-

1 材料与方法

-

1.1 实验材料

材料:聚丙烯腈(PAN,MW150 000 g·mo

l-1 ,湖北楚盛威化工有限公司);聚砜(PSF,E6010,德国BASF);间苯二胺(MPD,分析纯,天津市光复精细化工研究所);哌嗪(PIP,分析纯,上海晶纯生化科技股份有限公司);均苯三甲酰氯(TMC,98%,上海阿拉丁生化科技股份有限公司);正己烷(HEX,分析纯,广东光华科技股份有限公司);GO纳米片,由石墨粉(光谱纯,上海科丰实业有限公司)自制而成;牛血清白蛋白(BSA)、海藻酸钠(SA)、腐殖酸(HA)均为分析纯,Sigma-Aldrich;N,N-二甲基甲酰胺(DMF)、N-甲基吡咯烷酮(NMP)、无水乙醇、三乙胺(TEA)、氯化钠、氢氧化钠、无水氯化锂、碳酸氢钠均为分析纯,天津市科密欧化学试剂有限公司。 -

1.2 复合膜的制备方法

-

1.2.1 聚丙烯腈基膜的制备

通过相转化法制备聚丙烯腈基膜。将PAN或PSF、无水氯化锂、无水乙醇、DMF或NMP按一定比例混合,在60 ℃条件下充分搅拌12 h得到铸膜液,将搅拌好的铸膜液于60 ℃静置脱泡6 h;将脱泡后的铸膜液在玻璃板上刮制成一定厚度的溶液膜,立即浸入50 ℃加有5%DMF的凝胶浴中,待相分离基本完成并成膜后,用去离子水反复冲洗以去除残留的有机物,在去离子水中保存至少24 h后,45 ℃下,将完全相分离的膜浸泡在1.5 mol·

L-1 氢氧化钠溶液中羧化1.5 h,用去离子水不断冲洗羧化后的膜至洗出液pH达中性即可。 -

1.2.2 复合正渗透膜的制备

在室温下,配制一定浓度的MPD或PIP水溶液(调节pH为9),将一定量的TMC溶解于正己烷配制成有机溶剂。将聚丙烯腈基膜晾干后浸没在MPD水溶液中一定时间,取出待膜完全干燥后装入自制的膜池中,倒入TMC有机溶液使其完全覆盖膜表面反应一定时间,然后经过热处理即可得到复合正渗透膜,从膜池上拆卸下来保存在去离子水中备用。

-

1.2.3 氧化石墨烯改性复合正渗透膜的制备

在制备复合正渗透膜(同1.2.2节)的基础上,向MPD水溶液中加入0.075%的GO纳米片,超声处理至少3 h使其均匀溶解从而配制成GO/MPD共混水溶液,完成氧化石墨烯与水相单体的物理共混改性,然后通过界面聚合法完成GO改性复合正渗透膜的制备。

-

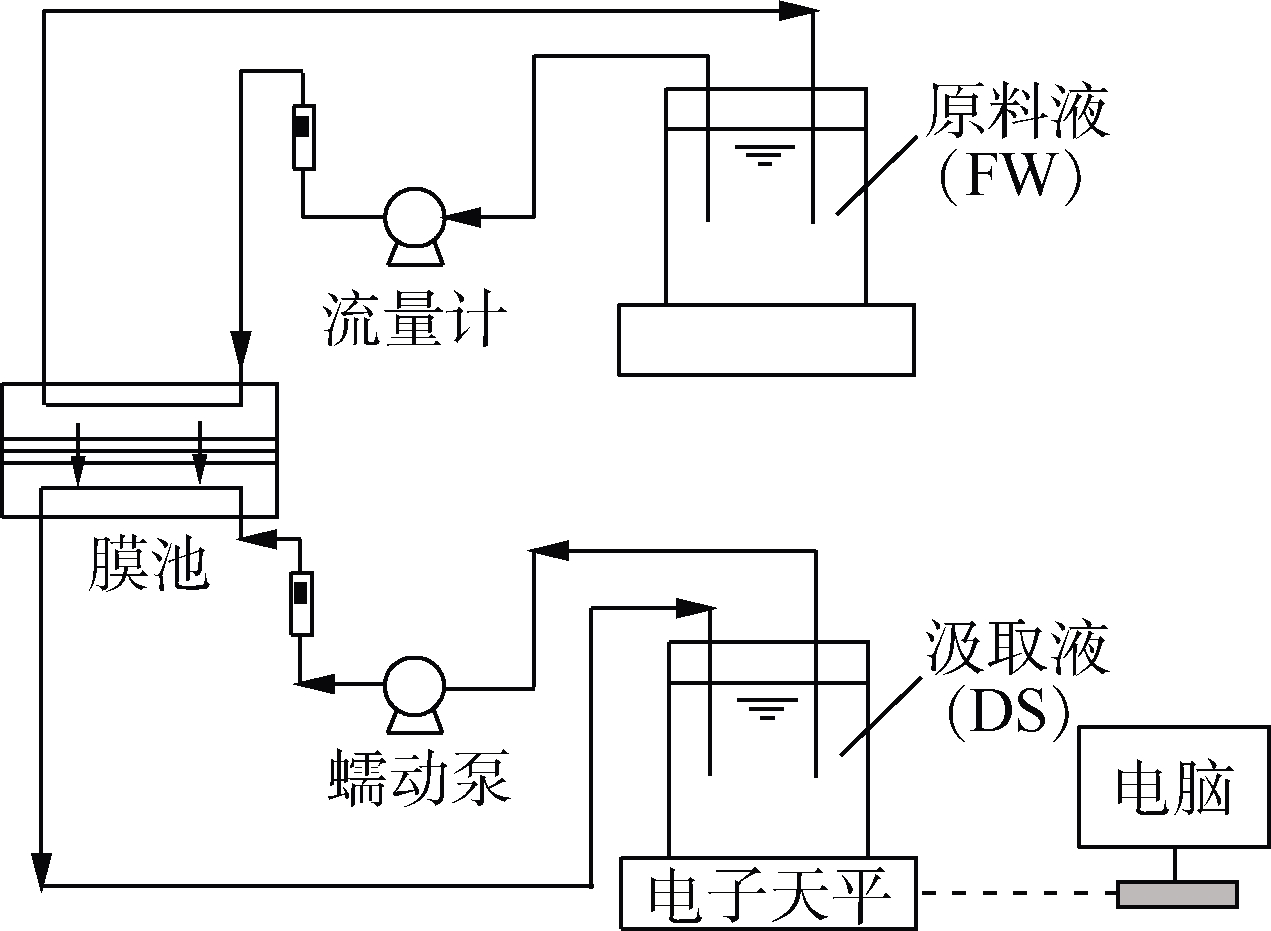

1.3 复合膜的性能评价方法

采用小型错流正渗透试验装置如图1所示,膜池中间放置膜片,有效膜面积为39.1 c

m2 。以FO模式(即活性层朝向原料液)运行,错流速度保持在7.25 cm·s-1 。通过电脑实时监测汲取液的重量变化,计算水通量。实验中汲取液为1 mol·L-1 NaCl溶液,原料液为去离子水,两者温度均控制在(20±1) ℃。按式(1)计算出纯水通量Jw:

式中:Δm为Δt内汲取液增加的质量,g;Δt为时间,h;ρ为水的密度,g·c

m-3 ;A为膜的有效面积,m2 。按式(2)计算出截留率R:

式中:ρp为汲取液中盐分的最终质量浓度,mg·

L-1 ;ρf为原料液中盐分的初始质量浓度,mg·L-1 。 -

1.4 复合膜的抗污染性能评价及表征方法

汲取液为1 mol·

L-1 的NaCl溶液,基线溶液的组成为10 mmol·L-1 NaCl和1 mmol·L-1 NaHCO3 ,在基线溶液的基础上分别加入质量浓度为50 mg·L-1 的SA、HA、BSA配制出污染液,用10 mmol·L-1 的HCl和NaOH将原料液的pH调至7。在FO模式下,错流速度为7.25 cm·s-1 进行污染实验。利用固体Zeta电位仪、接触角测定仪、傅里叶变换红外光谱仪、原子力显微镜分别测定膜的吸附性、亲水性、表面聚合物结构、表面形貌及粗糙度,以此对复合正渗透膜及其GO改性膜进行系统地表征。

-

2 结果与讨论

-

2.1 基膜对复合正渗透膜性能的影响

-

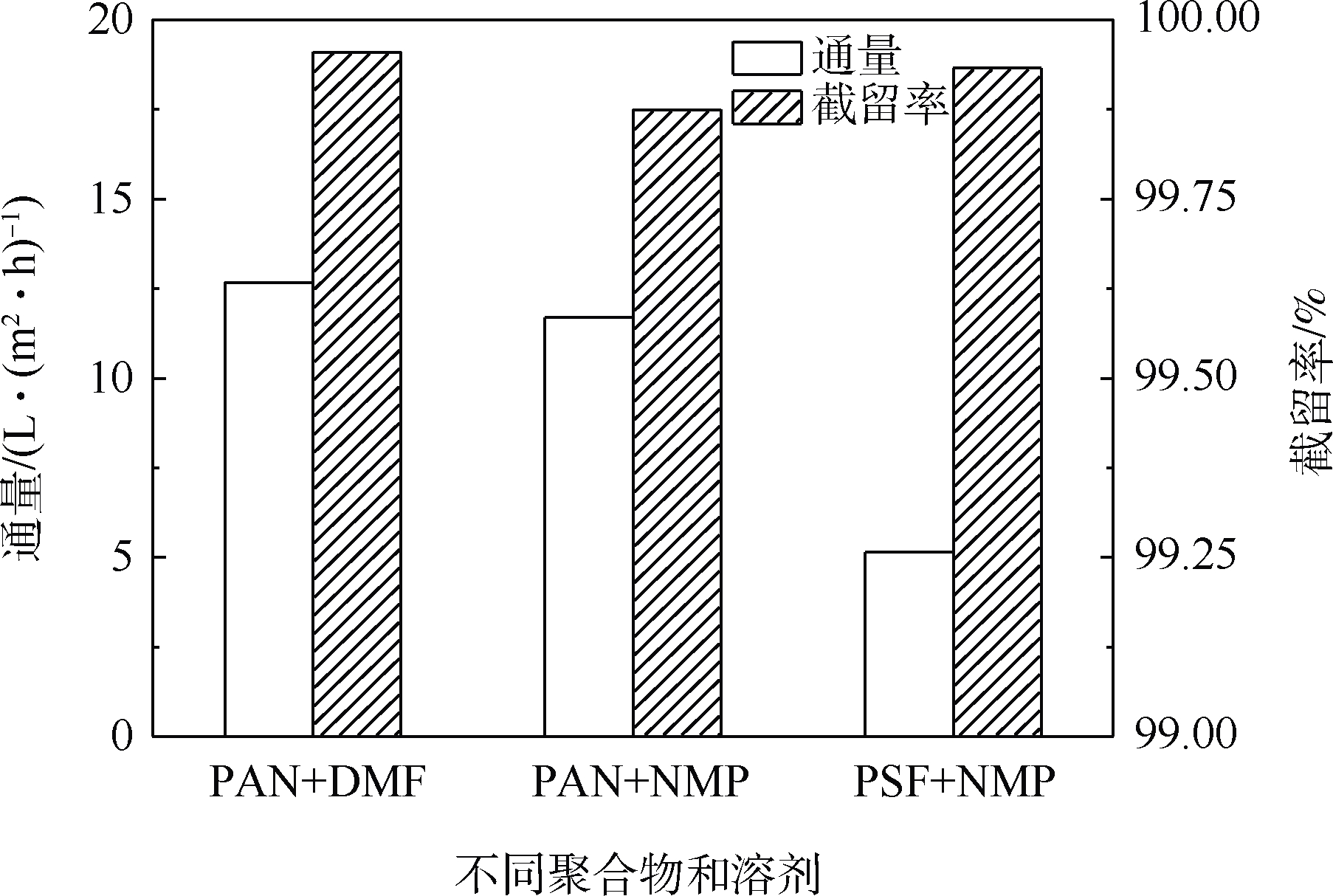

2.1.1 不同聚合物和溶剂对复合正渗透膜性能的影响

实验分别以PAN、PSF为聚合物,DMF、NMP为溶剂制备基膜,在相同的操作条件下,使用界面聚合法制备复合正渗透膜,膜性能比较如图2所示。采用PAN作为聚合物,DMF作为溶剂时制备的复合正渗透膜的水通量和截留率最佳。虽然PAN+NMP的水通量也较高,但相转化形成的支撑层结构不利于形成致密的活性面导致其截留率较低。以PSF为聚合物,NMP为溶剂制得的复合正渗透膜的活性层孔径过小,阻碍渗透过程,故水通量较低。

-

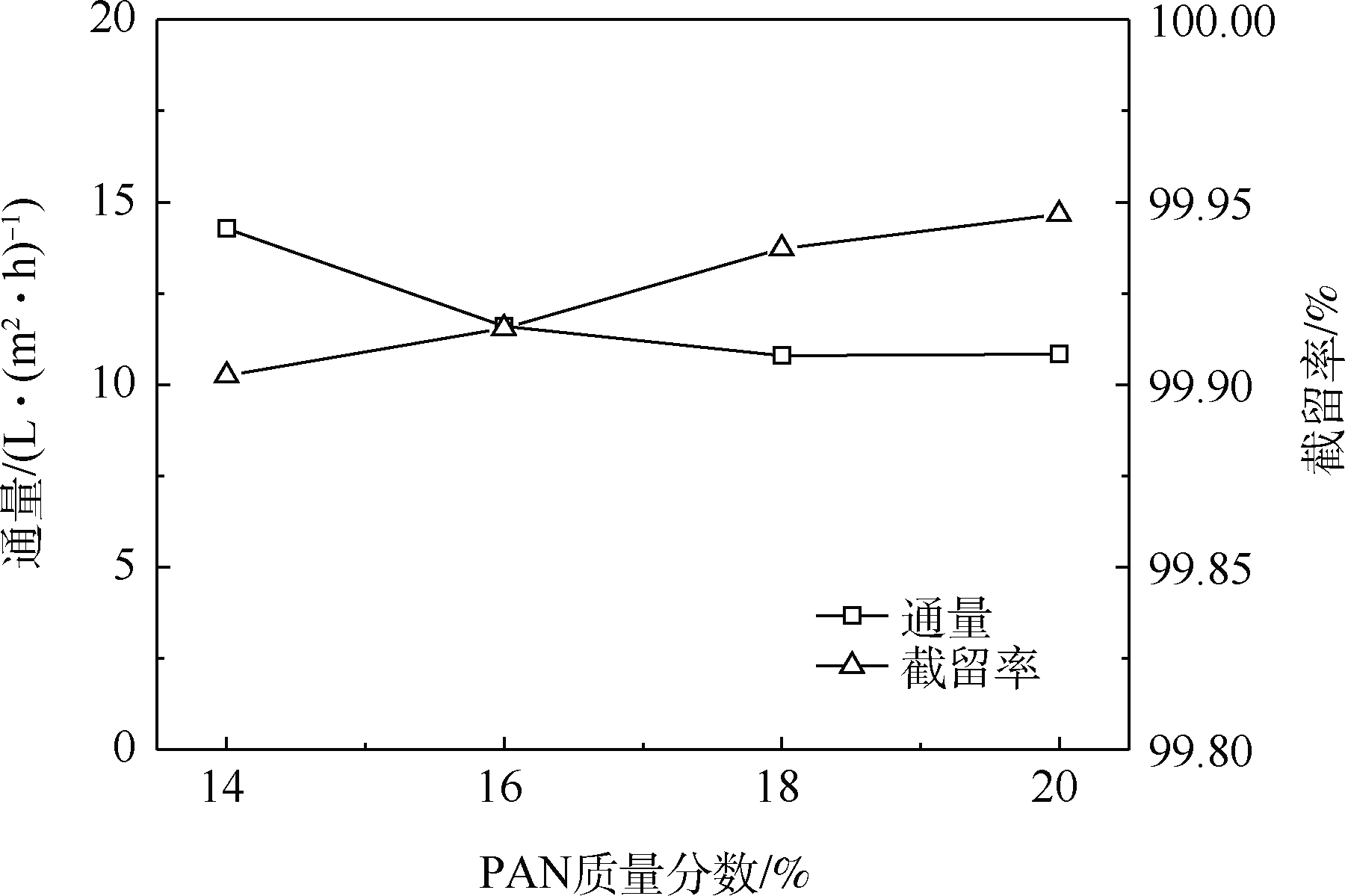

2.1.2 PAN浓度对复合正渗透膜性能的影响

图3是PAN质量浓度对复合正渗透膜性能的影响。随着PAN浓度的增加,复合膜的水通量逐渐下降而截留率缓慢上升。这主要是因为随着聚合物浓度的增大,高分子大量聚集,聚丙烯腈支撑层的多孔结构越来越致密,故膜的通量下降;进行界面聚合时形成的表面活性层越来越

厚[11] ,使得截留率逐渐上升,故适宜的PAN质量分数为16%。 -

2.2 界面聚合条件对复合正渗透膜性能的影响

-

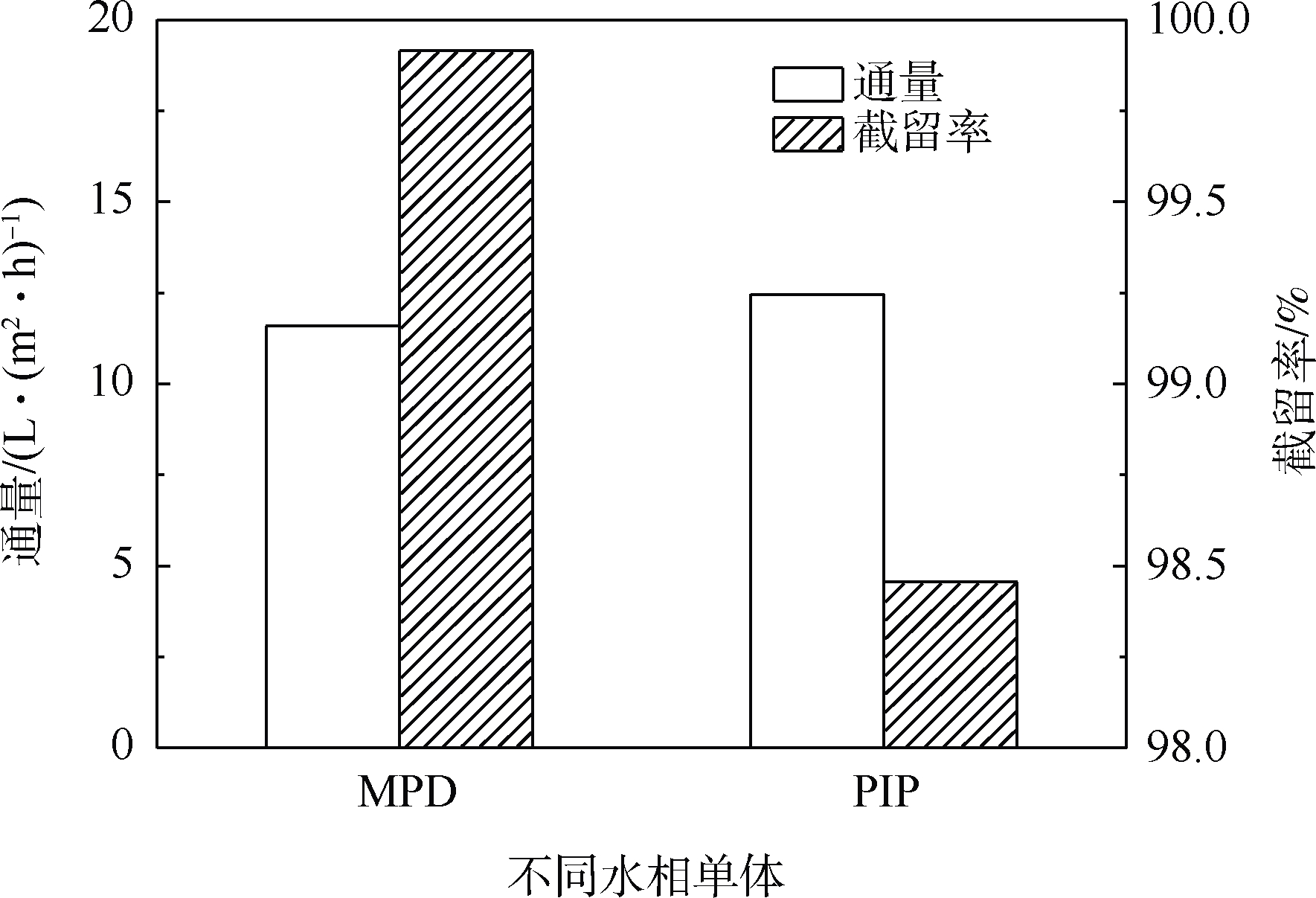

2.2.1 不同水相单体对复合正渗透膜性能的影响

图4是不同水相单体对复合膜性能的影响结果。水相单体为PIP的复合正渗透膜的水通量略高于以MPD为水相单体制备的复合正渗透膜的通量,但前者的截留率要远小于后者。这主要是由于MPD与PIP分子结构的差异所致。含有脂肪链的PIP分子链较柔软,易形成孔径大,自由体积高的聚酰胺活性层;而MPD分子结构中含有苯环,分子处于低能态,易形成结构紧密的聚酰胺

膜[12] 。因此,PIP复合膜的通量稍高于MPD复合膜,而截留率远小于。故选择适宜的水相单体为MPD。 -

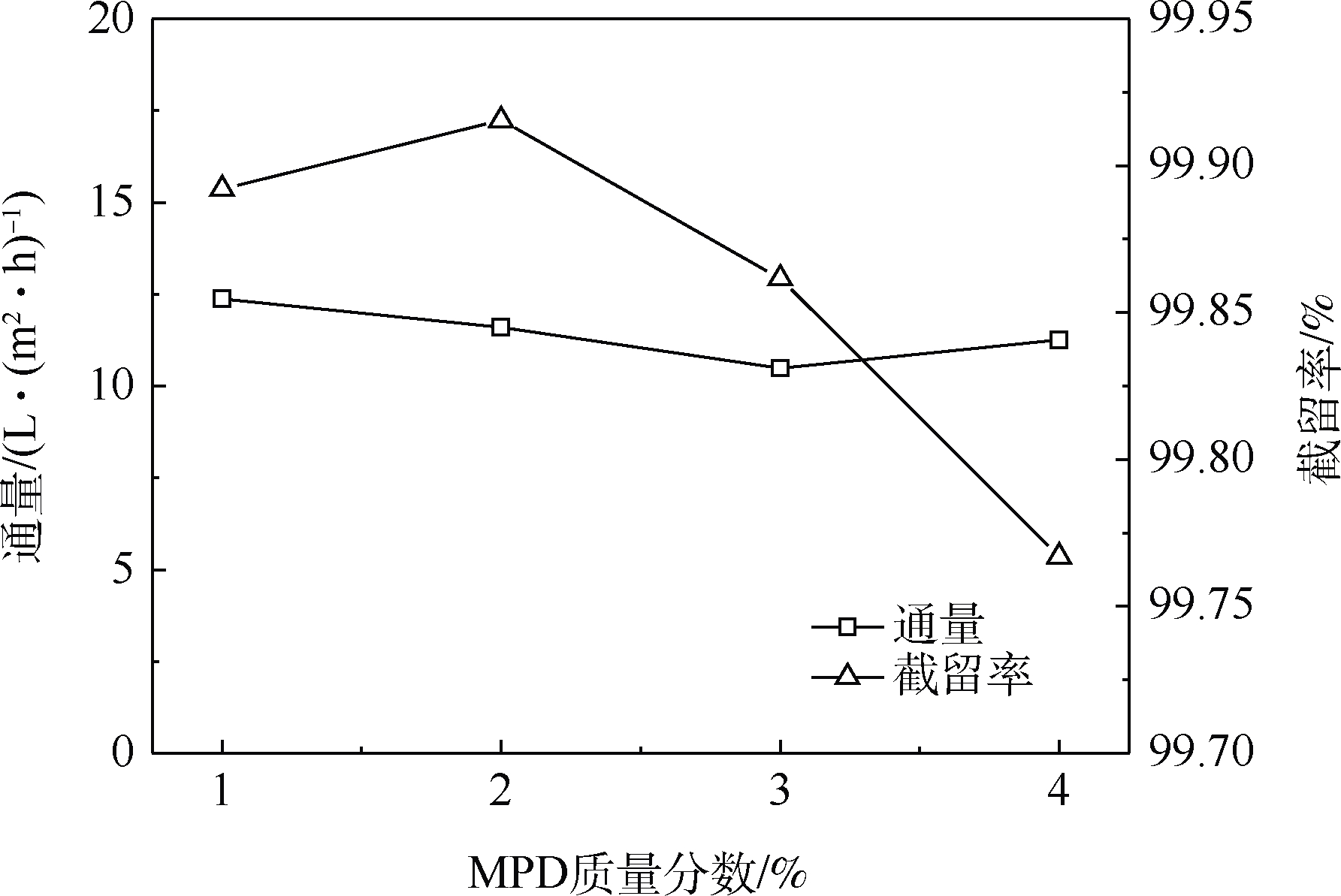

2.2.2 MPD浓度及反应时间对复合正渗透膜性能的影响

图5是MPD浓度对复合膜性能的影响。随着MPD浓度的增加,复合膜的水通量先缓慢减小后增大;而截留率则是先上升后迅速下降。这是因为随着MPD浓度的不断增加,界面聚合形成的活性层厚度越来越大,使得膜通量下降,截留率上升;当MPD浓度过高时,聚合反应的交联度较小,生成的活性层比较疏松,从而导致截留率迅速减小。故选择适宜的MPD质量分数为2%。

图5 MPD浓度对复合正渗透膜性能的影响

Fig.5 Effect of MPD concentration on the performance of composite forward osmosis membrane

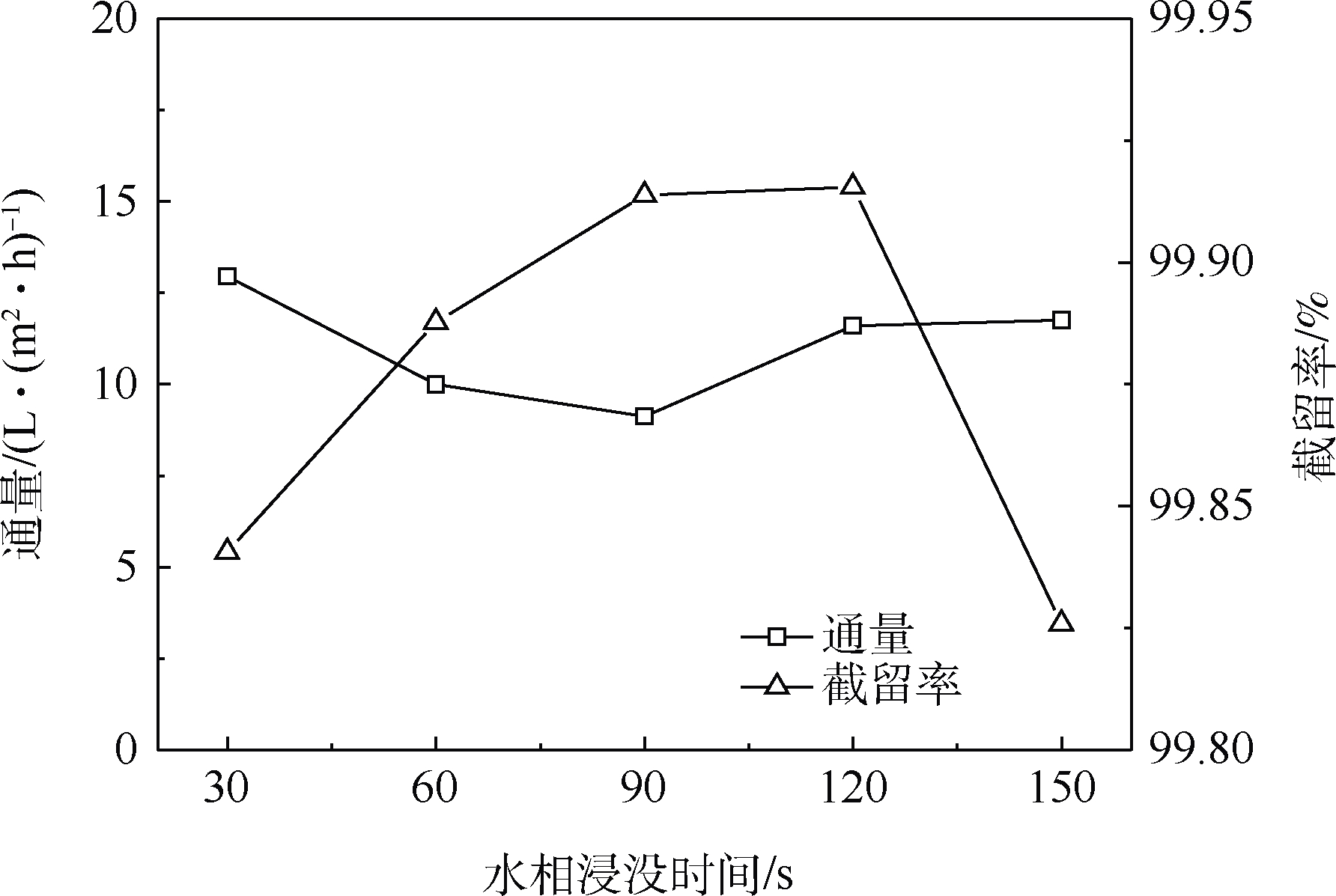

图6是水相浸没时间对复合膜性能的影响。随着水相浸没时间的增大,水通量先减小再缓慢增大后趋于稳定;而截留率先增大后下降。这主要是因为基膜刚接触水相溶液时,由于浸没时间太短,基膜表面附着一层不牢靠的水相溶液,与TMC反应后形成的活性层结合力较弱,易于从基膜表面分离,故通量大且截留率低;随着浸没时间增大,有机相与水相接触面积逐渐增加,活性层孔径缩小且越来越致密,因此通量减小而截留率上升;但浸没时间过长,水相溶液会渗入到支撑层结构中无法与有机相反应,从而使得截留率减

小[8] 。故选择最佳水相浸没时间为120 s。 -

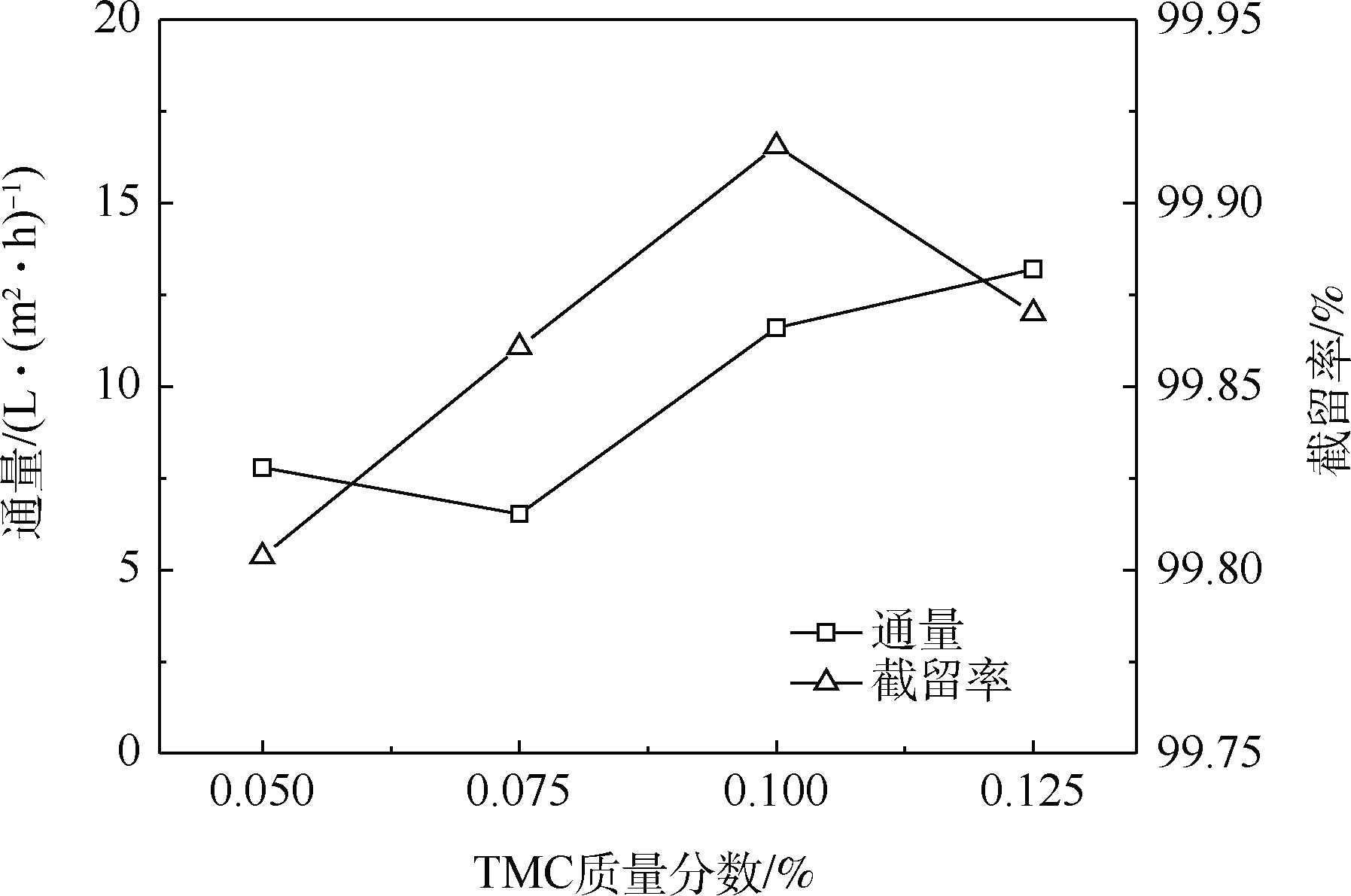

2.2.3 TMC浓度及反应时间对复合正渗透膜性能的影响

图7是TMC浓度对复合膜性能的影响。随着TMC浓度的增加,复合膜的水通量先减小后增大;而截留率先增大后减小。这是因为随着TMC浓度的增加,界面聚合形成的活性层交联度增大,网状结构更致密,故通量减小而截留率增大;当TMC浓度过大时,水相中的MPD很快被耗尽,余留下的TMC的酰氯基团转化为亲水性较大的羧基,导致活性层结构变得疏松,此时通量增大,截留率下降。所以选择最适宜的TMC质量分数为0.1%。

图7 TMC浓度对复合正渗透膜性能的影响

Fig.7 Effect of TMC concentration on the performance of composite forward osmosis membrane

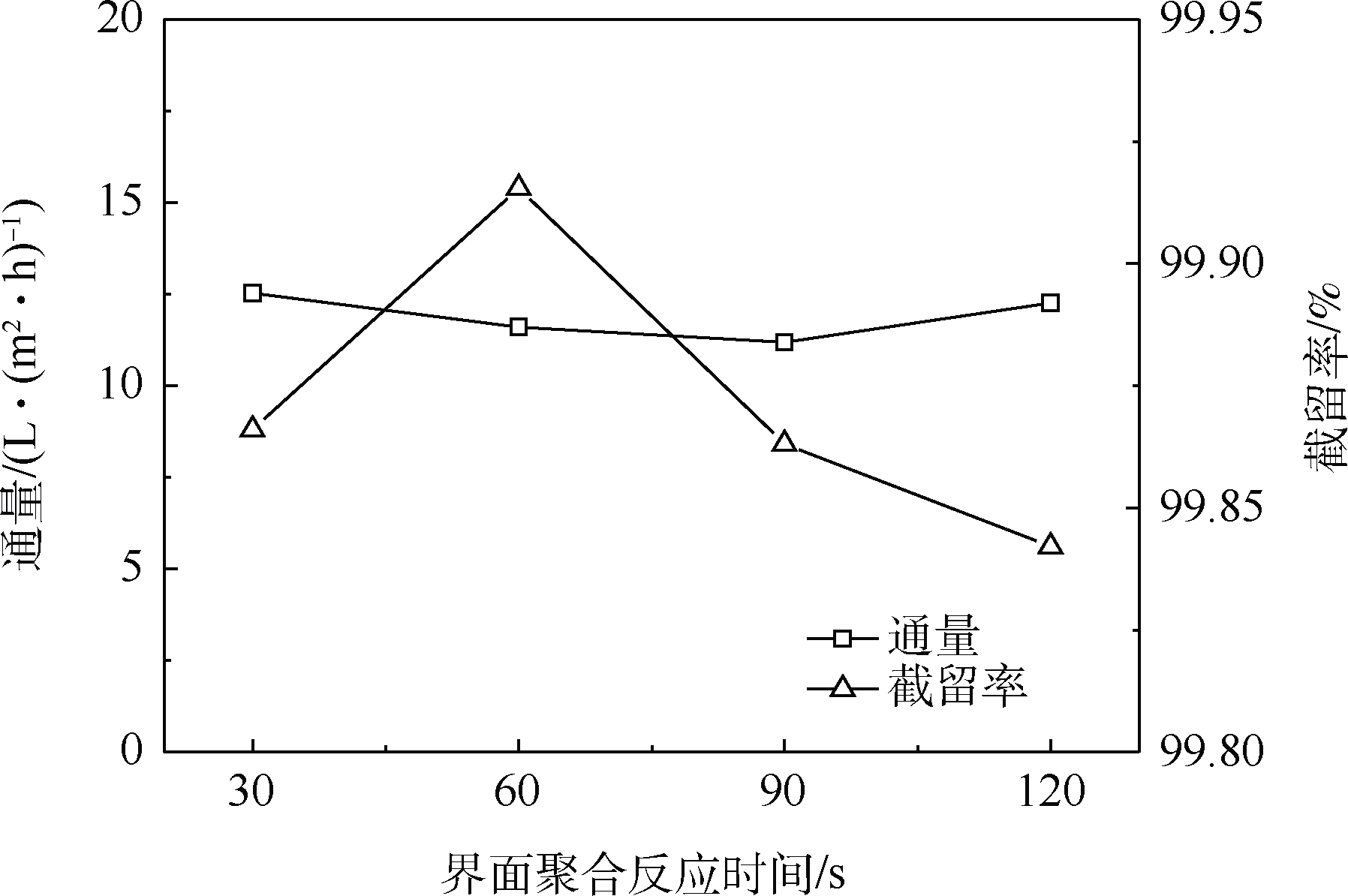

图8是界面聚合反应时间对复合膜性能的影响。随着界面聚合反应时间的延长,复合膜的通量缓慢下降后缓慢上升,基本保持稳定,而截留率先增大后减小。这主要是因为随着反应时间的增加,界面聚合形成的活性层越来越致密,所以膜的截留率不断增大;但反应时间过长的话,水相和有机相溶液透过形成的活性层反应,由于两者的浓度不同,活性层会阻碍单体之间的界面聚合从而形成不完善的网状结构,导致通量上升,截留率下降。故适宜的界面聚合反应时间为60 s。

-

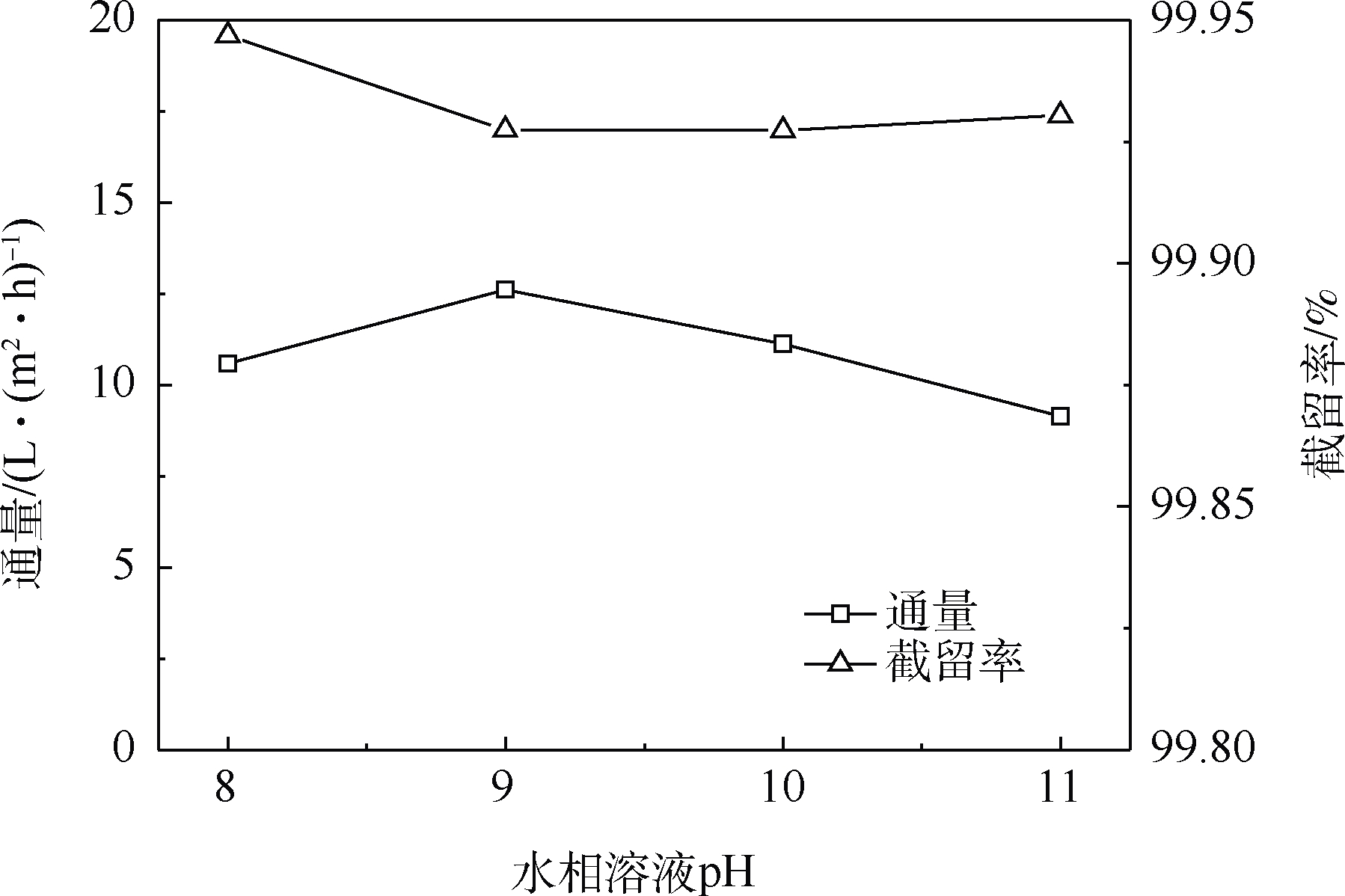

2.2.4 水相溶液pH对复合正渗透膜性能的影响

芳香聚酰胺层的形成伴随有HCl的形成,HCl会与间苯二胺反应影响活性层的交联度,实验中采用三乙胺来调节水相溶液的pH以去除产生的HCl。图9是水相溶液pH对复合膜性能的影响。随着水相溶液pH的增大,复合膜的通量先增大后减小;而截留率先减小后缓慢增大。这是因为当水相溶液pH在8~9时,TMC的酰氯基团会发生水解,形成的活性层不够完善,因此通量增大,截留率降低;但当水相溶液pH大于9时,HCl逐渐被去除,有利于界面聚合反应进行,并且O

H- 会抑制胺的电离,增加MPD的活性,促进其向有机相扩散,形成较致密的活性层,所以截留率增大而通量减小[9] 。故选择最佳水相溶液pH为9。 -

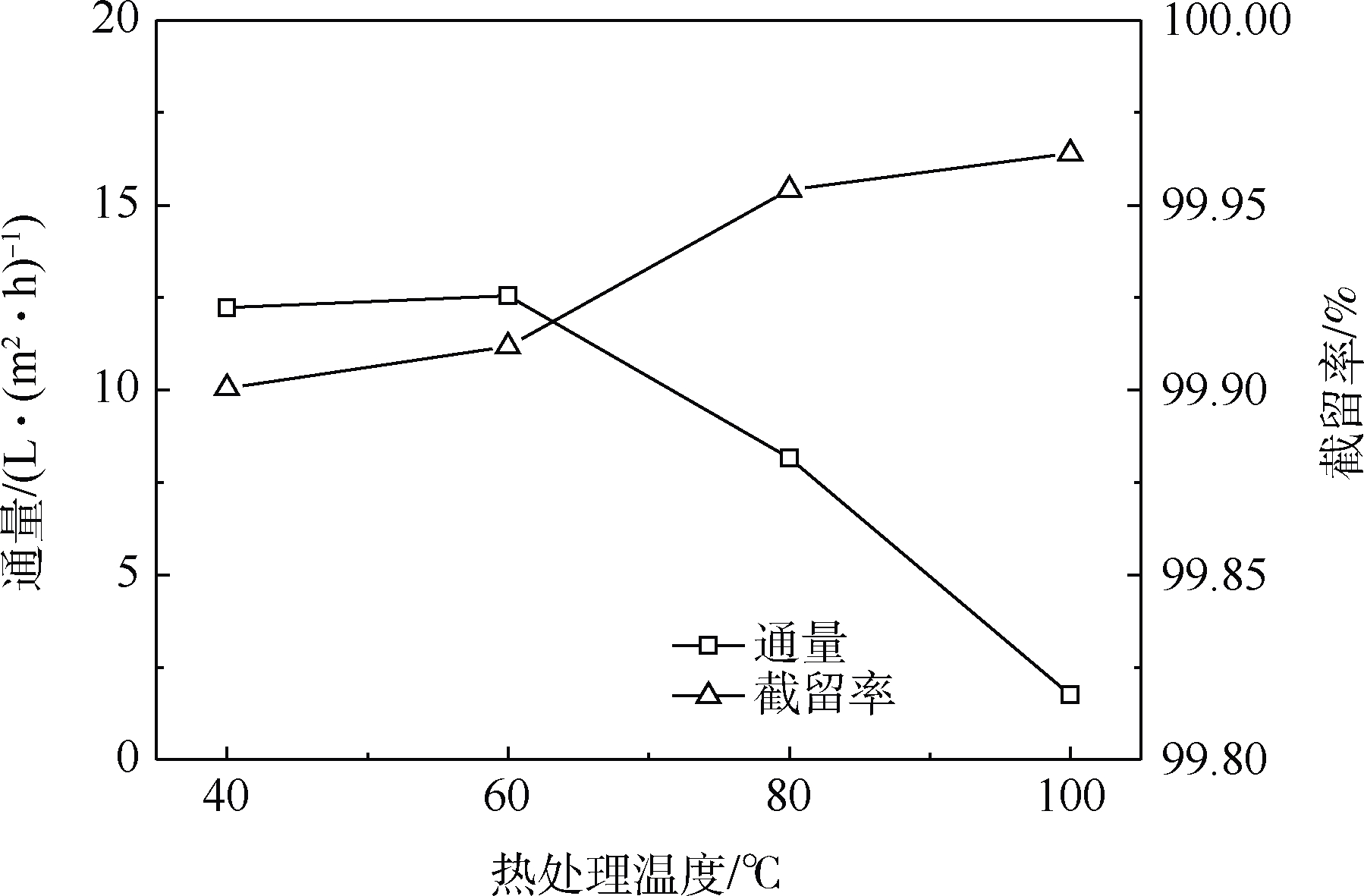

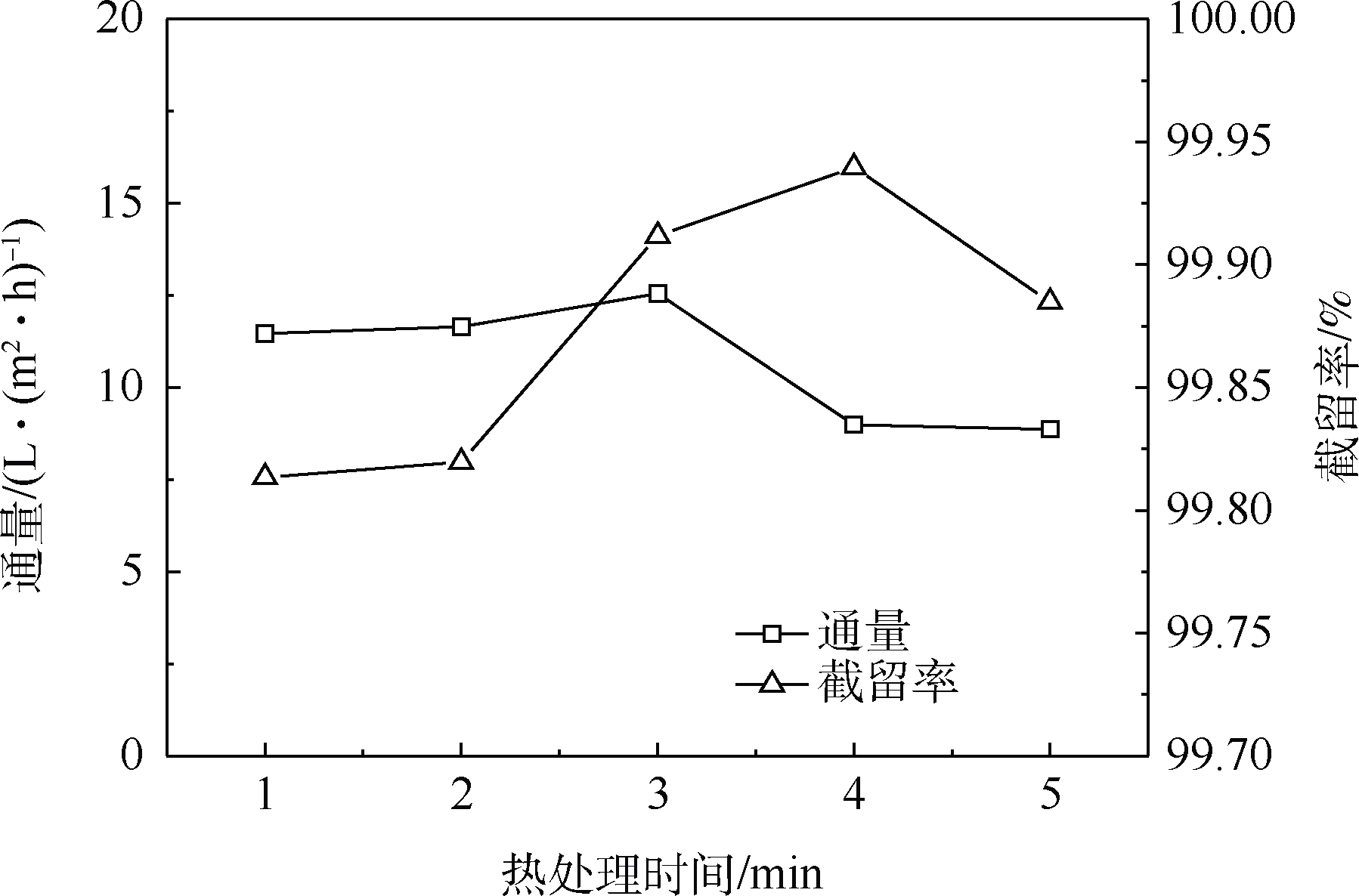

2.2.5 热处理温度及热处理时间对复合正渗透膜性能的影响

图10是热处理温度对复合膜性能的影响。膜的通量先趋于稳定后大幅度下降,而截留率不断上升。这是因为高温有利于高分子链的运动,MPD的扩散阻力降低,使与TMC反应的MPD的量增加,聚酰胺分子质量及交联度提高,活性层变得致密,故截留率增

大[10] ;但过高的热处理温度会使活性层与基膜发生不同程度的膨胀,导致网状结构及支撑层的孔径发生皱缩,所以通量大幅度下降。故选择适宜的热处理温度为60 ℃。

图10 热处理温度对复合正渗透膜性能的影响

Fig.10 Effect of curing temperature on the performance of composite forward osmosis membrane

图11是热处理时间对复合膜性能的影响。随着热处理时间的延长,通量和截留率都是先增大后减小。其原因是热处理可以提高活性层中未反应的胺基与酰氯基团的碰撞概率,增加活性层的交联度,从而使截留率增

大[13] ;但热处理时间过长,会导致聚合物降解或丢失端基,使聚合物分子质量和交联度降低,所以截留率下降。故选择适宜的热处理时间为3 min。 -

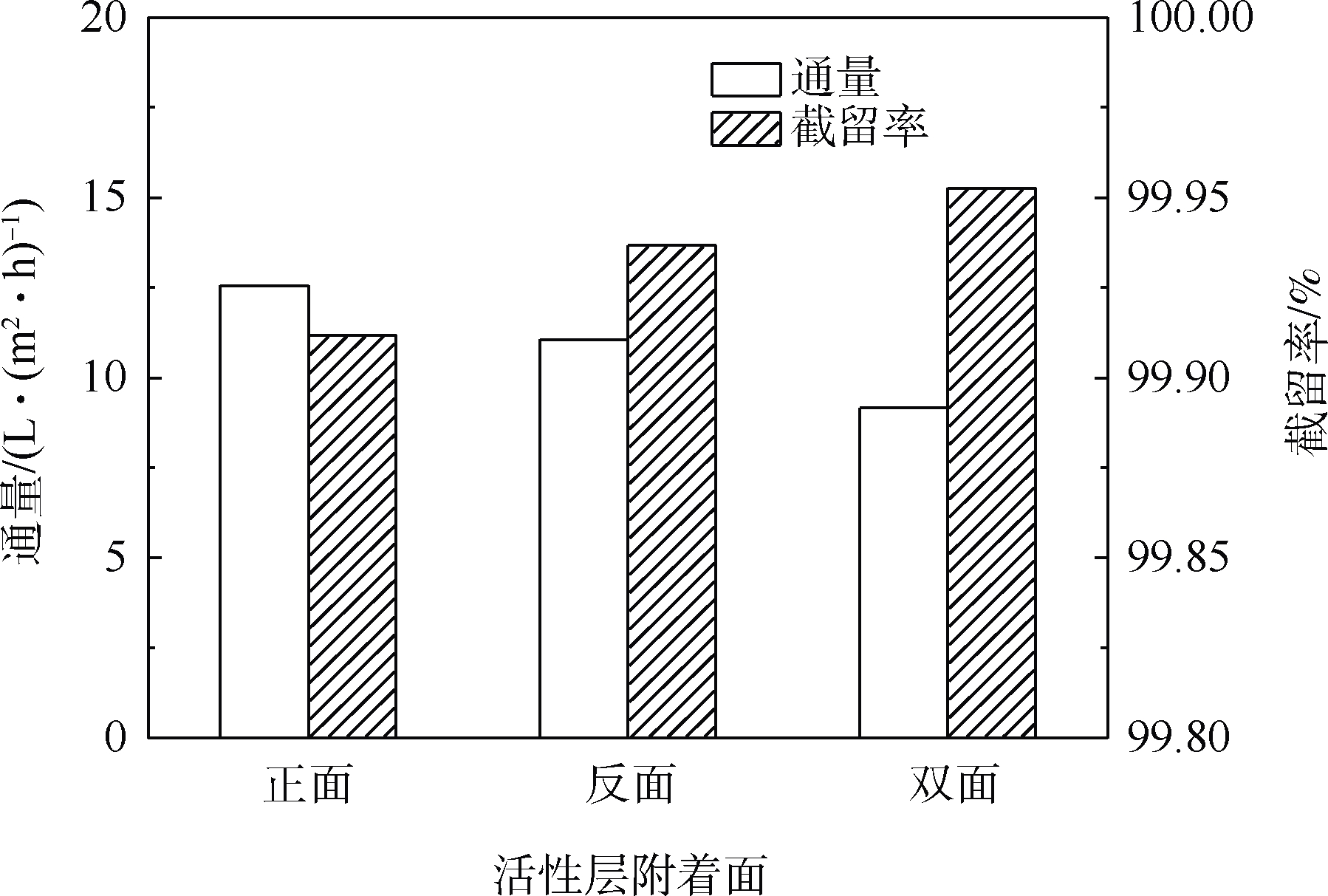

2.2.6 活性层附着面对复合正渗透膜性能的影响

图12是活性层附着面对复合膜性能的影响。因为在基膜的双面都存在致密的活性层,所以截留率最大而通量最低,其复合膜性能与活性层单面附着差异不大,综合考虑通量与截留率,不宜采用活性层双面附着;因为基膜反面相比于正面较粗糙,增大了MPD与TMC的接触面积,提高聚合物分子量及交联度,形成的活性层较致密,所以反面附着的截留率稍大于正面,通量则稍小于正面,但总体来说两者的复合膜性能相似。活性层附着在正面和反面制得的复合膜在pH=7时测定出固体表面Zeta电位分别为-16.85 mV和-7.15 mV。可知正面附着的Zeta电位的绝对值要高于反面,这说明前者形成的聚酰胺膜的稳定性较高,不易被破坏或分离,有利于之后加入氧化石墨烯进行改性,附着在膜上的石墨烯不容易剥离,制备稳定的氧化石墨烯改性复合膜。故最适宜的活性层附着面是正面。

-

2.3 氧化石墨烯改性复合膜的性能优化

-

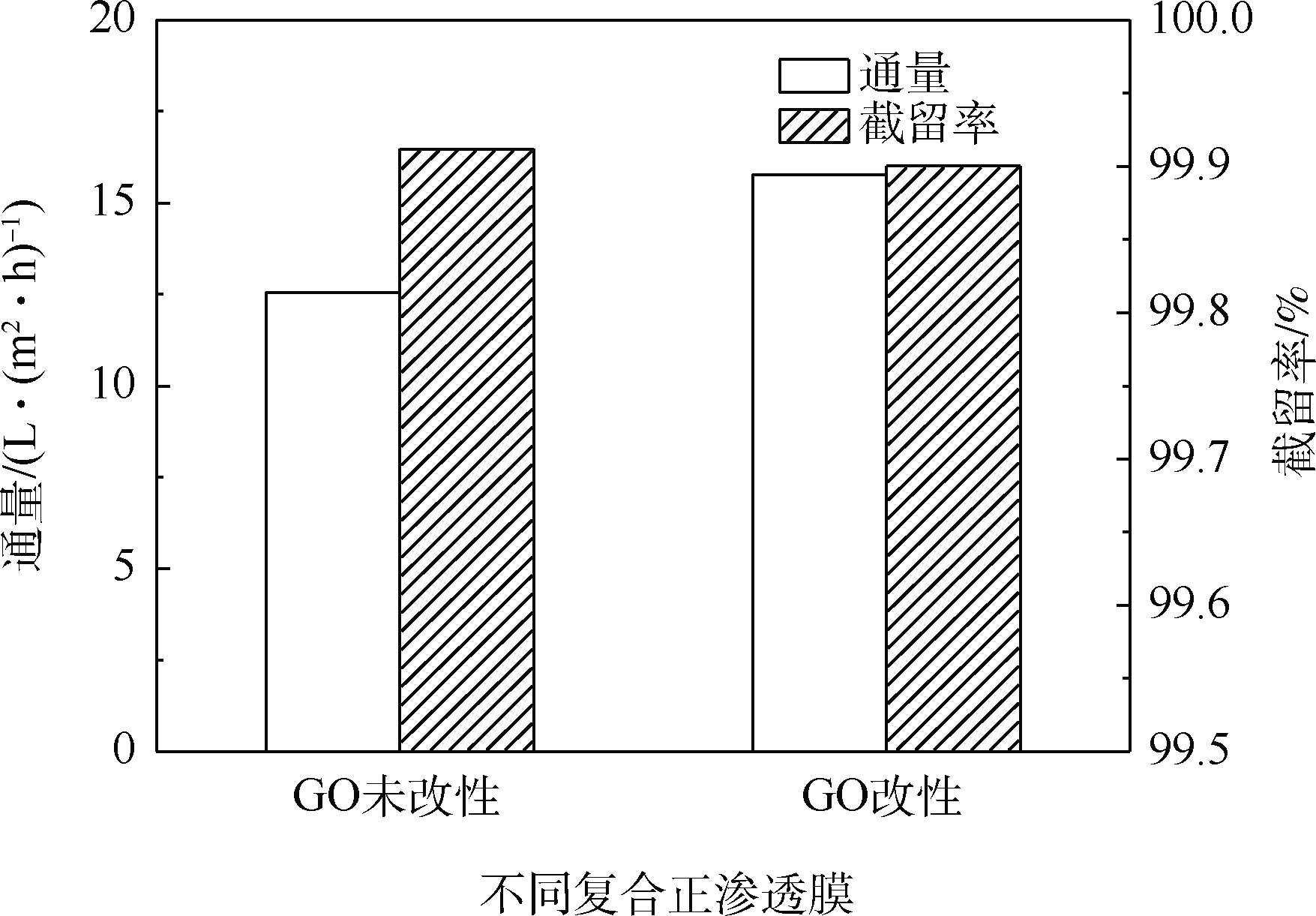

2.3.1 纯水通量和截留率

图13是未加入GO和加入GO所制得的复合膜的通量和截留率比较。可以看出,经GO改性后的复合正渗透膜,其通量有所提高而截留率基本不变,通量和截留率分别为15.77 L·(

m2 ·h)-1 和99.90%。与商业HTI-CTA膜的通量(10.55 L·(m2 ·h)-1 )和截留率(99.94%)相比,截留率相似,通量是其的1.49倍。这主要是因为氧化石墨烯拥有独特的二维结构,单层氧化石墨烯厚度仅为1个碳原子,长度可达几百nm甚至几μm,可在膜表面形成层层堆叠的GO片层结构,水分子可以通过GO片层间的缝隙,其他粒径大于缝隙间距的溶质则被截留。

图13 未加入GO和加入GO所制得的复合膜的通量和截留率比较

Fig.13 Comparison of pure water fluxs and salt rejection rates of composite membranes modified and unmodified by GO

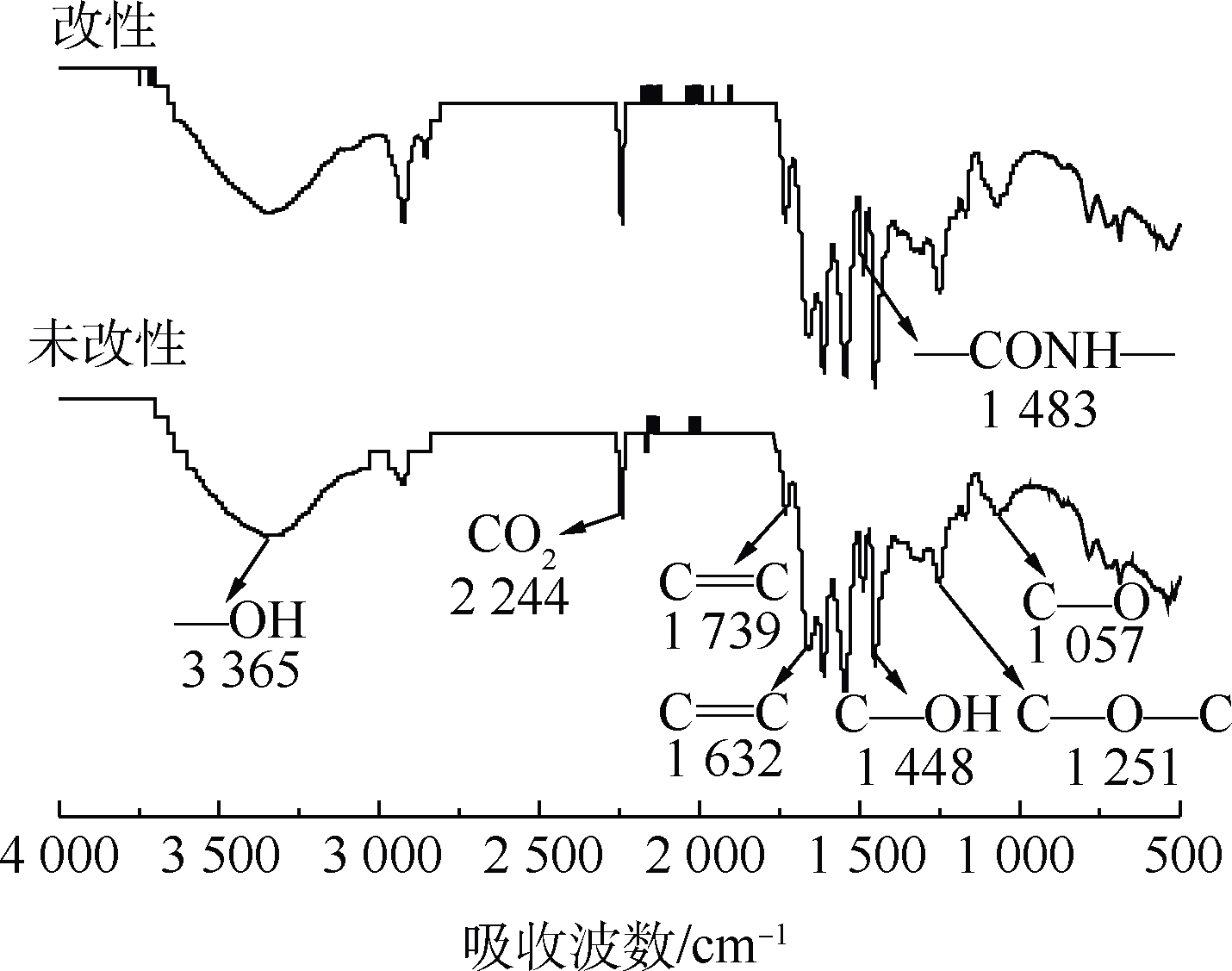

GO纳米片上存在各种含氧官能团,图14是氧化石墨烯改性和未改性复合正渗透膜的红外光谱图,可以看出当经氧化石墨烯改性后,膜表面的羟基、羧基、碳碳双键、环氧基、烷氧基等含氧官能团的吸收峰有着不同程度的增强,从而导致复合膜的亲水性增强,并且未被氧化的部分石墨烯因其疏水性强可促进水分快速通过GO片层,由于GO改性复合膜的吸水能力和快速水分扩散性,使其在亲水分离中表现出优异的性

能[14] 。

图14 GO改性和GO未改性复合膜的活性层红外光谱图

Fig.14 FTIR of the active layer on the pristine and GO modified composite membranes

测定出GO改性复合膜的接触角(37.89°)小于未改性复合膜的接触角(47.63°),接触角越小,润湿能力越强,亲水性越好,并且在pH=7时前后两者的固体表面Zeta电位分别为-24.43 mV和-16.85 mV。由于氧化石墨烯的含氧官能团分布在膜表面时,其质子容易失去,使膜带有更多负电荷,因此经GO改性后,复合膜的稳定性增

强[15] 。 -

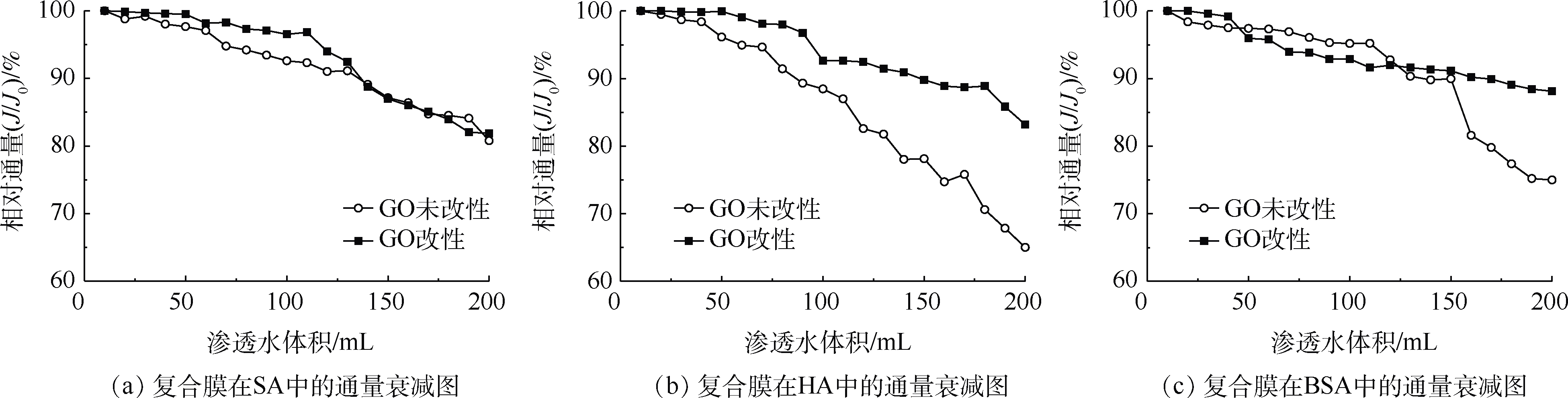

2.3.2 抗污染性能

膜运行过程中通量下降程度是评价膜污染的重要参数。图15是氧化石墨烯改性和未改性复合正渗透膜分别在SA、HA、BSA污染中的通量衰减变化。GO改性复合膜在3种污染过程中的通量下降均比未改性的复合膜缓慢,在水分从原料液渗透到汲取液200 mL后依然可以保持在85%左右,经GO改性后,复合膜的抗污染能力得到比较好的提升。这主要是因为GO纳米片层的间距较大,污染物不易堵塞;而且GO上存在多种亲水性含氧官能团,使得污染物不易吸附在膜表面而形成滤饼层,降低膜污

染[16] 。 -

2.4 复合正渗透膜的表面形貌

图16是GO改性和未改性复合膜的三维表面形貌图。在图16中,X、Y轴代表原子力显微镜的扫描范围,Z轴代表相对高度。由图16可以看出,GO改性和未改性复合正渗透膜的表面形貌有明显的差异。未改性复合膜的表面形成了一层较为粗糙的多孔网状结构聚合层;而GO改性的复合膜表面可以看见层状叠覆,形成波状褶皱的致密GO层;GO改性和未改性复合膜的平均粗糙度(Ra)分别为65.8 nm和48.2 nm,前者粗糙度较大。这些都说明了GO片层在膜表面的生成。

-

3 结论

1) 不同基膜组成所制备的复合膜的性能研究表明,最佳基膜组成:16%的PAN为聚合物,DMF为溶剂。

2) 不同界面聚合条件下制备的复合膜的性能研究表明,最佳界面聚合条件为:将基膜浸没在2%的MPD水相溶液(pH=9)中120 s,然后与0.1%的TMC进行界面聚合反应60 s从而生成活性层,且活性层正面附着,最后于60 ℃下热处理3 min。

3) 向水相溶液中加入氧化石墨烯进行物理共混改性,复合膜表面会形成一种具有不同含氧官能团的层层堆叠式GO片层,导致其亲水性增大,膜水通量上升26%,截留率依然保持在99.90%以上;而且复合膜的抗污染能力得到明显提高。

-

参 考 文 献

-

1

SHAFFER D L, WERBER J R, JARAMILLO H, et al. Forward osmosis: Where are we now?[J]. Desalination, 2015, 356: 271-284.

-

2

KIM C K, KIM J H, ROH I J, et al. The changes of membrane performance with polyamide molecular structure in the reverse osmosis process[J]. Journal of Membrane Science, 2000, 165(2): 189-199.

-

3

RAHIMPOUR A, JAHANSHAHI M, MORTAZAVIAN N, et al. Preparation and characterization of asymmetric polyethersulfone and thin-film composite polyamide nanofiltration membranes for water softening[J]. Applied Surface Science, 2010, 256(6): 1657-1663.

-

4

肖维溢, 管盼盼, 王铎. 新型聚酰胺复合正渗透膜的制备与表征[J]. 功能材料, 2016, 47(s1): 127-133.

-

5

XU K, FENG B, ZHOU C, et al. Synthesis of highly stable graphene oxide membranes on polydopamine functionalized supports for seawater desalination[J]. Chemical Engineering Science, 2016, 146: 159-165.

-

6

倪木子, 夏圣骥, 袁方竹, 等. 新型氧化石墨烯膜的制备及去除天然有机物研究[J]. 水处理技术, 2016, 42(8): 40-47.

-

7

方鹏, 曹兵, 淡宜, 等. 界面聚合法制备聚酰胺纳滤膜及工艺条件对纳滤膜性能的影响[J]. 高分子材料科学与工程, 2011, 27(10): 1-3.

-

8

王磊, 呼佳瑞, 苗瑞, 等. 聚酰胺复合纳滤膜的制备与表征[J]. 膜科学与技术, 2014, 34(5): 16-21.

-

9

谢颂京. 复合反渗透膜的制备研究[D]. 天津: 天津工业大学, 2017.

-

10

邱实, 吴礼光, 张林, 等. 界面聚合工艺条件对反渗透复合膜性能的影响[J]. 化工学报, 2008, 59(8): 2027-2034.

-

11

GHOSH A K, HOEK E M V. Impacts of support membrane structure and chemistry on polyamide-polysulfone interfacial composite membranes[J]. Journal of Membrane Science, 2009, 336(1): 140-148.

-

12

汤蓓蓓, 徐铜文, 武培怡. 界面聚合法制备复合膜[J]. 化学进展, 2007, 19(9): 1428-1435.

-

13

赵卷. 界面聚合法制备分离CO2固定载体复合膜[D]. 天津: 天津大学, 2006.

-

14

职瑞, 王磊, 王佳璇, 等. 双分离层复合纳滤膜的制备及其性能[J]. 环境工程学报, 2018, 12(6): 1600-1608.

-

15

黄倩雯, 楚英豪. 氧化石墨烯性质及其应用前景[J]. 四川化工, 2017, 20(6): 30-32.

-

16

ZHANG Y, SU Y, PENG J, et al. Composite nanofiltration membranes prepared by interfacial polymerization with natural material tannic acid and trimesoyl chloride[J]. Journal of Membrane Science, 2013, 429(4): 235-242.

-

1

全文HTML

摘要

以聚丙烯腈(PAN)为制膜基材,采用界面聚合法制备复合正渗透膜,研究了不同基膜组成、界面聚合条件对复合膜性能的影响及抗污染性能,并进一步添加氧化石墨烯(GO)进行共混改性,优化复合正渗透膜性能。结果表明,最佳基膜组成为,以16%的PAN为聚合物,以N,N-二甲基甲酰胺(DMF)为溶剂。最佳界面聚合条件为,将基膜浸没在2%的间苯二胺(MPD)水相溶液(pH=9)中120 s,然后与0.1%的均苯三甲酰氯(TMC)进行界面聚合反应60 s从而生成活性层,且活性层正面附着,最后于60 ℃下热处理3 min,所得复合膜具有较好的渗透性能。此外,经GO改性后,复合膜表面形成一种具有不同含氧官能团的层层堆叠式GO片层,导致膜的水通量上升了26%,截留率依然保持在99.90%以上,并且复合膜的抗污染能力得到明显提高。

Abstract

The composite forward osmosis (FO) membranes were fabricated by interfacial polymerization method using polyacrylonitrile (PAN) as the substrate in this study. Then the effects of casting solution composition and interfacial polymerization conditions on the properties of synthetic FO membranes, as well as their anti-fouling properties, were investigated in detail. Furthermore, graphite oxide (GO) was added to blend modifying the composite FO membrane and optimize its performance. Results showed that the optimum casting solution was composed of 16% PAN as polymer and N,N-dimethylformamide (DMF) as solvent. The optimum interfacial polymerization conditions were following: immersing the base membrane in 2% m-phenylenediamine (MPD) water solution with pH=9 for 120 s, and conducting the interfacial polymerization with 0.1% trimesoyl chloride (TMC) for 60s to form active layer which was attached to the front surface of membrane, finally producing the composite FO membrane with good permeability after 3 min heating treatment at 60 ℃. In addition, a stacked GO sheet with different oxygen-containing functional groups was formed on the surface of FO membrane after GO modification, which contributed to a 26% increase in water flux and above 99.90% rejection rate, meanwhile the anti-fouling property of synthetic FO membrane was also significantly enhanced.

正渗透(FO)是一种新型膜分离技术,指水利用渗透压差驱动自发地从原料液侧通过选择性半透膜到达汲取液侧,而溶质分子和离子留在原溶液中的过

本研究采用界面聚合法制备复合正渗透膜,分别研究不同基膜组成、界面聚合条件和活性层附着面对复合膜性能的影响,探索复合正渗透膜的最佳基膜配方和聚合条件;在最佳条件下的水相溶液中加入一定量氧化石墨烯制备GO改性复合正渗透膜,比较加入GO前后两者的膜性能及抗污染能力,并对他们的表面结构进行表征。

图9 水相溶液pH对复合正渗透膜性能的影响

Fig.9 Effect of the pH of aqueous phase on the performance of composite forward osmosis membrane

百度学术

百度学术

下载:

下载: