA≥90%)。

紫外分光光度计(TU-1901,北京普析通用仪器有限责任公司)、光催化反应仪(PL-02,北京普林塞斯科技有限公司)、pH计(PHS-3C,上海天达仪器有限公司)、ESR检测仪(A300,布鲁克)。

1.2 实验与分析方法

用重铬酸钾和去离子水配置模拟不同浓度的Cr(Ⅵ)废水。采用石英玻璃圆底试管作为反应瓶(V=50 mL),先将一定浓度的PS、FA和模拟废水取至反应瓶混合均匀,置于光催化反应仪里,开启磁力搅拌(400 r·min−1)和紫外光源(P=500 W)进行反应(预开启紫外灯管30 min保证光强稳定),按照既定时间取样分析,每组实验另外设置2个平行实验组。

Cr(Ⅵ)含量采用二苯碳酰二肼分光光度法(GB 7467-1987)测定;采用ESR进行检测分析主要自由基种类,ESR检测条件:中心磁场为350.00 mT;扫描宽度为15.00 mT;扫描时间为30.00 s;微波功率为3.99 mW;调制幅度为0.10 mT;转化时间为40.00 s。

2. 结果与讨论

2.1 UV活化PS耦合FA体系降解Cr(Ⅵ)对比及还原机制分析

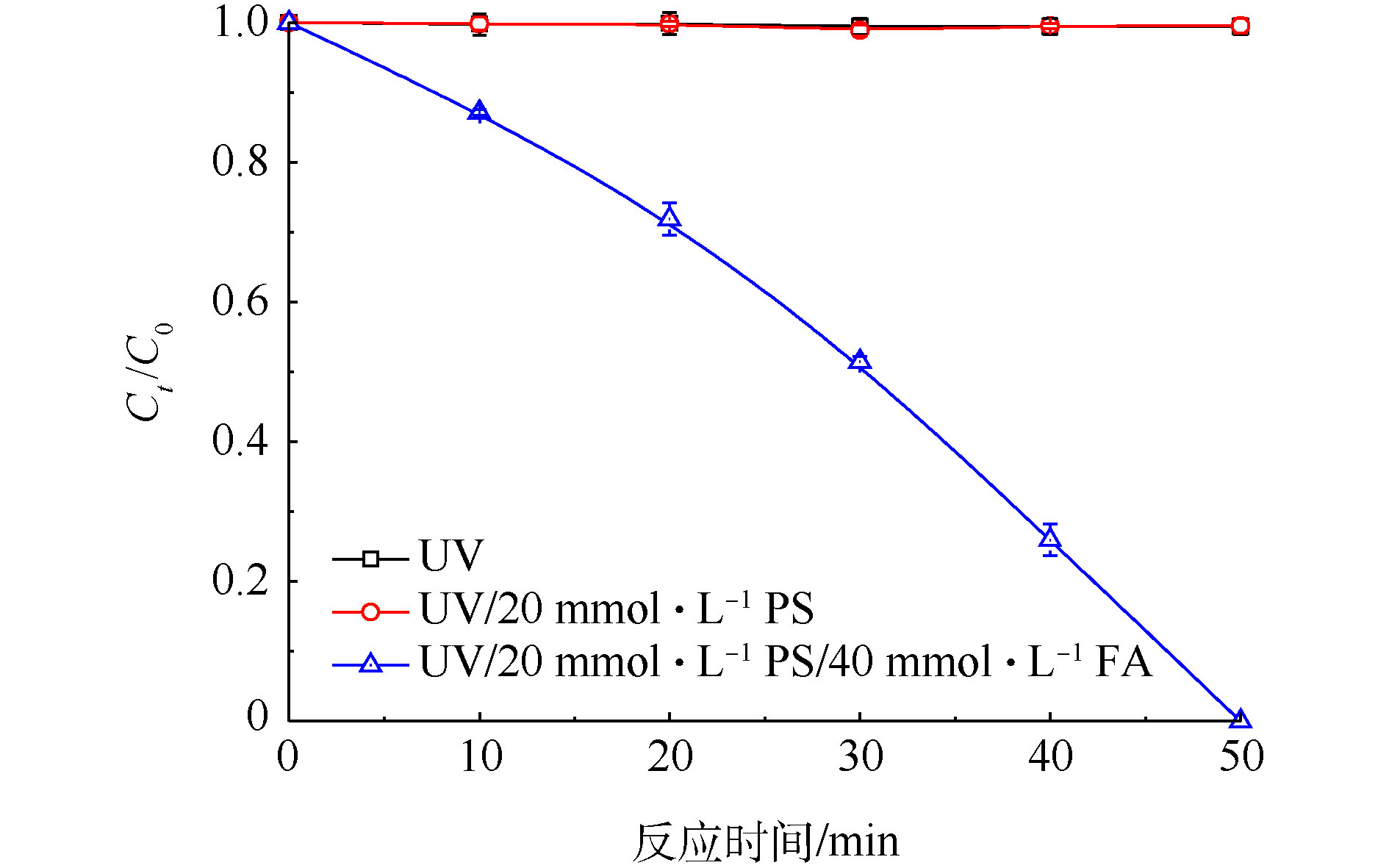

在Cr(Ⅵ)初始浓度为200 mg·L−1条件下,分别对比了单独UV、UV/PS和UV/PS/FA体系对Cr(Ⅵ)的还原效率,实验结果如图1所示。由图1可知,当PS和FA分别为20 mmol·L−1和40 mmol·L−1,初始pH为2.4(未调节),单独UV和UV/PS体系在50 min内对Cr(Ⅵ)没有还原去除效果;当向UV/PS体系中加入FA之后,在50 min内Cr(Ⅵ)的去除率高达100%。由此可见,UV/PS/FA体系对高浓度Cr(Ⅵ)具有很好的去除效果。

有研究表明,水分子在真空紫外(VUV,λ=185 nm)照射的条件下能够产生具有还原性的原生态氢(H · )和水合电子(

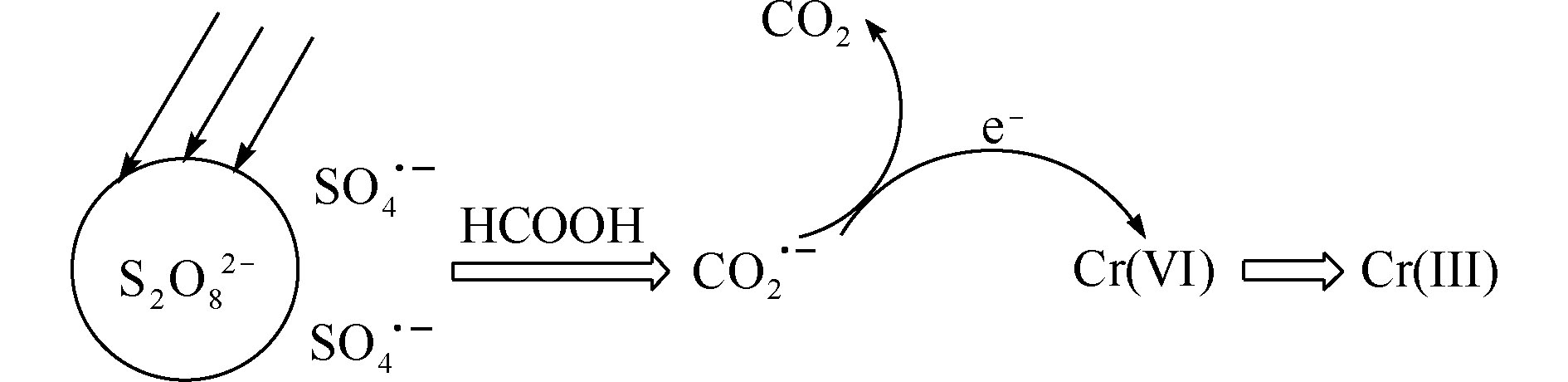

e−aq )[16-19],见式(3)~式(5)。为避免H · 和e−aq 对本体系带来的干扰,实验所用紫外光波长范围为200~350 nm,故单独UV对Cr(Ⅵ)不存在还原效果。UV活化PS过程中会产生SO⋅−4 和HO · ,加入FA之后,Cr(Ⅵ)去除效果明显增强,这是由于FA可以与SO⋅−4 反应产生CO⋅−2 ,通过CO⋅−2 与Cr(Ⅵ)的相互作用,进而高效还原Cr(Ⅵ)为Cr(Ⅲ)。H2O+hv185nm⟶e−aq+H++HO⋅ (3) H2O+hv185mm⟶H⋅+HO⋅ (4) H⋅+H2O⟶H3O++e−aq,k=3.6×108L⋅(mol⋅s)−1 (5) 2.2 反应自由基的ESR表征

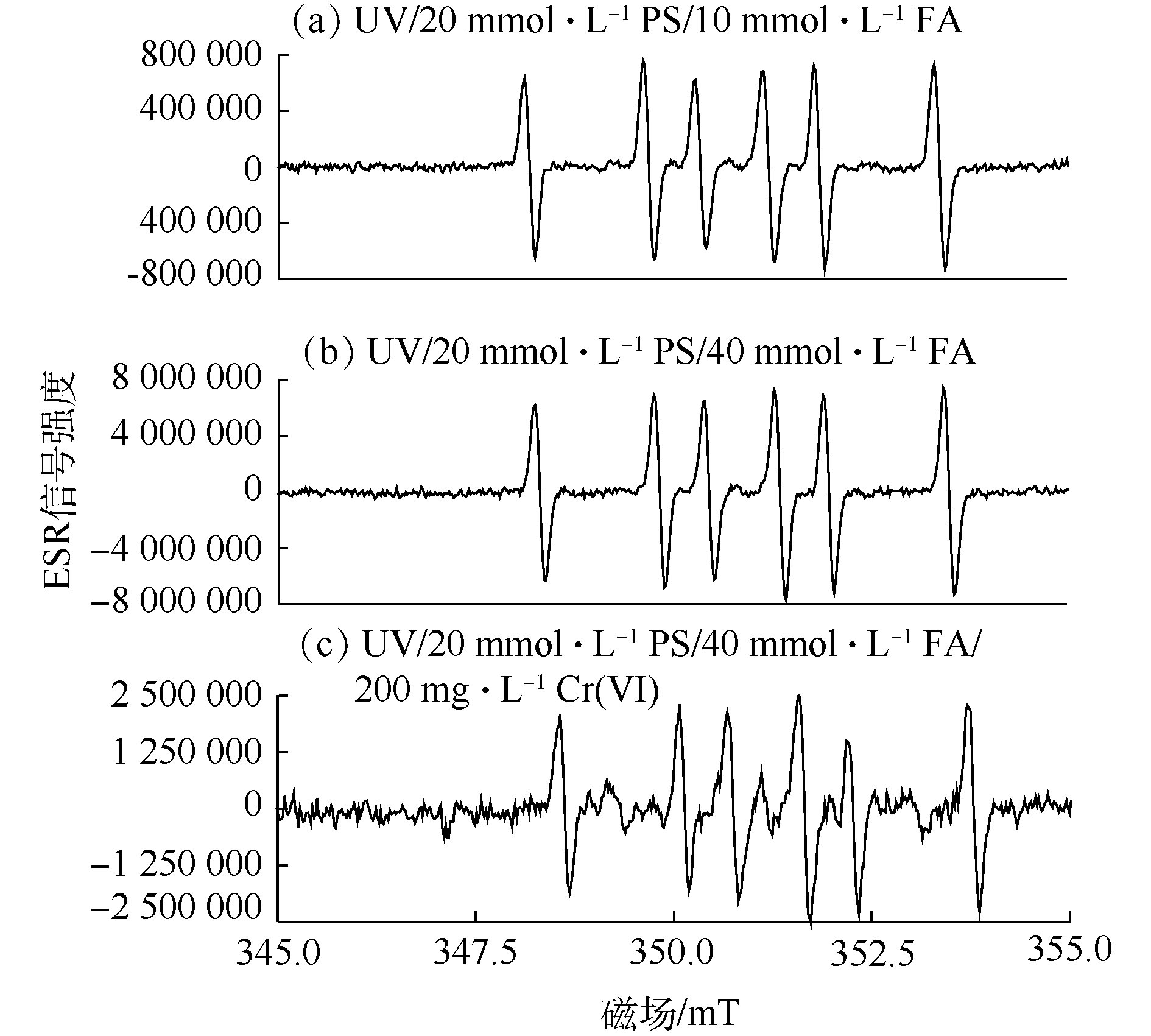

为了进一步探明UV/PS/FA的活化机制及对Cr(Ⅵ)的还原机理,以DMPO为自由基捕获剂,采用ESR对体系中的自由基进行了检测分析。在PS浓度为20 mmol·L−1条件下,通过改变FA和Cr(Ⅵ)的浓度,以UV照射15 min所捕获的自由基信号峰强度为依据,考察了自由基信号强度与FA浓度、Cr(Ⅵ)浓度之间的变化关系,结果如图2所示。由ESR表征结果可知,图2(a)~图2(c)均出现了明显且强度相同的DMPO-

CO⋅−2 加合物信号峰,与LIU等[20]和VILLAMENA等[21]报道的DMPO-CO⋅−2 加合物峰值相一致,从而证实了UV/PS/FA体系确实可以产生CO⋅−2 。通过比较图2(a)和图2(b)可知,在没有Cr(Ⅵ)干扰的条件下,FA浓度由10 mmol·L−1上升至40 mmol·L−1时,UV/PS/FA体系中出现的DMPO-CO⋅−2 加合物信号峰强度得到明显提高,这表明升高FA浓度可以提高CO⋅−2 产率,证明FA直接参与了CO⋅−2 的生成反应。由图2(b)和图2(c)可以看出,UV/PS/FA体系中有Cr(Ⅵ)存在时,DMPO-CO⋅−2 加合物信号峰强度明显减弱,这说明体系中产生的CO⋅−2 可以与Cr(Ⅵ)发生反应,并将Cr(Ⅵ)还原去除,初步推断反应机理如图3所示。2.3 单因素影响实验

2.3.1 PS浓度对Cr(Ⅵ)还原效果的影响

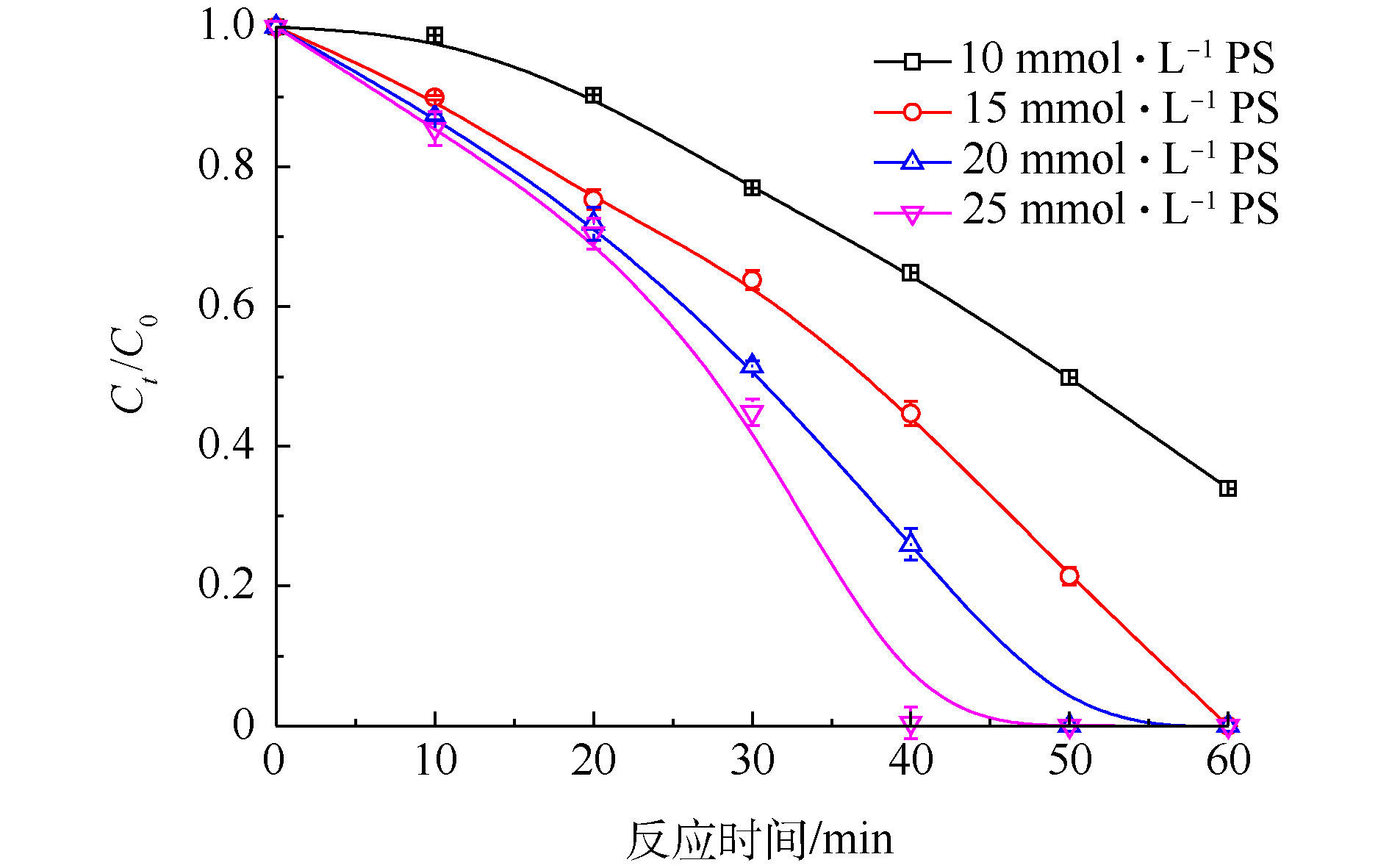

当初始Cr(Ⅵ)浓度为200 mg·L−1,FA浓度为40 mmol·L−1,PS浓度为10~25 mmol·L−1时,反应在60 min内,Cr(Ⅵ)去除率的变化情况如图4所示。从图4可以看出,当PS浓度为10 mmol·L−1时,在40 min内Cr(Ⅵ)去除率仅为35.2%;当PS增加为25 mmol·L−1时,Cr(Ⅵ)去除率提高至100%,PS对Cr(Ⅵ)的还原具有明显的促进效果。导致上述结果的主要原因是:随着PS浓度的增加,体系可以产生更多的

SO⋅−4 [22],而随着SO⋅−4 的增加,提高了FA的利用率,加快了体系产生CO⋅−2 的速率,进而增强了Cr(Ⅵ)还原的效率。2.3.2 初始pH的影响

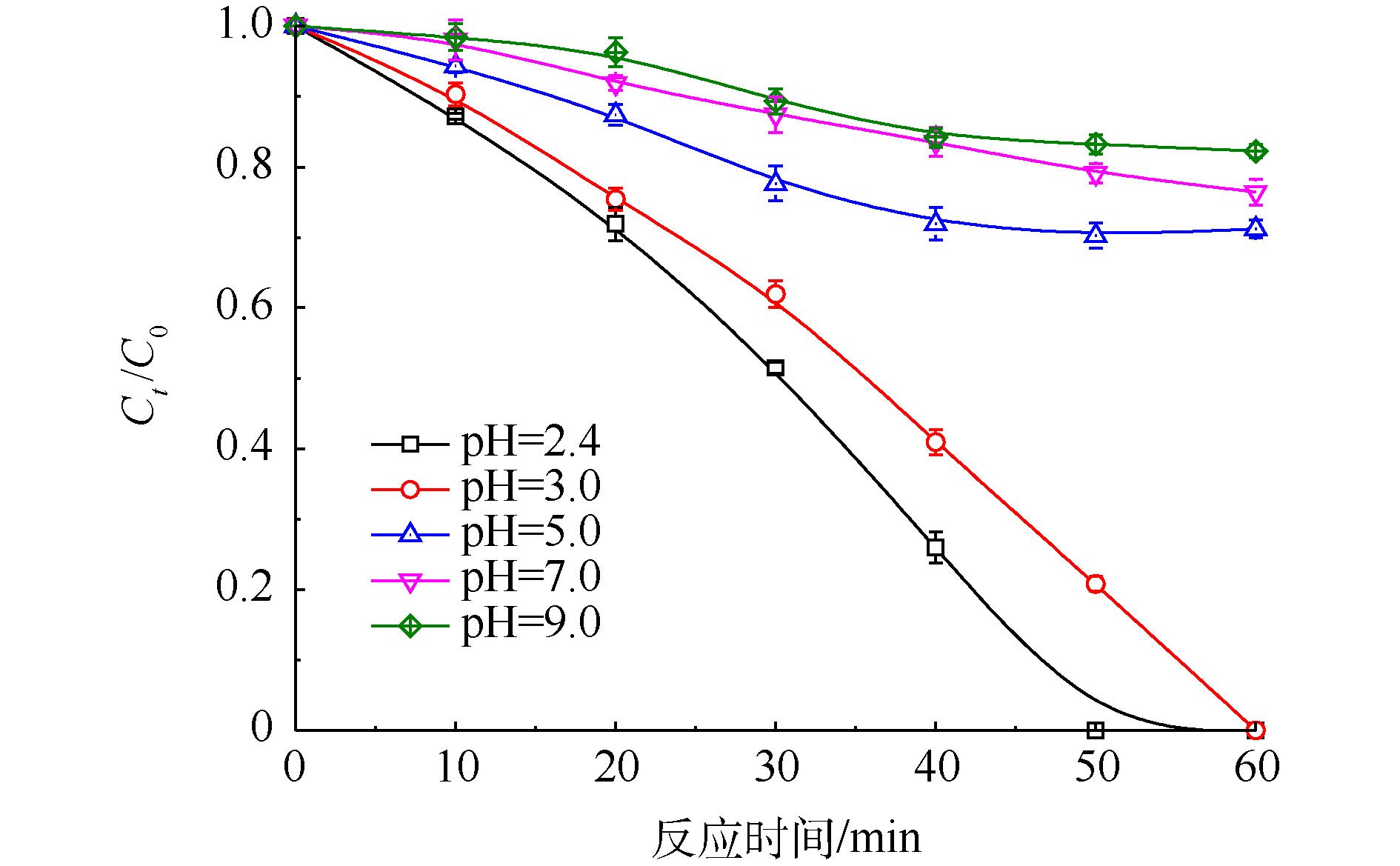

初始Cr(Ⅵ)浓度为200 mg·L−1、PS浓度为20 mmol·L−1、FA浓度为40 mmol·L−1时,考察在60 min内,随着初始pH改变,Cr(Ⅵ)去除率的变化趋势,实验结果见图5。反应前后体系pH存在微弱改变,由图5可知,随着pH由2.4升高到9.0时,Cr(Ⅵ)还原效率呈现明显的下降趋势。当pH=2.4时,在50 min内Cr(Ⅵ)可以完全被去除;当pH=9.0时,Cr(Ⅵ)在50 min内的去除率仅为16.8%。这说明UV/PS/FA在酸性条件下具有较好的还原效果,而在中性尤其是碱性条件下,还原性能会受到明显抑制。这是因为FA的pKa=3.75,改变体系pH会影响FA在溶液中的存在形态,即分子态(HCOOH)或离子态(HCOO−),两者与

SO⋅−4 的反应速率常数存在差异性,FA分子态更容易与SO⋅−4 反应产生CO⋅−2 [20],因此,随着pH的升高,Cr(Ⅵ)还原效率逐渐降低。2.3.3 无机离子的影响

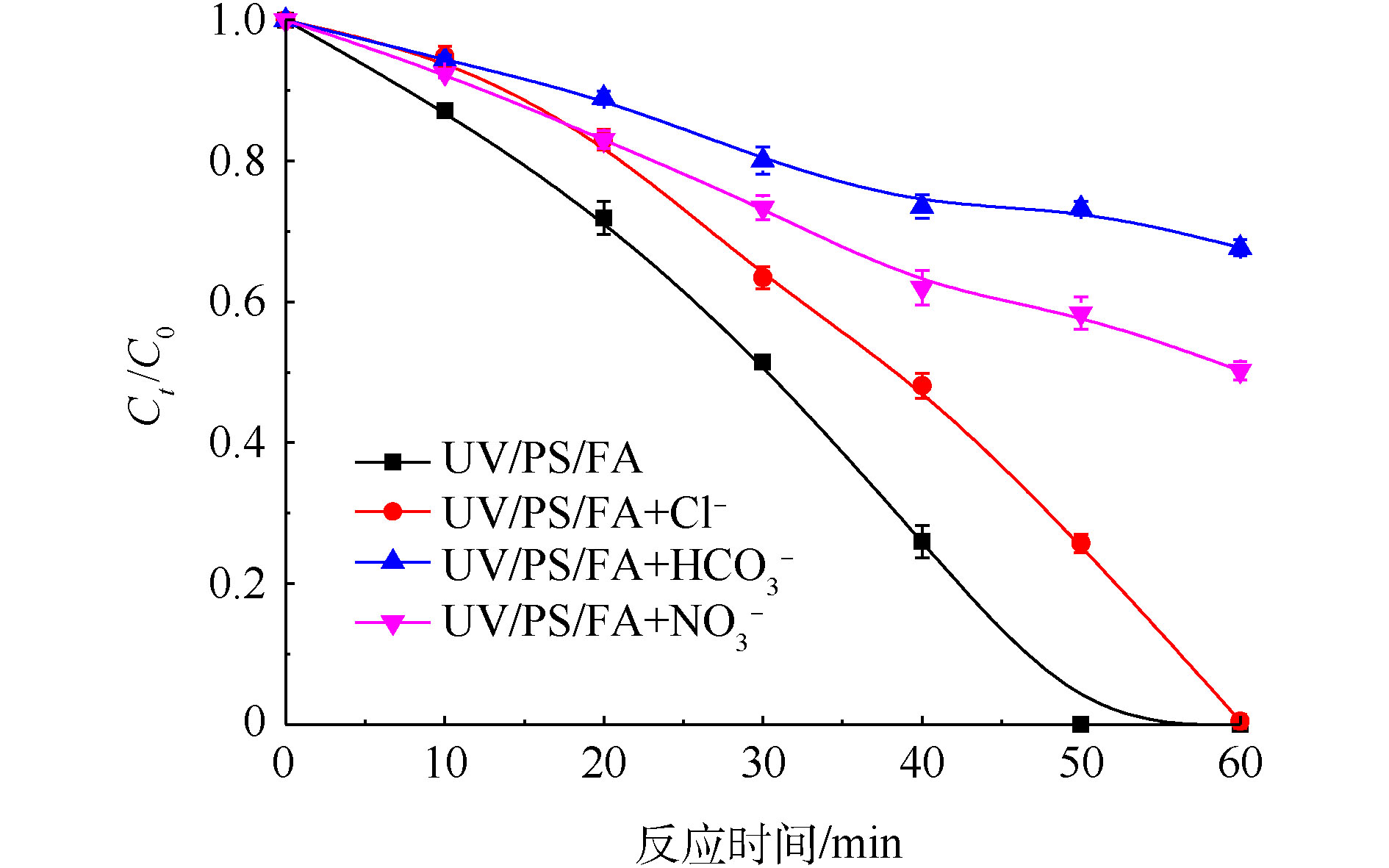

图6为初始Cr(Ⅵ)浓度为200 mg·L−1、PS浓度为20 mmol·L−1、FA浓度为40 mmol·L−1,水中常见阴离子Cl−、

HCO−3 和NO−3 对UV/PS/FA体系降解Cr(Ⅵ)的影响,每种离子浓度均为100 mmol·L−1。由图6可知,Cl−、HCO−3 和NO−3 3种离子均会抑制Cr(Ⅵ)的还原去除,在相同浓度条件下,其抑制程度强弱的顺序为HCO−3 >NO−3 >Cl−。当Cl−浓度为100 mmol·L−1时,50 min内Cr(Ⅵ)的去除率由100%降低为74.3%,这表明高浓度的Cl−对Cr(Ⅵ)降解存在严重的抑制效果。其主要原因是:Cl−可以与SO−4 反应生成低活性的氯自由基(Cl · )和超氯自由基(Cl⋅−2 ),从而减少了体系SO−4 的量[23],见式(6)和式(7);同时,生成的Cl⋅−2 会进一步与HCOOH发生反应[24],故Cl−抑制了体系中CO⋅−2 的产生,从而进一步抑制了Cr(Ⅵ)的降解。XU等[25]在四氯化碳降解研究中也发现,低浓度Cl−存在微弱抑制效果,高浓度Cl−的抑制效果更加明显。当

NO−3 投加量是100 mmol·L−1时,50 min内Cr(Ⅵ)去除率降低为41.6%。推断原因是:溶液中NO−3 的增加会消耗体系中氧化性自由基SO⋅−4 [26](式(8)),虽然反应产物为硝酸根自由基(NO⋅3 ),可以替代SO4·−与HCOOH反应产生主要还原性自由CO⋅−2 [27](式(9)),但增加的反应步骤,大大降低了整体的反应速率,因此,NO−3 对Cr(Ⅵ)还原亦表现出抑制作用。当体系中

HCO−3 浓度为100 mmol·L−1时,对体系还原Cr(Ⅵ)的抑制效果最为明显,50 min去除率降低至26.7%。这是由于当溶液中加入HCO−3 ,会使溶液pH升高,由2.3.2节可知,提高pH不利于Cr(Ⅵ)降解。此外,随着HCO−3 浓度的增加,其会与体系产生的SO⋅−4 发生反应并产生具有氧化性的碳酸根自由基(CO⋅−3 )(见式(10)),从而降低SO⋅−4 与FA反应产生CO⋅−2 的概率[28],且过量的HCO−3 还可能与CO⋅−2 相互反应产生CO⋅−3 [29](见式(11)),故高浓度HCO−3 也会抑制Cr(Ⅵ)的还原。SO⋅−4+Cl−⟶SO2−4+Cl⋅ (6) Cl−+Cl⋅⟶Cl⋅−2 (7) NO−3+SO⋅−4⟶SO2−4+NO⋅−3 (8) HCOOH+NO⋅3⟶NO−3+CO⋅−2+2H+ (9) SO⋅−4+HCO−3⟶CO⋅−3+SO2−4+H+ (10) HCO−3+CO⋅−2⟶HCO−2+CO⋅−3 (11) 2.3.4 天然有机物(NOM)的影响

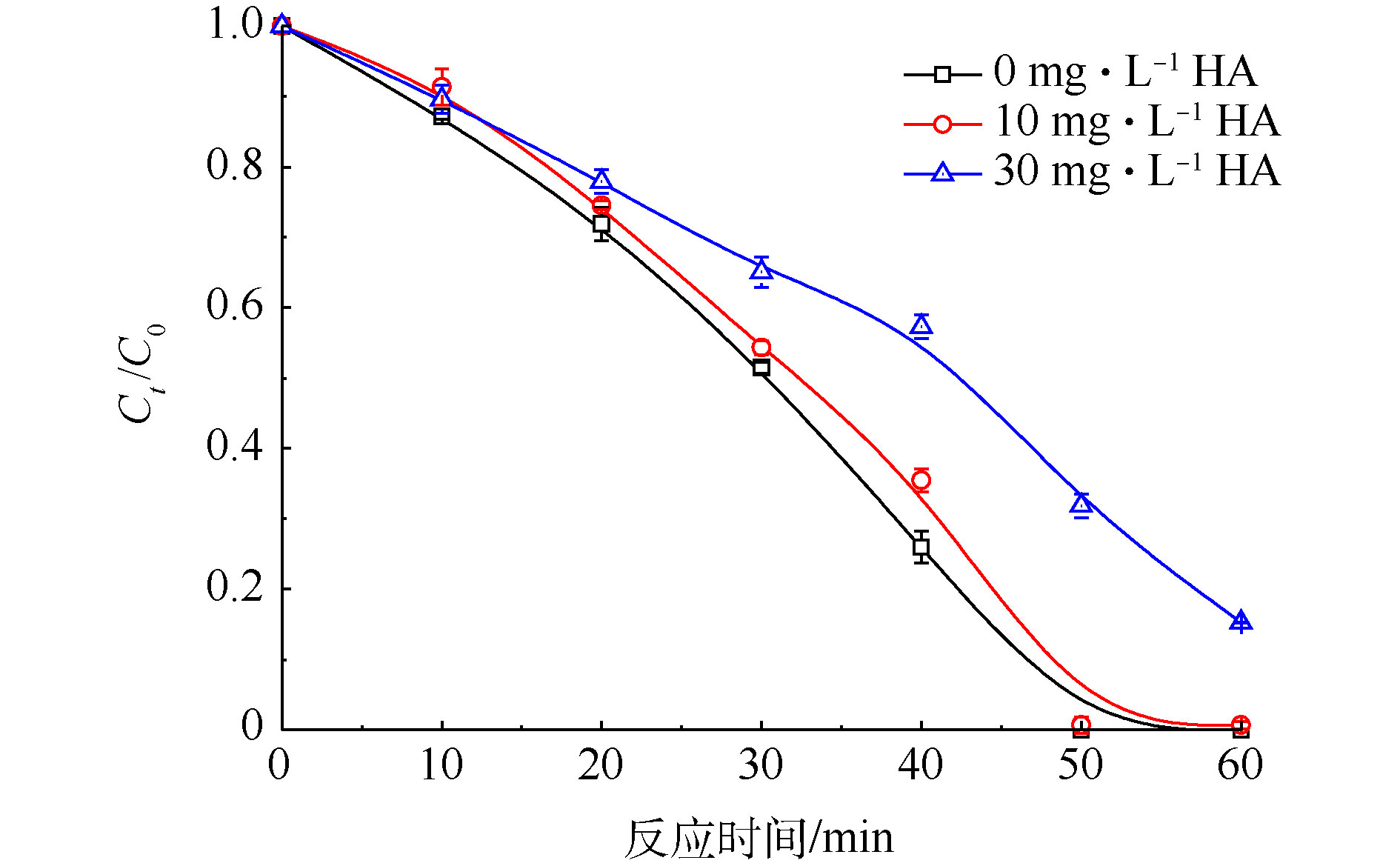

腐殖酸(HA)是天然水体中的主要有机物[30]。实验中以HA模拟自然水体中的有机物,当Cr(Ⅵ)初始浓度为200 mg·L−1、PS浓度为20 mmol·L−1、FA浓度为40 mmol·L−1时,考察不同浓度HA对Cr(Ⅵ)降解效果的影响,实验结果见图7。由图7可知,当HA浓度为0 mg·L−1时,50 min内Cr(Ⅵ)的去除率为100%;当HA浓度提高到30 mg·L−1时,Cr(Ⅵ)的去除率降低为68.1%。因此,HA会抑制Cr(Ⅵ)的还原。这可能是由于HA是一种天然有机物,会与强氧化性的自由基反应得到矿化[31],故HA的加入会减少

SO⋅−4 的量,从而抑制CO⋅−2 的产生,最终降低了Cr(Ⅵ)还原去除速率。2.3.5 Cr(Ⅵ)初始浓度的影响及动力学拟合

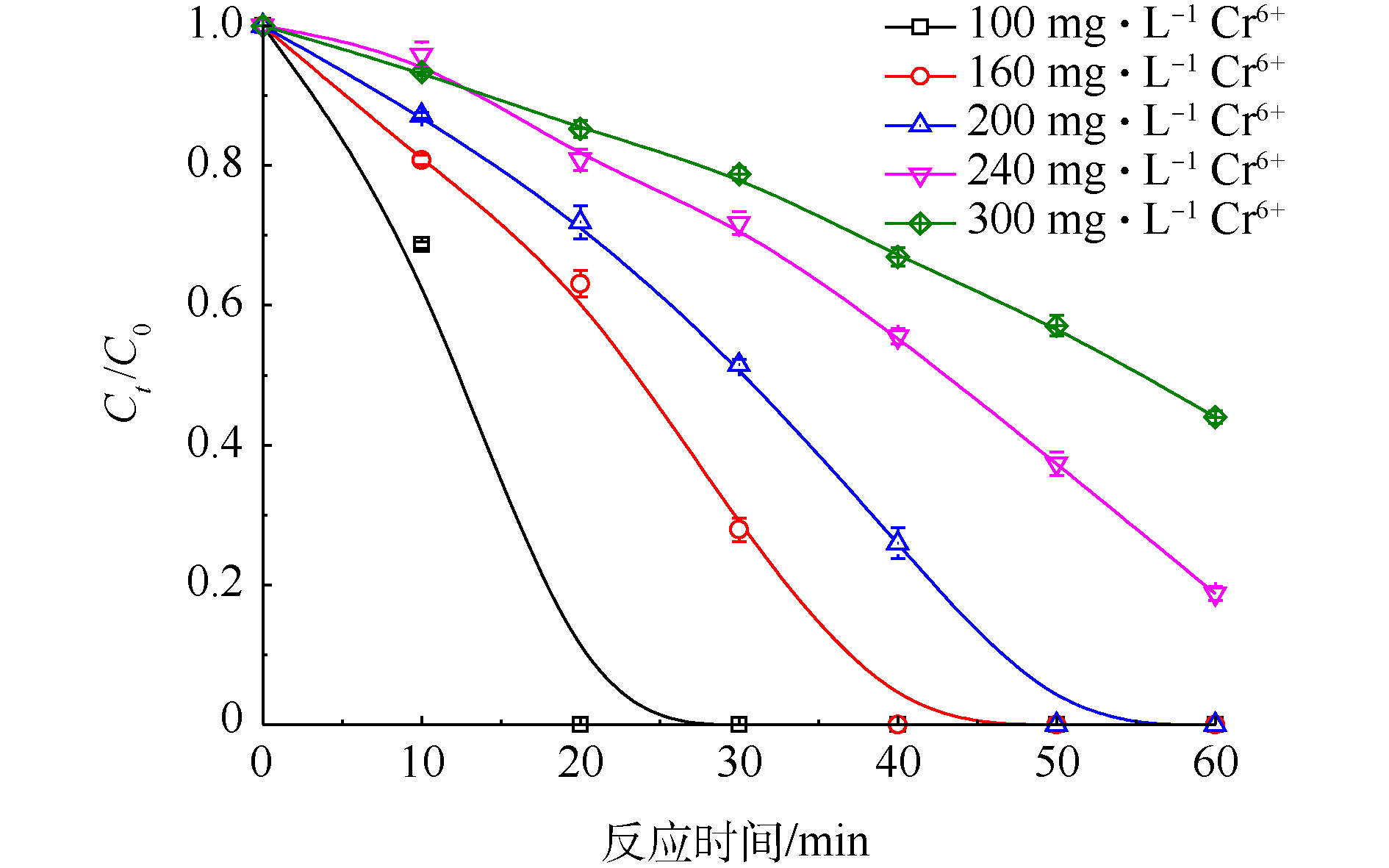

当PS浓度为20 mmol·L−1、FA浓度为40 mmol·L−1时,改变Cr(Ⅵ)初始浓度,考察Cr(Ⅵ)初始浓度对Cr(Ⅵ)去除的影响,实验结果见图8。由图8可知,Cr(Ⅵ)去除率随着Cr(Ⅵ)初始浓度的增加而降低,但UV/PS/FA体系对不同浓度的Cr(Ⅵ)都有很好的去除效果。当Cr(Ⅵ)初始浓度为100 mg·L−1时,20 min内Cr(Ⅵ)去除率就可以到达100%,将Cr(Ⅵ)完全去除,当Cr(Ⅵ)初始浓度提高为300 mg·L−1时,在60 min内的去除率仅为56%。这是因为当PS和FA浓度一定时,单位时间内产生的

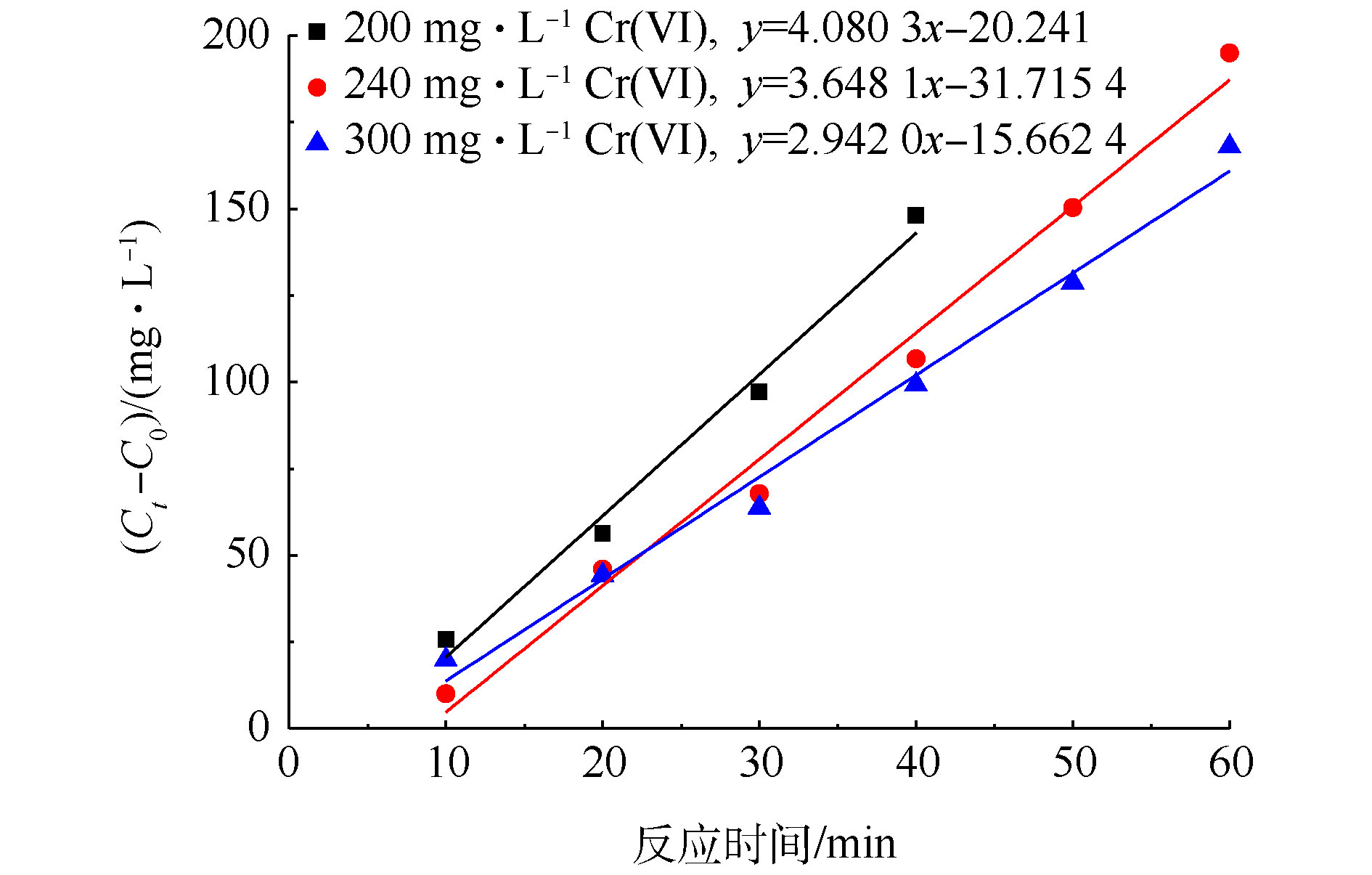

SO⋅−4 和CO⋅−2 的量基本维持不变,CO⋅−2 还原Cr(Ⅵ)的能力也是一定的,随着Cr(Ⅵ)浓度的增加,被还原Cr(Ⅵ)的量与起始Cr(Ⅵ)的量的比值下降,表观去除率变小。当初始Cr(Ⅵ)浓度为200、240和300 mg·L−1时,在一定的反应时间内,对Cr(Ⅵ)的还原过程进行反应动力学拟合,拟合结果如图9所示。由图9可知,dC与dt有很好的线性关系,这说明UV/PS/FA降解Cr(Ⅵ)的反应符合零级反应动力学。通过拟合得到Cr(Ⅵ)不同初始浓度下还原速率常数(见表1)。由表1可知,当Cr(Ⅵ)初始浓度为200 mg·L−1、PS浓度为20 mmol·L−1、FA浓度为40 mmol·L−1时,Cr(Ⅵ)还原反应速率常数为78.467 μmol·(L·min)−1。WANG等[32]发现Fe(III)浓度为179.1 μmol·L−1,pH为1.0时,均相光催化还原Cr(Ⅵ)也遵循零级动力学反应方程式,且反应动力学常数仅为0.934 μmol·(L·min)−1,相对而言,UV/PS/FA体系对Cr(Ⅵ)具有更加高效的还原效率。

表 1 不同初始浓度下Cr (VI) 的还原反应速率常数Table 1. Zero-order rate constant of Cr (VI) reduction with different initial concentrationsCr(VI)初始浓度/(mg·L−1) k/(μmol·(L·min)−1) R2 200 78.467 0.981 240 70.156 0.986 300 56.577 0.985 3. 结论

1)采用UV/PS/FA体系,实现了对高浓度Cr(Ⅵ)的还原处理。当Cr(Ⅵ)初始浓度为200 mg·L−1、PS浓度为20 mmol·L−1、FA浓度为40 mmol·L−1时,在反应50 min后Cr(Ⅵ)基本完全被还原去除。对反应过程中的活性自由基采用ESR技术进行表征,证实了

CO⋅−2 的存在。2)UV/PS/FA体系在酸性条件下具有较强的还原能力,随着体系pH的升高还原作用呈现明显下降趋势。随着体系中PS浓度的升高,Cr(Ⅵ)去除率逐渐提高。水溶液中存在的HA、Cl−、

HCO−3 和NO−3 都会在不同程度对Cr(Ⅵ)的还原产生抑制作用。3)对不同初始浓度下Cr(Ⅵ)降解过程进行动力学分析推导,可知其符合零级反应动力学,且初始Cr(Ⅵ)浓度为200、240和300 mg·L−1时对应的反应速率常数分为78.467、70.156和56.577 μmol·(L·min)−1。本研究为Cr(Ⅵ)废水的处理提供了高效的还原方法。

-

点击查看大图

点击查看大图

计量

- 文章访问数: 2034

- HTML全文浏览数: 987

- PDF下载数: 919

- 施引文献: 0

下载:

下载: